Device and method for online monitoring metal abrasive particles of oil in large-caliber oil return pipe

A metal abrasive particle and monitoring device technology, applied in the direction of measuring device, particle size analysis, particle and sedimentation analysis, etc., can solve the problems of high probability of missed detection, inability to use engineering monitoring, low detection sensitivity, etc. The effect of missed detection probability and sensitivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

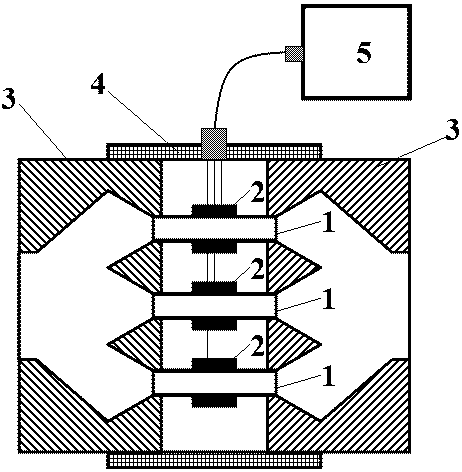

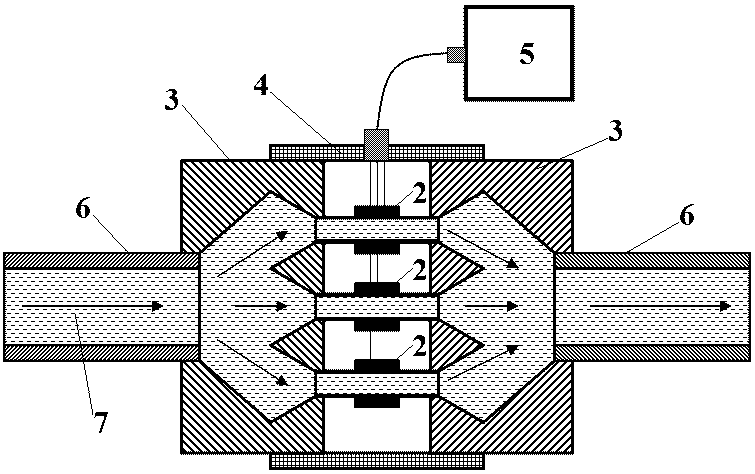

[0012] Examples such as figure 1 , an online large-diameter oil return pipe oil metal abrasive particle monitoring device, including a plurality of shunt conduits 1, a plurality of external through-type eddy current detection probes 2, two porous end face adapters 3, a fixed pipe 4, and a multi-channel eddy current detection Instrument 5 is characterized in that: one end of the porous end face transfer pipe 3 is a porous end face, the hole is in the shape of a trumpet, the narrow mouth of the hole faces outside the pipe, and the wide mouth faces in the pipe, and the mouth of the other end of the porous end face transfer pipe 3 is Trumpet shape, the narrow mouth of the nozzle faces the outside of the pipe, and the wide mouth faces the inside of the pipe. It is used to connect and fix the large-diameter oil return pipe 6 to be inspected. The hole in the shape of the horn can realize the drainage function, greatly reducing the resistance to the flow of the oil 7, and at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com