Crack detection system and method for high-speed rail contact line based on laser ultrasound

A technology of laser ultrasonic and crack detection, which is applied in the direction of material analysis, measuring devices, and processing detection response signals using sound waves/ultrasonic waves/infrasonic waves, etc., which can solve problems such as large safety hazards, difficult maintenance, and difficulty in detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

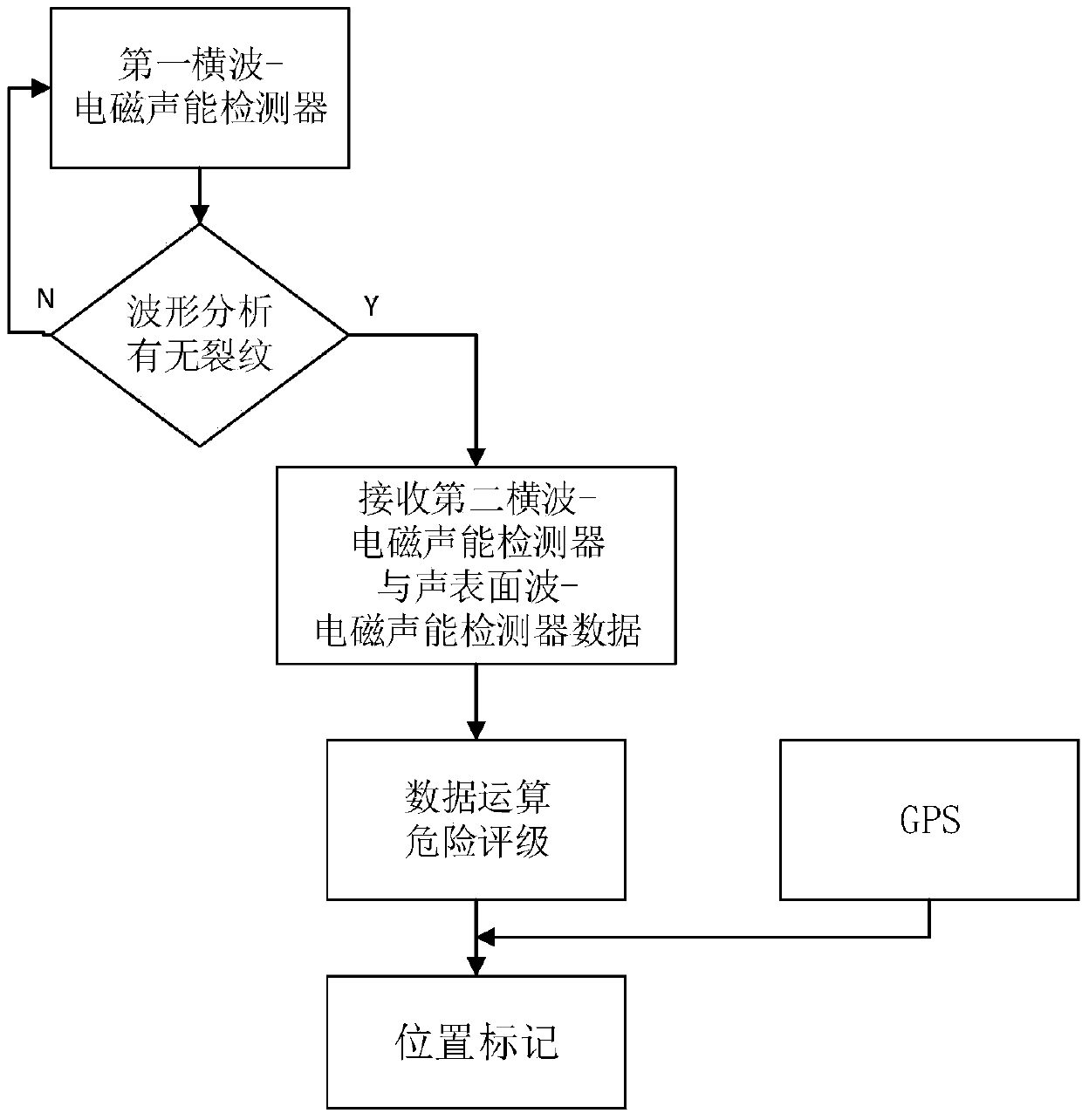

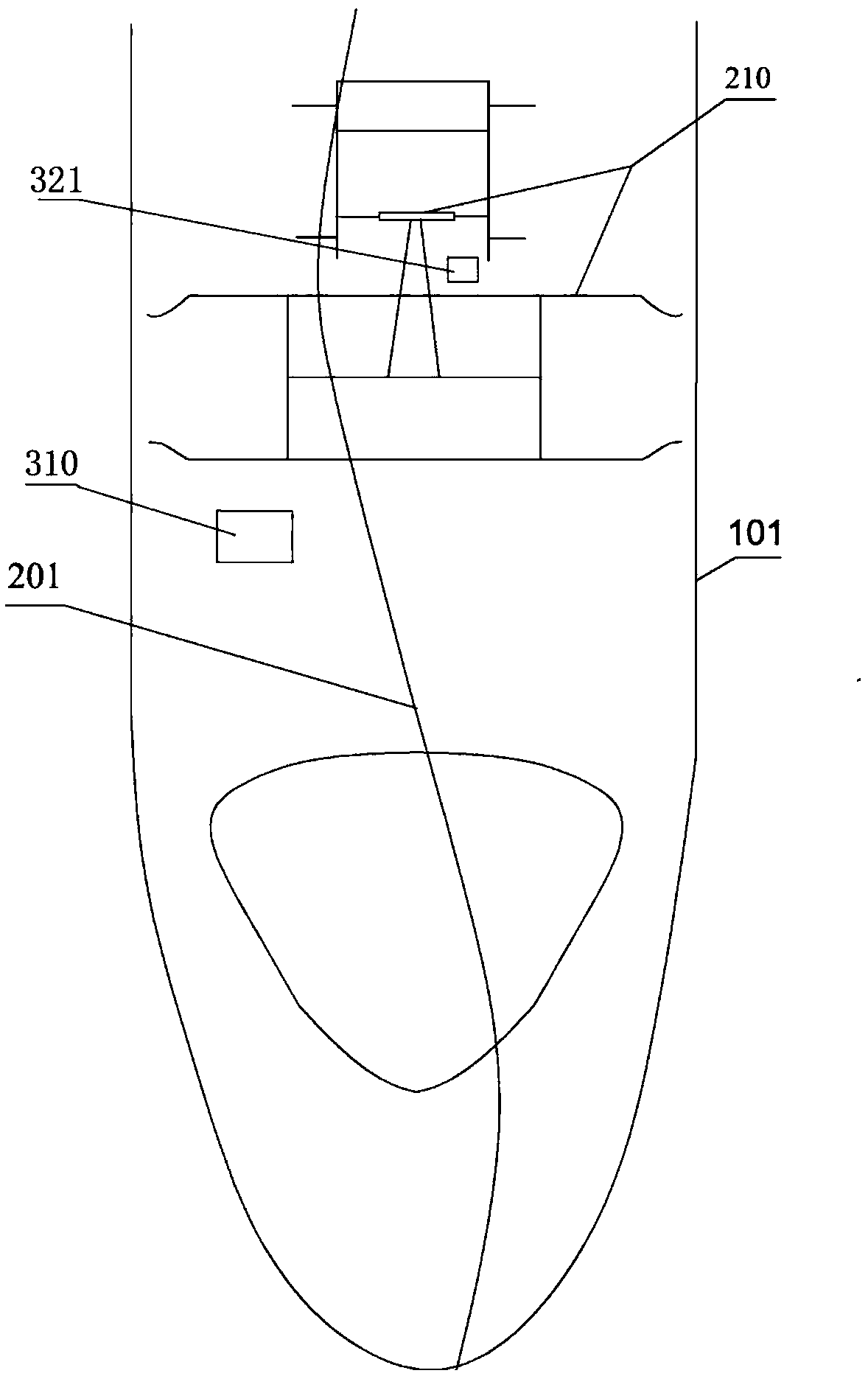

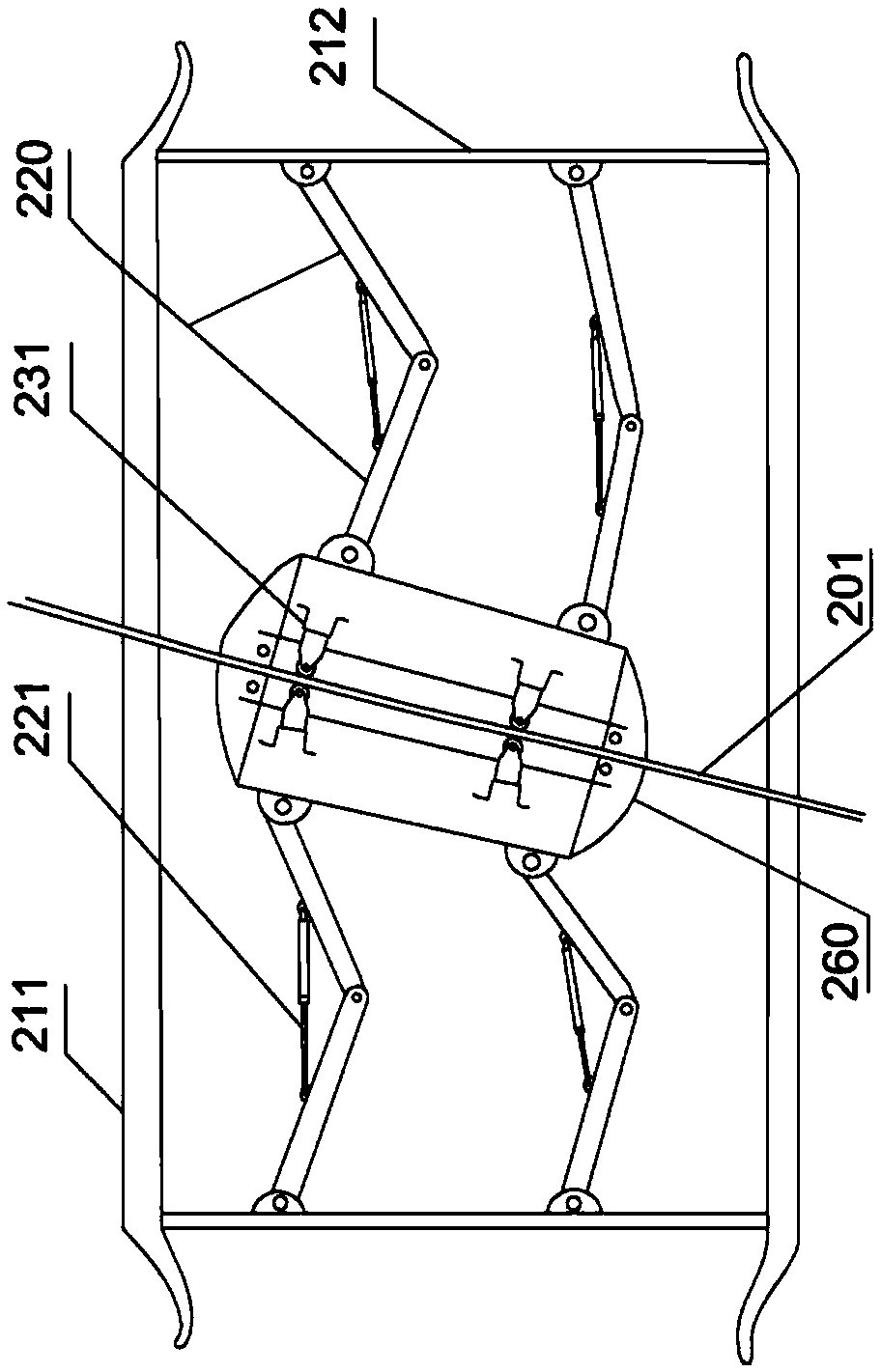

[0082] A laser-ultrasonic-based crack detection system for high-speed rail contact lines, with a contact line follower 200 and a laser ultrasonic detection device; the contact line follower 200 includes a lifting bow 210, a transmission mechanism 220, and a half-section cavity 230; the lifting bow 210 is installed It is installed on the roof of the detection train 101, and the two sides of the lifting bow 210 are connected to the half-section cavity 230 through two corresponding sets of identical transmission mechanisms 220; the laser ultrasonic testing device is installed in the half-section cavity 230, and the laser ultrasonic testing device includes Control processing unit 310, laser ultrasonic excitation device and ultrasonic receiving device 330; The control processing unit 310 is located in the compartment of the detection vehicle, which is convenient for the operator to control and operate, and it includes a laser control module, a data analysis module, a display module, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com