Jet code detection method and system

A detection method and coding technology, applied in the field of coding, can solve the problems of low detection reliability, missed detection and false detection, and low efficiency of manual observation and detection of coding, so as to achieve automation and intelligence, improve recognition, and improve The effect of recognition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiment of the present application solves the technical problems of low efficiency and low reliability of manual detection in the prior art by providing a coding detection method, and achieves the technical effects of improving detection efficiency, avoiding false detection and missing detection, and improving reliability.

[0040] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

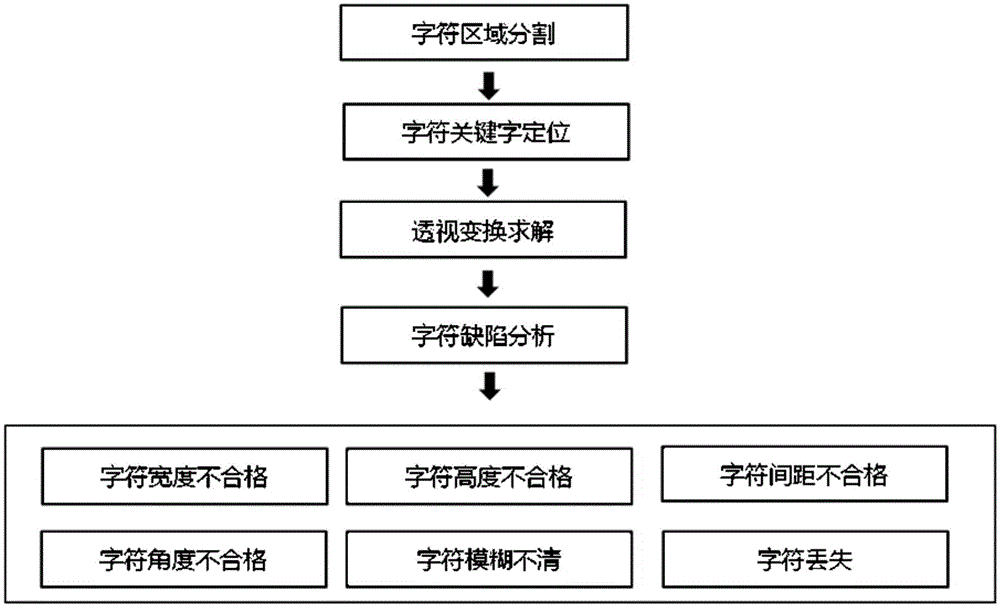

[0041] A coding detection method, comprising:

[0042] Set the character template;

[0043] Segment the character area, obtain the inkjet image to be inspected, and determine the approximate area of the inkjet character through template matching;

[0044] Character keyword positioning, through template matching, determine the position of the keyword, and obtain the exact position of the remaining variable characters;

[0045] Perspective transformation solution, by match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com