A method for quality loss assessment and early warning of key assembly process in complex precision equipment assembly workshop

A technology of assembly process and assembly workshop, applied in data processing applications, instruments, biological neural network models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

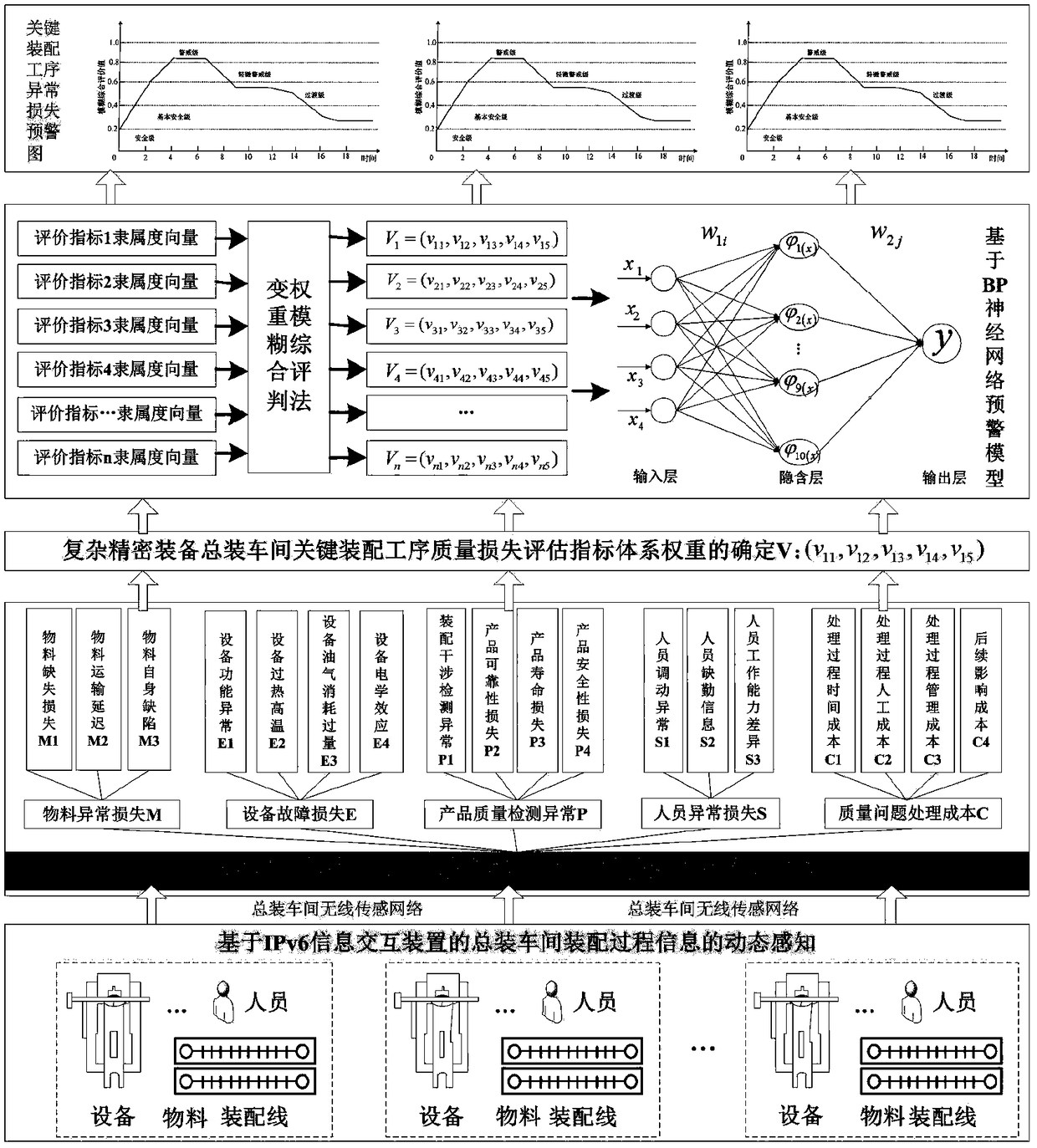

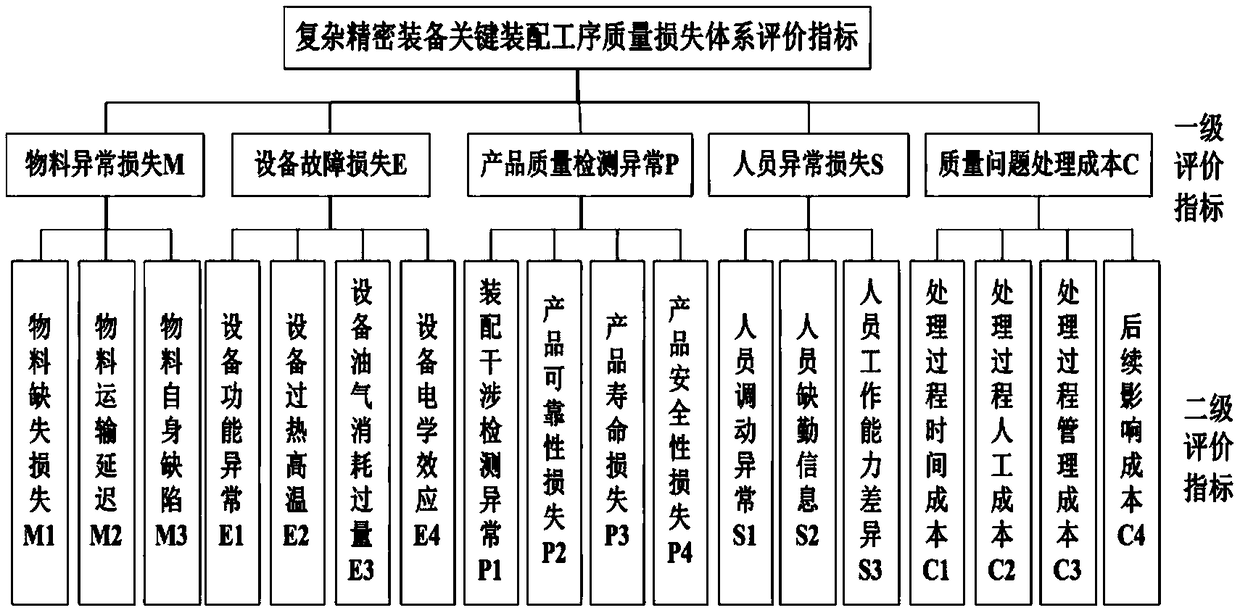

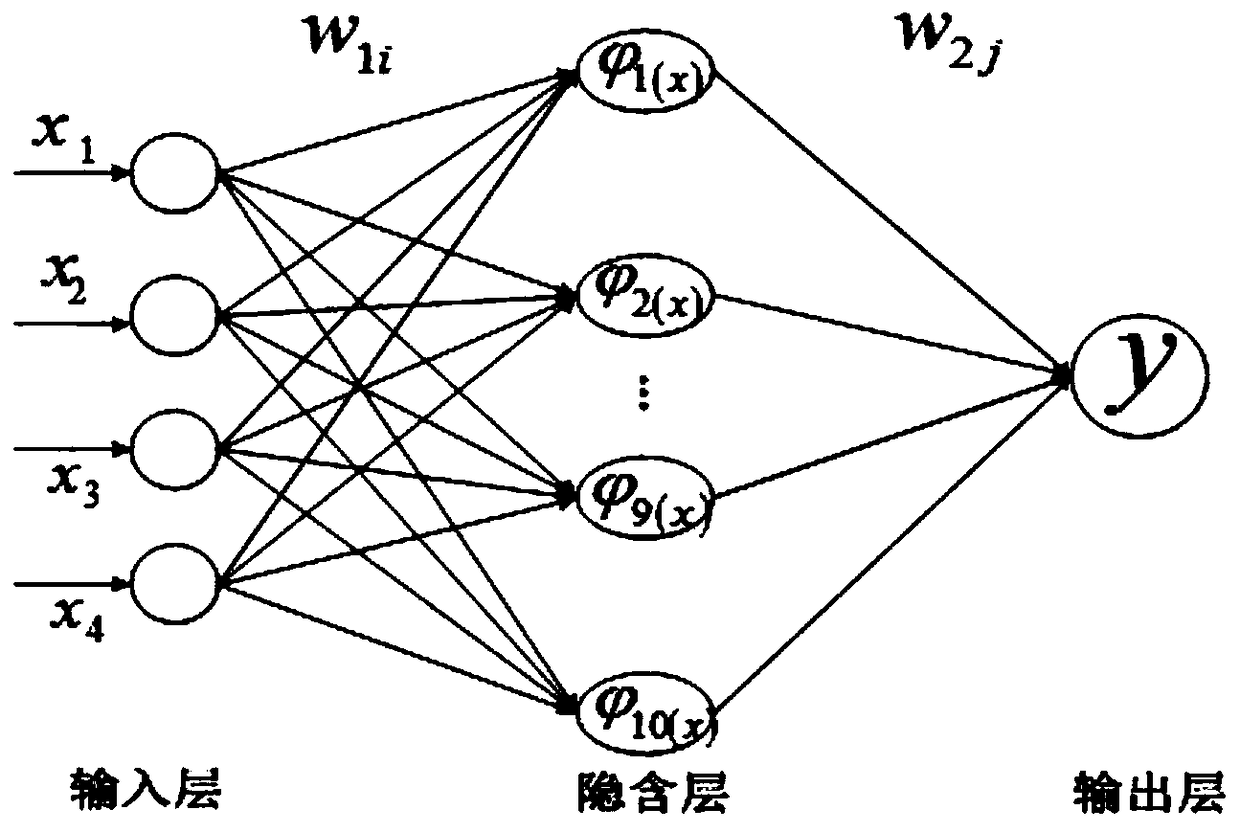

[0039] 1) Establishment of quality loss assessment index system for key assembly processes in complex precision equipment assembly workshops

[0040] In the actual assembly process of the assembly workshop of complex precision equipment, there are many factors affecting the quality loss of key assembly processes, including equipment factors, material factors, personnel factors, and quality factors. Once the quality of complex precision equipment is abnormal during the assembly process, it will not only consume enterprise resources to deal with the fault problem, but also affect the production progress, production cost, and customer satisfaction of subsequent processes. Therefore, to evaluate the quality loss of key assembly processes in the assembly workshop of complex precision equipment, it is necessary to comprehensively consider the influence of failure or loss factors such as materials, equipment, personnel, and quality in the assembly production process, so as to improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com