Patents

Literature

95results about How to "Realize quality control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

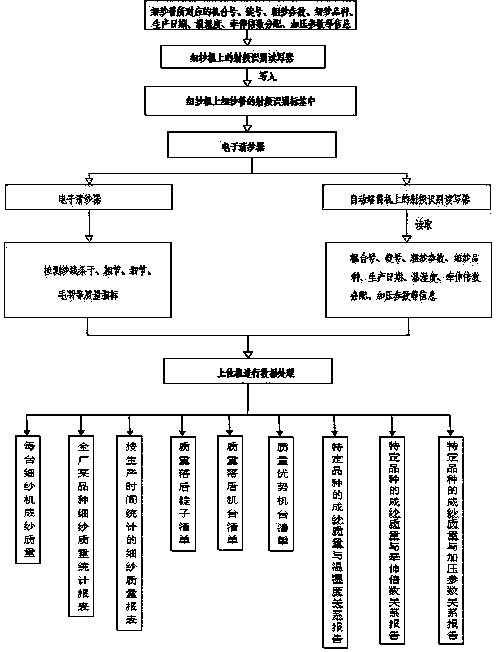

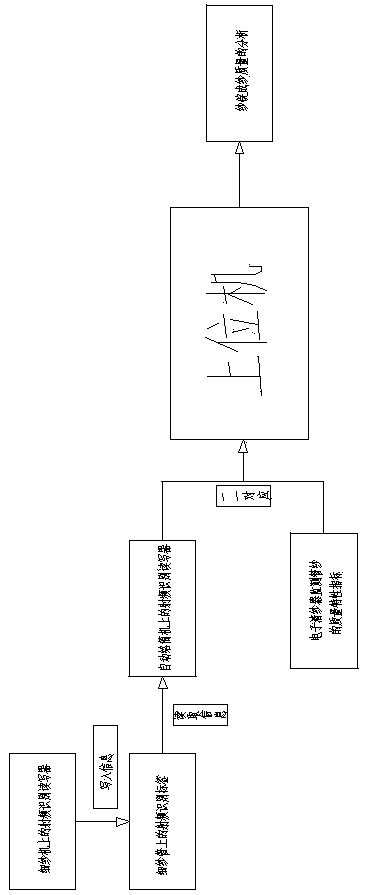

Method and system for comprehensively monitoring and tracing ring spinning yarn quality

InactiveCN107904720ARaise the level of spinning qualityQuality improvementTextiles and paperYarnQuality level

The invention discloses a method and system for comprehensively monitoring and tracing the ring spinning yarn quality. Before doffing, the information, including the machine number, the ingot number,parameters of adopted rough yarn, the variety of spun yarn, the production date of the spun yarn, spinning temperature and humidity, draft multiple distribution and draft pressurizing parameters, of aspinning machine are written to a radio frequency identification tag of a corresponding spun yarn tube through a radio frequency identification reader-writer; when bobbin yarn enters a doffing station, the radio frequency identification reader-writer reads the information in radio frequency identification tags of all spun yarn tubes, then makes the information matched with the quality characteristic indexes including evenness, slugs, snicks, neps and hairiness, detected by an electronic yarn clearer on a yarn channel, of the bobbin yarn corresponding to the spun yarn tubes one by one, and reports the information to an upper computer, and finally, the analysis and tracing of the yarn forming quality of all spindles are achieved through a data analysis system of the upper computer. By meansof the method, the spinning quality levels of all spinning machines are improved, poor spindles in all the spindles are pointed out, and the quality monitoring of all the spindles is achieved.

Owner:HUNAN UNIV OF ARTS & SCI

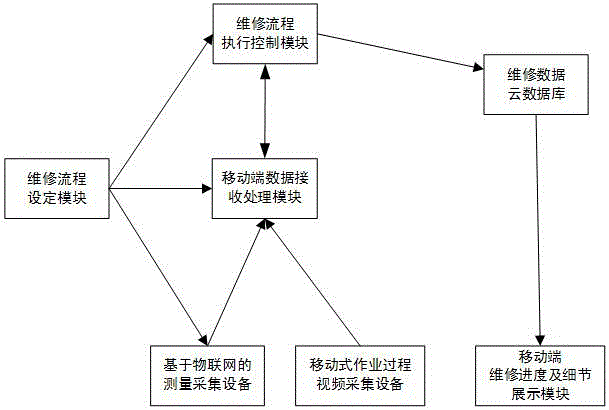

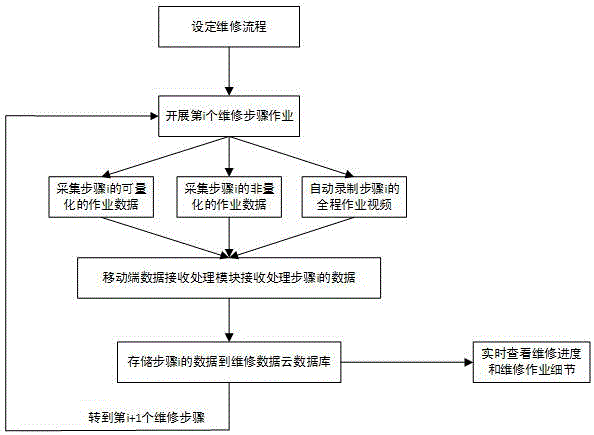

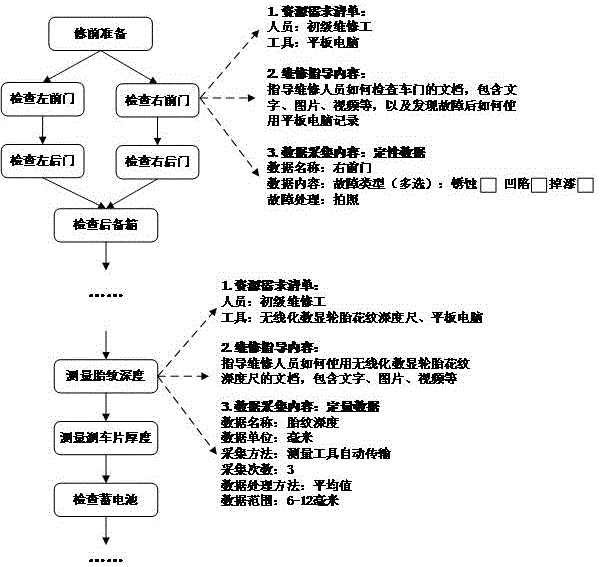

Automobile repair and maintenance process monitoring and displaying system and method based on internet of things

InactiveCN106022619ACheck the maintenance progress in real timeView maintenance job details in real timeResourcesCommerceExecution controlComputer science

The invention discloses an automobile repair and maintenance process monitoring and displaying system and method based on an internet of things. The system comprises a repair flow setting module, a repair flow execution control module, a mobile end data receiving and processing module, a measuring and collection device based on the internet of things, a mobile working process video collection device, a mobile end repair progress and detail display module and a repair data cloud database. The method is applicable to automobile repair and maintenance monitoring of an automobile repair enterprise, and compared with the prior art, the method has the effects that 1), quality monitoring automation and datamation of the repair work process are realized; 2) the transparency in the repair work process is improved, and repair integrity degree is increased; and 3) the work efficiency is improved based on repair guidance of repair steps, and the training time is shortened.

Owner:张红叶 +1

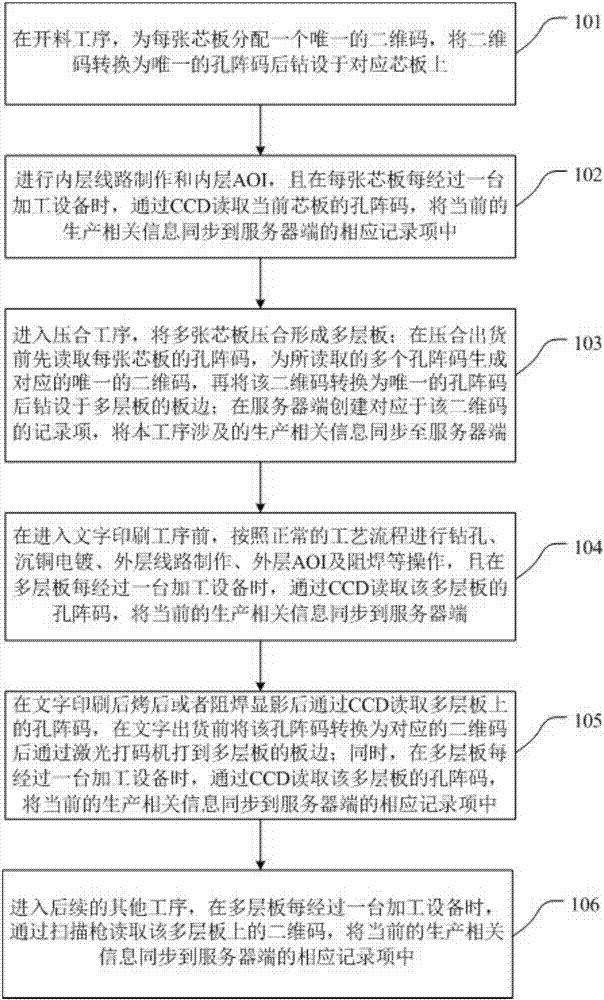

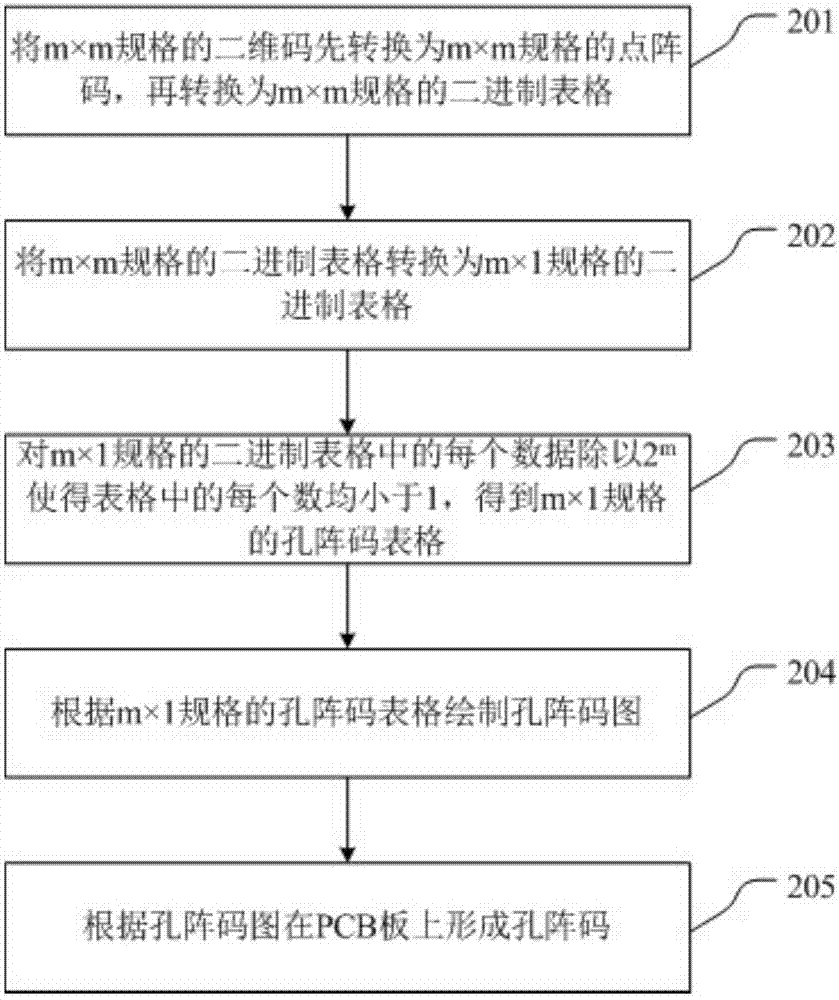

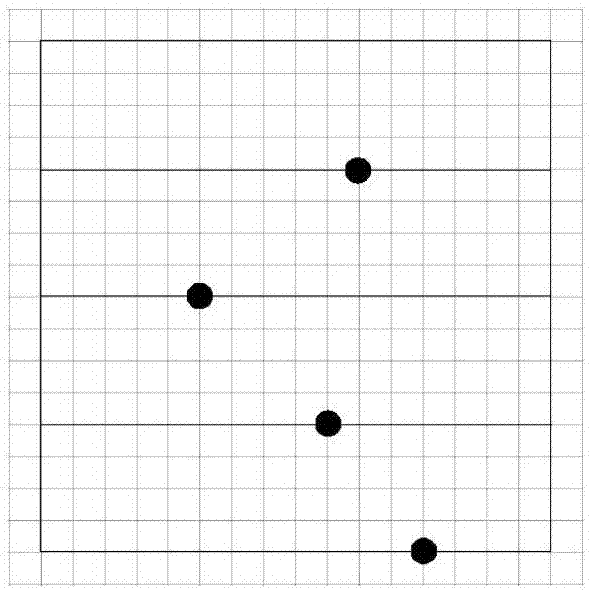

Efficient method for quality tracing of multilayer PCB

ActiveCN107992917AAccurate identificationRealize quality controlCo-operative working arrangementsResistParallel computing

The invention discloses an efficient method for quality tracing of a multilayer PCB. The method includes the steps of distributing two-dimensional codes for each core plate in a cutting process, converting the two-dimensional codes into aperture array codes and drilling the aperture array codes in the corresponding core plates; in a press fit process, reading the aperture array codes on each coreplate, combining all the read aperture array codes to generate corresponding two-dimensional codes, and converting the corresponding two-dimensional codes into aperture array codes and then drilling the aperture array codes in the multilayer board; after a solder resist process, reading the aperture array codes on the multilayer board, and converting the aperture array codes into corresponding two-dimensional codes and drilling the two-dimensional codes in the multilayer board. A method for conversion from a two-dimensional code to an aperture array code includes the steps of converting the two-dimensional code into a binary form with a m * m specification, and dividing the binary form into at least two parts; converting each part into an aperture array code local graph; and combining allthe obtained aperture array code local graphs into a complete aperture array code graph, and finally forming the aperture array code on the PCB. According to the efficient method for quality tracing of the multilayer PCB, the two-dimensional code can be converted into the aperture array code with a smaller number of apertures, the processing workload is reduced, and it is effectively ensured thattracing markers are accurately identified.

Owner:GUANGDONG ZHENGYE TECH

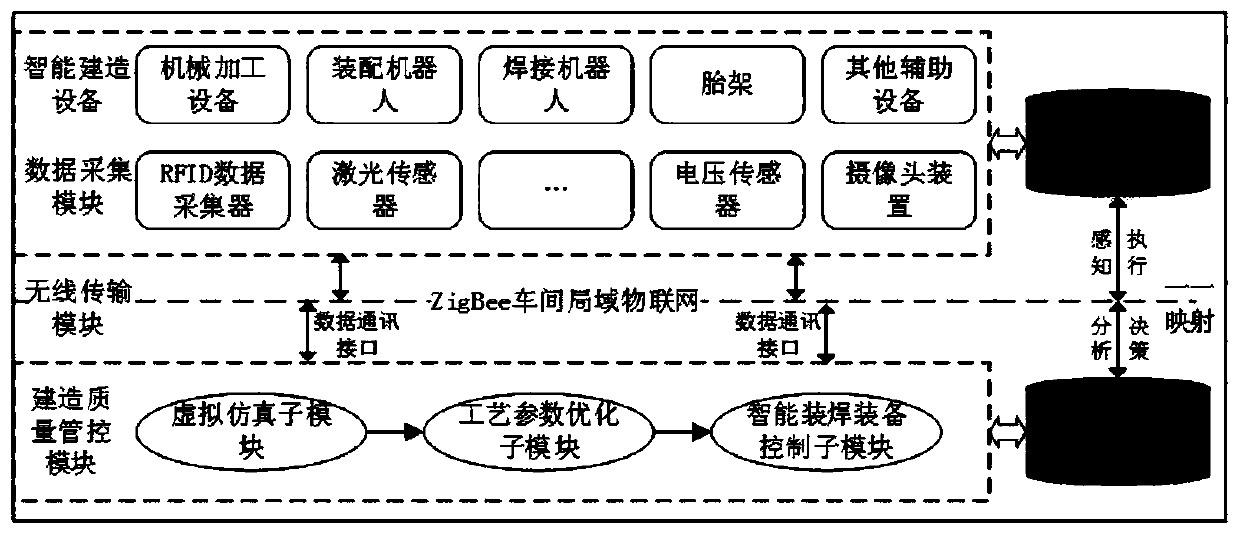

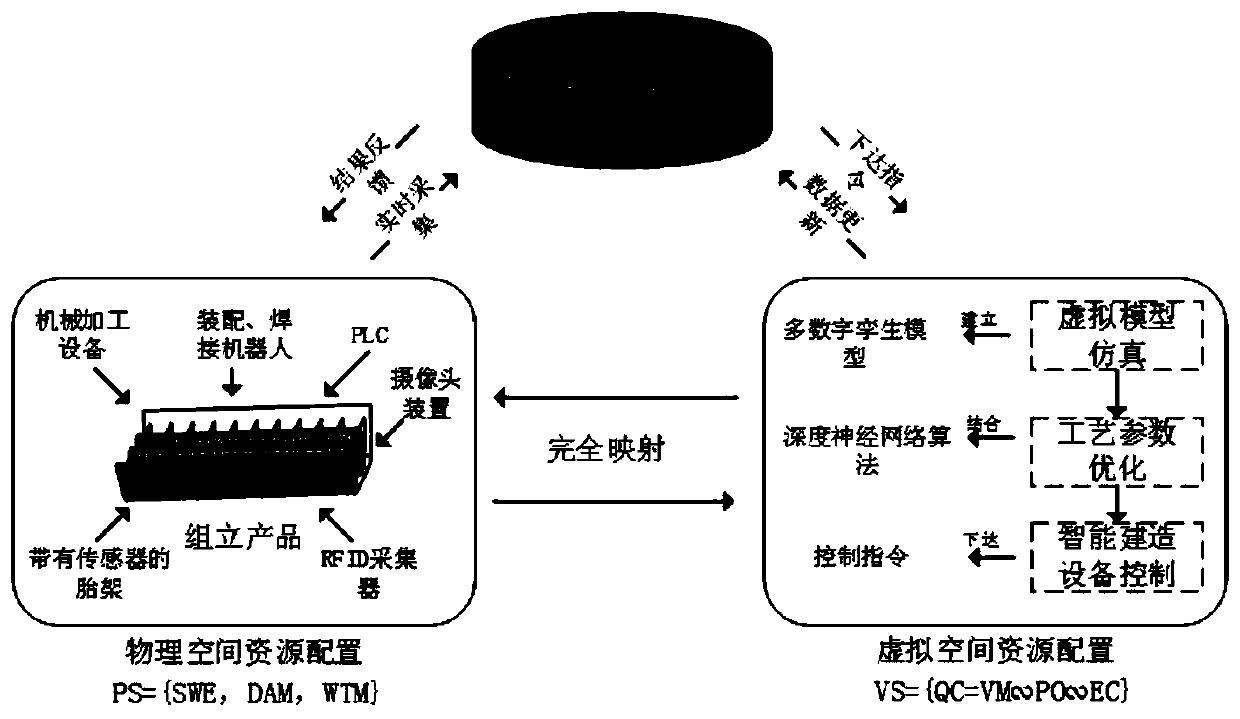

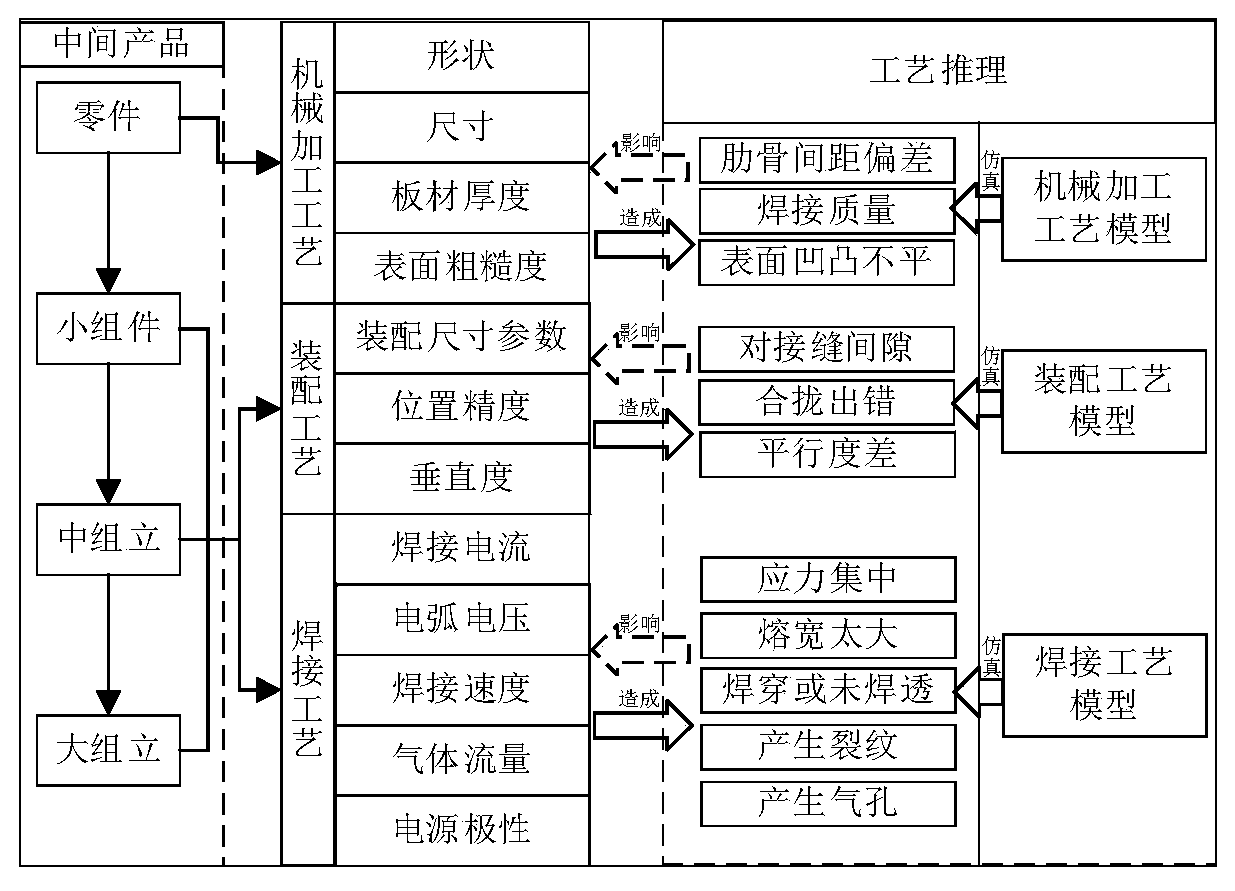

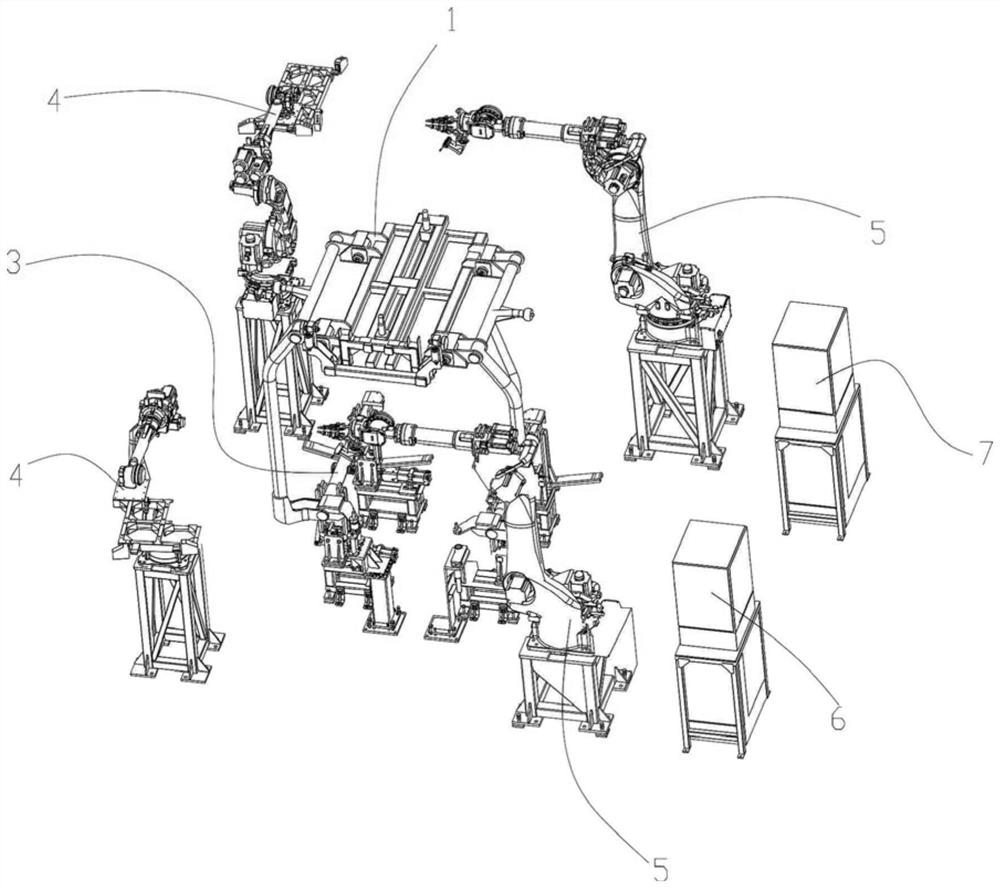

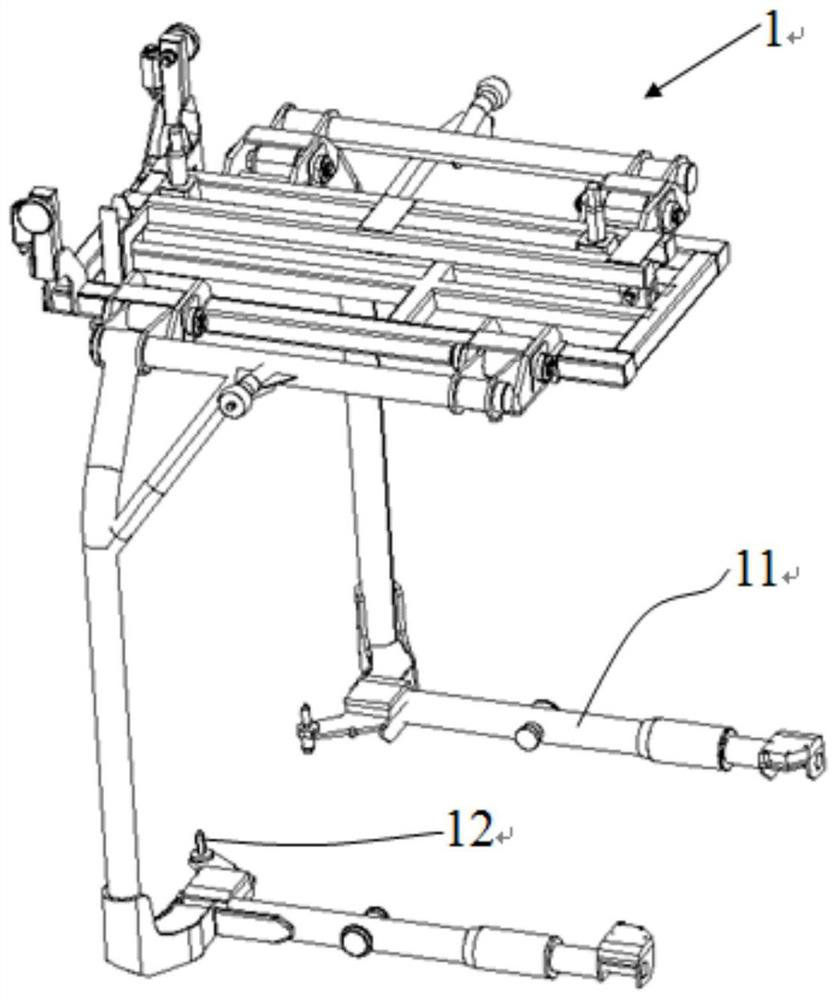

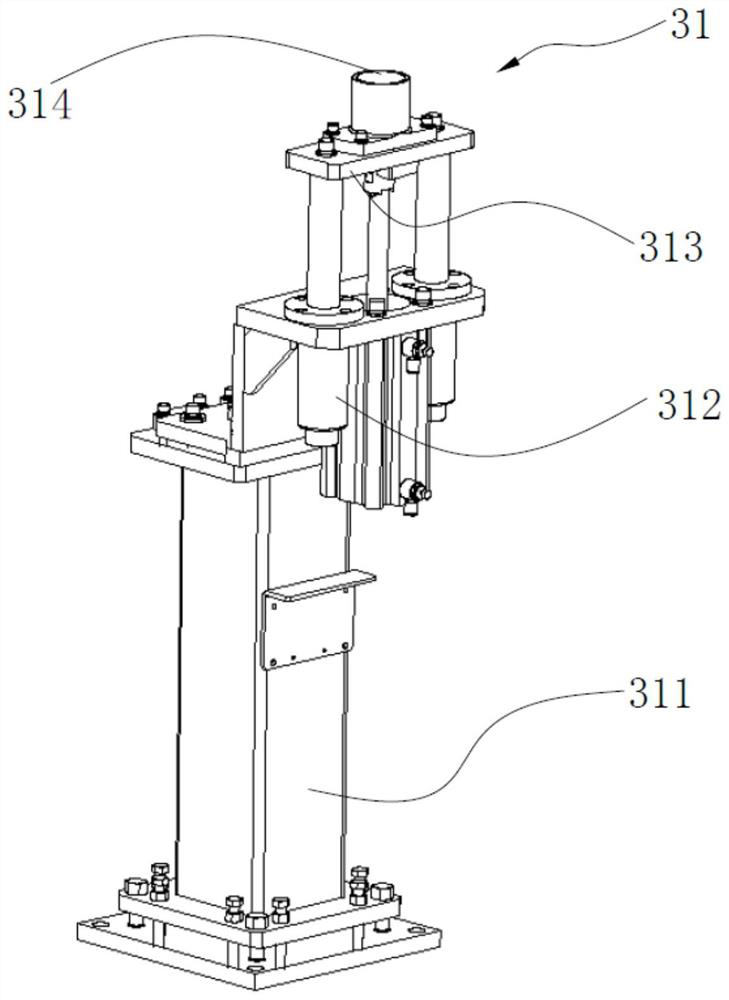

Twin data-driven ship assembly product quality control system and configuration method

ActiveCN110705882ARealize quality controlOptimizing Process ParametersResourcesManufacturing computing systemsQuality control systemData acquisition

The invention discloses a twin data-driven ship assembly product quality management and control system and a configuration method. The system is composed of intelligent construction equipment, a dataacquisition module, a wireless transmission module and a construction quality management and control module. The intelligent construction equipment forms an assembly product manufacturing production line according to a construction process, the data acquisition module acquires assembly product process data and equipment current operation state data in real time, and the wireless transmission module is used for communication between the data acquisition module and the construction quality control module. The construction quality management and control module firstly fuses process data, equipment state data and historical data to form twin data. Secondly, a multi-digital twinning model is established and simulated to obtain process parameters to be optimized, the process parameters are optimized according to a deep neural network algorithm, and finally the process parameters are converted into an instruction which can be recognized by intelligent construction equipment, thereby finishingquality control of a ship assembly product. The invention further provides a configuration method of the system, and the operational feasibility of the system is further explained.

Owner:JIANGSU UNIV OF SCI & TECH

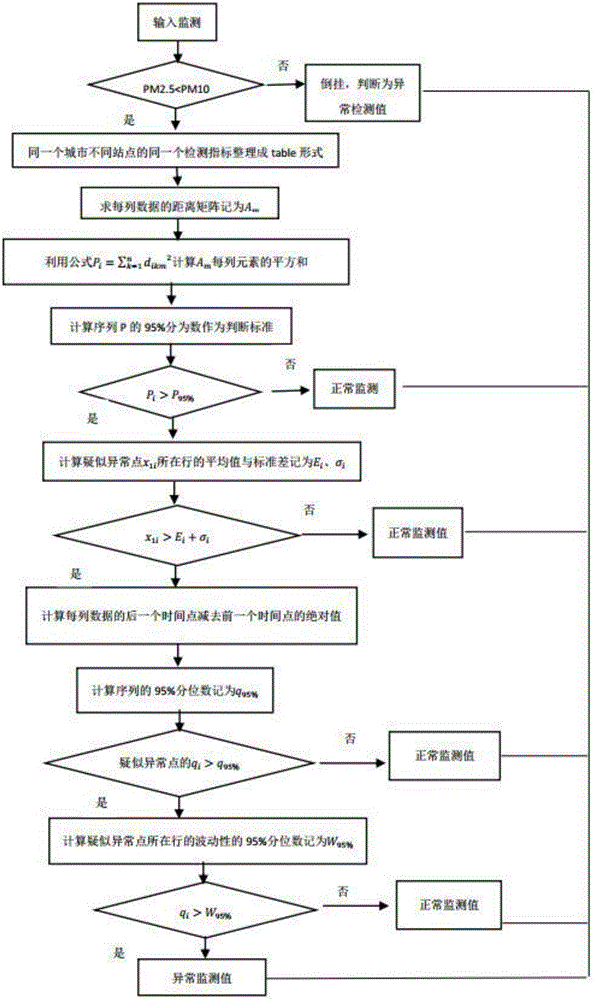

Similar distance discrimination-based single index data quality control method

ActiveCN107436277AQuality assuranceGuaranteed timelinessMeasurement arrangements for variableParticle suspension analysisDistance discriminationAnomaly detection

The invention relates to a similar distance discrimination-based single index data quality control method. The above single index is an atmosphere environment single index. The method includes the following steps: S1, comparing the PM2.5 concentration with the PM10 concentration in each station, judging whether the concentrations are abnormal detection values or not, and carrying out next step calculation if not; S2, introducing detection data in a timed sequence; S3, screening normal values through the outlier degree P, and judging the remaining detection values as suspected abnormal values; S4, judging the suspected abnormal values screened in step S3 as normal monitoring values when the suspected abnormal values are in a 1 standard deviation range, and confirming the suspected abnormal values if the suspected abnormal values are not in the above range; S5, calculating the fluctuation degree q of the suspected abnormal values determined in S4, judging whether the suspected abnormal values are normal monitoring values or not, and confirming the suspected abnormal values if not; S6, calculating the volatility w of the detection data in each station at the suspected abnormal value confirmation time, and judging whether the detection data are abnormal or not through the w95% value; and S7, finally judging the values confirmed in step 1 and step 6 as abnormal values. The existence or not of the abnormal phenomenon of the data is judged from the data distance, the data fluctuation and the correlation among the stations. The method achieves the automatic auditing mechanism of the data, and effectively guarantees the data quality.

Owner:SUN YAT SEN UNIV +1

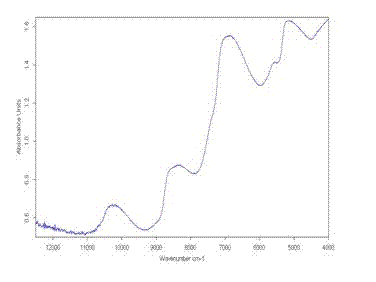

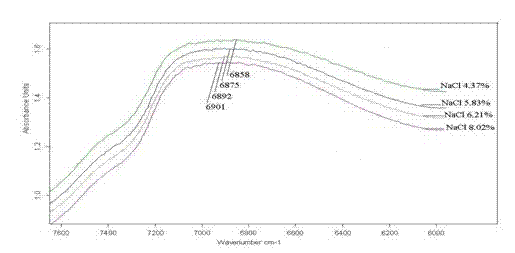

A method for rapid detection of salt content in Fuling mustard by near-infrared spectroscopy

InactiveCN102297845ARapid determinationReliable predictionsColor/spectral properties measurementsSalt contentNear infrared spectra

The invention relates to a method for rapidly detecting the salt content in Fuling pickled mustard by using near-infrared spectroscopy. The detection steps of the method of the invention include sample collection, standard determination of the salt content of each sample, collection of each sample spectrum establishment, inspection model, product detection and classification, and the like. The method of the present invention has the characteristics of no need for pretreatment, no pollution, on-line detection, and simultaneous determination of multiple components, and is more environmentally friendly, fast, simple and quick, and can use chemometrics to establish a qualitative and quantitative method for determining the salt content in pickled vegetables such as Fuling mustard. quantitative model. The innovation of the present invention is that the near-infrared spectrum cannot reflect the characteristic absorption peak of inorganic table salt, but different Na+ and Cl- ions are released due to the different content of table salt in the sample, which affects the absorption peak of water, so the content of table salt can be quickly determined by modeling , and at the same time perform clustering according to the salt content into low-salt, medium-salt and high-salt beneficial effects.

Owner:杨季冬

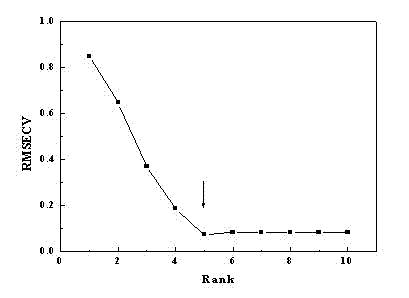

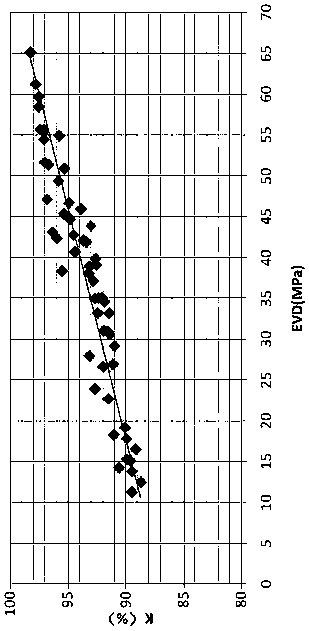

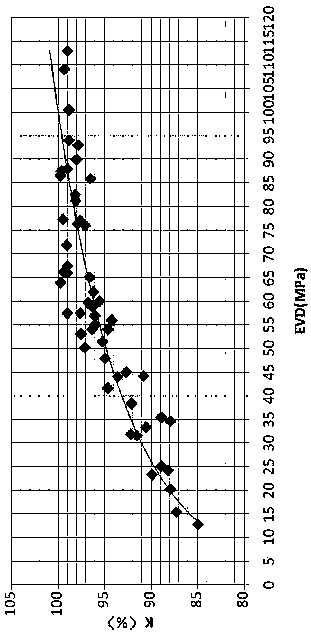

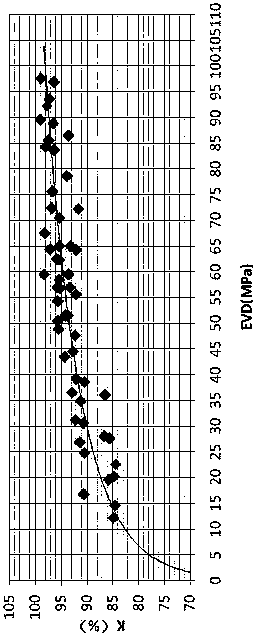

Rapid detection method for highway roadbed compaction quality

InactiveCN108396723AReal-time understanding of construction statusSimple and fast operationIn situ soil foundationEeg dataDeformation modulus

The invention relates to a rapid detection method for the highway roadbed compaction quality. The method comprises the following steps that firstly, in construction fields of roadbeds different in soil texture, a to-be-detected roadbed soil area is selected, a test point is selected at random, the dynamic deformation modulus Evd value of the point is tested, and data are recorded; secondly, another test point is selected, the roadbed compaction degree is detected through a sand filling method, and data are recorded; thirdly, the first step and the second step are repeatedly conducted, and therelation of the dynamic deformation modulus Evd value and the roadbed compaction degree K of each soil texture is established; fourthly, field testing is conducted; fifthly, data collection is clickedfrom a data collection software main interface, a testing instrument starts to conduct testing and transmission, and a background part conducts calculation and conversion according to the Evd and K correlation of the soil texture corresponding to the roadbed, and the compaction degree K is obtained; and sixthly, a detection result is uploaded to a roadbed compaction quality background managementsystem through the network, and the data are checked. The rapid detection method is rapid and convenient to conduct, data are accurate and reliable, the rapid detection method is applicable to the construction site, and the quality information can be reflected in real time.

Owner:甘肃省交通规划勘察设计院股份有限公司 +2

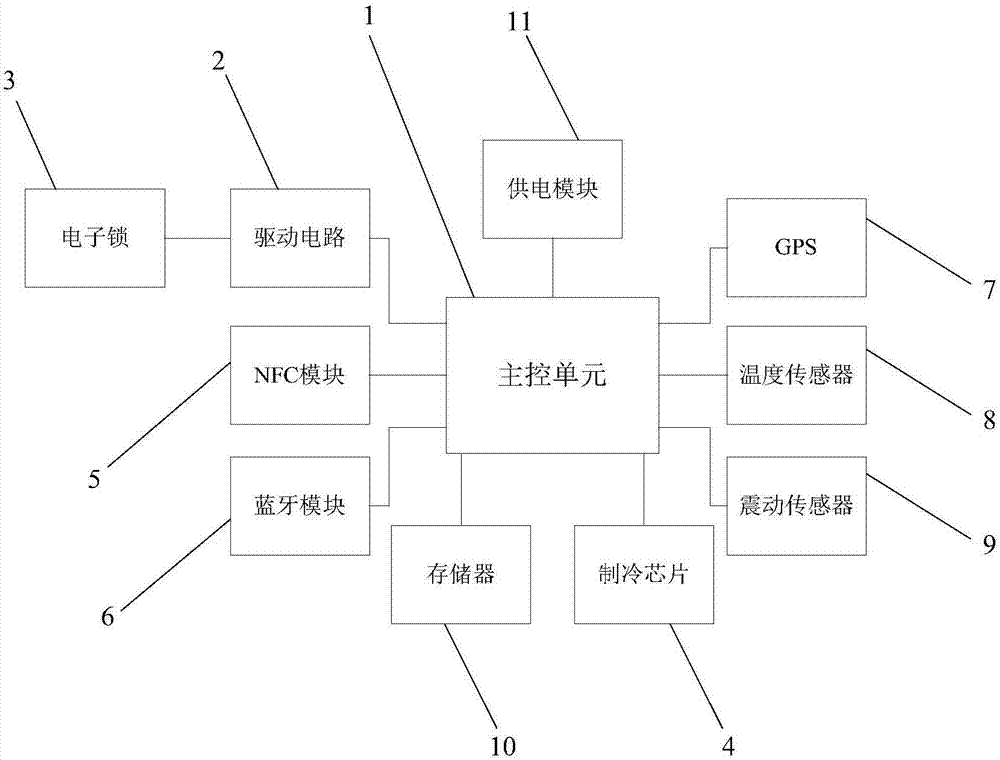

Intelligent and movable refrigerator and management method

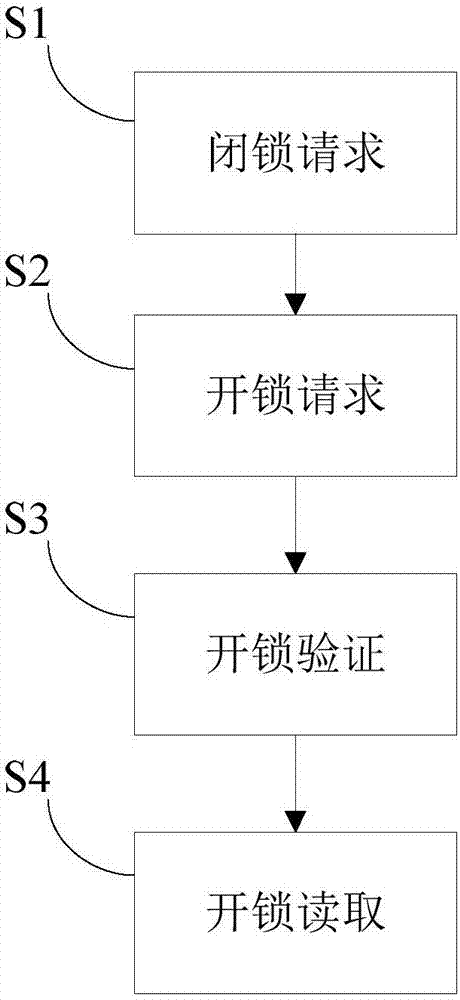

InactiveCN107235230APrevent leakageReduce pollutionShock-sensitive articlesLocking devicesTemporal informationPassword

The invention provides a management method of an intelligent and movable refrigerator. The management method comprises the steps that firstly, a first terminal sends unique identification of the refrigerator to a first server, the unique identification is identified as a first request, the first servo records order information and delivery time information, and a corresponding relation is established with a database of a second server; secondly, the second server sends the unique identification to the first server, the unique identification is identified as a second request, and the second terminal receives a verification request; thirdly, the first server receives verification information input through the second terminal, verification is carried out with the order information, and after verification is successful, receiving time information is recorded, the unique identification is sent to the second server, and a corresponding refrigerator password is obtained; and fourthly, the second terminal receives the refrigerator password and carries out matching unlocking, the temperature data in the refrigerator is read, and the receiving time information and the delivery time information which are sent by the first server are received. By means of the method, safe transportation can be effectively guaranteed, and inquiring and tracing of the receiving time information and the delivery time information facilitate responsibility judgment.

Owner:广东派特埃尔生物科技有限公司

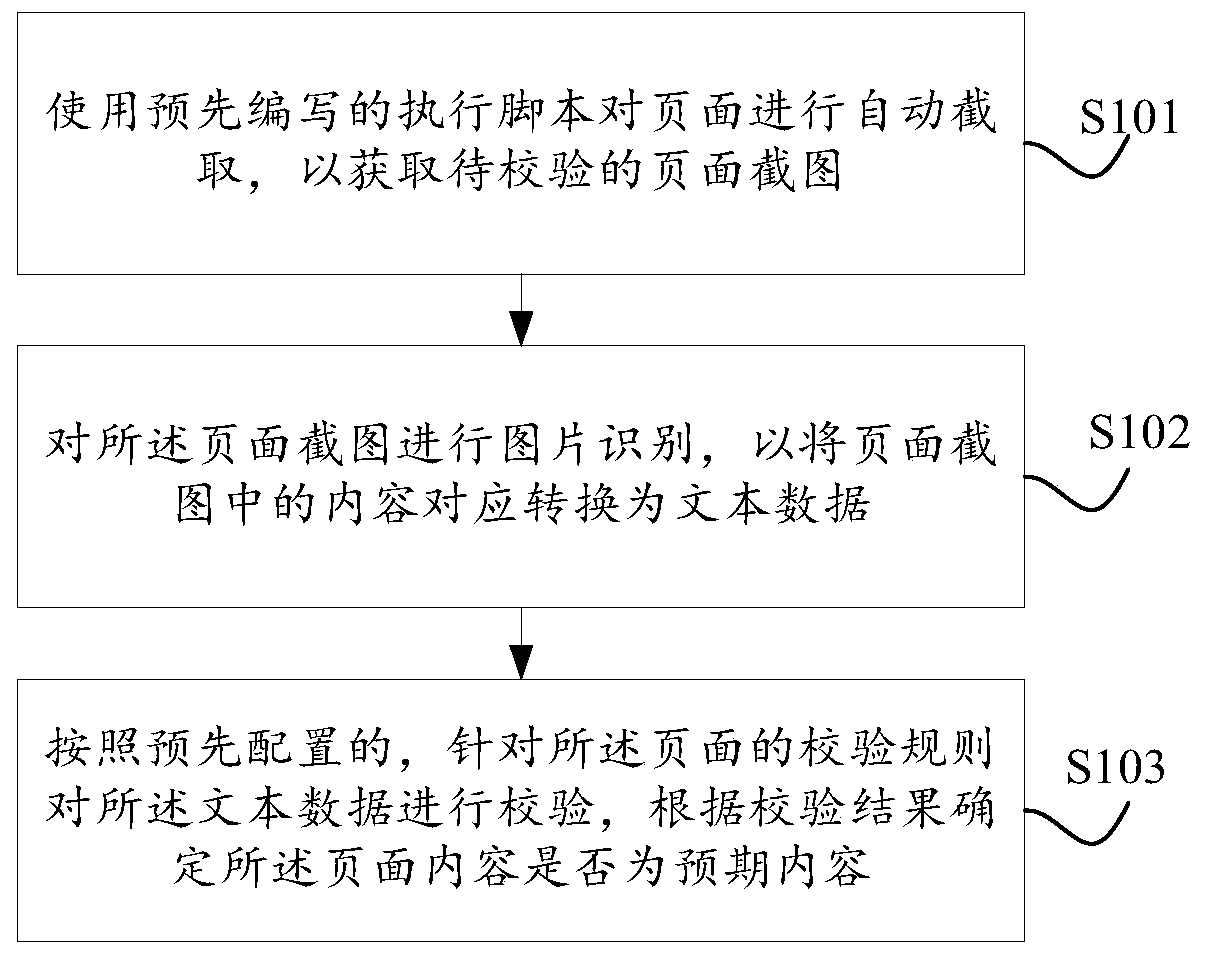

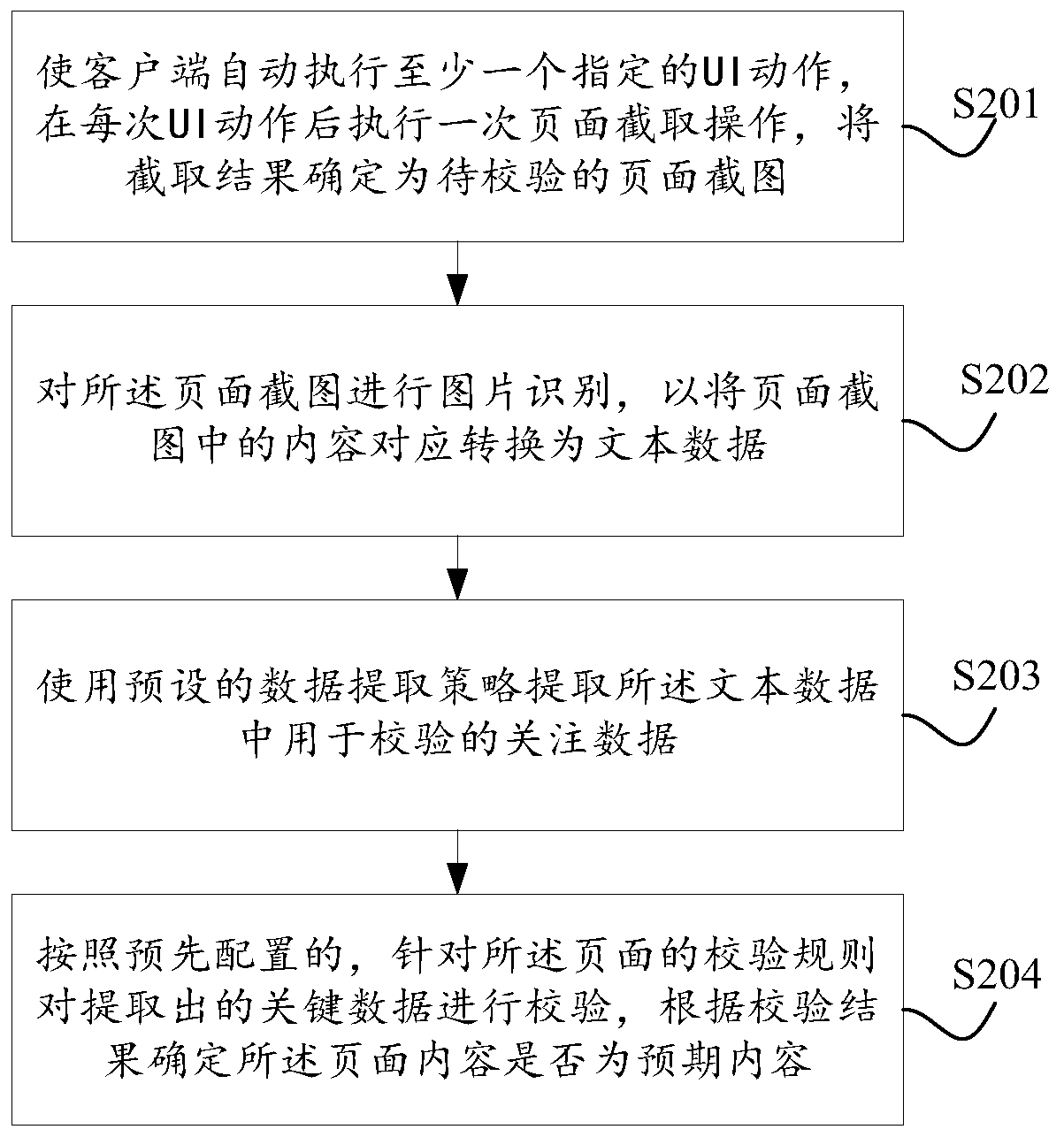

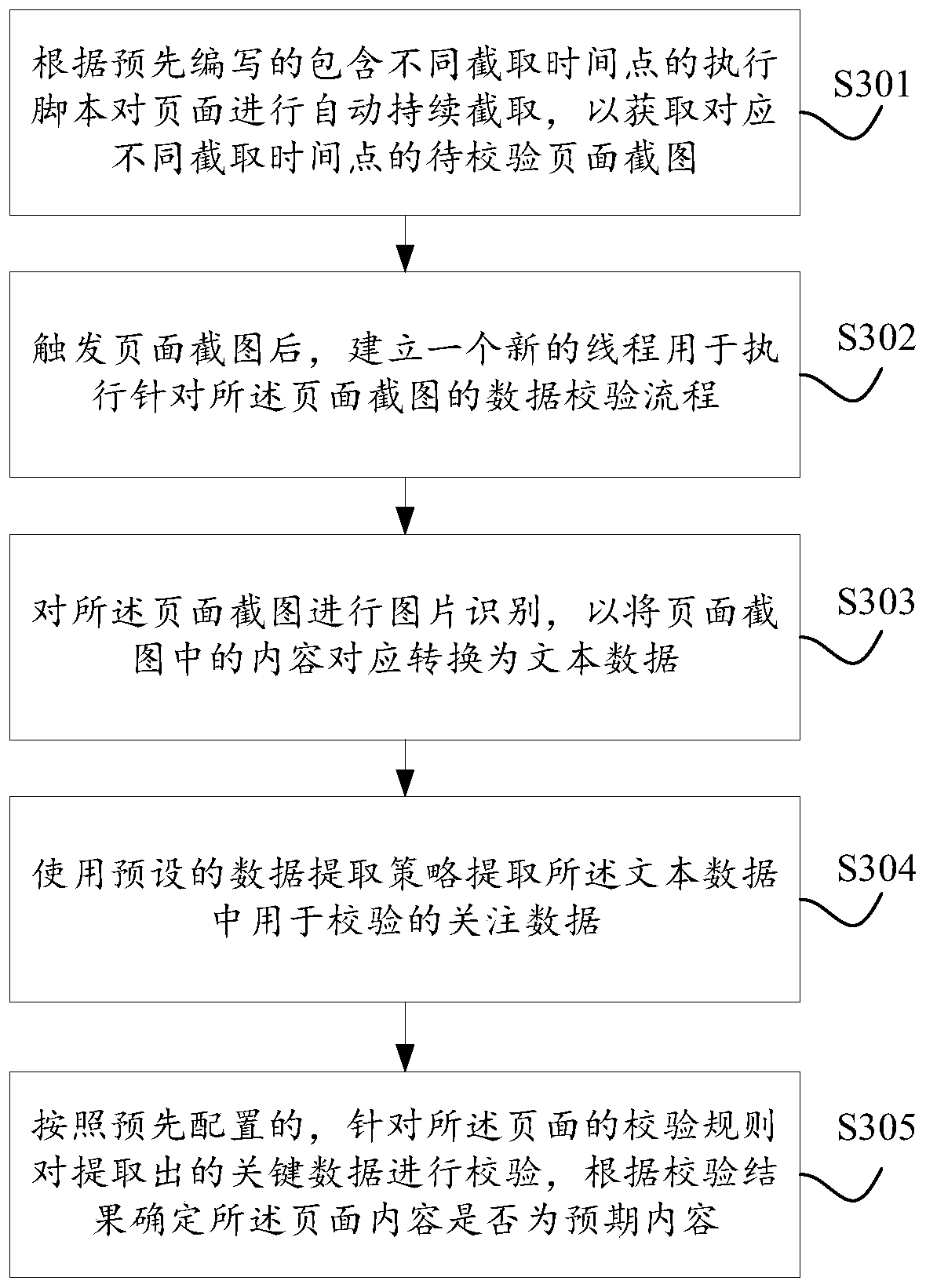

An automatic page data verification method and device

PendingCN109901968ARealize quality controlExamples cannot be limitedHardware monitoringData verificationQuality monitoring

The invention provides an automatic page data verification method and device. The method comprises the following steps: firstly, automatically intercepting a page by using a pre-compiled execution script to obtain a page screenshot to be verified; Carrying out picture identification on the page screenshot to correspondingly convert the content in the page screenshot into text data; And verifying the text data according to a pre-configured verification rule for the page, and determining whether the page content is expected content or not according to a verification result, thereby determining whether the content displayed on the page is correct or not, and realizing quality monitoring for the real-time content of the page.

Owner:ADVANCED NEW TECH CO LTD

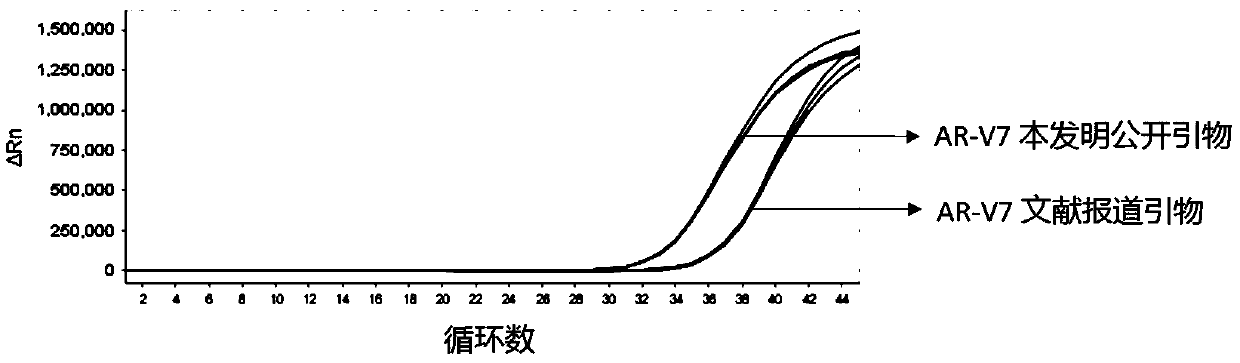

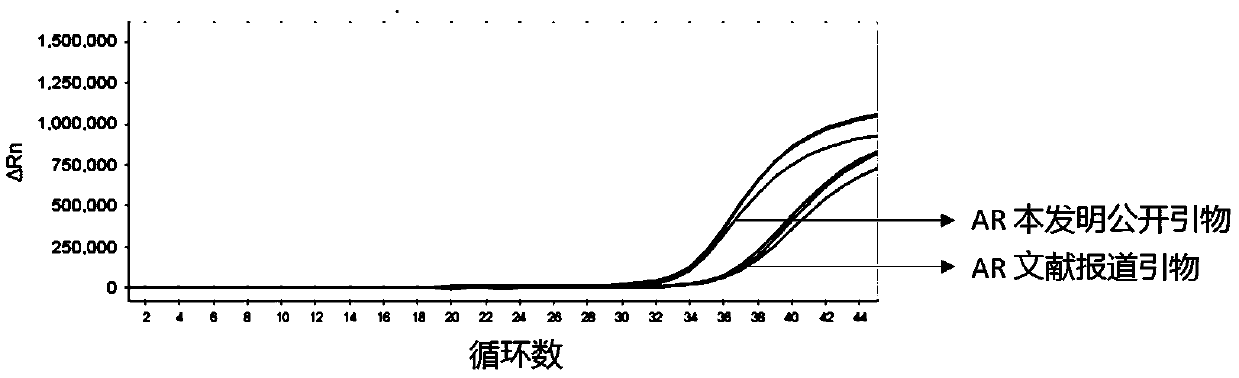

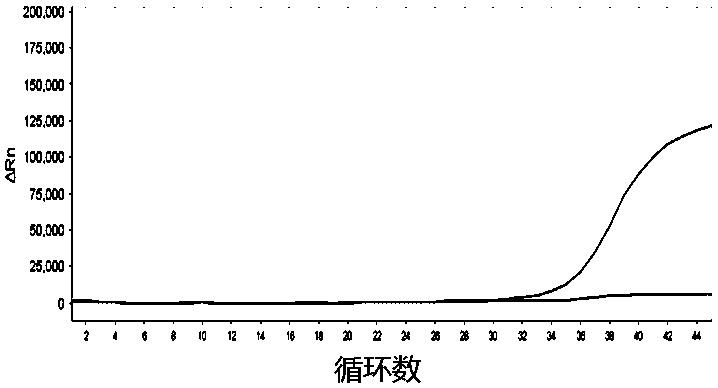

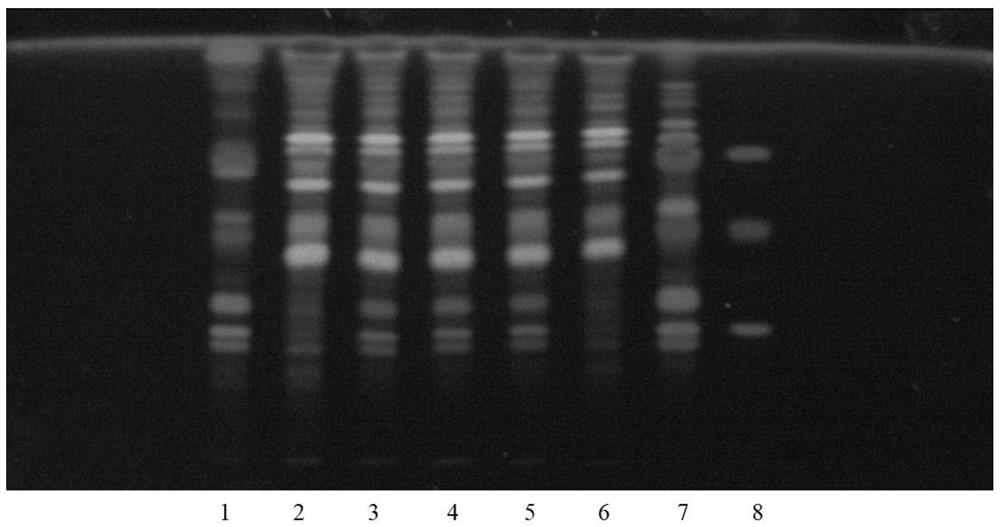

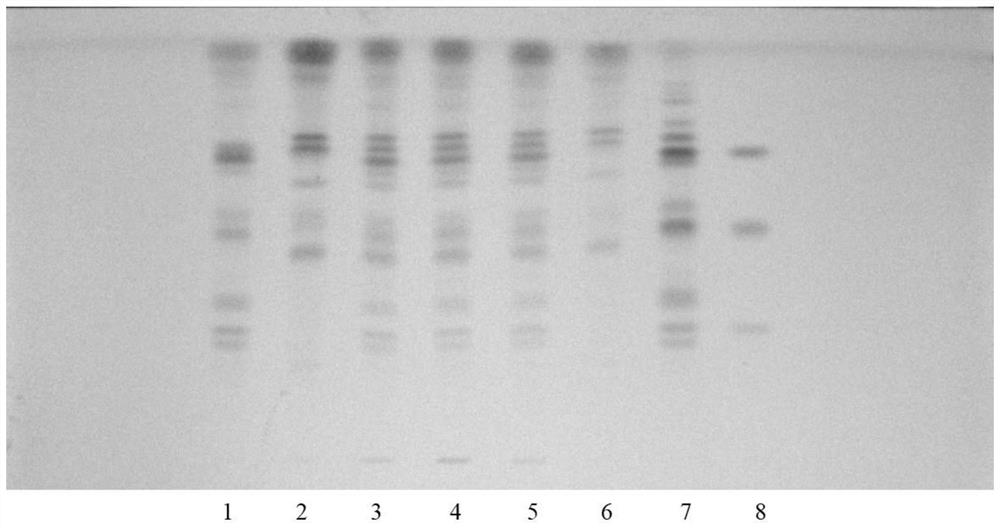

Primer, probe and reagent kit for quick and quantitative detection by AR-V7 fluorescent qRT-PCR method

ActiveCN110923299AAvoid the problem of not being easy to scale upShorten the lengthMicrobiological testing/measurementDNA/RNA fragmentationExosomePcr method

The invention discloses a primer and probe for detecting AR-V7 and ARE, and provides a reagent kit for detecting AR-V7 and AR based on the primer and probe. The reagent kit comprises an exosome extraction reagent, an exosome nucleic acid extraction reagent, an AR-V7 detection reagent by a qRT-PCR method. Samples for the reagent kit are broad and easy to obtain, the success rate for preparing exosomes is high, exosome nucleic acid is automatically extracted, the required operation time is short, and the operation errors are low. Besides, according to an one-step method qRT-PCR reagent providedby the invention, the operation flows are simplified, the experiment period is shortened, the efficiency is improved, and the sample contamination or detection fault risks in the middle process can also be reduced.

Owner:3D BIOMEDICINE SCI & TECH CO LTD

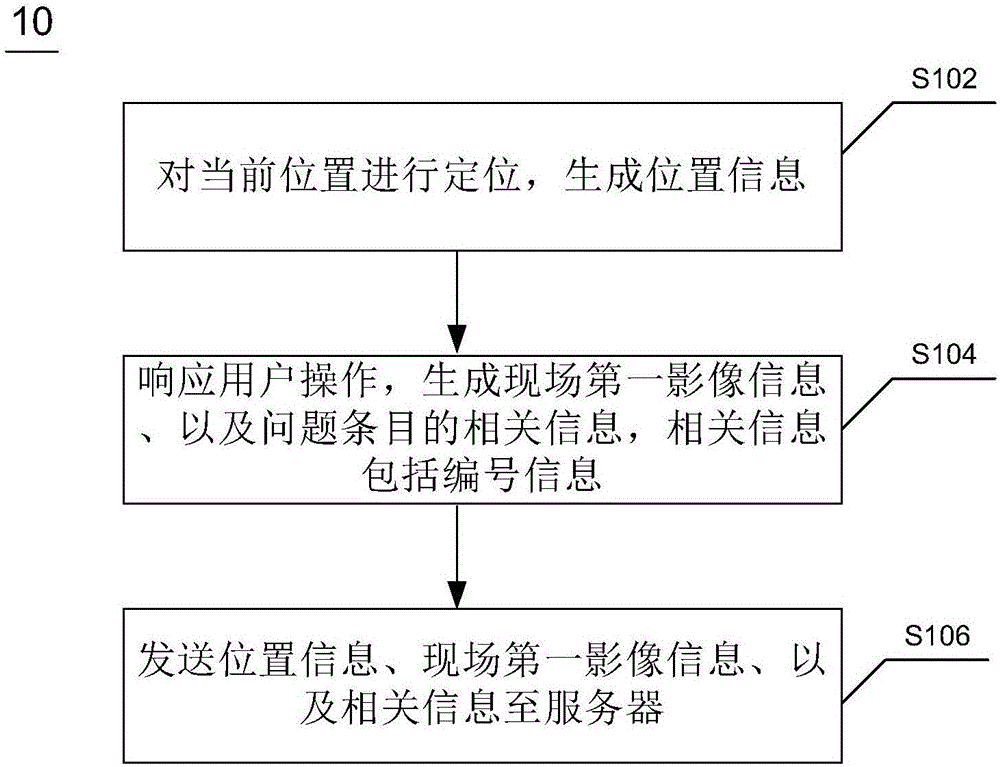

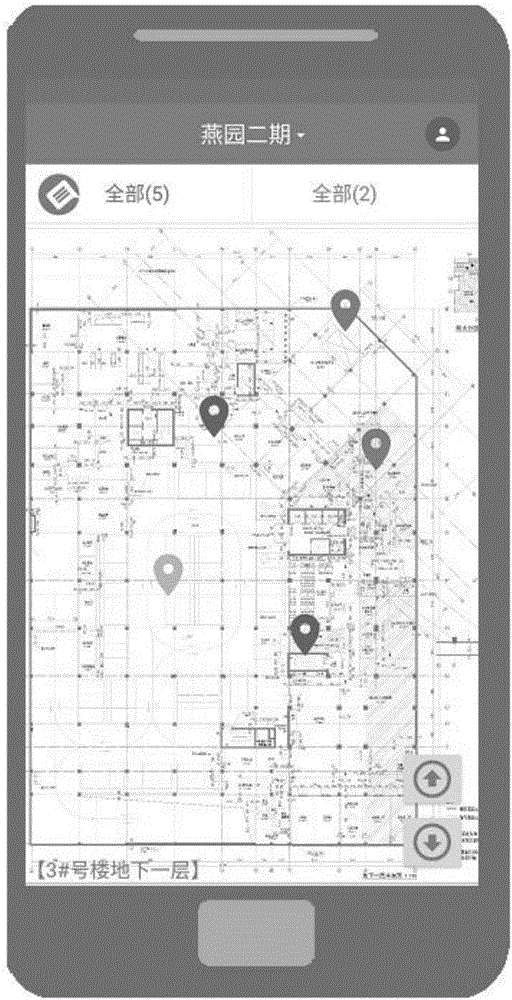

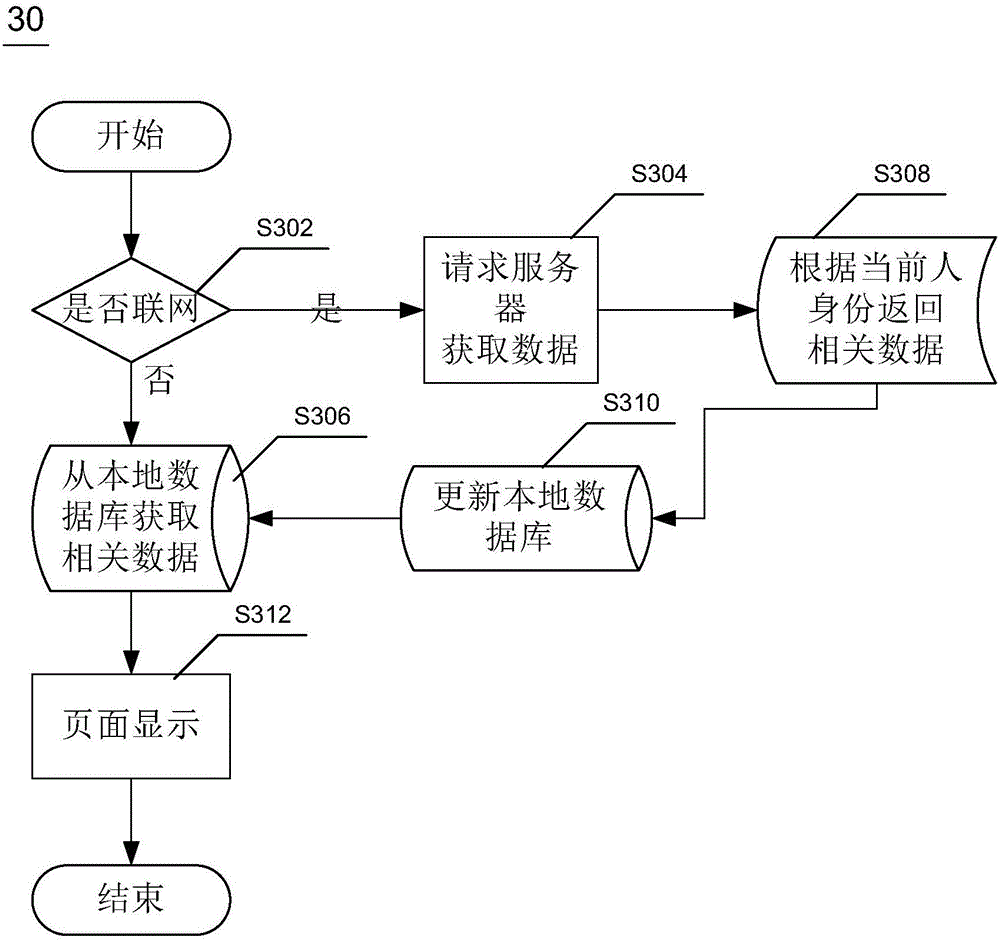

Method, system and mobile terminal for monitoring constructional engineering

ActiveCN106779585APinpoint Engineering ProblemsRealize quality controlOffice automationRelevant informationComputer terminal

The invention discloses a method, a system and a mobile terminal for monitoring constructional engineering. The method comprises the steps that a current location is positioned to generate location information; a response is made to user operation, and first site image information and relevant information of problem items are generated, wherein the relevant information comprises number information; and the location information, the first site image information and the relevant information are sent to a server. Through the method, the system and the mobile terminal for monitoring constructional engineering, engineering problems can be precisely positioned, and quality monitoring in a full cycle of constructional engineering is realized.

Owner:TAIKANG LIFE INSURANCE CO LTD +1

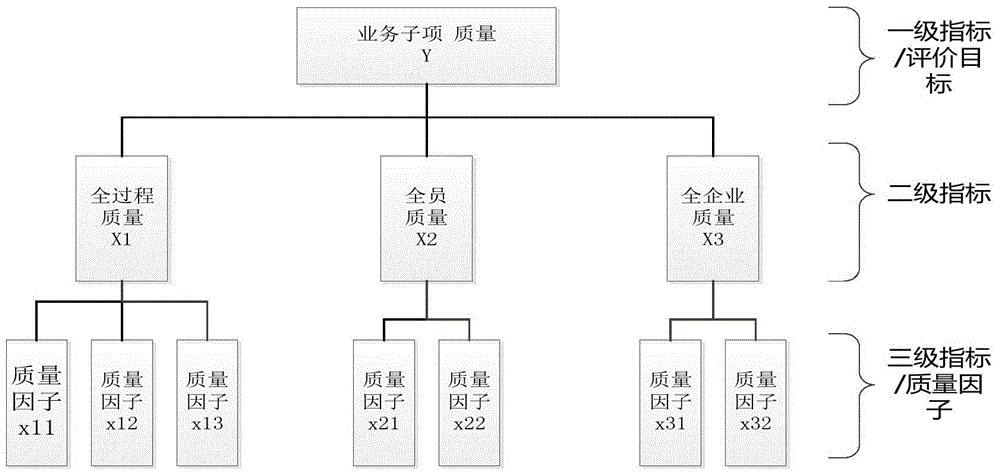

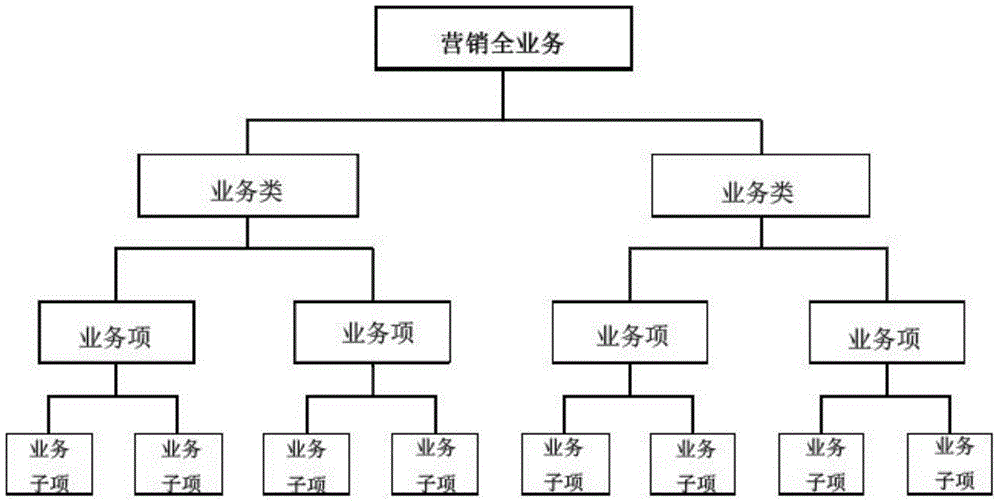

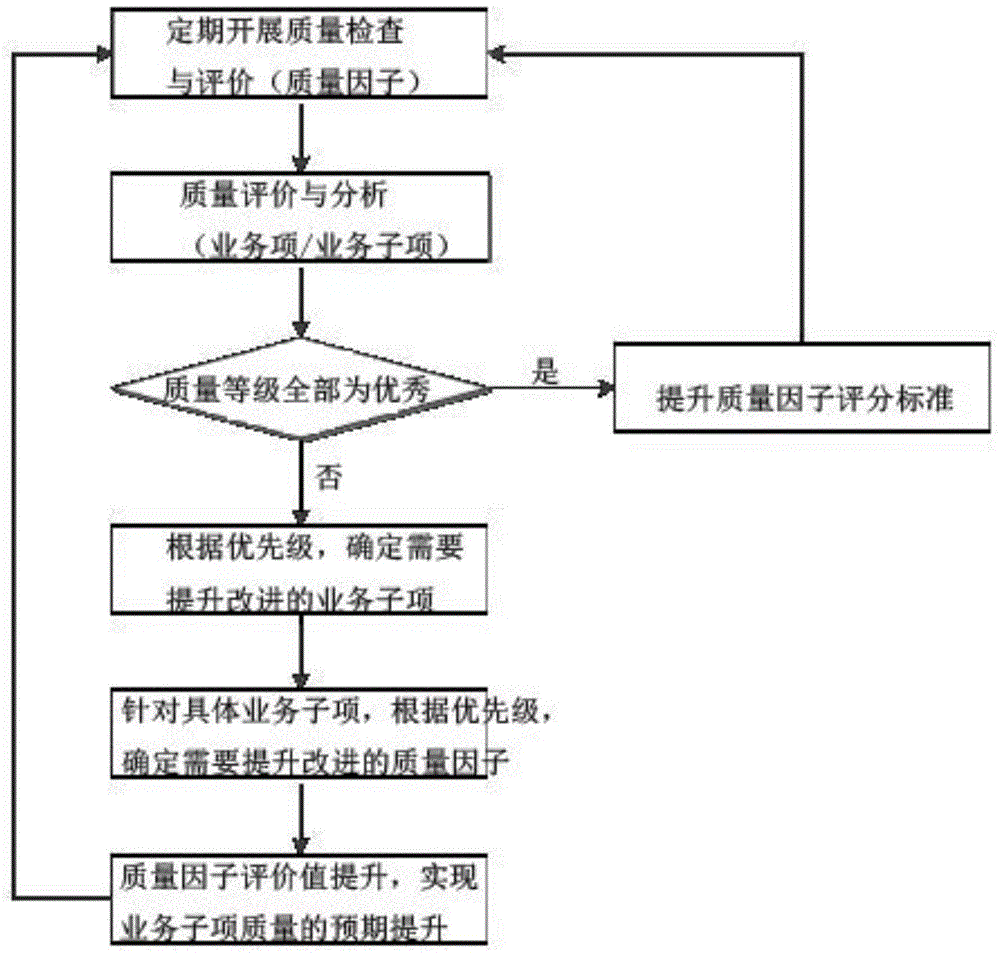

Three-whole one-center service quality management and control system applied to electric power marketing business

InactiveCN105574623ARealization of spiral circulation promotionRealize quality controlResourcesControl systemBusiness class

The invention provides a three-whole one-center service quality management and control system applied to an electric power marketing business. The three-whole one-center service quality management and control system is characterized by comprising four layers of sequentially connected business architecture systems including the marketing all business, the business class, the business item and the business sub item; the business item or the business sub item is the minimum business unit capable of independently meeting the requirements of customers, and are called as 'on-center'; the 'three-whole' refers to whole process, whole personnel and whole enterprise; and the spiral upgrading is performed on the system on the basis of the business architecture systems by a management method, an evaluation method and a quality evaluation algorithm model. The three-whole one-center service quality management and control system is beneficial to enterprise efficiency improvement and timely quality monitoring.

Owner:普华讯光(北京)科技有限公司

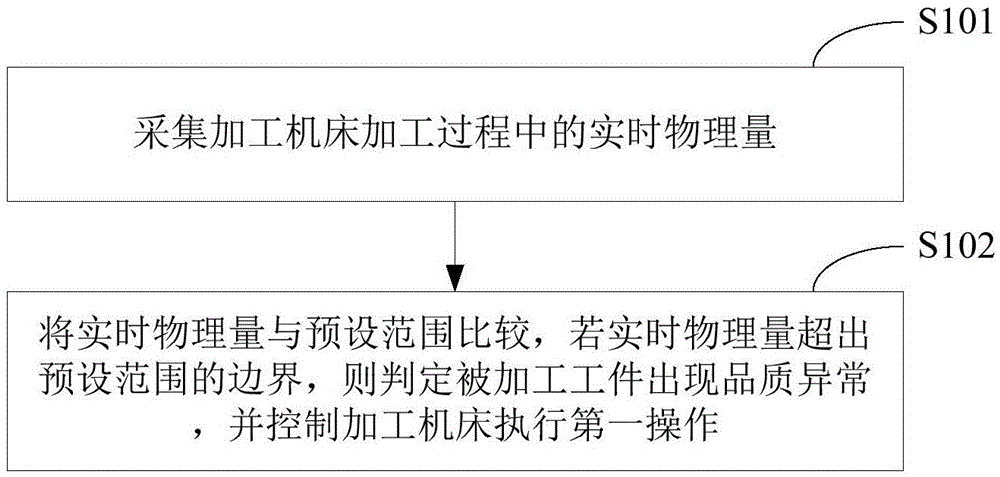

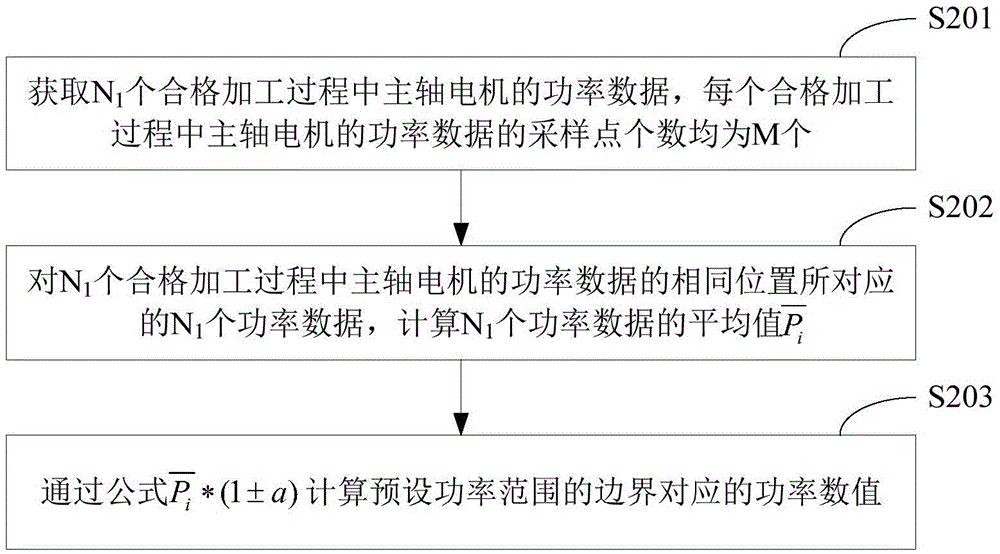

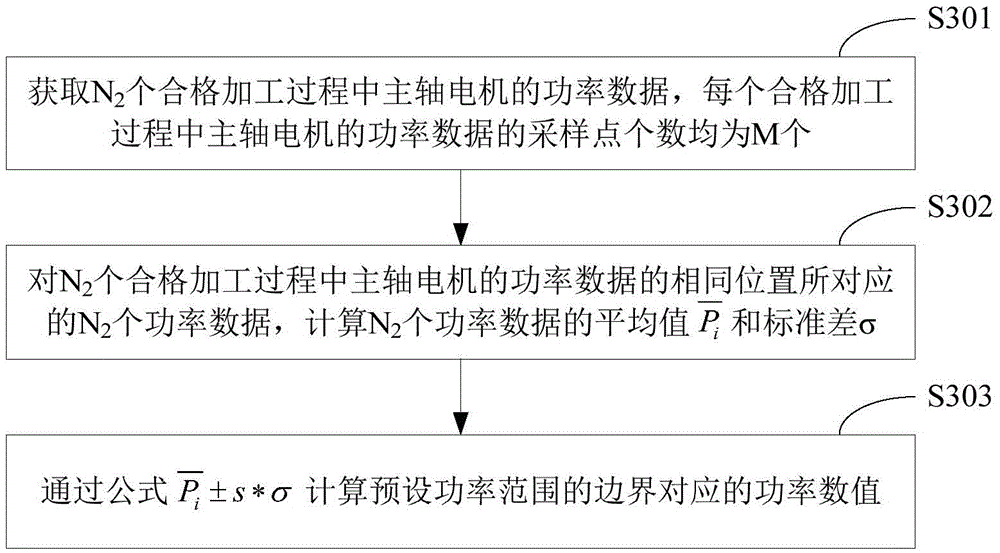

On-line quality control method and system for machining, and processing machine tool

ActiveCN105573250AAvoid bad batchesTimely detection of quality problemsProgramme controlComputer controlQuality control systemQuality control

The invention discloses an on-line quality control method for machining. The on-line quality control method for machining includes the steps: acquiring the real time physical quantity during the machining process of a processing machine tool; and comparing the real time physical quantity with a preset range, and determining that a machined workpiece is abnormal in quality and controlling the processing machine tool to perform a first operation if the real time physical quantity exceeds the boundary of the preset range, wherein the first operation includes closing down the machine tool immediately, closing down the machine tool after finishing the current process, or keeping on machining and giving an alarm. The on-line quality control method for machining can timely discover the quality problem during the machining process and realize quality control during the production process, and can prevent occurrence of reject batch for the machined products. The invention also discloses an on-line quality control system for machining, and a processing machine tool.

Owner:INTELLIGENT GRINDOCTOR TECH SHENZHEN CO LTD

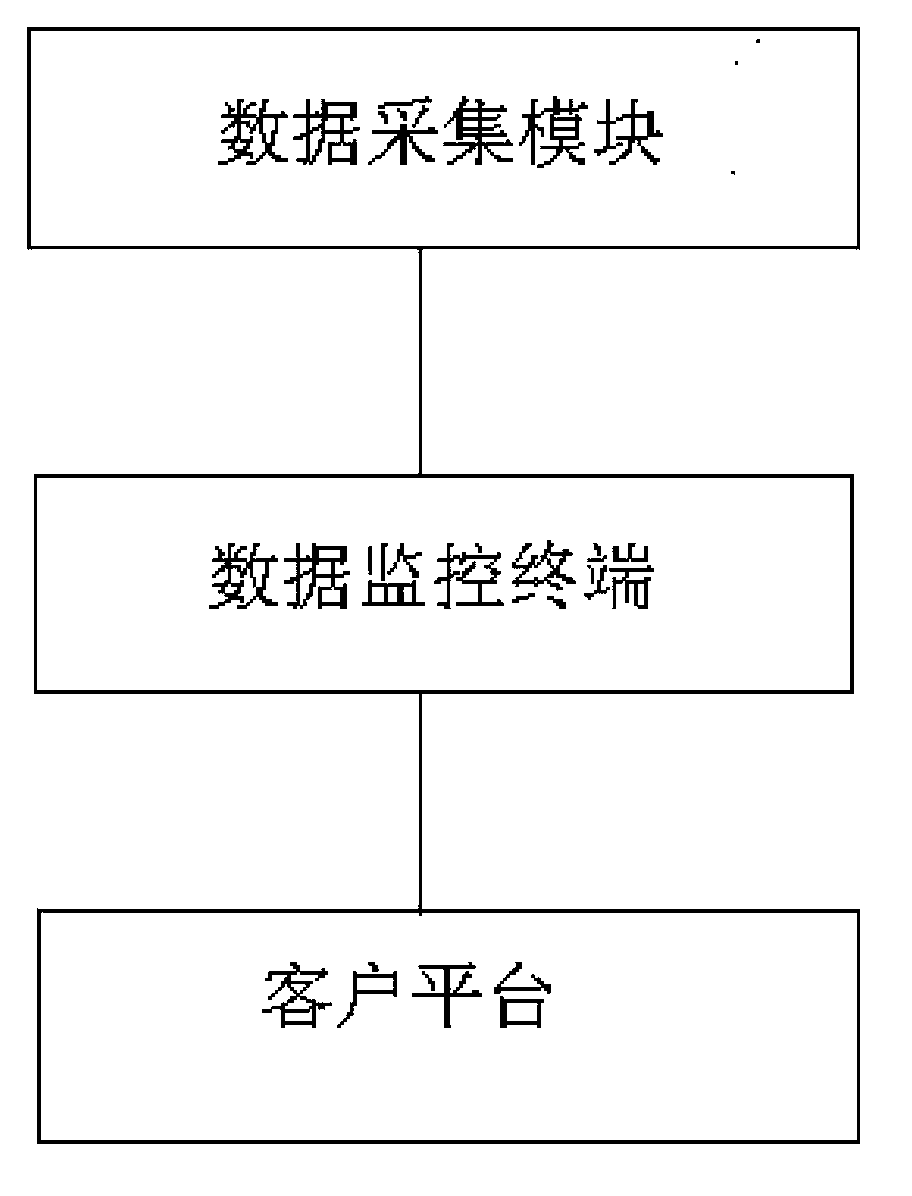

Vaccine quality dynamic monitoring platform

InactiveCN103903110AEffective monitoringEfficient managementSensing record carriersLogisticsData monitoringDynamic monitoring

The invention discloses a vaccine quality dynamic monitoring platform which includes a data acquisition module, a data monitoring terminal and a customer platform. The data acquisition module is connected with the data monitoring terminal through a wireless communication manner. The customer platform is connected with the data monitoring terminal through a wireless communication manner. The vaccine quality dynamic monitoring platform not only realizes automatic monitoring of a vaccine storage temperature, but also can form a monitoring network, so that storage and use of vaccines are monitored effectively and alarm and rejection are carried out timely when a problem happens and thus the security of vaccine use is improved and loss is reduced to the largest degree.

Owner:JIANGSU SESAN TECH

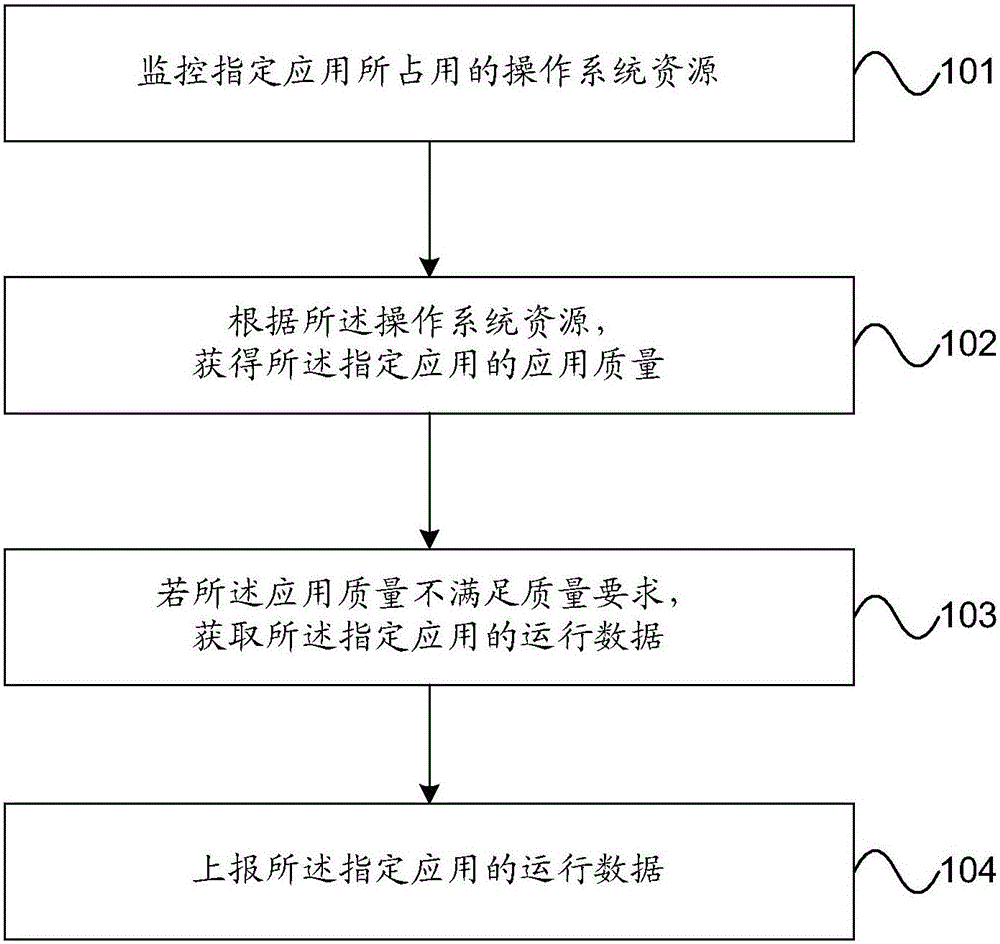

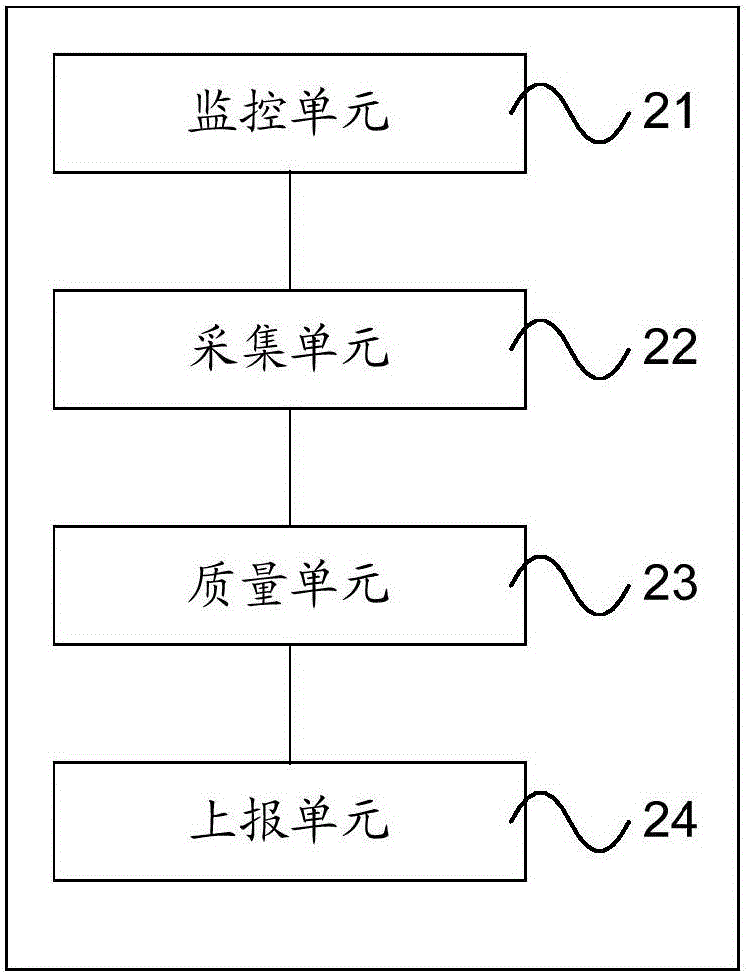

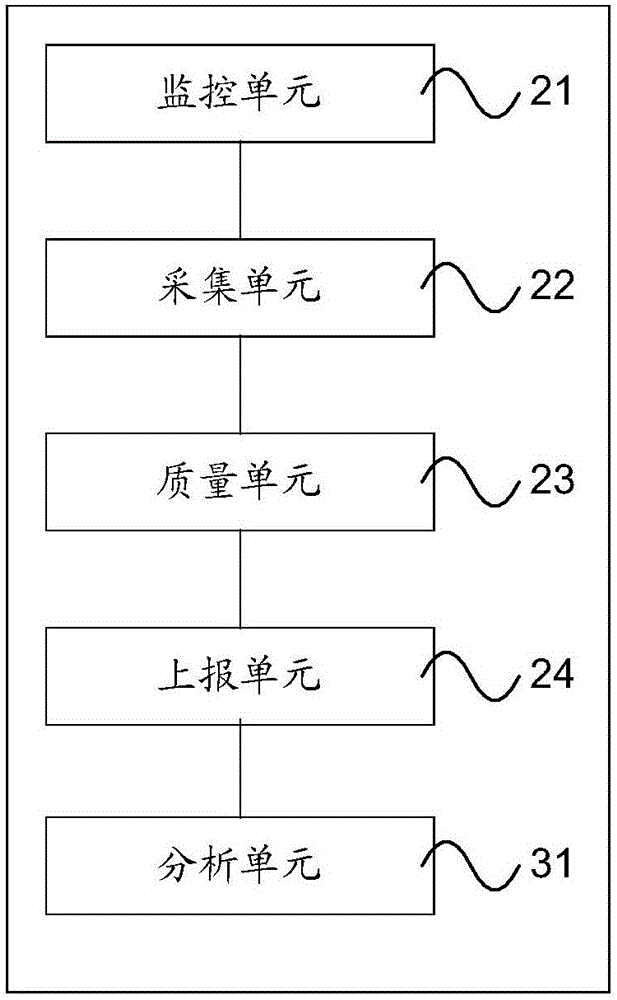

Method and device for monitoring quality of application

ActiveCN106095660AEasy to operateImprove accuracyHardware monitoringMonitor qualityQuality monitoring

The invention provides a method and device for monitoring the quality of an application. According to the embodiment, operation system resources occupied by the designated application are monitored, then the application quality of the designated application is acquired according to the operation system resources, if the application quality does not meet quality requirements, running data of the designated application is further acquired, the running data of the designated application can be reported, and the quality of the application can be monitored without user participation. Operation is easy, the accuracy is high, and therefore the quality monitoring efficiency and reliability of the application are improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

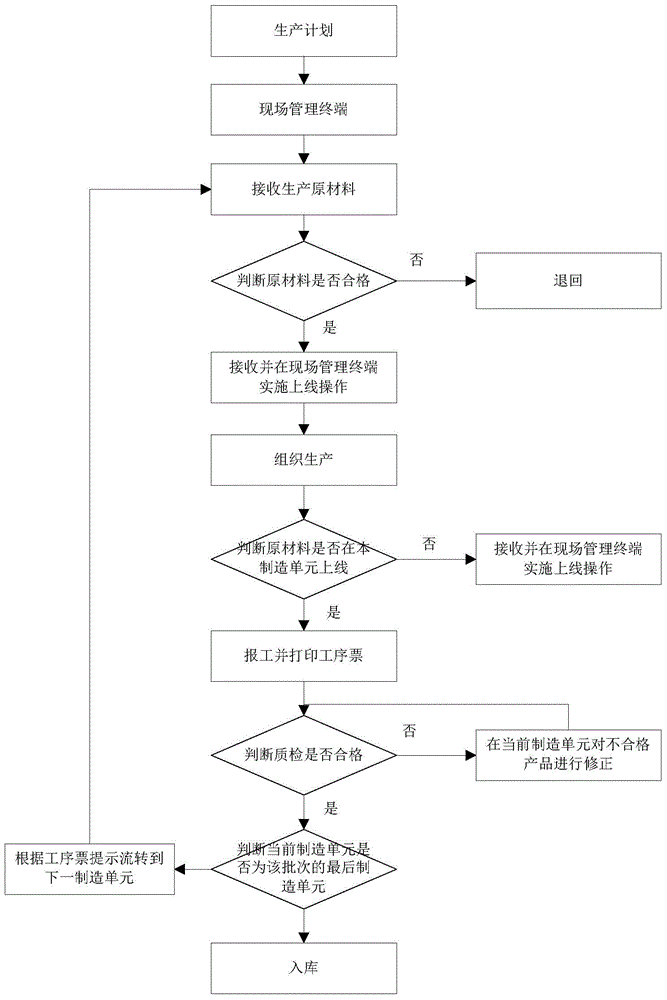

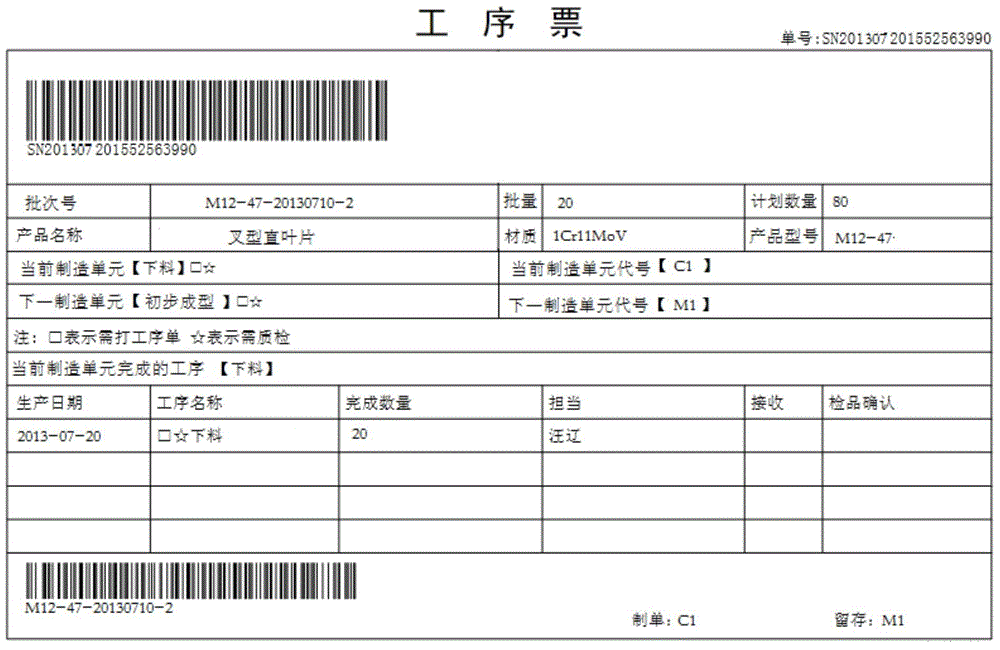

Goods-in-process monitoring method used for blade production

InactiveCN104460569ARealize quality controlMaster the quantity in real timeTotal factory controlProgramme total factory controlNumerical controlEngineering

The invention discloses a goods-in-process monitoring method used for blade production. The goods-in-process monitoring method includes the steps that a server obtains the processing technologies and the production plans of the same batch of blades and distributes the production plans, NC programs, processing technology cards and quality testing requirements to site management terminals of corresponding manufacturing units according to the processing technologies of the blades; the site management terminal of the current manufacturing unit obtains production raw materials according to the corresponding production plan and the corresponding processing technology, the site management terminal judges whether the obtained production raw materials are qualified or not according to an inspection report, filled by a quality inspector, of the prior manufacturing unit, if the obtained production raw materials are qualified, the site management terminal completes feeding of the production raw materials on the current manufacturing unit, a numerical control center downloads the corresponding NC program from the site management terminal, the obtained production raw materials are processed through the NC program, the processing result is reported to the server through the site management terminal, and a working procedure bill is printed. By means of the goods-in-process monitoring method, goods-in-process monitoring and goods-in-process management on the blades can be achieved, and related enterprises can be assisted in improving the working efficiency and the accuracy of related persons.

Owner:HUAZHONG UNIV OF SCI & TECH

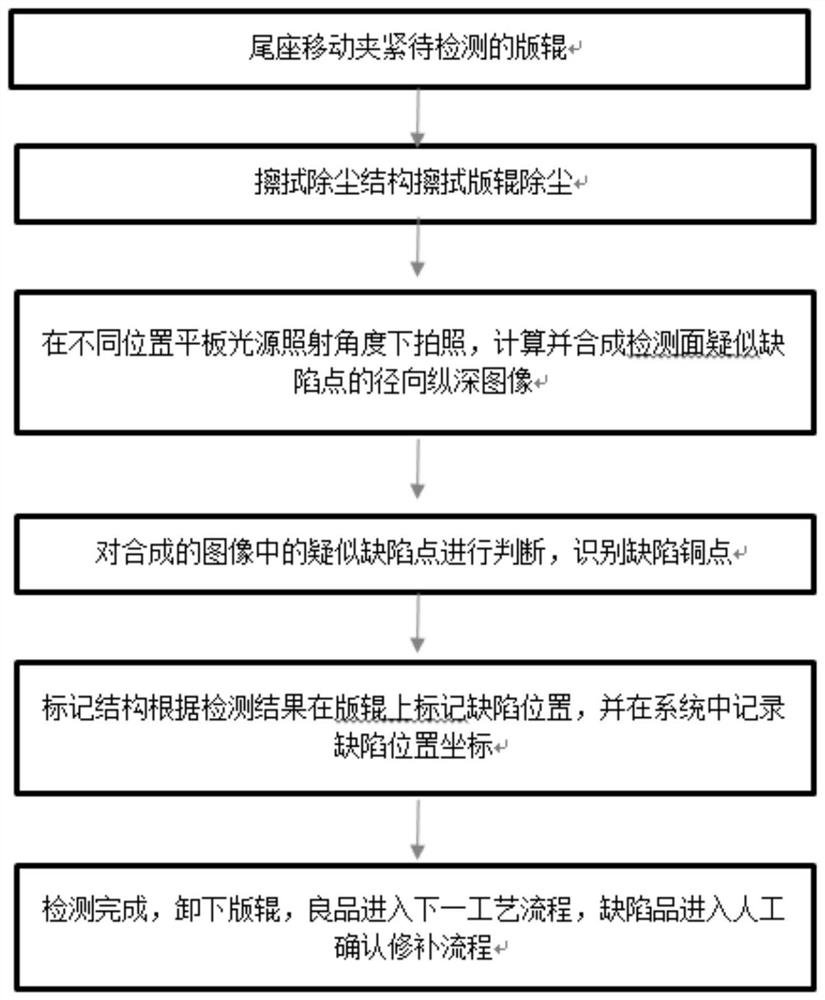

Method for detecting surface defects of intaglio roller by using 3D photographing technology

ActiveCN112432949AImprove the accuracy of judgmentReduce distractionsOptically investigating flaws/contaminationCleaning using toolsVisual inspectionCopper

The invention discloses a method for detecting surface defects of an intaglio roller by using a 3D photographing technology. In the manufacturing process of the intaglio roller, a steel body is platedwith copper, and is ground to enable a copper surface to be bright and smooth, and pit defects are generated on the surface of a ground copper layer due to the defects of the steel body or the defects generated in the electroplating process, in the gravure printing industry, the defects are called as copper points, namely the surface defects of the printing roller, and the defects have an obviouscharacteristic that all the defects are in a concave state, so that the copper point can be accurately found as long as whether the defect is concave or not can be judged. According to the invention,the problem of missing inspection caused by visual fatigue of manual inspection is solved, the problem of over-inspection caused by non-real defect interference of dust, water spots and the like during traditional industrial visual inspection is also solved, the accuracy of defect detection can be ensured on the premise of ensuring the detection efficiency, missing inspection and over-inspectionare avoided, and the inspection quality of a gravure plate roller after grinding is greatly improved.

Owner:东莞东运机械制造有限公司

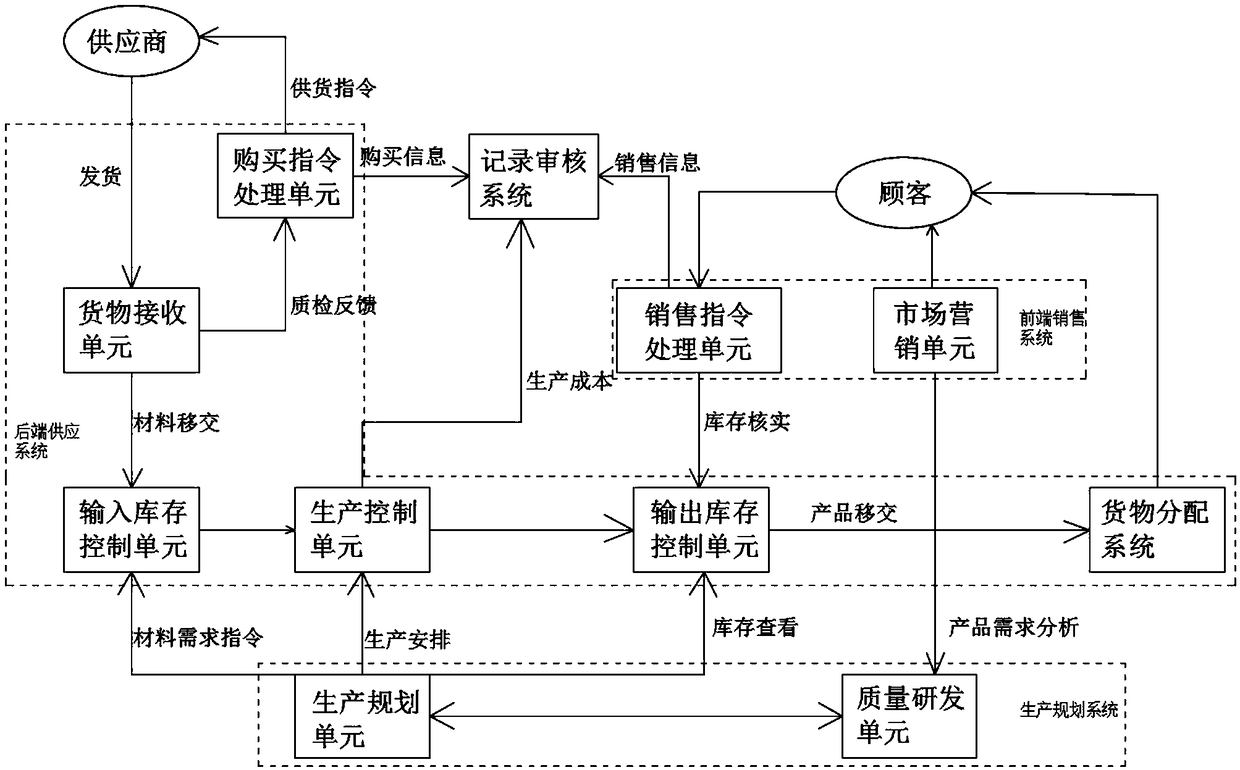

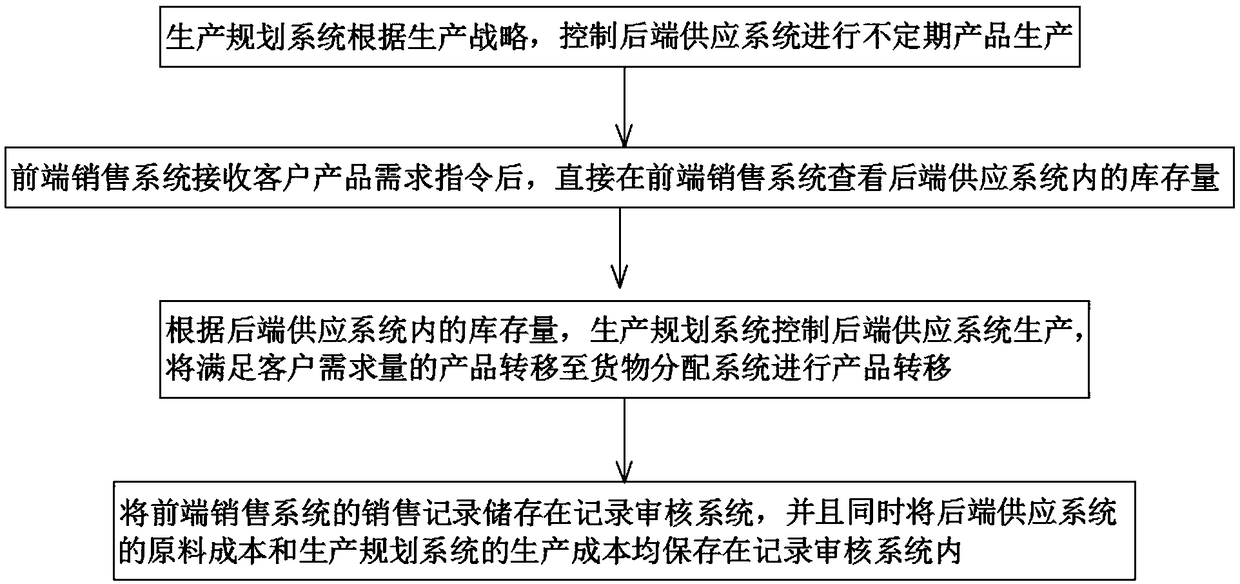

An engineering enterprise information integration management system and method

InactiveCN109360043AConvenience to workImprove economyBuying/selling/leasing transactionsLogisticsInstruction processing unitInformation resource

The invention discloses an engineering enterprise information integration management system, which includes a front-end sales system, a back-end supply system, a production planning system, a recording and auditing system which are conneted via a wireless network. The front-end sales system specifically includes a marketing unit that interfaces directly with the customer, and a sales instruction processing unit that receives customer demand instructions directly, A sales order processing unit is mainly used for storing product inventory information, and product association information directlyassociated with the product inventory information, A sales order processing unit transfers sales records to a records review system, and the marketing unit delivers production notifications to the production planning system, The front-end sales system and the back-end supply system can update the data synchronously, and the front-end sales system can directly control the product stock-out, improve the network economy and speed economy of the enterprise information management, integrate the information resources scattered in all levels of the enterprise organically, and greatly improve the abundance and condensation of the enterprise information resources.

Owner:CHINA ROAD & BRIDGE

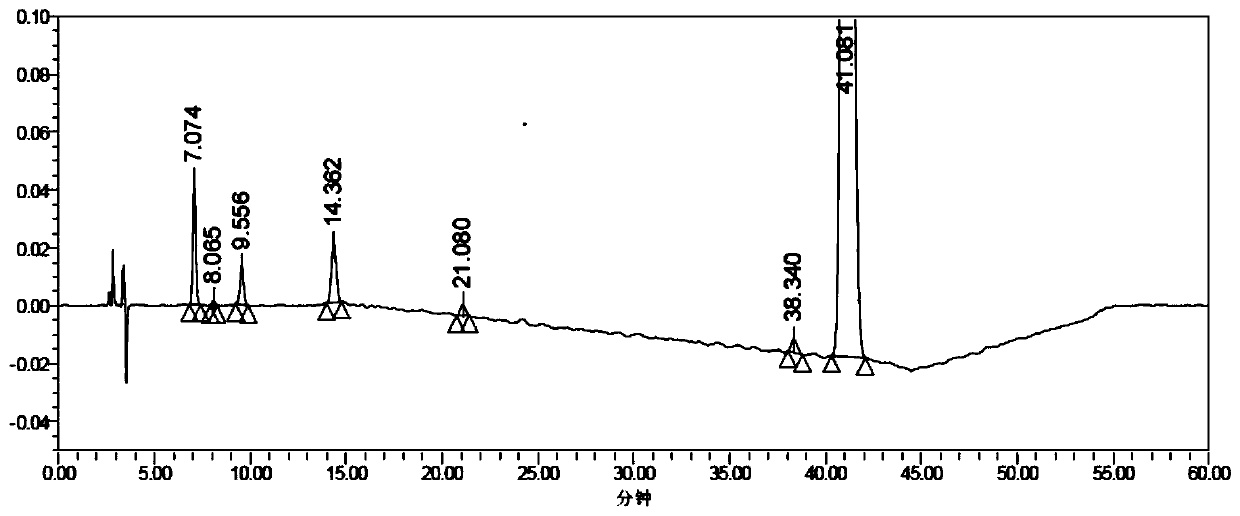

Method for separating and measuring related substances contained in loxoprofen Acid and salt thereof

ActiveCN109725074AQuality improvementRealize quality controlComponent separationChromatography columnLoxoprofen

The invention provides a method for separating and measuring related substances contained in loxoprofen acid and salt thereof. The method comprises the steps of: injecting loxoprofen Acid and salt thereof samples into a liquid chromatograph for separation and detection, wherein the chromatographic column of the liquid chromatograph is a C8-C18 column, and the mobile phase is an aqueous phase-organic phase mixed in a certain ratio. The method can realize quantitative and qualitative measure of the related substances contained in loxoprofen Acid and salts thereof, thereby the quality of loxoprofen Acid and salt thereof is effectively controlled, and more effective quality monitoring of loxoprofen Acid and salt product thereof is realized. According to the method of the invention, there is practical guiding significance on improving the quality of related products. In addition, the method is strong in specificity, high in accuracy, convenient to operate, and worthy of being widely popularized and applied.

Owner:康美(北京)药物研究院有限公司 +2

Automatic automobile body coating system

InactiveCN112138968ASolve the costSolve the inability to guarantee the coating trajectoryLiquid surface applicatorsImage analysisControl systemCoating system

The invention discloses an automatic automobile body coating system. The automatic automobile body coating system comprises a lifting appliance, a positioning device, a visual device, a coating device, a liquid supply system and a control system, wherein the lifting appliance is used for lifting an automobile body; the positioning device is used for quickly positioning the lifting appliance so asto stop the automobile body on the lifting appliance from shaking; the visual device is used for scanning and photographing the automobile body; the coating device is used for coating the automobile body according to automobile body position comparison information data obtained by the visual device and detecting coating quality; the liquid supply system is used for providing coating liquid for thecoating device; the positioning device, the visual device, the coating device and the liquid supply system are all electrically connected with the control system; and the control system is used for controlling working states of the positioning device, the visual device and the coating device. The problems that an existing automobile body coating method is high in labor cost, and unable to guarantee stability of a coating track and a coating width are solved.

Owner:GUANGQI HONDA

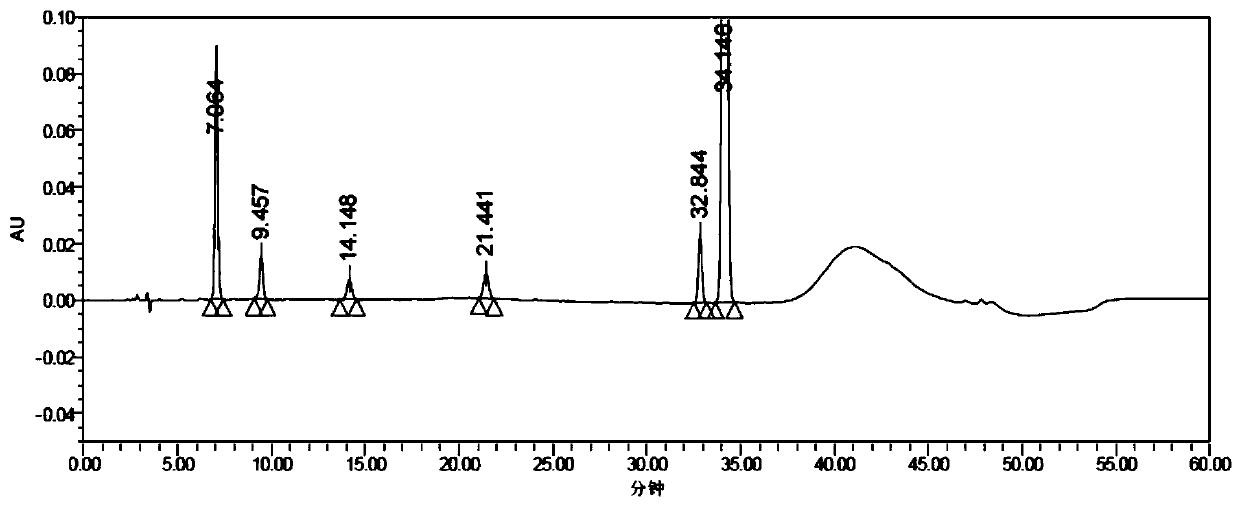

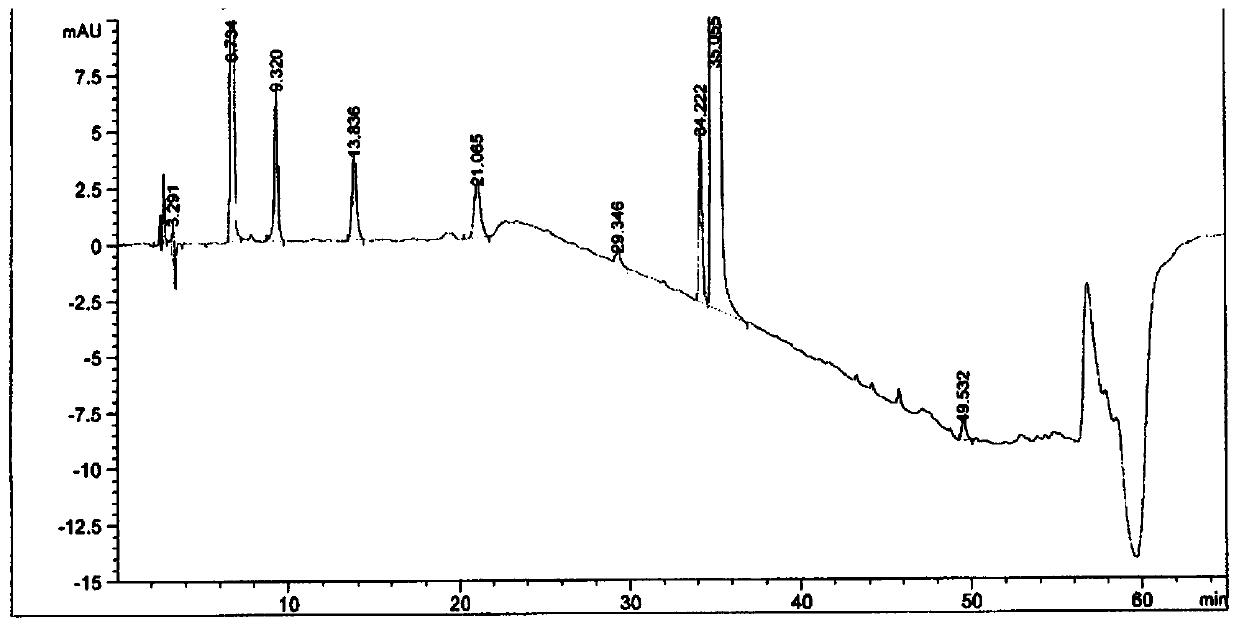

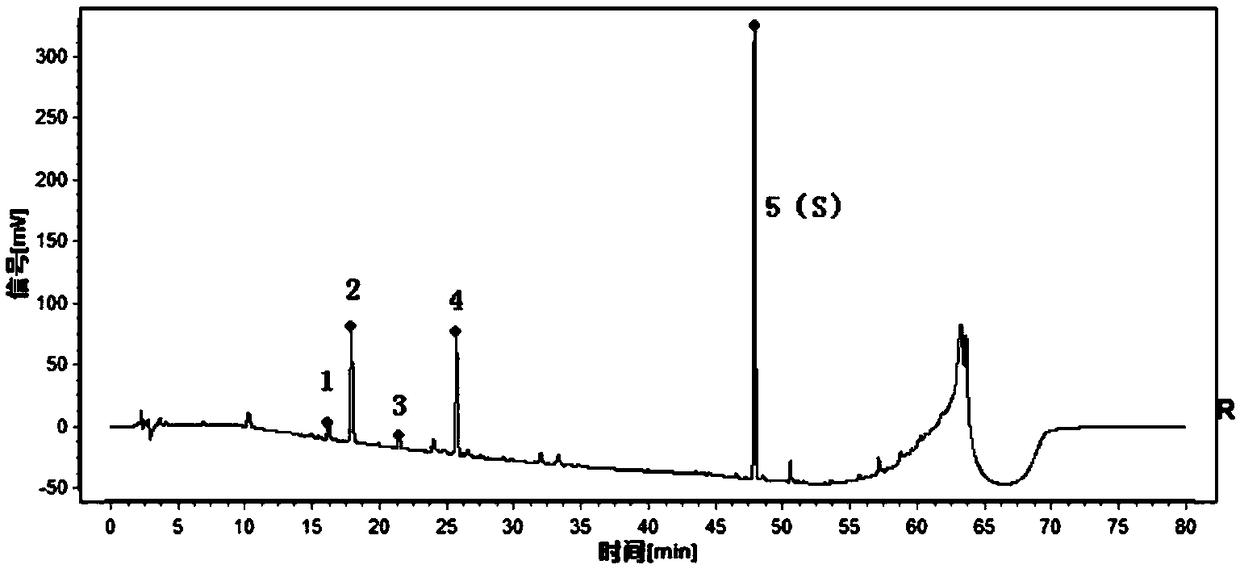

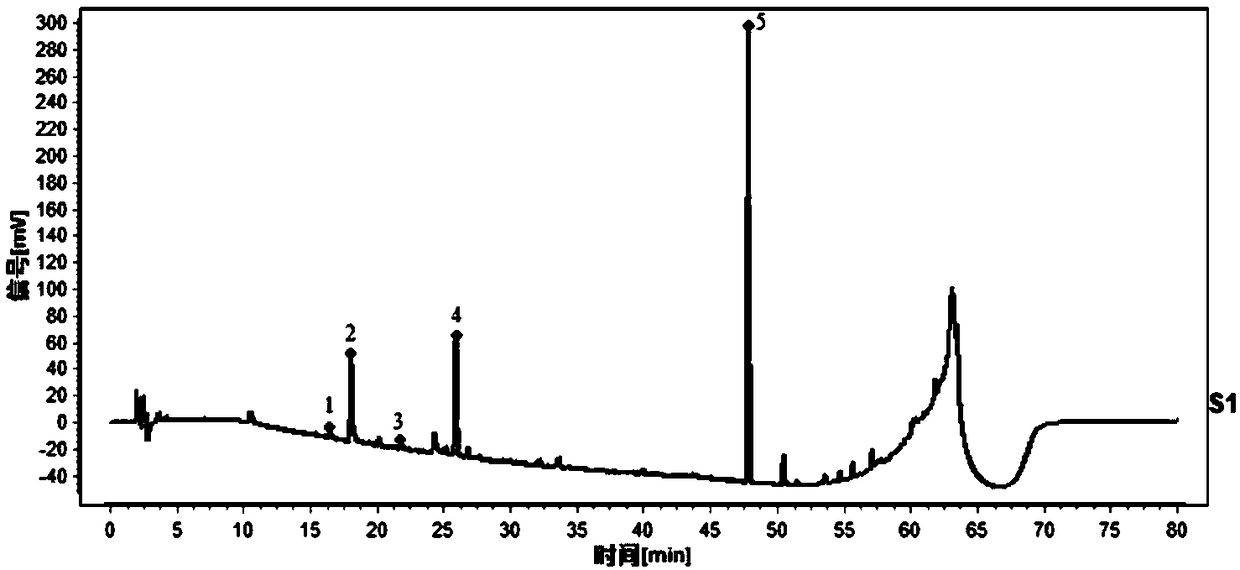

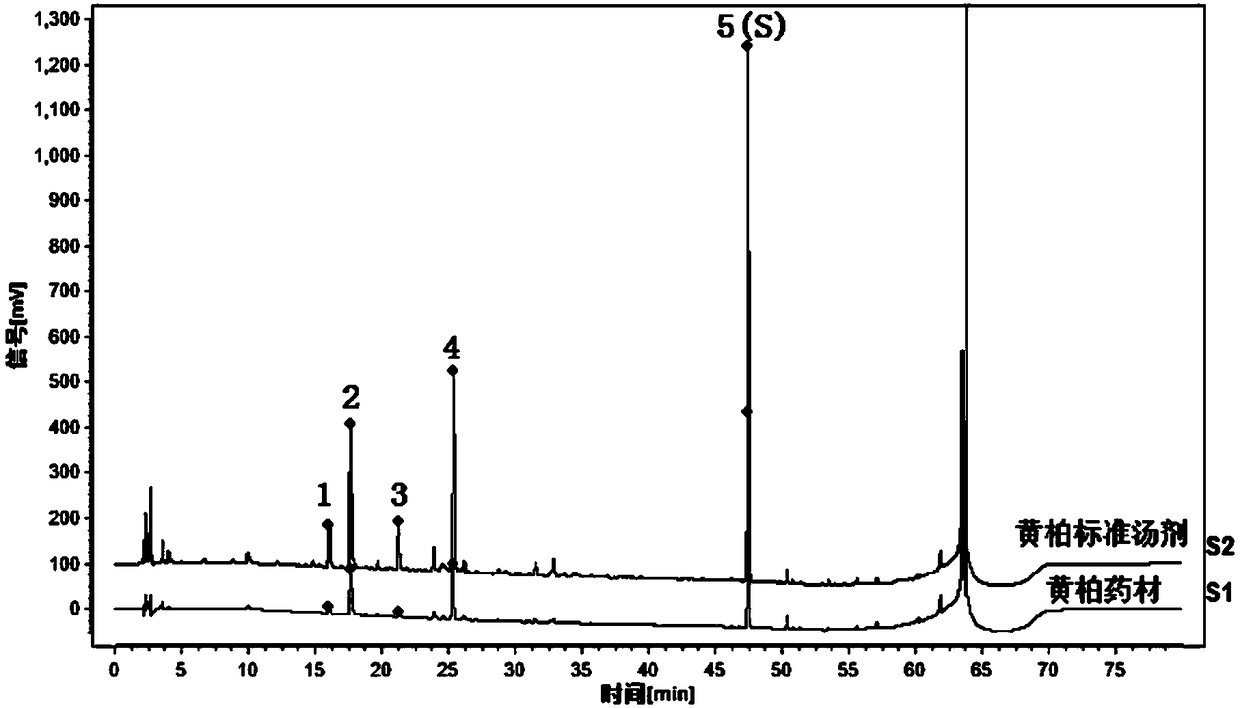

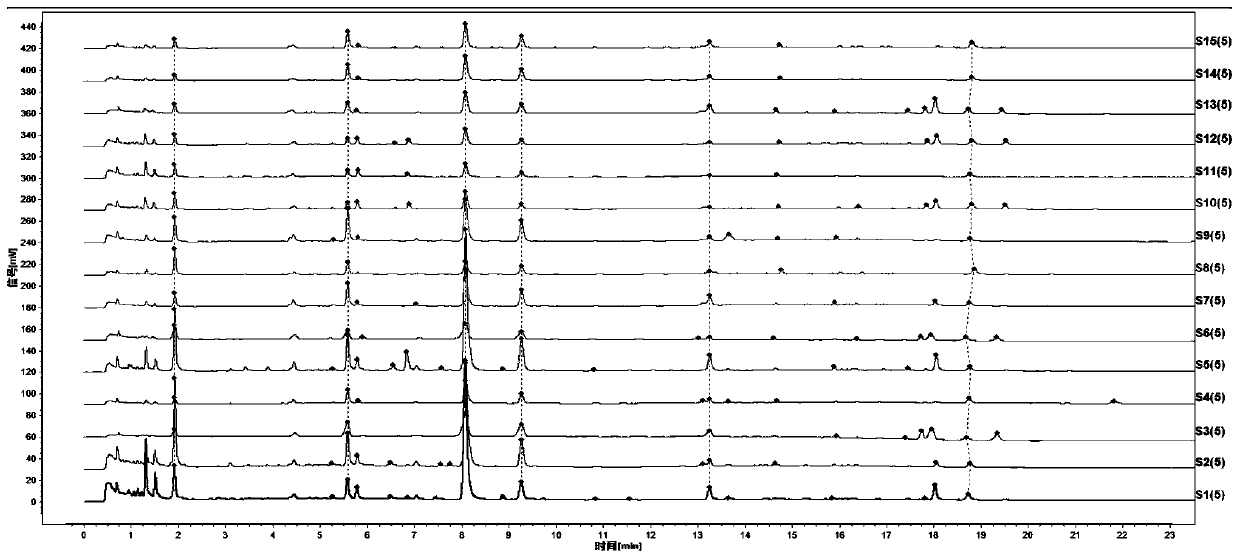

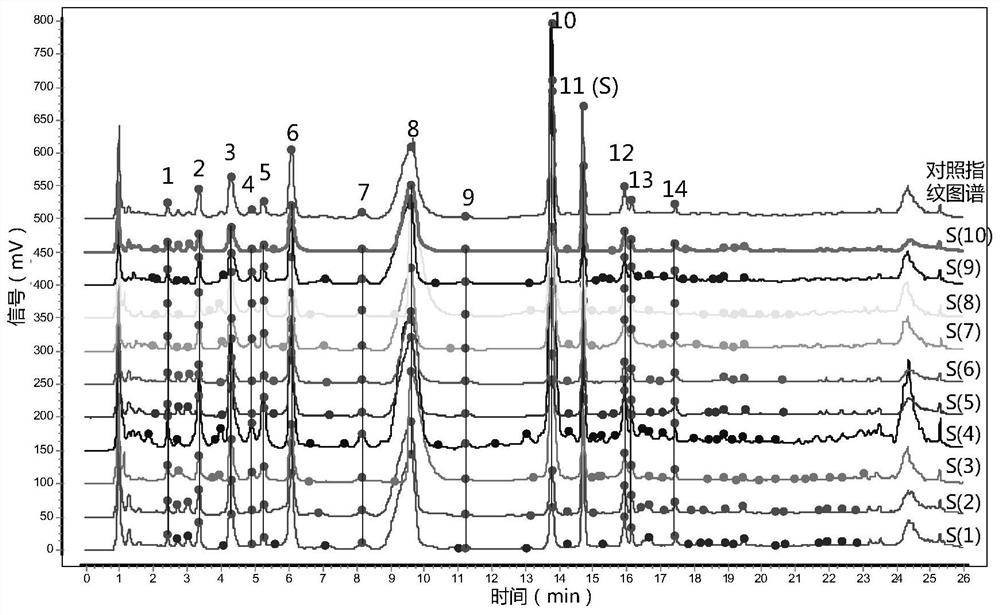

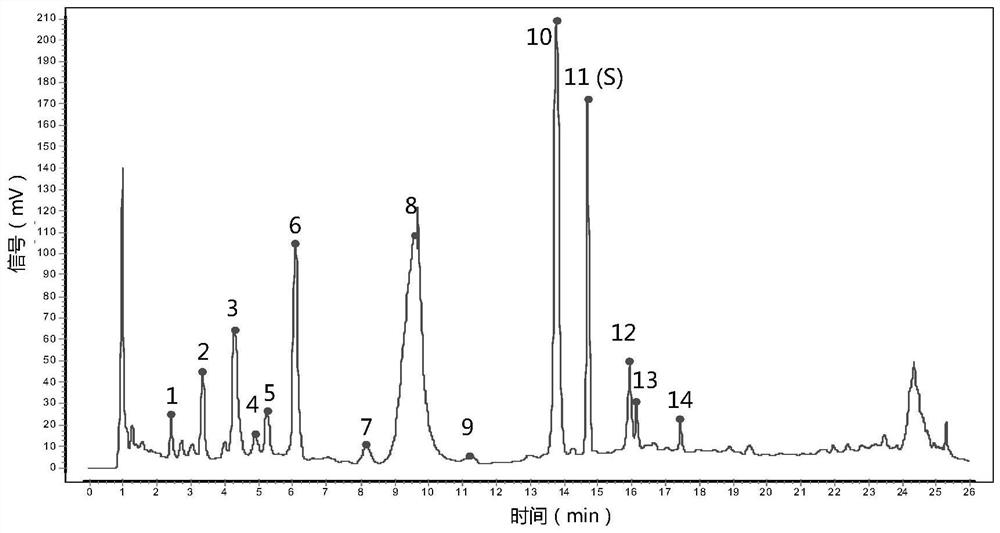

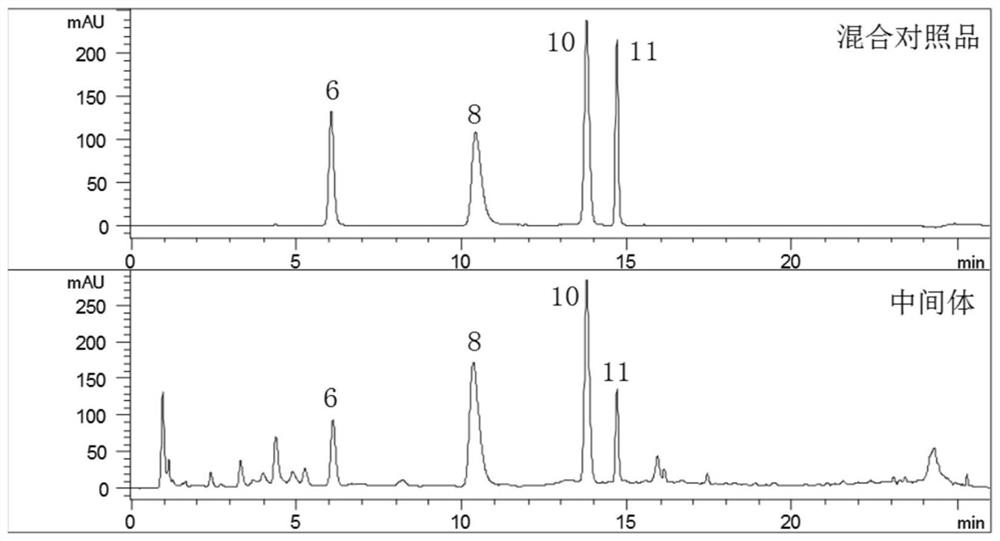

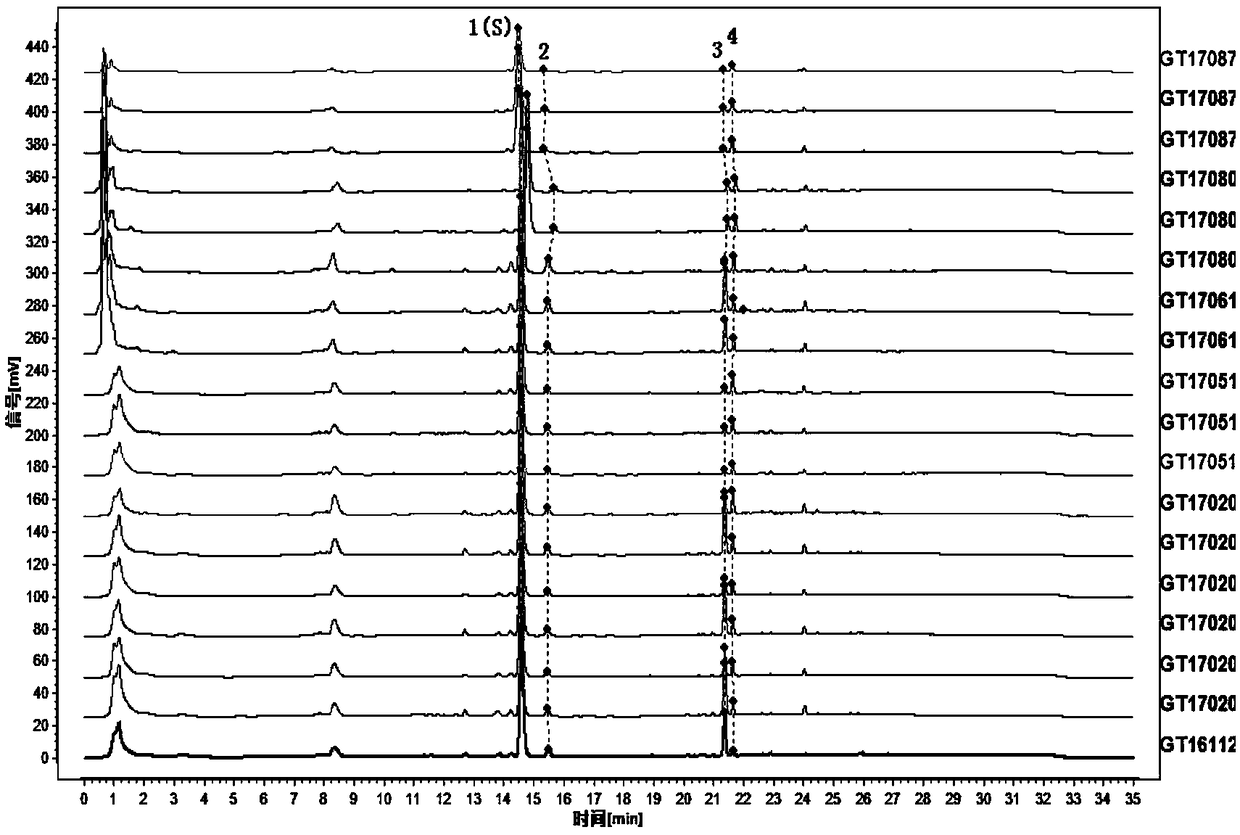

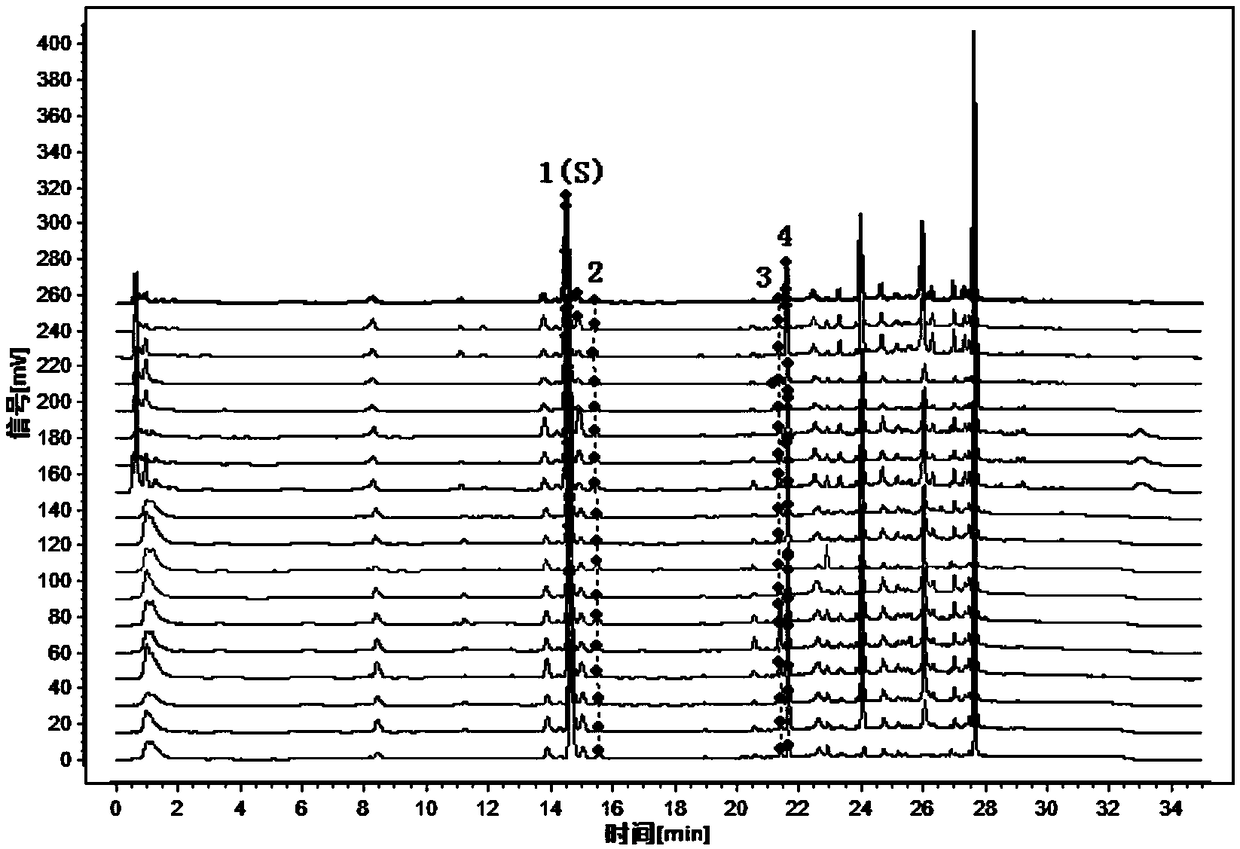

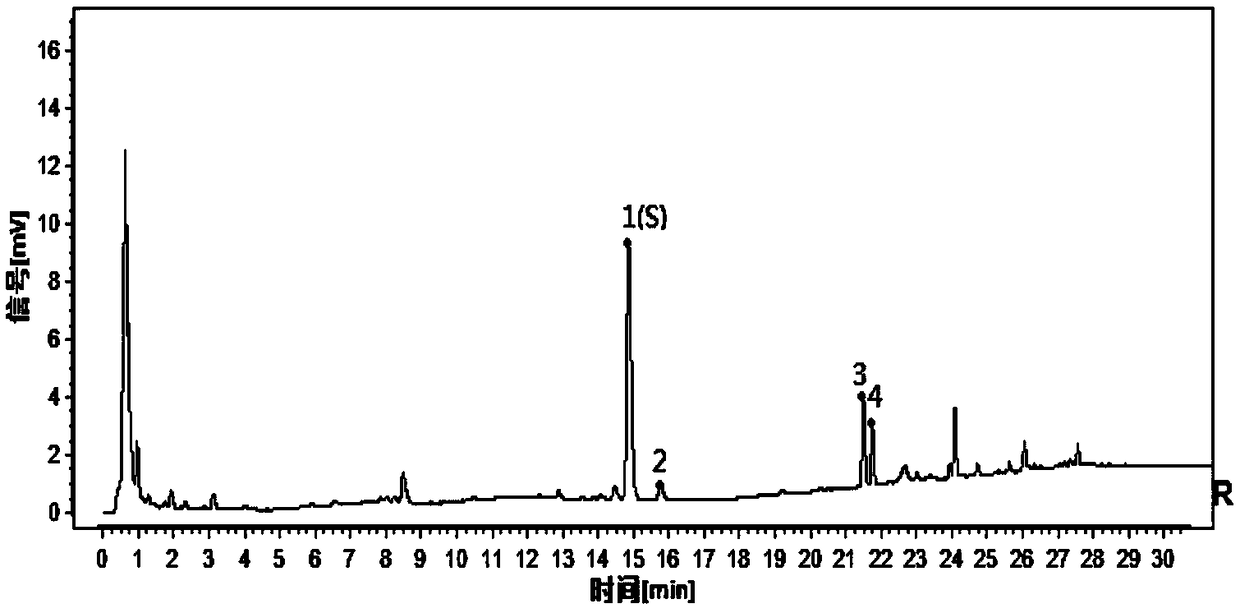

Construction method and detection method of HPLC feature map of golden cypress medicinal material

ActiveCN109374789AEasy to separateRich relevant informationComponent separationMedicineWater soluble

The invention relates to a construction method and a detection method of a HPLC feature map of a golden cypress medicinal material. The construction method comprises the following steps: reference solution preparation: preparing a golden cypress control medicinal material reference solution and a berberine hydrochloride and phellodendrine hydrochloride reference substance solution; sample solutionpreparation: preparing a golden cypress medicinal material sample solution and a decoction sample solution; high-performance liquid chromatography test: absorbing the control medicinal material reference solution, the reference substance solution, the medicinal material sample solution and the decoction sample solution; injecting into a liquid chromatograph, comparing a medicinal material samplemap with a decoction sample map, determining water soluble common peaks and obtaining the UPLC feature map of the golden cypress medicinal material. The HPLC feature map obtained by the construction method not only can qualitatively and quantitatively analyze the quality of the golden cypress medicinal material, but also can reflect the quality of golden cypress standard decoction as a reference.

Owner:GUANGDONG YIFANG PHARMA

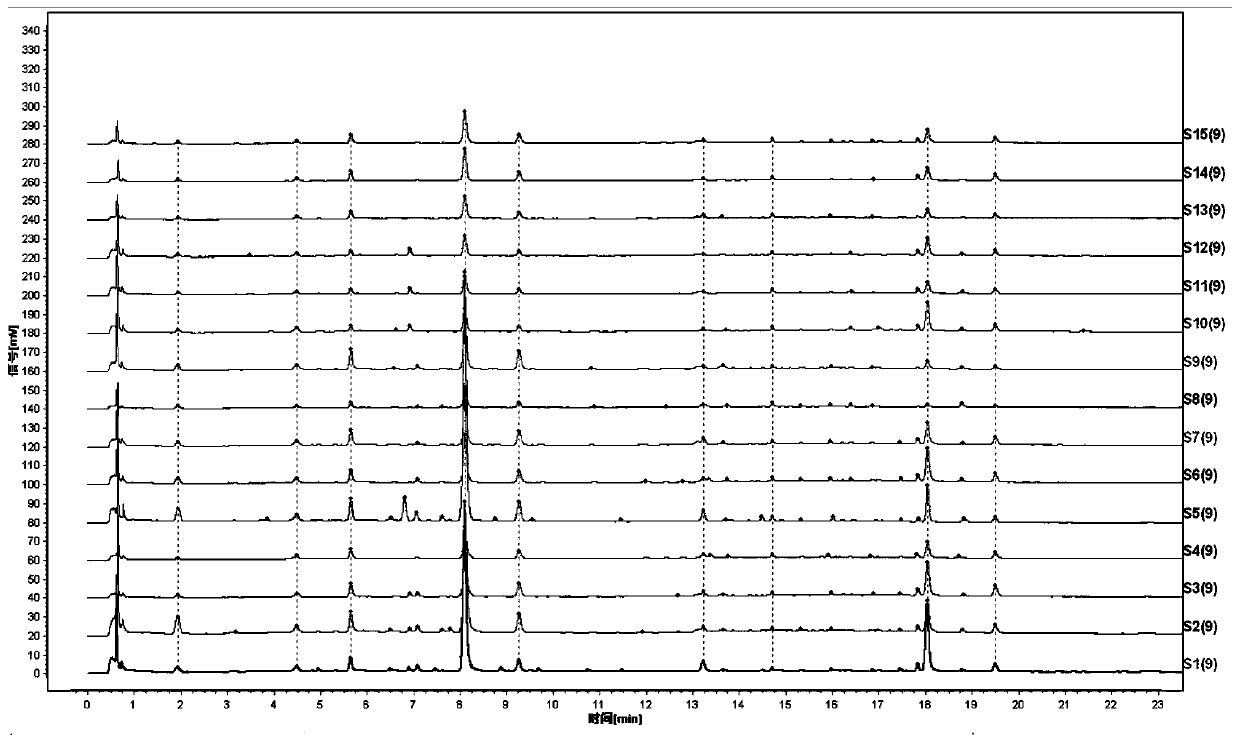

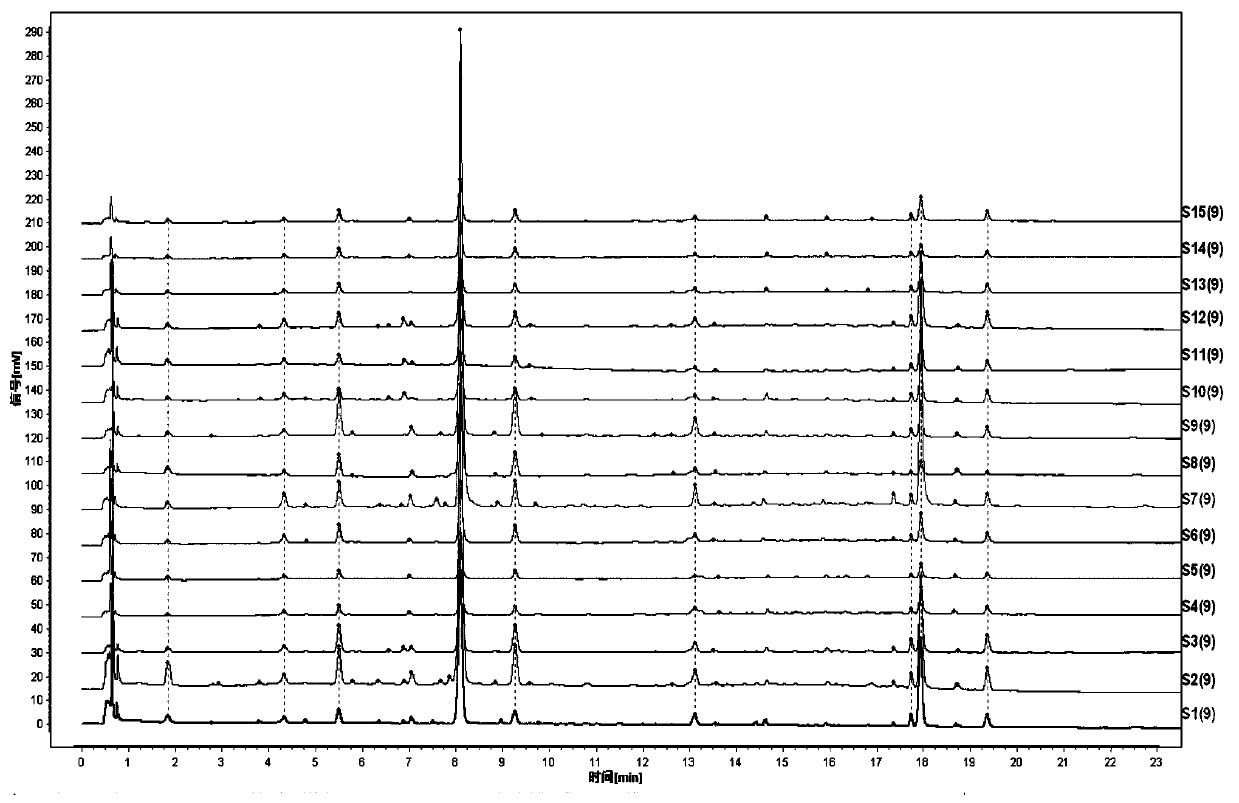

Construction method for Atractylodes macrocephala Koidz. medical material UPLC characteristic graph and detection method

InactiveCN109884219AQuantitativeOvercoming Durability Bias IssuesComponent separationChlorogenic acidTest sample

The invention relates to a construction method for an Atractylodes macrocephala Koidz. medical material UPLC characteristic graph and a detection method. The construction method for the characteristicgraph comprises the following steps of preparing a comparison substance reference solution by taking chlorogenic acid as a comparison substance; preparing a comparison medical material reference solution by through utilization of an Atractylodes macrocephala Koidz. comparison medical material; obtaining the Atractylodes macrocephala Koidz. medical material, Atractylodes macrocephala Koidz. decoction pieces, bran-fried Atractylodes macrocephala Koidz. decoction pieces, Atractylodes macrocephala Koidz. standard decoction and bran-fried Atractylodes macrocephala Koidz. standard decoction, addingan extraction solvent for extraction, carrying out filtering, obtaining subsequent filtrate as a test sample solution; and injecting the reference solution and the test sample solution into an ultrahigh performance liquid chromatograph (UPLC) for measurement, calibrating a water soluble common peak, and obtaining the Atractylodes macrocephala Koidz. medical material UPLC characteristic graph. The method is good in reproducibility and is accurate and reliable. Through utilization of the constructed UPLC characteristic graph, material basis of the Atractylodes macrocephala Koidz. standard decoction can be reflected, and effective control over quality of the Atractylodes macrocephala Koidz. medical material can be realized. A quality monitoring level of the Atractylodes macrocephala Koidz.medical material is improved. A high quality stable Atractylodes macrocephala Koidz. raw material for a clinic preparation containing the Atractylodes macrocephala Koidz. can be provided.

Owner:SINOPHARM GUANGDONG GLOBAL PHARMA CO LTD

Quantitative fingerprint spectrum analysis method for components in ginger ginger pinellia percolate

ActiveCN114563496ARealize quality controlDetect and evaluate qualityComponent separationBiologyHplc mass spectrometry

The invention discloses a quantitative fingerprint spectrum analysis method for components in ginger and ginger pinellia percolate. The method comprises the following steps: (1) preparing a test solution and a reference substance mixed solution; and (2) analyzing the reference substance mixed solution and the test solution by adopting a high performance liquid chromatograph to obtain the quantitative fingerprint spectrum of the components in the ginger and pinellia percolate. Wherein the chromatographic conditions are as follows: a high performance liquid chromatography system is selected as an instrument, and a Waters Atlants T3 chromatographic column (100mm * 2.1 mm, 3.0 [mu] m) is selected as a chromatographic column; a DAD detector is adopted; the flow rate is 0.30 mL / min, the column temperature is 25 DEG C, and the sample injection volume is 3-5 [mu] L; taking pure water and acetonitrile as mobile phases; and (3) selecting chromatographic peaks existing in chromatograms of different batches of ginger and ginger pinellia percolates as common peaks, calculating component contents of different batches of percolates, and calculating similarity, thereby providing scientific basis and technical support for quality control of the ginger and ginger pinellia percolates. The method provided by the invention makes up for the deficiency of a method for detecting chemical components of a common goldenrop capsule production intermediate.

Owner:浙江赞生药业有限公司

UPLC characteristic map construction method and detection method of ginger medicine

The invention relates to a UPLC characteristic map construction method and detection method of ginger medicine. The characteristic map construction method comprises the following steps of weighing 6-gingerol, 6-shogaol and 8-gingerol as reference substances, adding a solvent to dissolve the substances to obtain a reference solution; weighing the ginger medicine, adding an extraction solvent and heating for reflux extraction; then filtering and taking a filtrate as a test solution; taking a ginger standard decoction and preparing a standard decoction test solution by the same method; conductingultra-high performance liquid chromatography detection: drawing the reference solution, the test solution and the standard decoction test solution, injecting the solutions into a liquid chromatographrespectively and comparing an obtained test map and a standard decoction test map to determine the water-soluble common peak and obtain a UPLC characteristic map. The characteristic map can be used for qualitative and quantitative analysis of the quality of the ginger medicine, can ensure the quality of traditional ginger soup prepared by the medicine, and is also suitable for detecting other preparations containing the ginger.

Owner:GUANGDONG YIFANG PHARMA

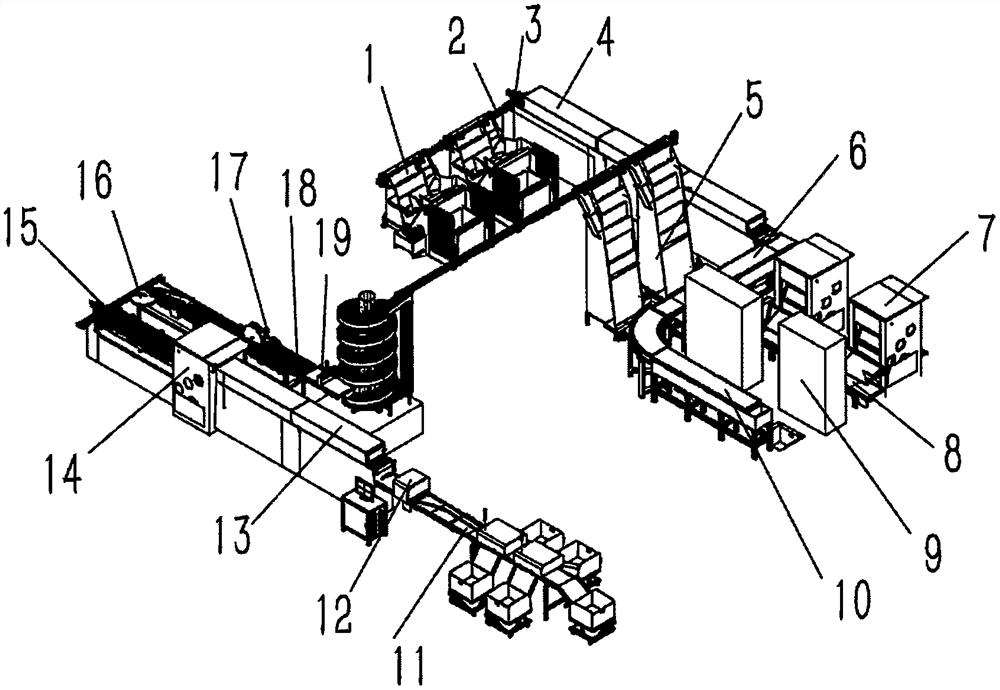

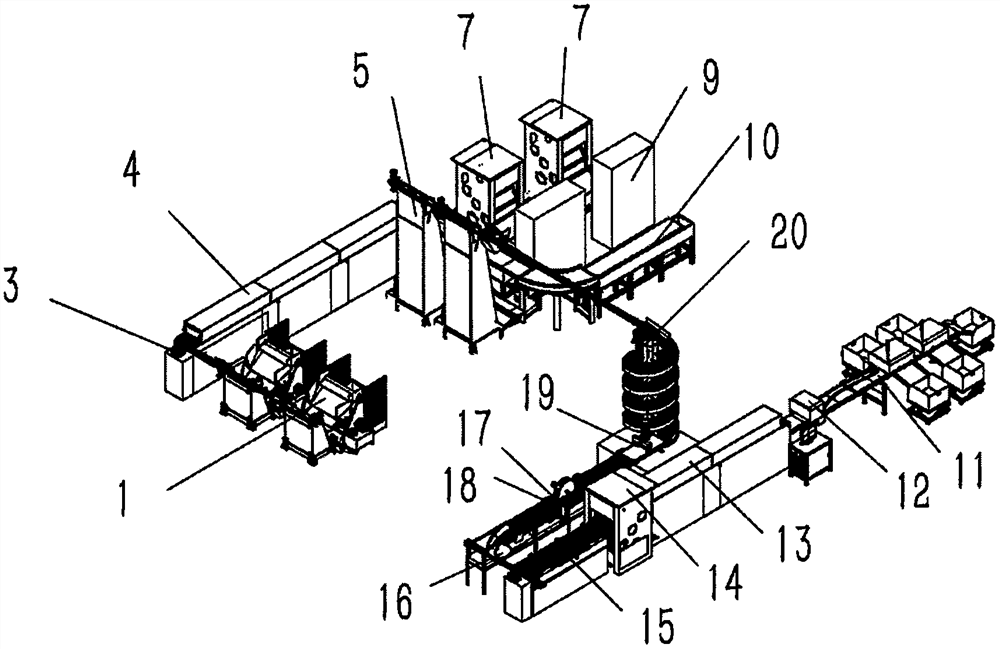

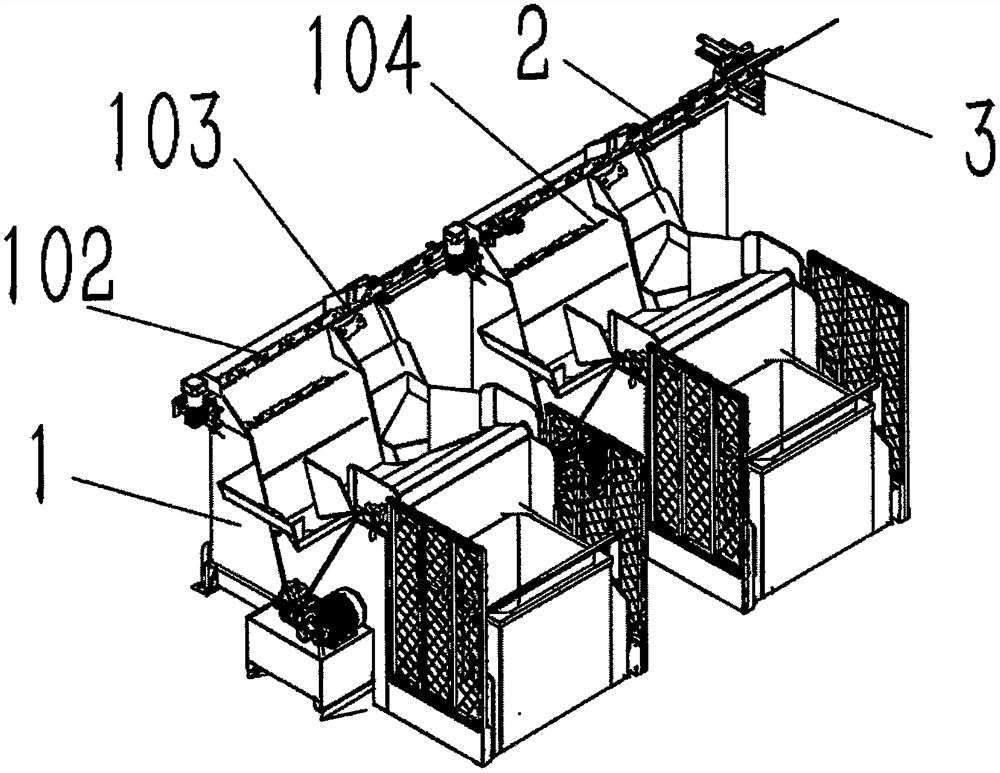

Automatic production line for steel backing surface treatment

ActiveCN113086543AImplement sortingImplement automatic classificationLiquid surface applicatorsControl devices for conveyorsProduction lineSand blasting

The invention discloses an automatic production line for steel backing surface treatment. The automatic production line is used for transforming an existing steel backing surface treatment production line and comprises a steel backing cleaning machine, a steel backing sand blasting machine and a steel backing glue spraying machine and further comprises an automatic feeding and conveying device, a cleaning, sequencing and conveying device, a cleaning, discharging and conveying device, a sand blasting, feeding and conveying device, a sand blasting, discharging and conveying device, a transferring, sequenching and conveying device, a sorting, overturning and conveying device, a glue spraying and sequencing device and a drying, discharging and sorting device according to the production sequence. The automatic production line for steel backing surface treatment has the beneficial effects that full automation, automatic feeding, automatic sequenching, automatic transferring, automatic glue spraying, automatic drying and automatic sorting of steel backing surface treatment are achieved.

Owner:RIZHAO POLYTECHNIC

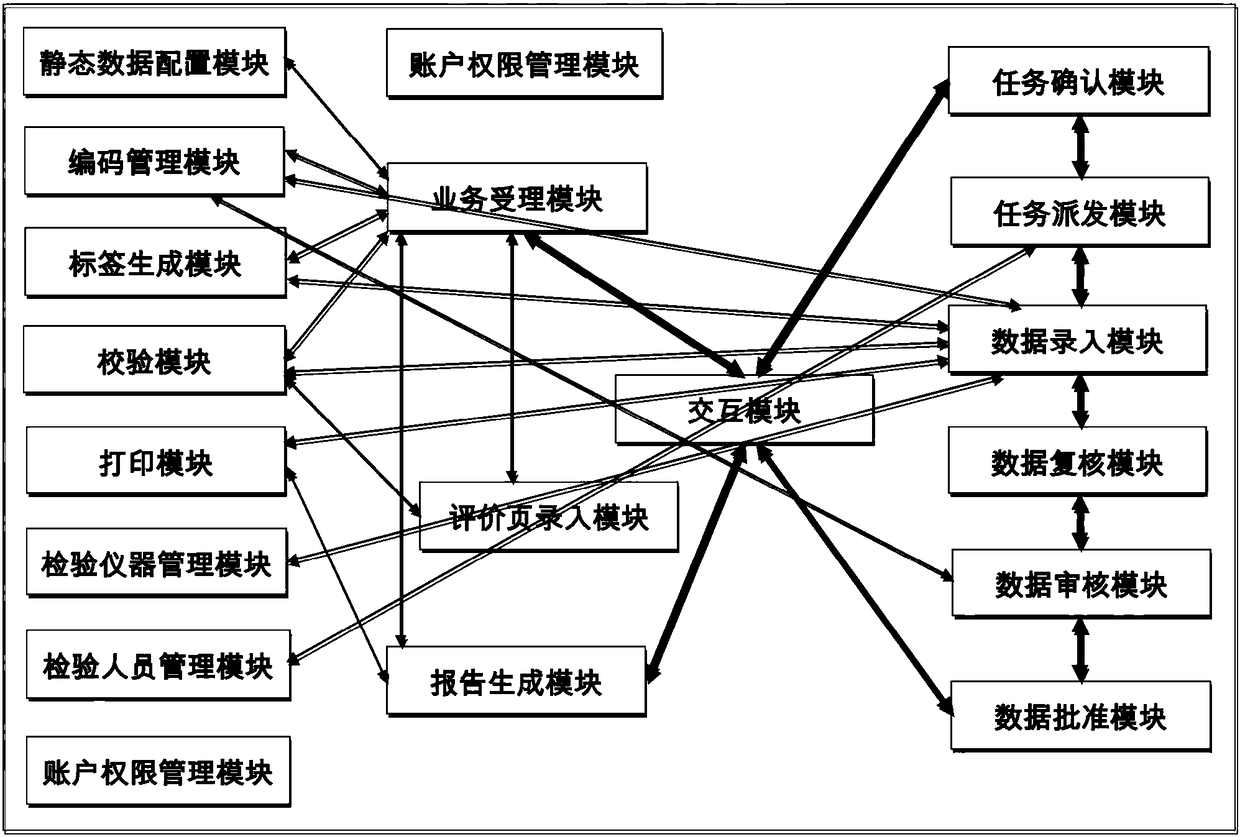

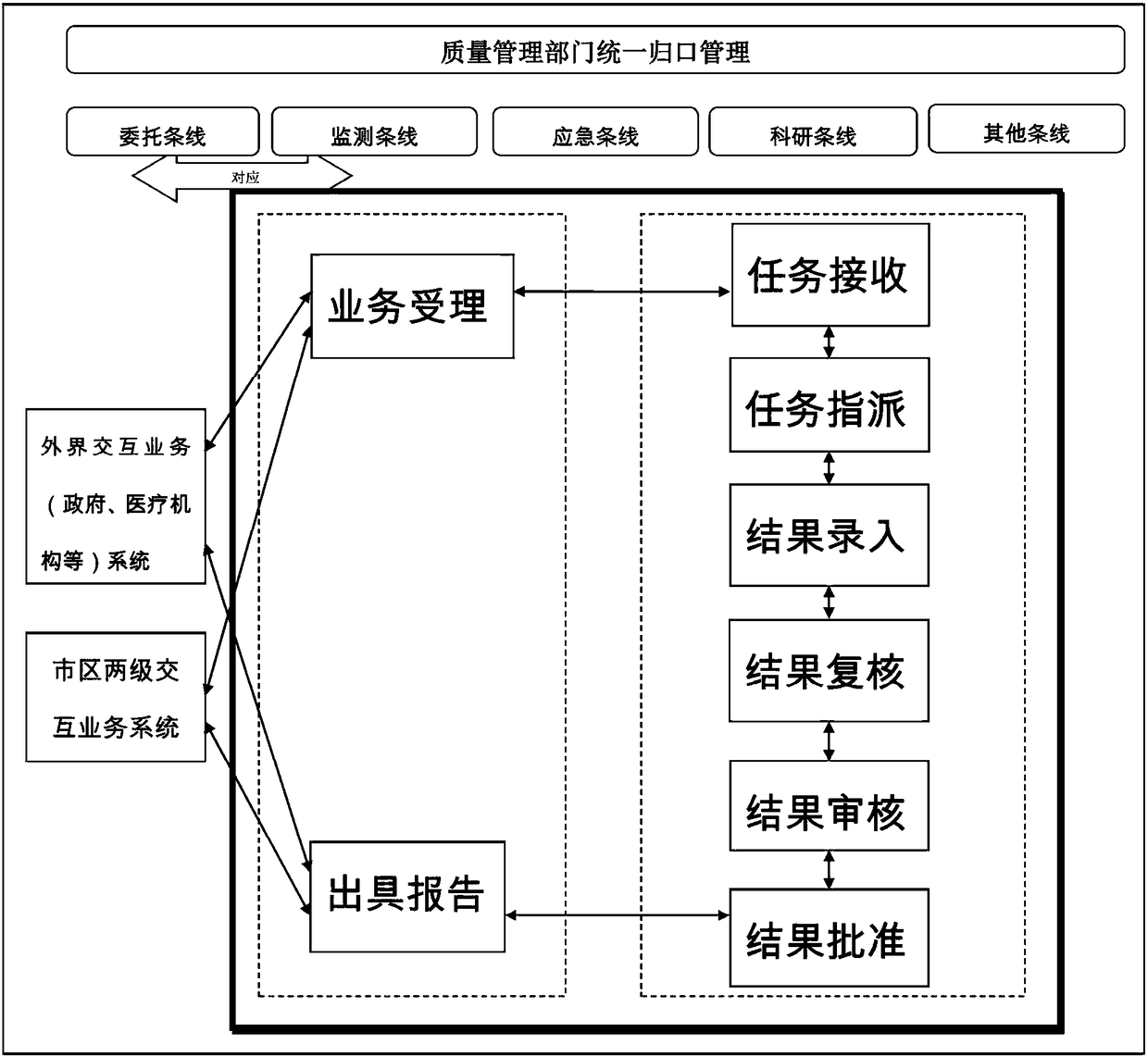

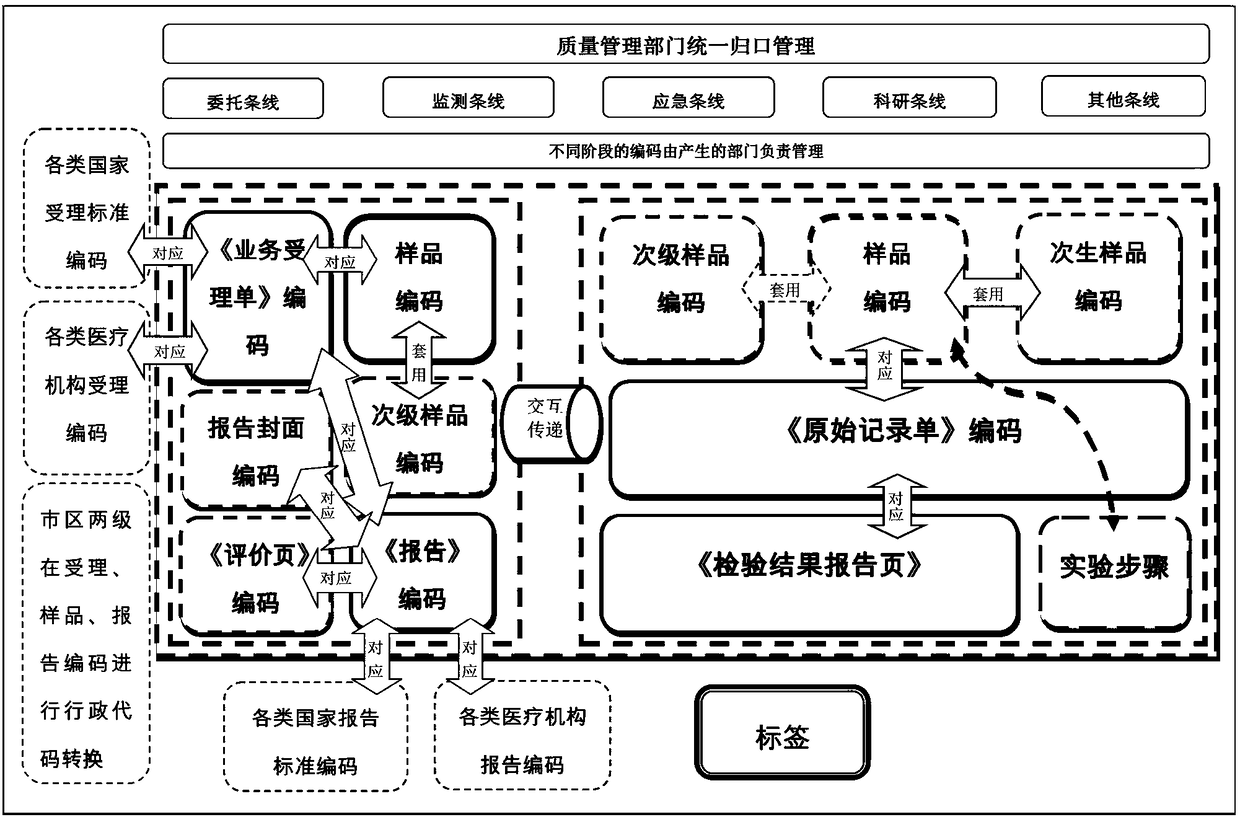

Laboratory inspection and detection system and method

InactiveCN108389035ARealize quality controlClear boundariesOffice automationResourcesPublic healthComputer module

The invention relates to a laboratory inspection and detection system and method, and the system comprises a system basic service module and a business processing module, which are connected with eachother. The system basic service module is used for providing basic services for the laboratory inspection and detection system, and carrying out the initialization of the business information. The business processing module is used for processing the business of the laboratory inspection and detection system based on the basic services provided by the system basic service module according to theinitialized business information. According to the invention, the system and method can achieve the unified management of public health inspection and detection businesses, and a public health inspection and detection platform is built, thereby achieving the high-efficiency management and standard operation of the detection process and detection data, and achieving the quality control of laboratory inspection and detection business in the whole process.

Owner:SHANGHAI MUNICIPAL CENT FOR DISEASE CONTROL & PREVENTION

Establishment method of radix ophiopogonis decoction material reference

PendingCN113759034AImprove stability and securityClear spotsComponent separationAgainst vector-borne diseasesGinsenoside Rb1Thin-layer chromatography

The invention discloses a method for establishing a radix ophiopogonis decoction substance reference. The method comprises the following steps: identifying radix ophiopogonis, ginseng, Chinese dates and liquorice by adopting a thin layer chromatography; constructing a characteristic spectrum to identify components in the radix ophiopogonis decoction; and determining the contents of methylophiopogon japonicus dihydrohomoisoflavone A, methylophiopogon japonicus dihydrohomoisoflavone B, liquiritin, glycyrrhizic acid, ginsenoside Rg1, ginsenoside Re and ginsenoside Rb1 in the radix ophiopogonis decoction. The method provided by the invention can comprehensively reflect the quality attribute of the traditional decoction of the radix ophiopogonis decoction, ensures the consistency of the quality of the radix ophiopogonis decoction preparation and the decoction, and comprehensively and effectively controls the product quality.

Owner:GUANGDONG YIFANG PHARMA

Internal mixing and compounding technology for improving fluidity of rubber material

The invention discloses an internal mixing and compounding technology for improving the fluidity of a rubber material. The internal mixing and compounding technology is characterized in that based on a rubber material fluidity analysis meter, fluidity data of the rubber material is measured in real time, and technological parameters in a rubber material internal mixing process are adjusted, thereby improving the product quality. The rubber material fluidity analysis meter detects the fluidity of the rubber material specifically, and has the advantages that the rubber material fluidity analysis meter is close to production, is wide in application and detects quickly. The rubber material fluidity analysis meter is extremely suitable for control and monitoring of the size stability of semi-finished products, fills a gap in the industry, provides great help for the quality control of tires, and plays an important role in improving the quality of the tires and stabilizing process control.

Owner:特拓(青岛)轮胎技术有限公司

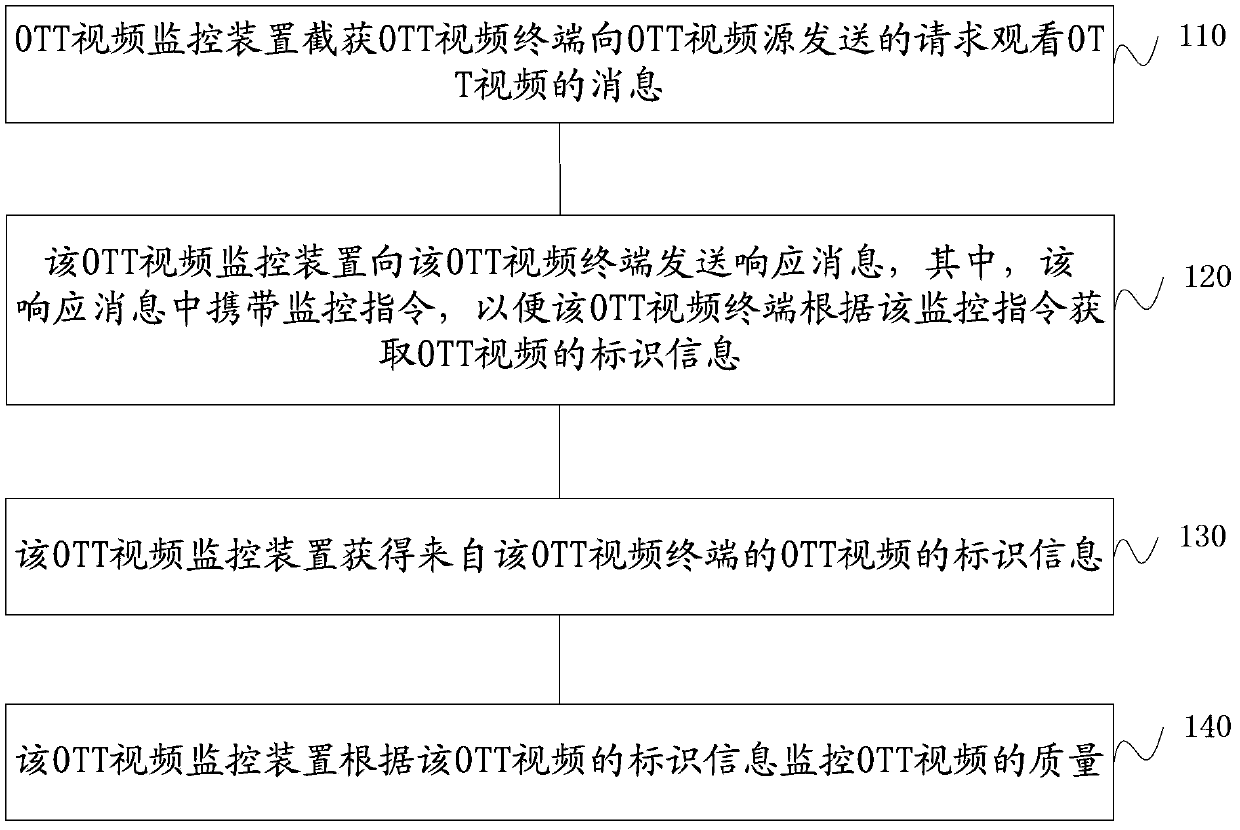

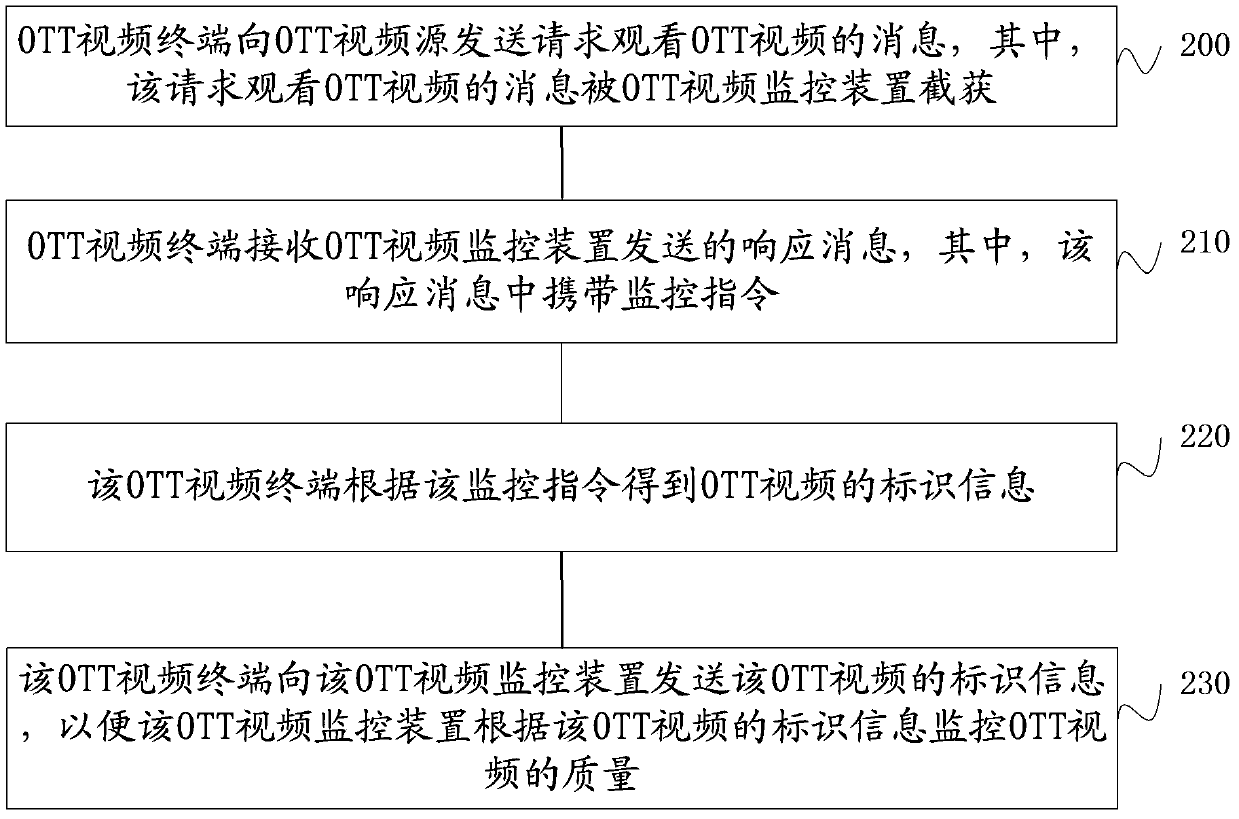

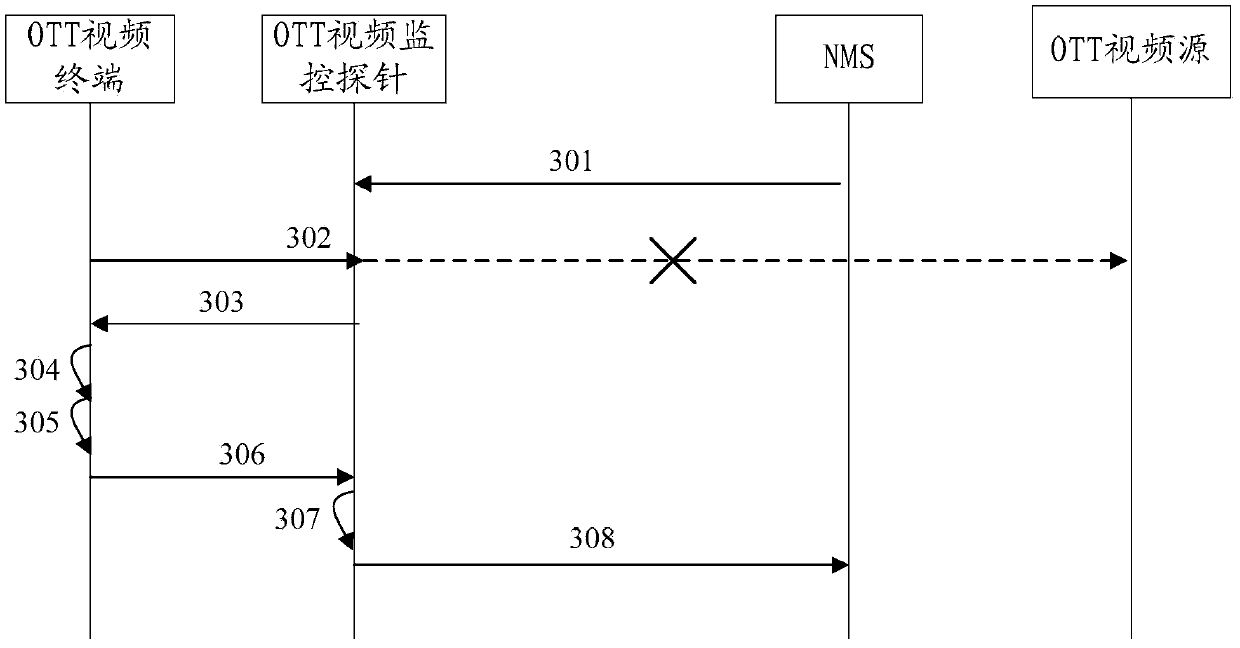

OTT video quality monitoring method, device and system

ActiveCN104185016ARealize quality controlTelevision systemsTransmissionVideo monitoringComputer terminal

Disclosed are an OTT video quality monitoring method, apparatus, and system, which can conveniently implement monitoring of OTT video quality. The method comprises: an OTT video monitoring apparatus intercepting an OTT video watching request message sent by an OTT video terminal to an OTT video source; the OTT video monitoring apparatus sending a response message to the OTT video terminal, the response message carrying a monitoring instruction, so that the OTT video terminal obtains OTT video identification information according to the monitoring instruction; the OTT video monitoring apparatus obtaining OTT video identification information from the OTT video terminal; and the OTT video monitoring apparatus monitoring OTT video quality according to the OTT video identification information. In the embodiments of the present invention, an OTT video monitoring apparatus is used to implement monitoring of OTT video quality, so that the monitoring of OTT video quality is conveniently implemented without the need of deployment on a network accelerator and an OTT terminal.

Owner:HUAWEI TECH CO LTD

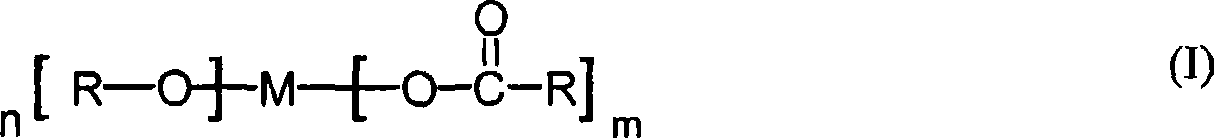

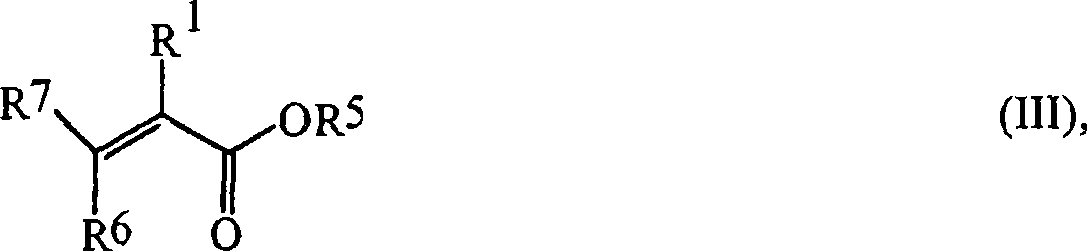

Improvement in quality control of a functional fluid

InactiveCN101511982AConvenient quality controlRealize quality controlThickenersAdditivesQuality controlBase oil

The present invention describes use of use of a metal compound to control the quality of a functional fluid. Additionally, the present invention concerns a method for controlling the quality of a functional fluid comprising the steps of: adding a metal compound to a component of a lubricant; mixing the component with a base oil; measuring the concentration of the metal compound in the functional fluid; and comparing the expected concentration of the metal compound with the measured concentration.

Owner:EVONIK OIL ADDITIVES GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com