Patents

Literature

38results about How to "Timely detection of quality problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

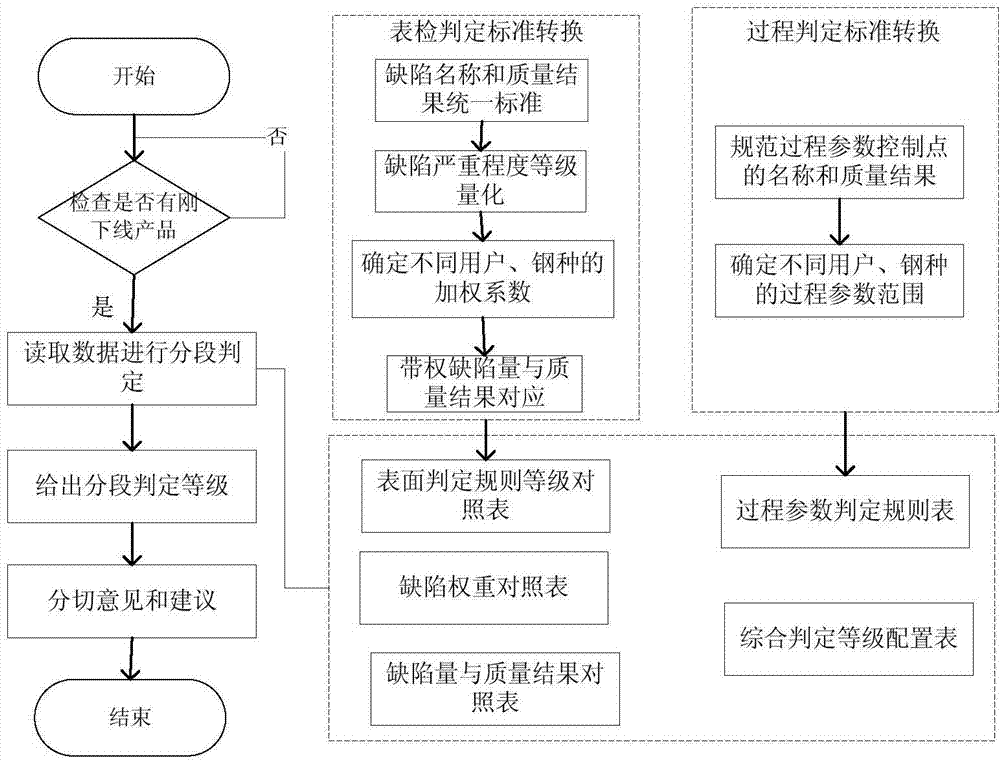

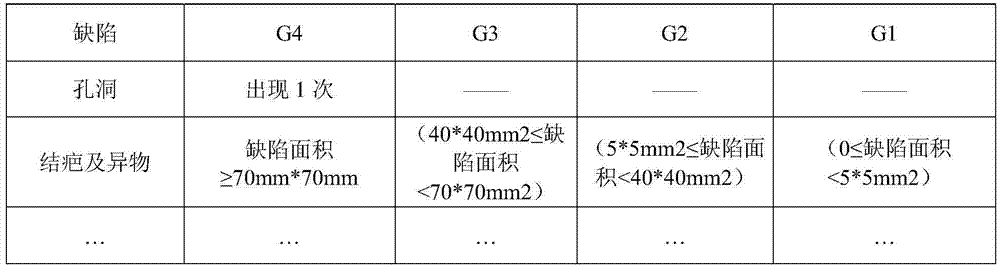

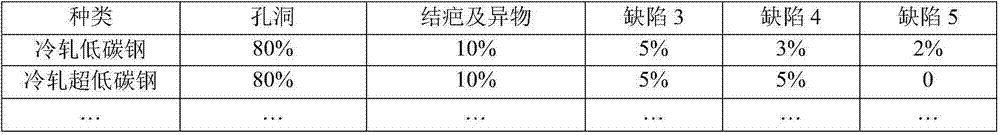

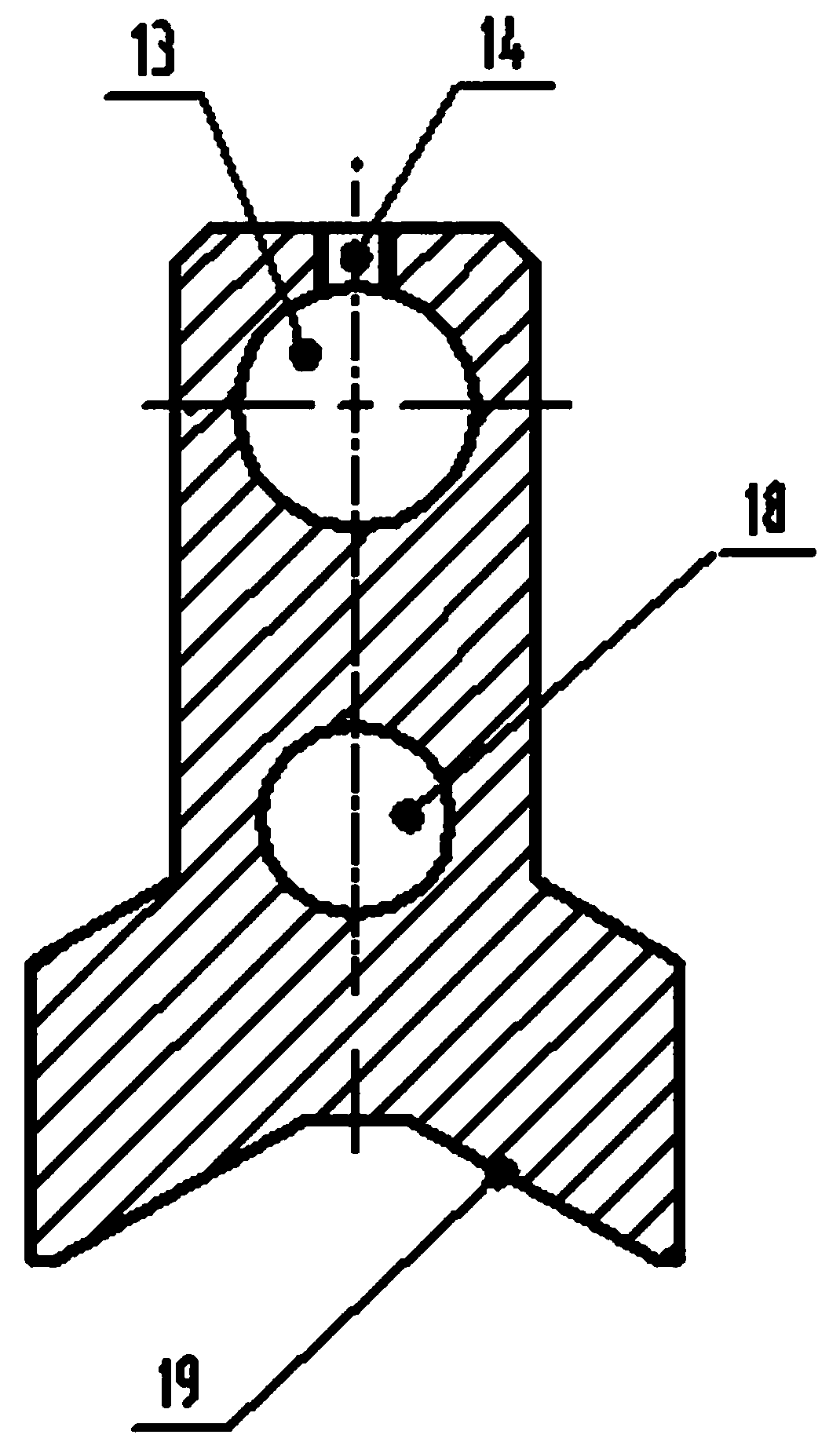

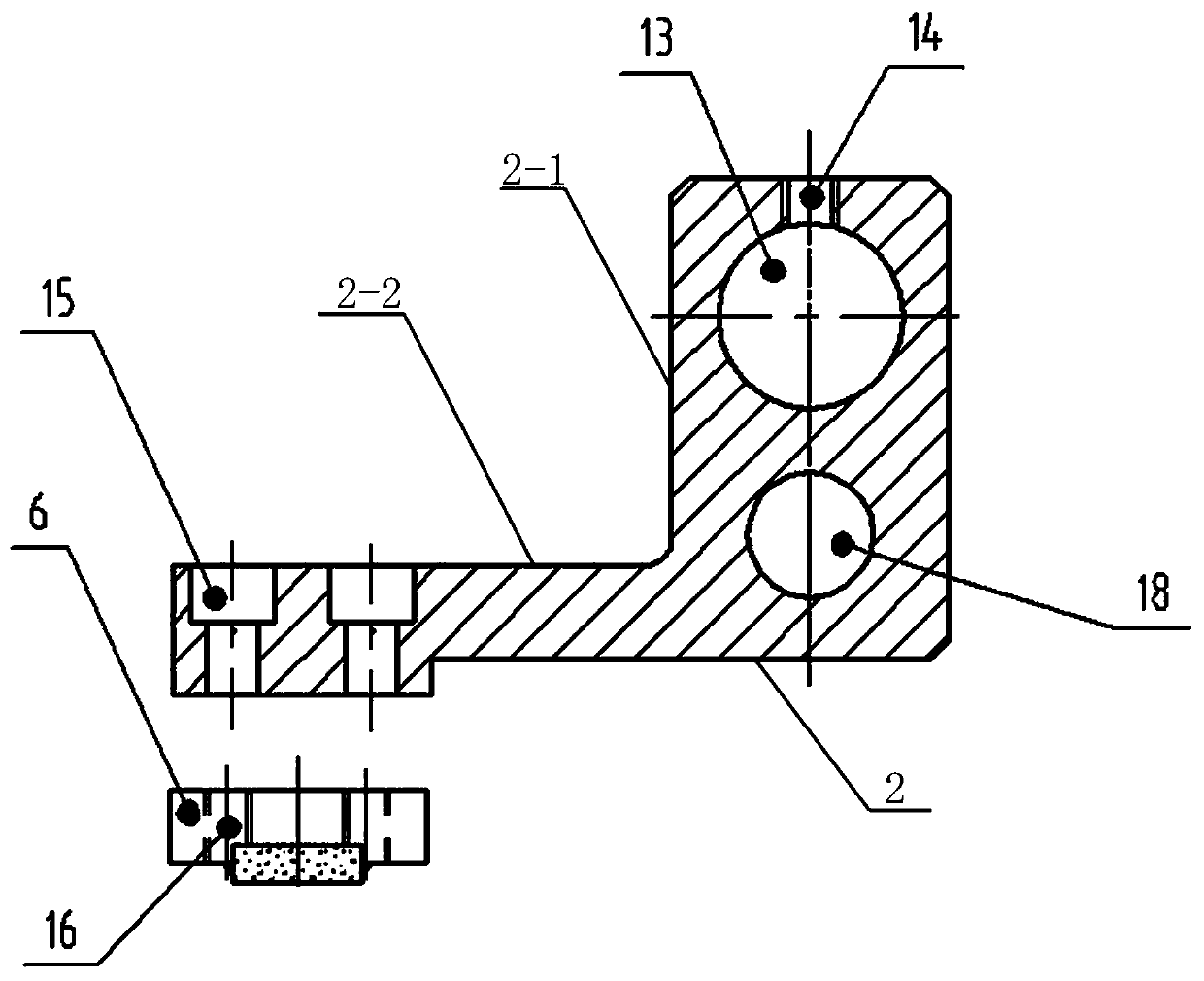

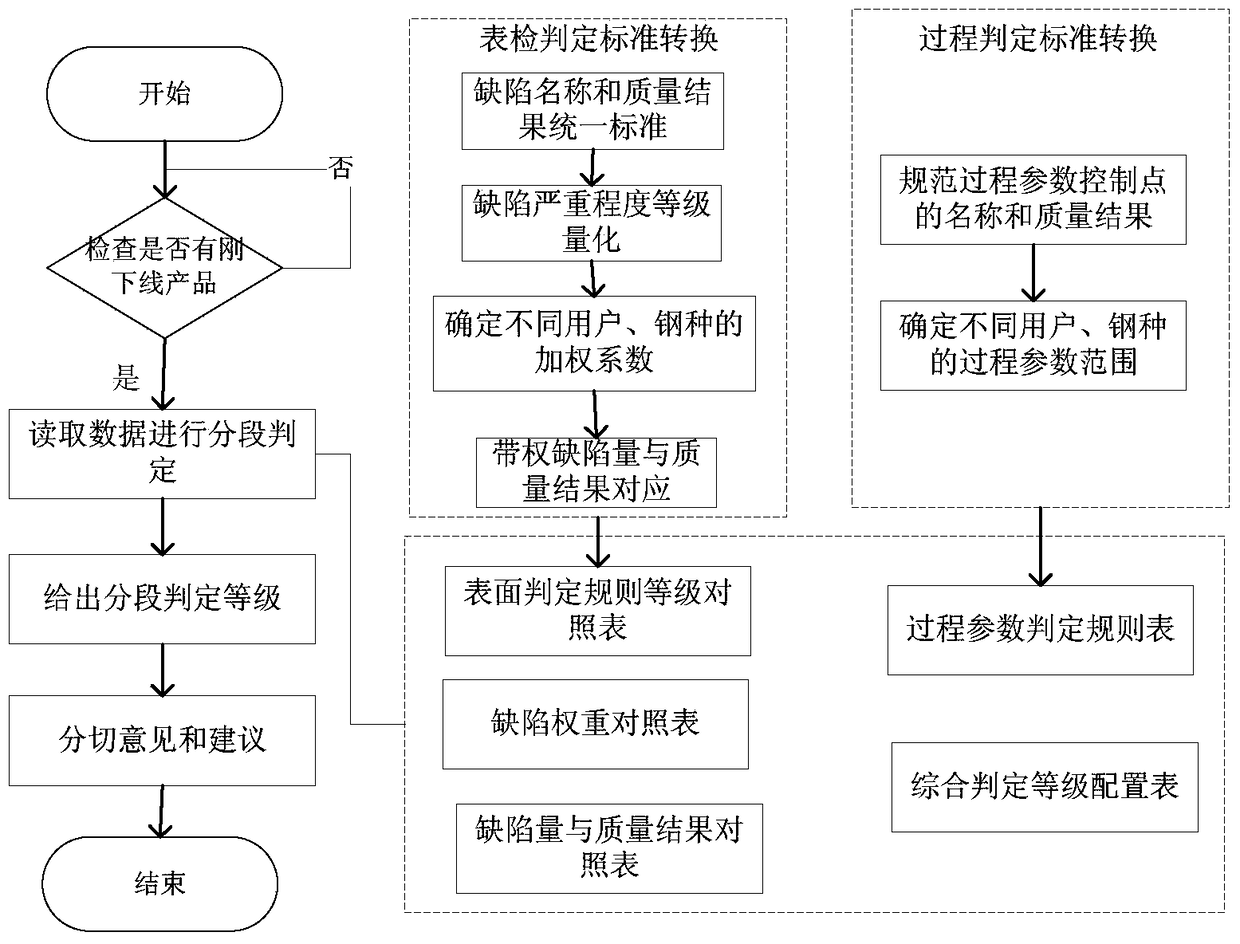

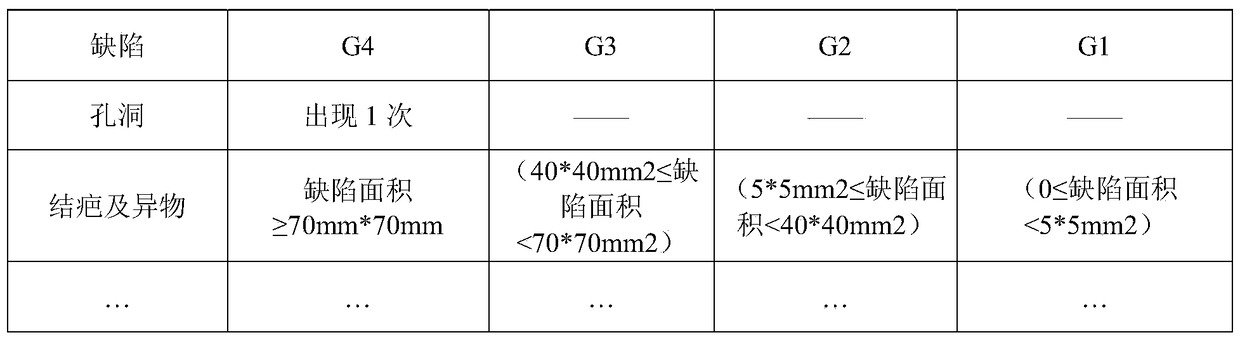

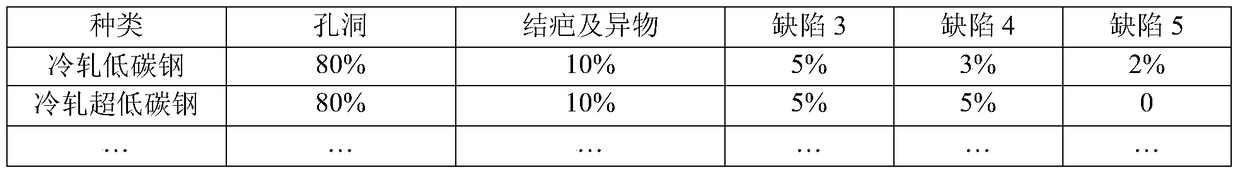

Segment-based multi-dimensional online quality evaluation system and method for steel coils

ActiveCN104751288AAchieve integrationImplementation checkResourcesManufacturing computing systemsQuality levelEconomic benefits

The invention belongs to the technical field of metallurgical industry manufacturing and informationization of the metallurgical industry and relates to a segment-based multi-dimensional online quality evaluation system and method for steel coils. production process data and surface detection data for use in quality evaluation are acquired through a data interface; when a steel coil is off a line, the steel coil is divided into a plurality of segments along the length; the acquired data are read; according to business rules and product quality standards, process and surface defect quality results are separately judged; comprehensive level of each segment and quality level of the steel coil are finally acquired. Primary secondary process parameters and instrument defect information are acquired, and the production process data is maximally integrated; the business quality standards and control plan operation procedures are quantitatively and systematically processed, segment-based dimensional evaluation is performed at the moment when products are off the line, comprehensive inspection of the steel coil is achieved, labor for data collection is freed, quality inspectors can be helped to find quality problems in time so as to make following treatment, and product quality and enterprise economic benefit are finally improved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

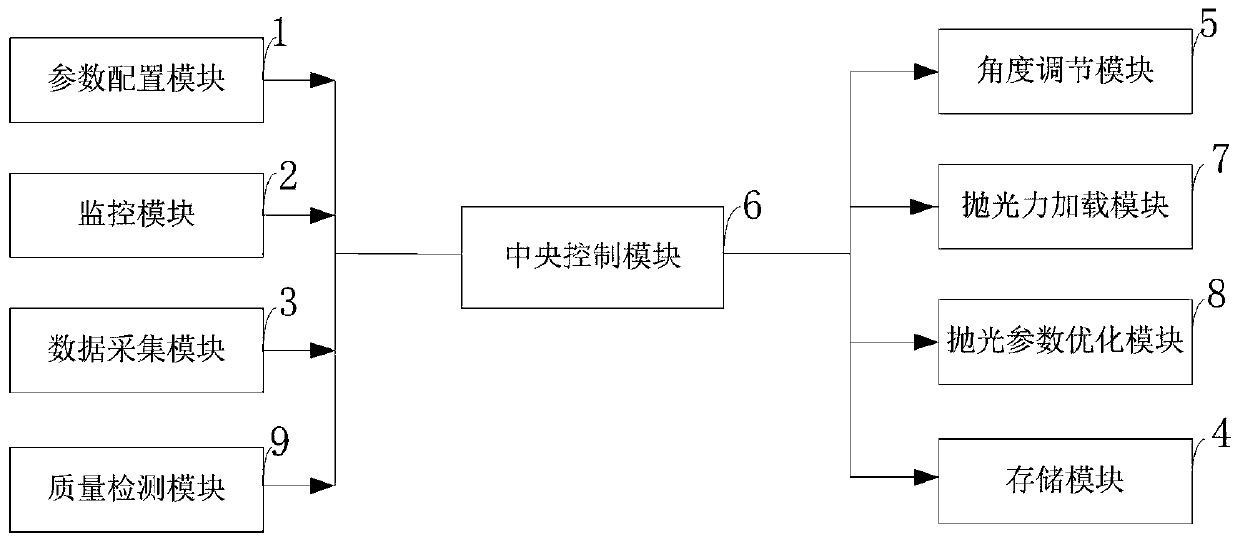

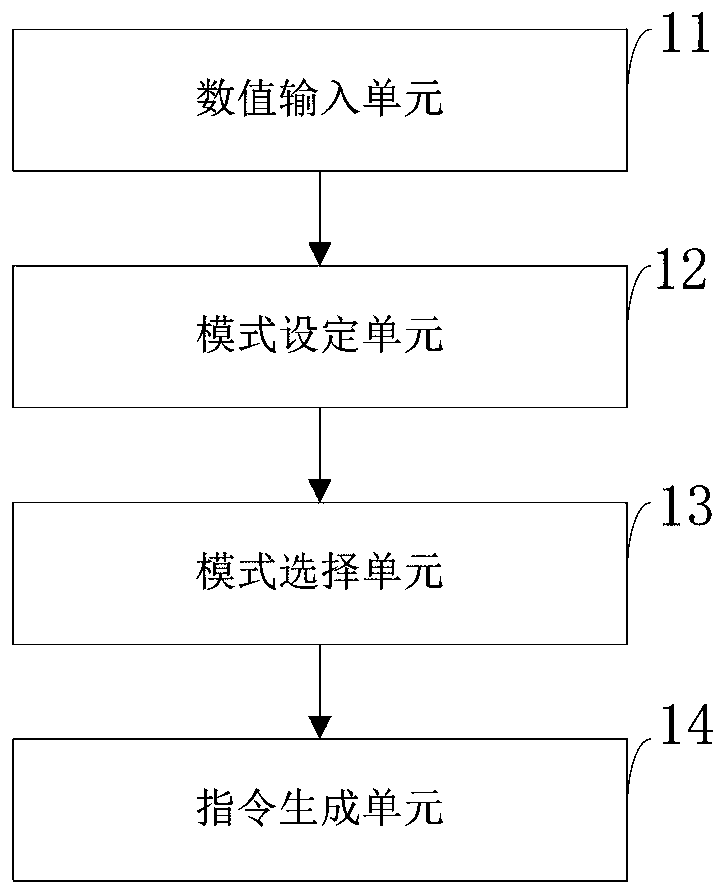

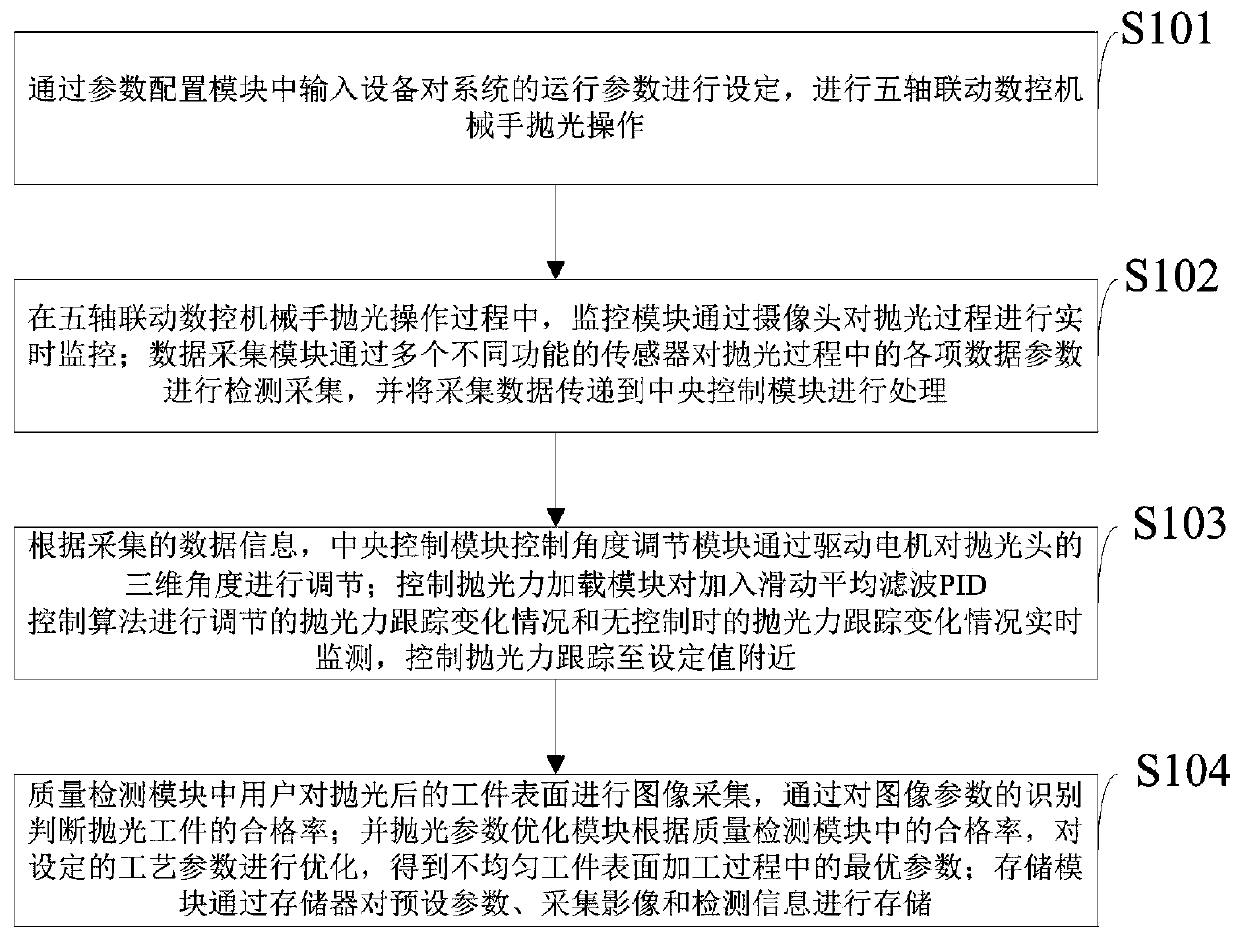

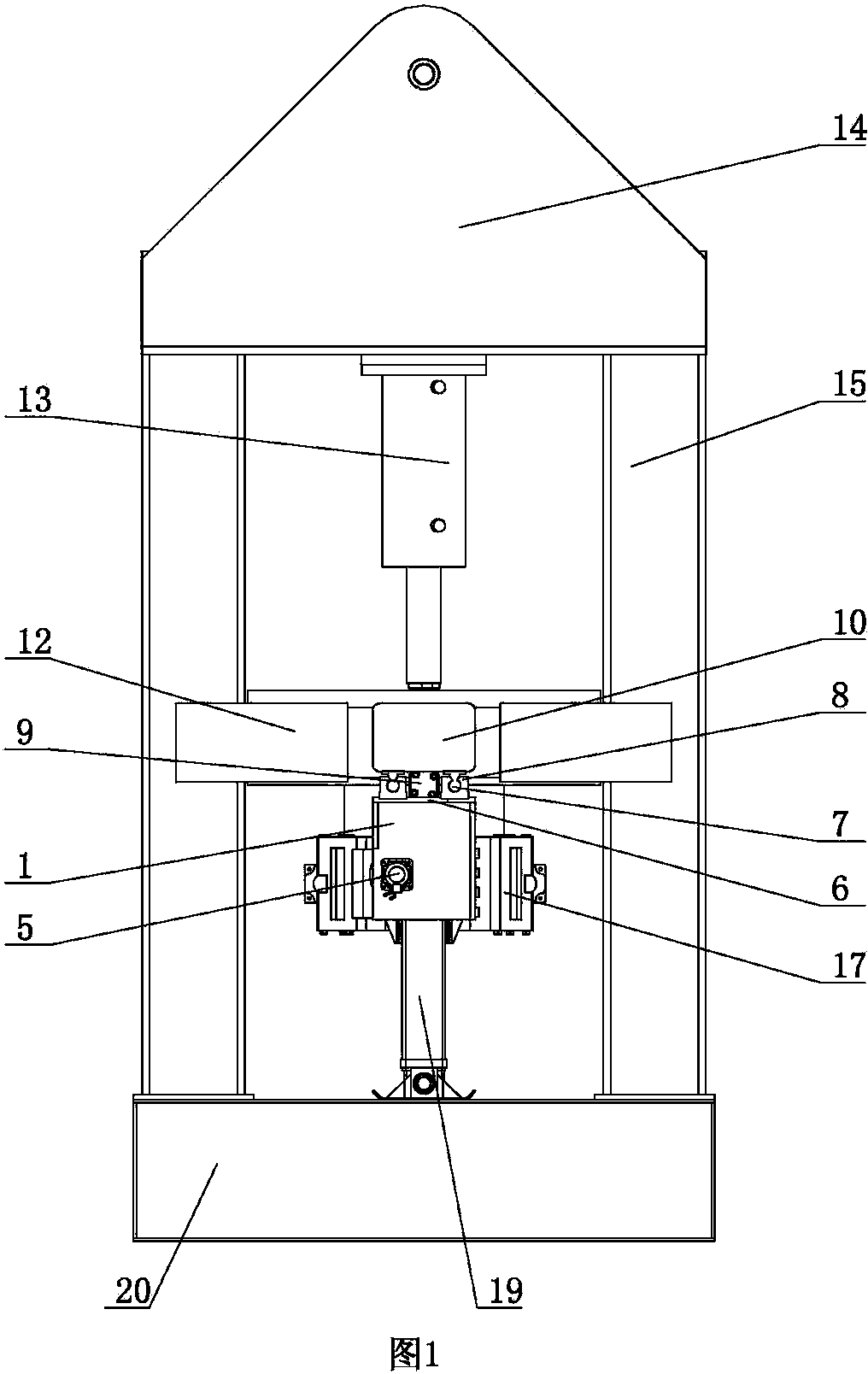

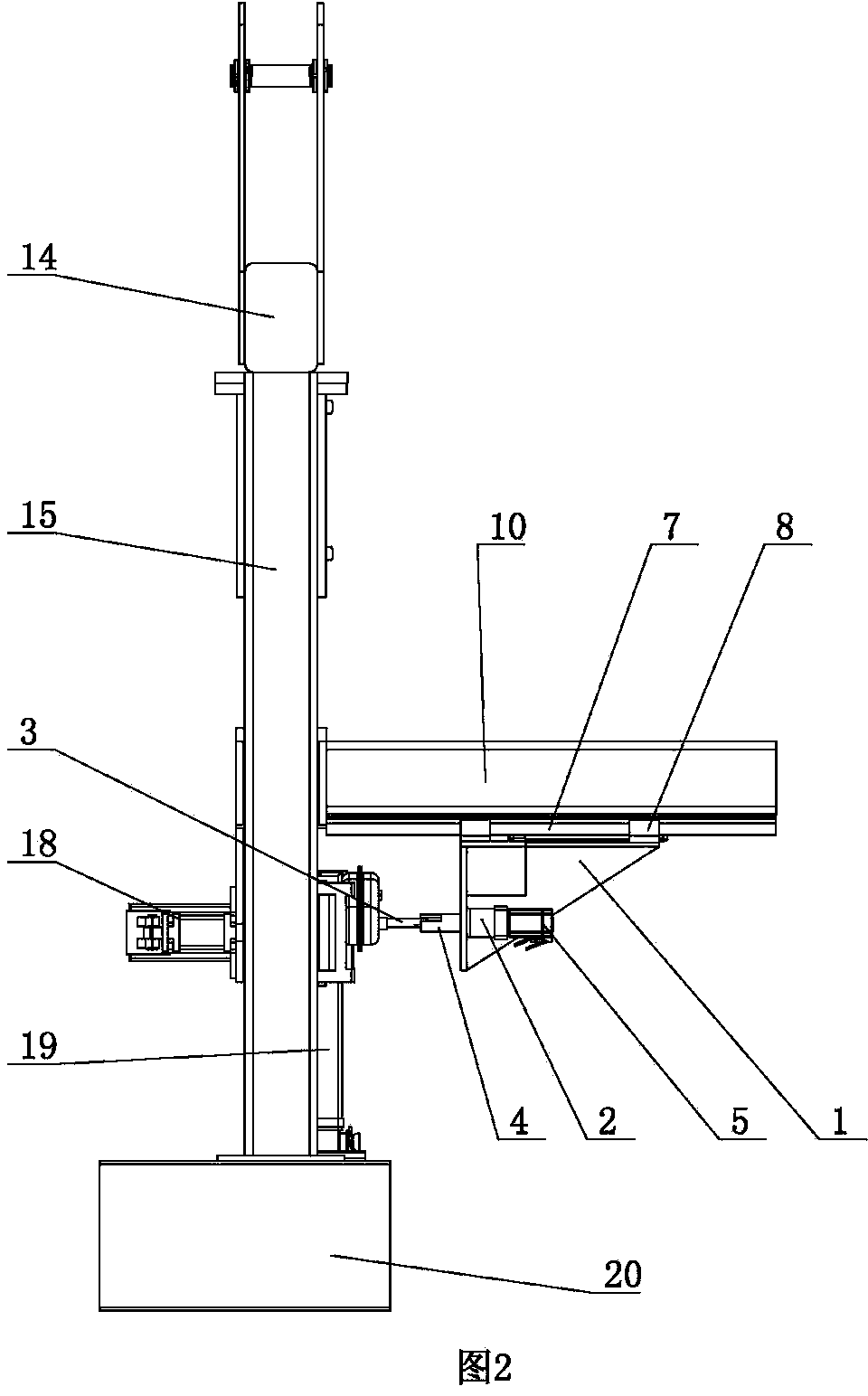

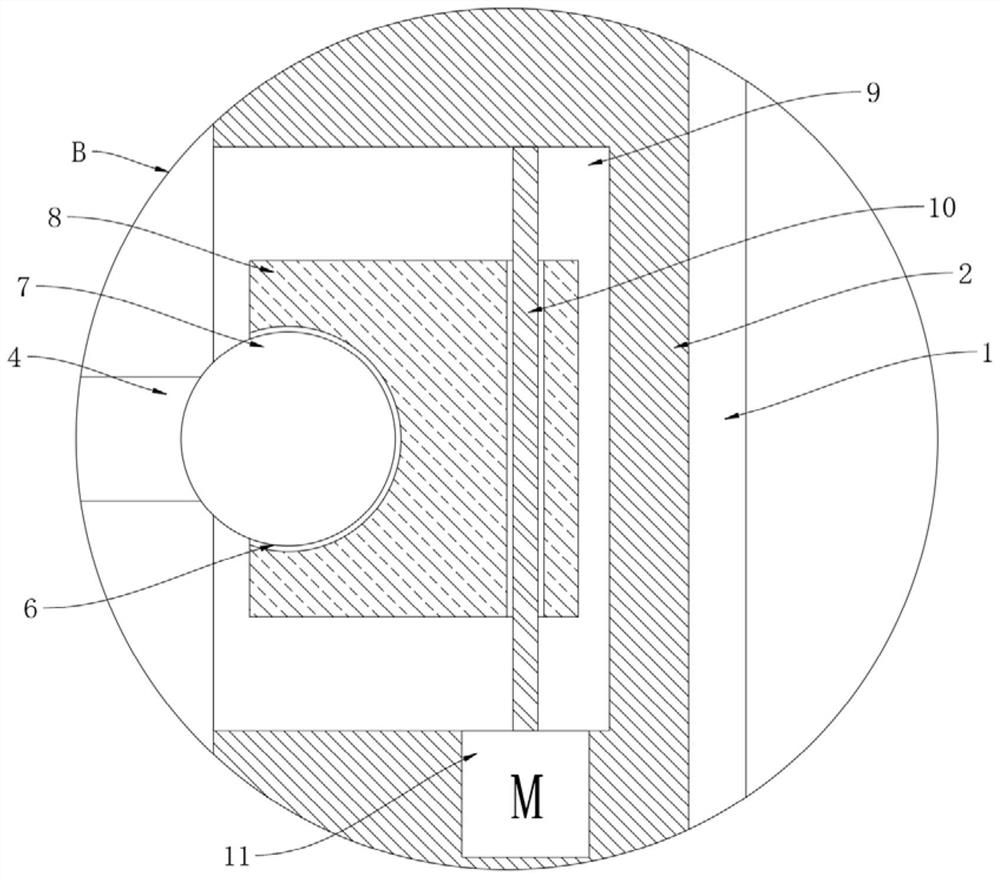

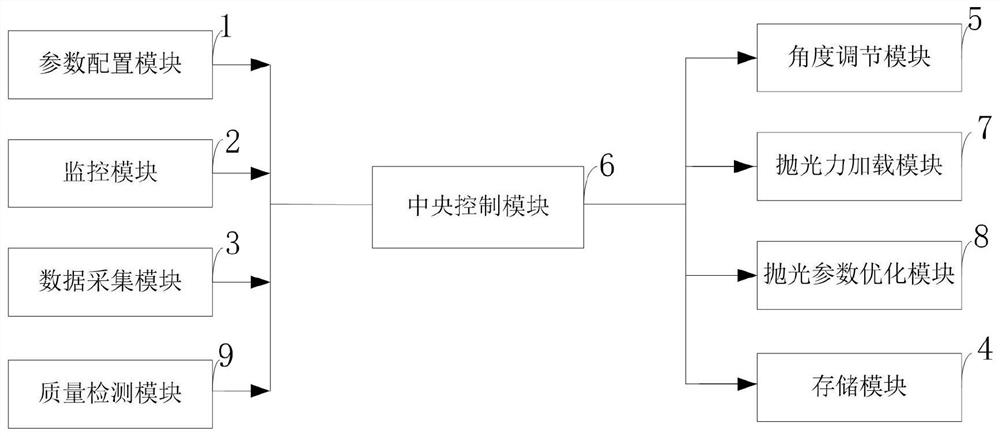

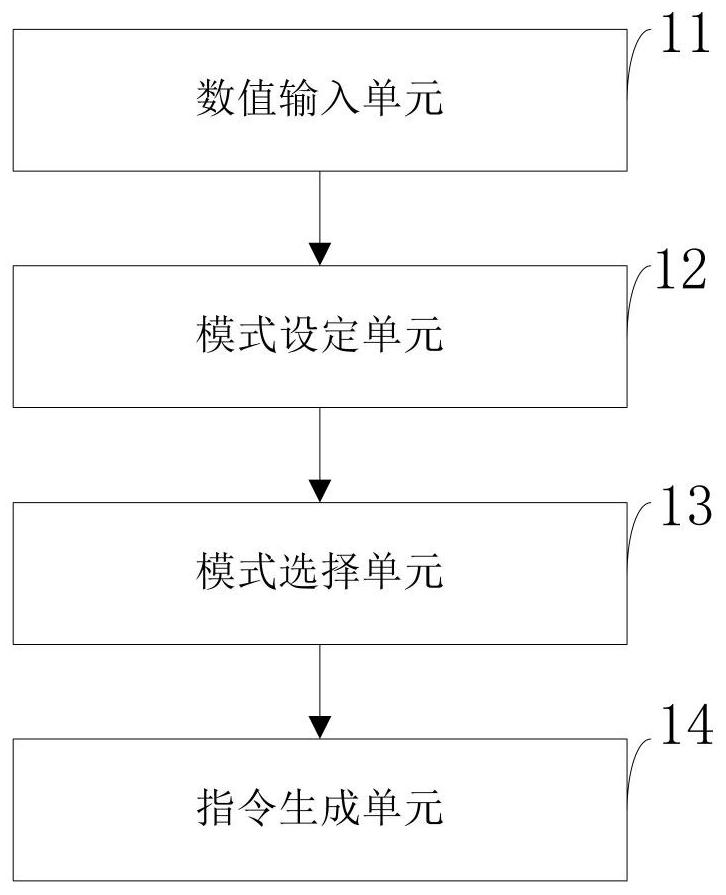

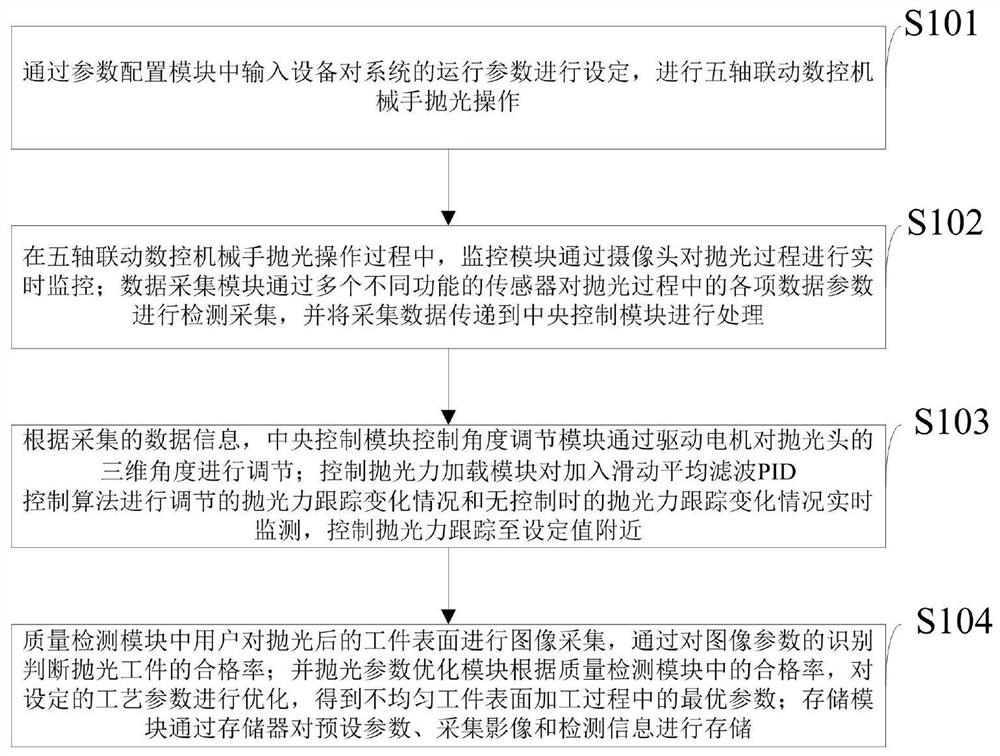

Five-axis linkage numerical control manipulator polishing control system and method

InactiveCN111468989AOptimizing Process ParametersAccurate and fast variable polishing force controlPolishing machinesAutomatic grinding controlNumerical controlControl system

The invention belongs to the technical field of machining, and discloses a five-axis linkage numerical control manipulator polishing control system and method. The five-axis linkage numerical controlmanipulator polishing control system comprises a parameter configuration module, a monitoring module, a data acquisition module, a storage module, an angle adjustment module, a central control module,a polishing force pneumatic loading module, a polishing parameter optimization module and a quality detection module. The parameter configuration module comprises a numerical value input unit, a modesetting unit, a mode selection unit and an instruction generation unit. The monitoring module monitors the polishing process in real time through a camera. The data acquisition module detects and acquires various data and parameters in the polishing process through a plurality of sensors with different functions. According to the five-axis linkage numerical control manipulator polishing control system and method, accurate and rapid tracking variable polishing force control can be achieved in the polishing process, the corresponding polishing force is controlled in real time, and the force control requirement of polishing machining can be effectively met; and on the premise that the polishing quality is guaranteed, the working efficiency is improved.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

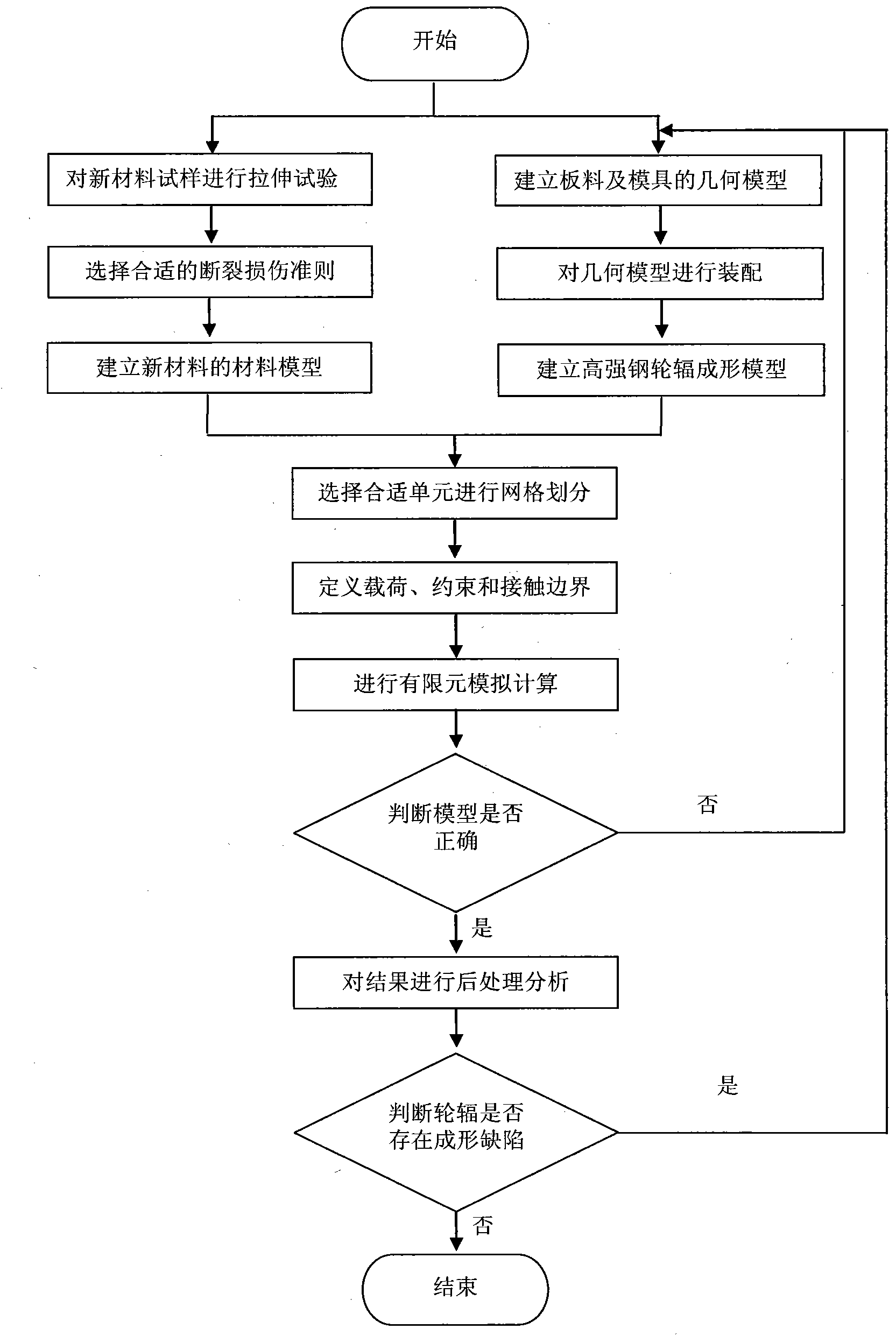

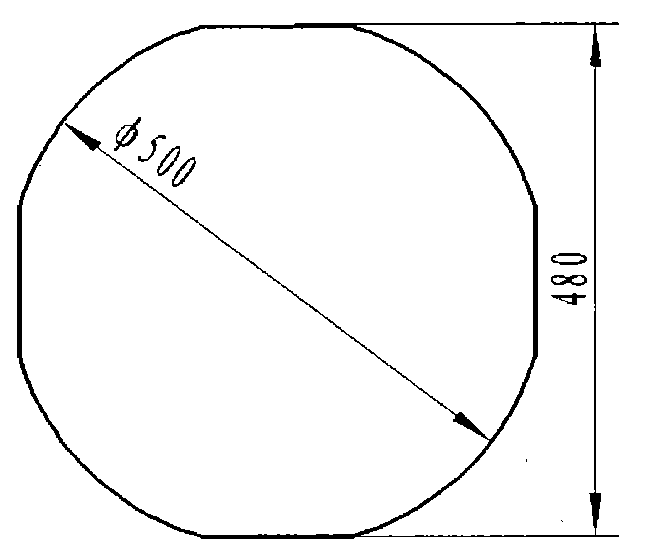

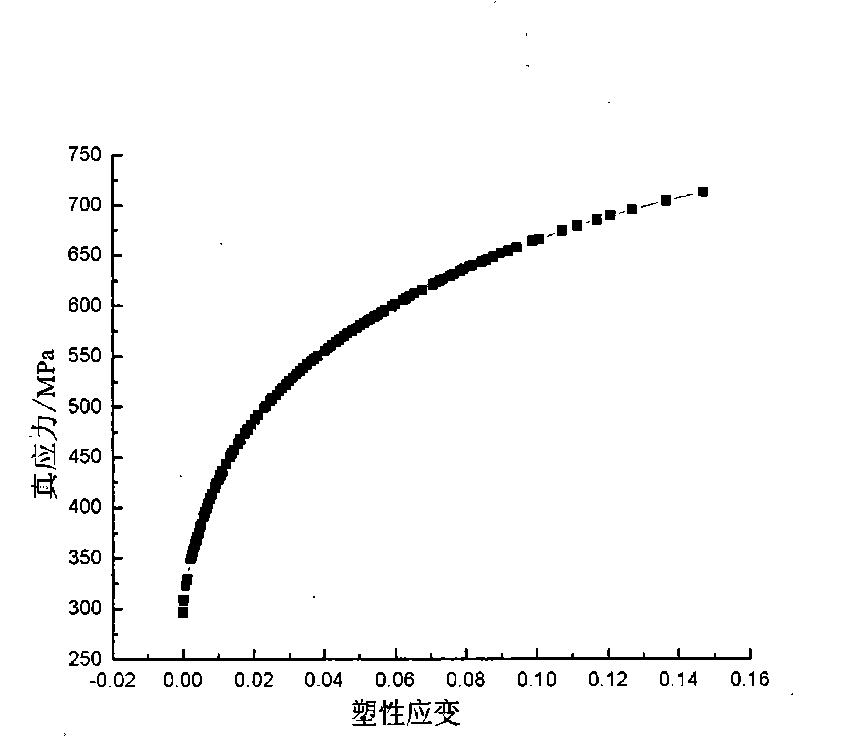

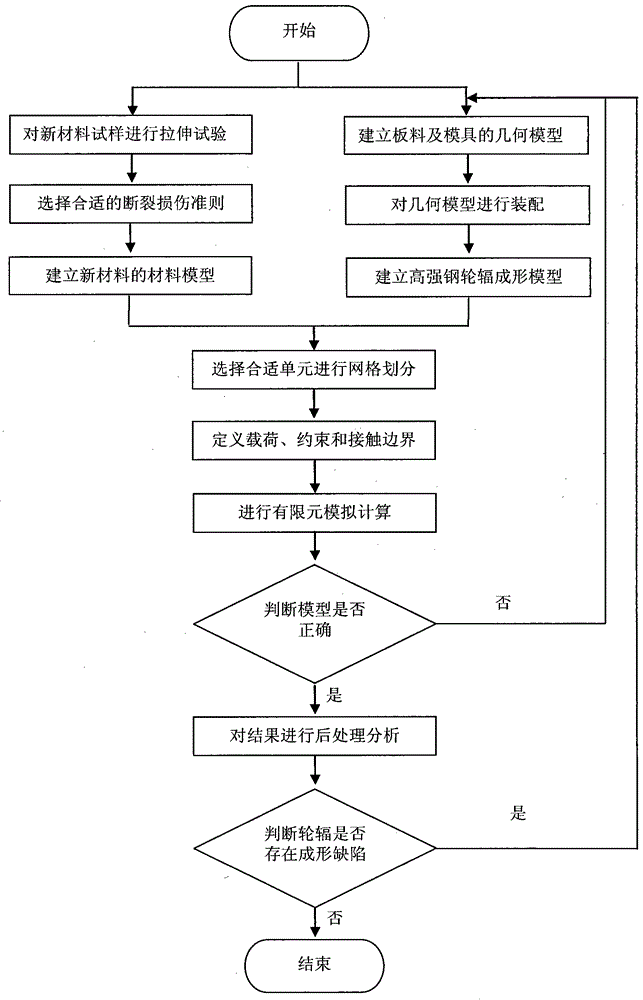

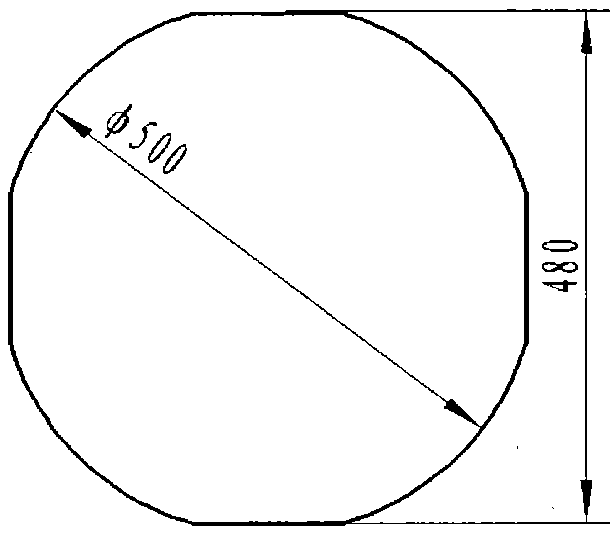

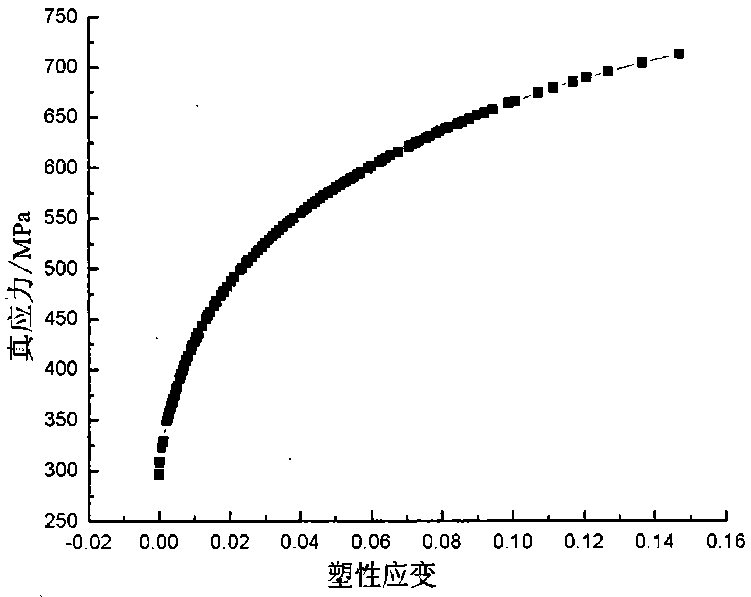

Numerical simulation method of novel high-strength steel spoke drawing punching combined process

InactiveCN104077439ATimely detection of quality problemsImproved process designSpecial data processing applicationsPunchingElement model

The invention discloses a numerical simulation method of a novel high-strength steel spoke drawing punching combined process. By means of establishment of an accurate finite element model, a forming process of a novel high strength steel plate for spoke production can be observed, distribution of wall thickness, stress, strain and damages in the spoke forming process can be obtained, possible forming defects such as excessively thinning and pull cracks of the plate in the spoke forming process can be discovered in time, forming properties of the plate can be evaluated in advance before the novel high strength steel plate is used for spoke actual production, thereby, the process design scheme can be effectively improved, mold parameters can be optimized, spoke product qualities are improved, rejection rate of products is reduced, large manpower and material inputs caused by trial and error can be avoided, the market competitiveness of the high-strength steel products is improved, application and development of novel high-strength steel wheels are facilitated, and the basis is provided for optimization of steel for high-strength wheels.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

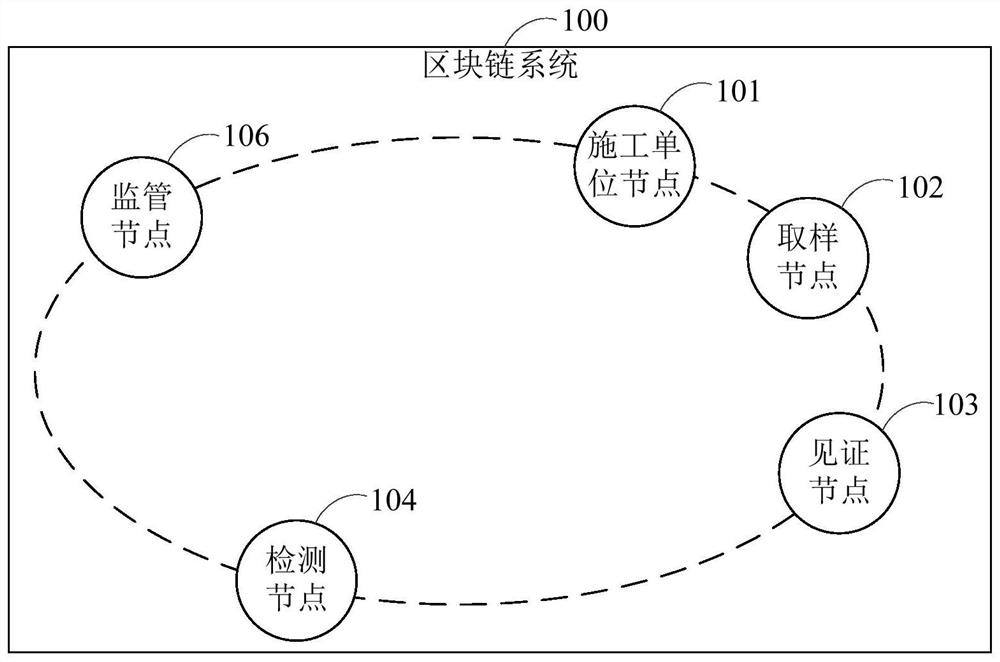

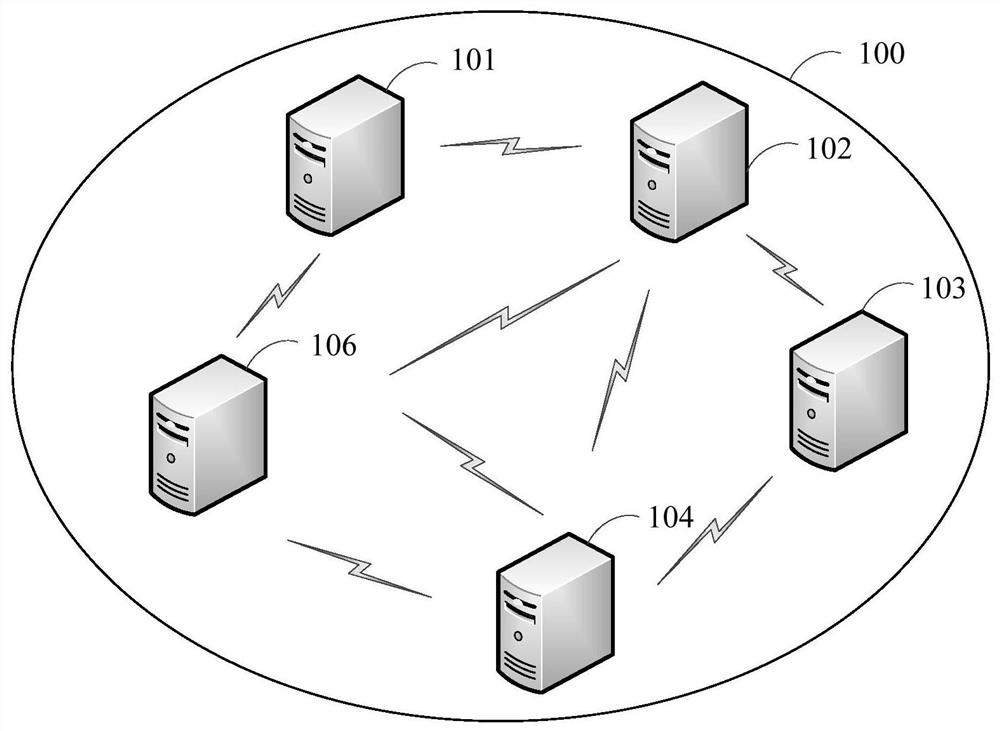

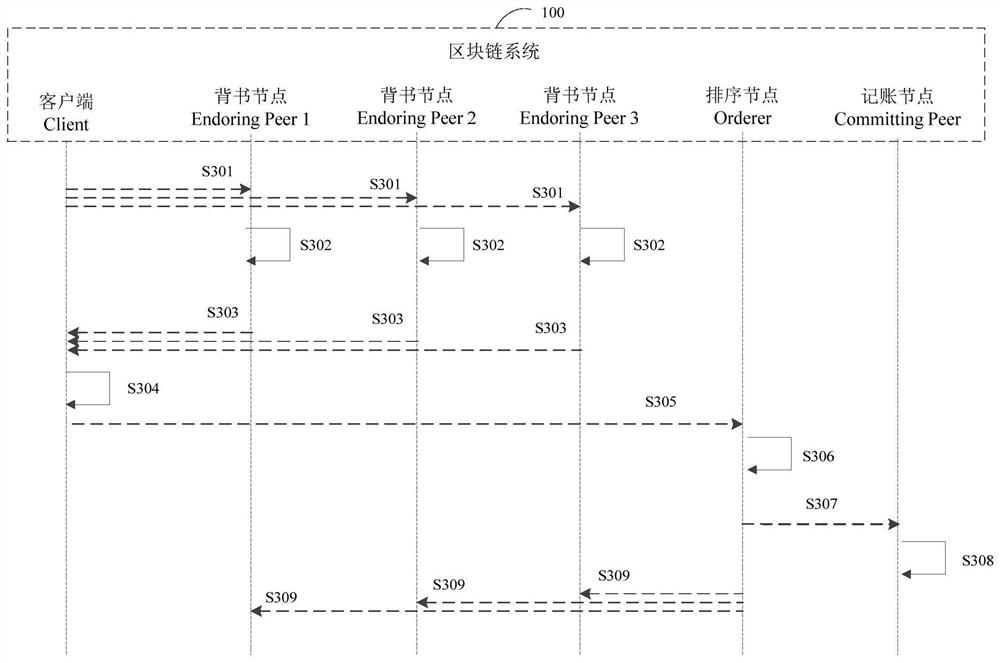

Block chain system for construction project quality detection and supervision

InactiveCN112184066APrevent the phenomenon of fake samplesTimely detection of quality problemsFinanceDatabase distribution/replicationReliability engineeringReal-time computing

The invention relates to a block chain system for construction project quality detection and supervision. The block chain system comprises a sampling node, a detection node and a supervision node. Thesampling node acquires an initial record on the block chain system, updates the initial record according to sampling information of sampling a detection sample by a sampler to obtain a sampling record, and performs uplink evidence storage on the sampling record on the block chain system; the sampling information comprises at least one of sampling time, a sampling place and a sampling photo; the detection node acquires a sampling record on the block chain system, updates the sampling record according to a detection result of the detection unit for detecting the detection sample to obtain a detection record, and performs uplink evidence storage on the detection record on the block chain system; the supervision node obtains the detection record on the block chain system, and can supervise the whole construction project quality detection process according to the detection record, so that a supervision unit can conveniently and timely discover the quality problem, the supervision strengthis enhanced, and the construction project quality is ensured.

Owner:GUANGZHOU YUEJIAN SANHE SOFTWARE

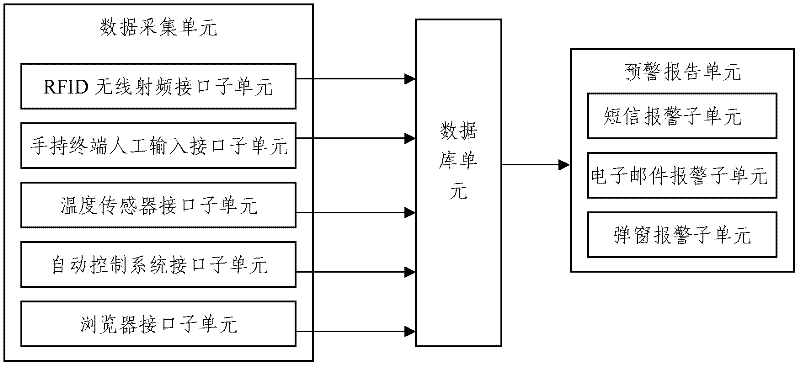

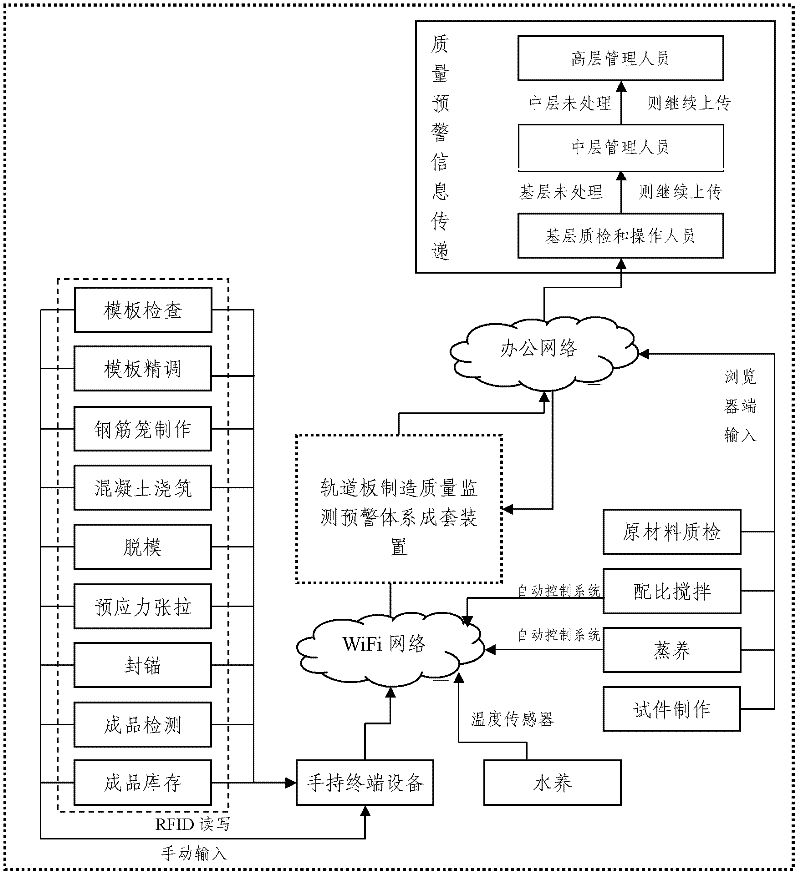

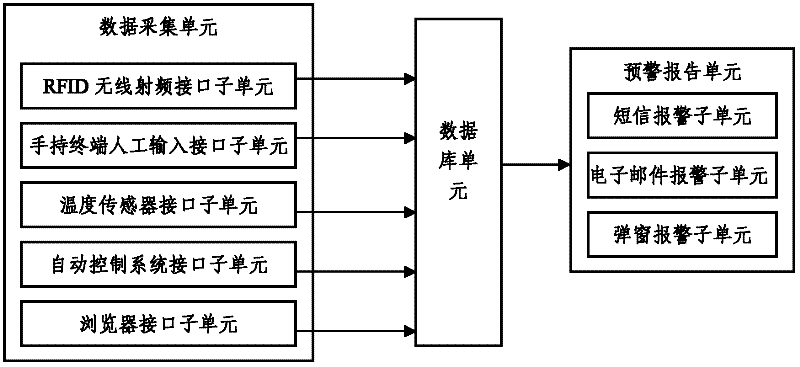

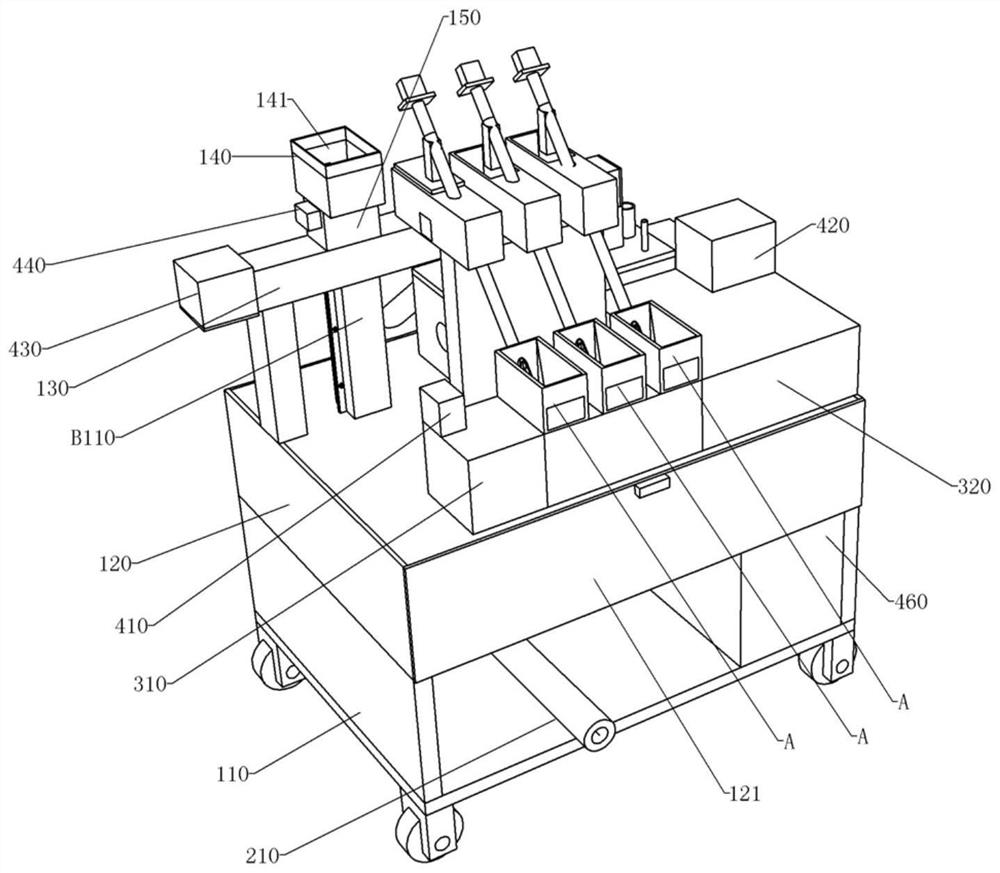

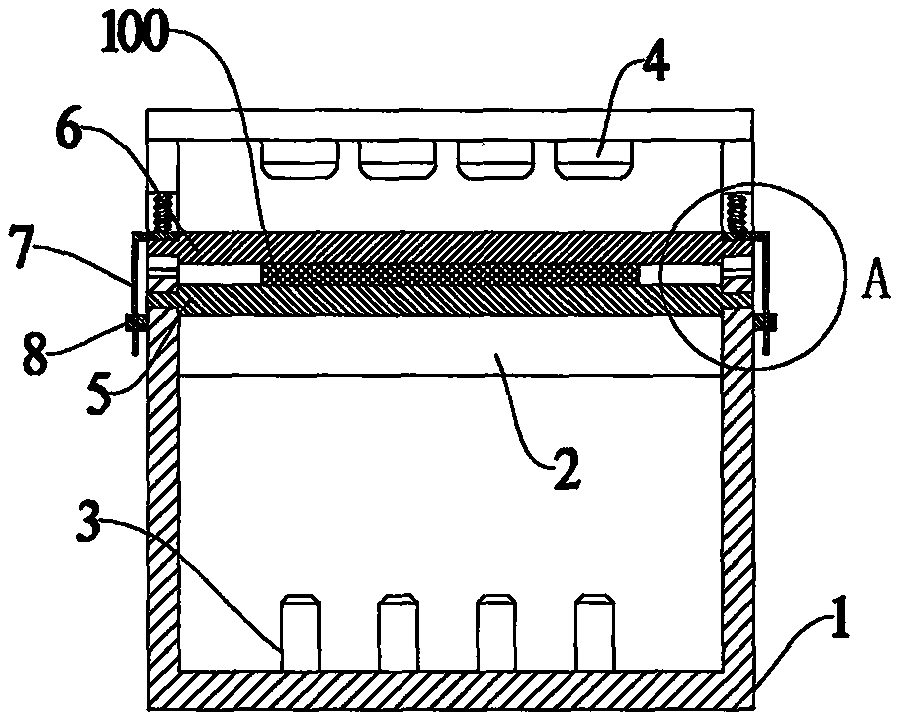

Slab manufacture quality monitoring pre-warning system package device

ActiveCN102253668ATimely detection of quality problemsSolve quality problemsProgramme total factory controlDynamic monitoringComputer science

The invention discloses a slab manufacture quality monitoring pre-warning system package device, and relates to the technical field of quality monitoring pre-warning. The device comprises a database unit, as well as a data collection unit and a pre-warning report unit which are connected with the database unit, wherein the data collection unit is used for collecting each quality monitoring parameter in a slab producing process, and transmitting the quality monitoring parameter to the database unit; and the database unit is used for determining whether the quality monitoring parameter exceeds the threshold of a standard design parameter, and transmitting the quality monitoring parameter to the pre-warning report unit if the quality monitoring parameter exceeds the threshold of the standard design parameter. By utilizing the device, real-time dynamic monitoring of the slab manufacture process and timely quality pre-warning are realized for the first time in the slab precise manufacture industry, critical data can be reviewed, regenerated and re-derived by adopting an Internet of things technology, and powerful assurance is provided to slab construction and operation maintenance, thus the device has significant meanings in assuring high-speed rail quality, constructing digital railways and improving the railway operation intelligent level.

Owner:BEIJING MAGGRP TECH +1

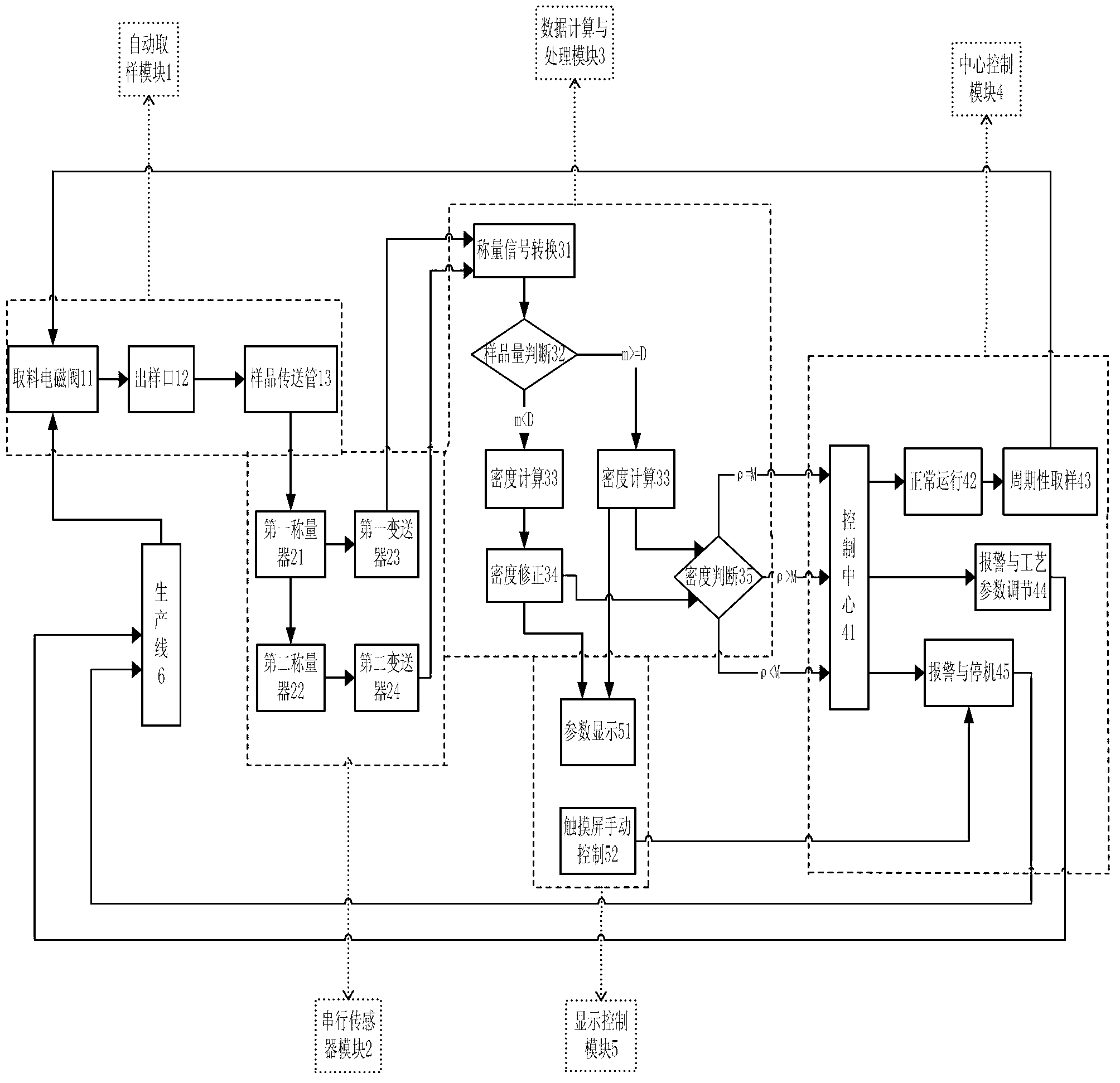

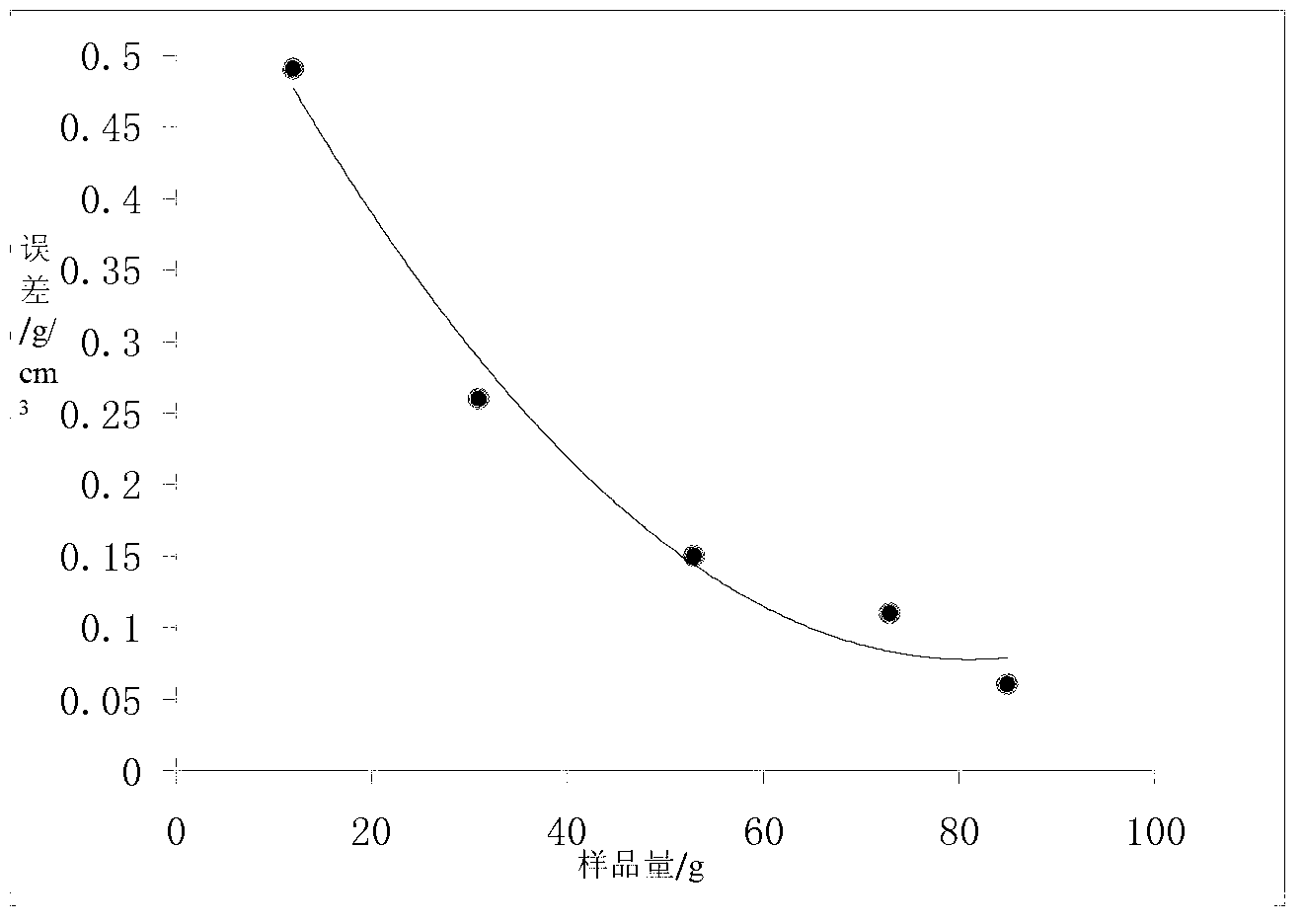

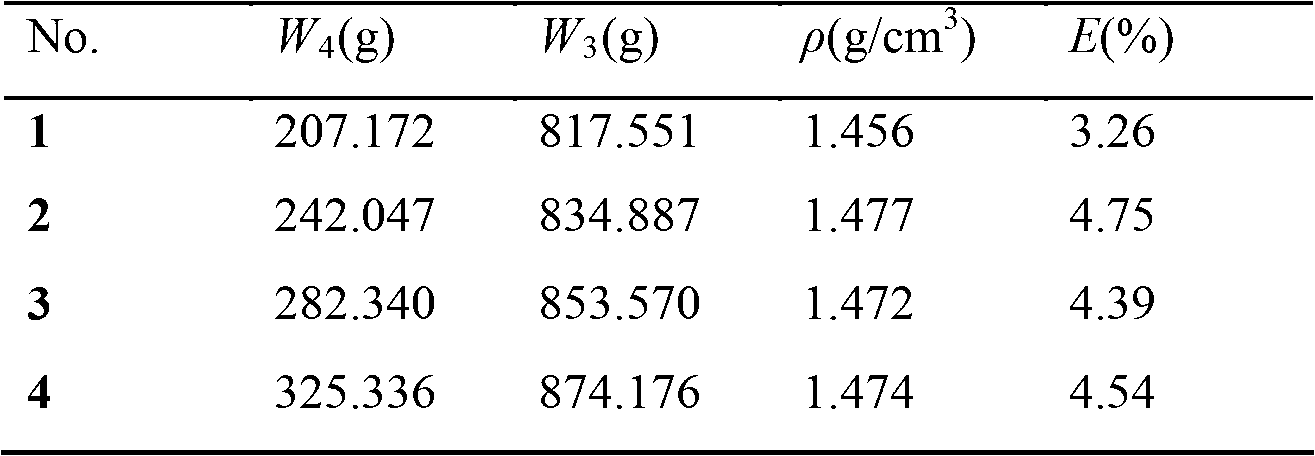

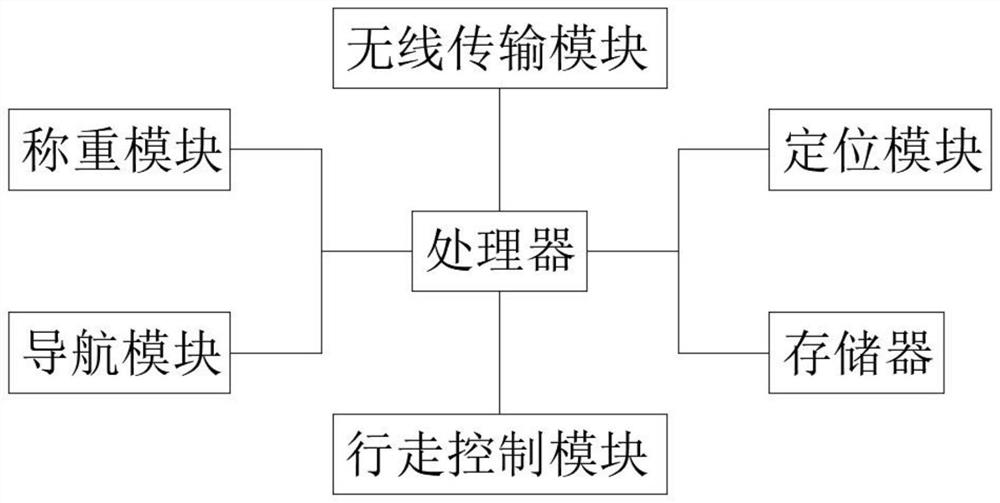

On-line rapid detection system for density of emulsion explosive semi-finished product

ActiveCN102798580AIncrease productivityTimely detection of quality problemsSpecific gravity measurementSolenoid valveEmulsion explosive

The invention relates to an on-line rapid detection system for density of an emulsion explosive semi-finished product, which comprises an automatic sampling module, a serial sensor module, a data processing and calculating module, a center control module and a display control module. The system is characterized in that a feeding solenoid valve in the automatic sampling module is switched on, the automatic on-line sampling is realized through a sample outlet and a sample transmission pipe; the sample enters into the serial sensor module through the sample transmission pipe, the sample quality and volume signals can be obtained by two weighing machines and transmitters, and are transmited to the data processing and calculating module; the density detection value is obtained by a weighing signal transition unit, a sample amount determine unit, a density calculating unit and a density correction unit, when the density detection value is provided in the preset value scope, the system enables normal operation; when the density value is greater than the preset value scope, the alarm is carried out, and the feeding speed of a density conditioning agent is changed, the density of the emulsion explosive semi-finished product is adjusted; when the density value is less than the preset value scope, the alarm is carried out and the system is stopped, then the operation is continued after the technological parameter is changed. The on-line rapid detection system can realize the integrated function of automatic sampling, rapid detection and machine stopping by alarming.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

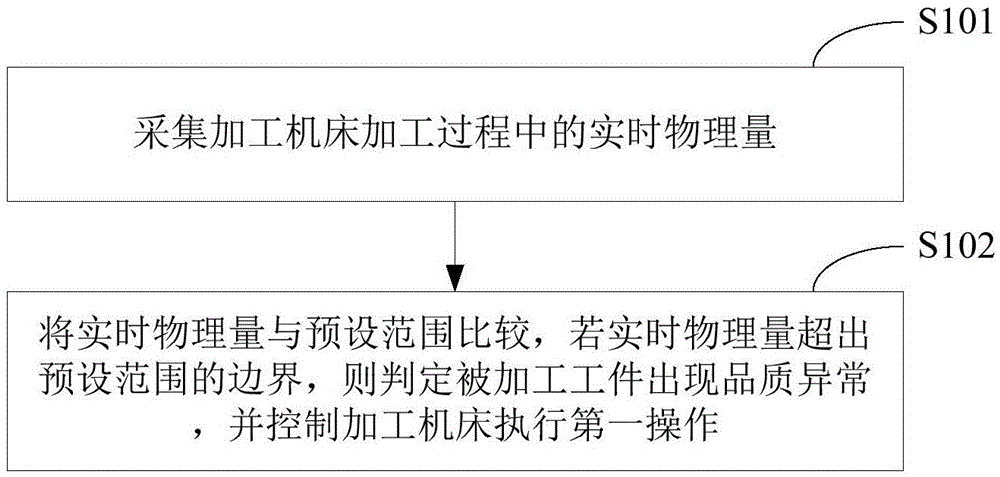

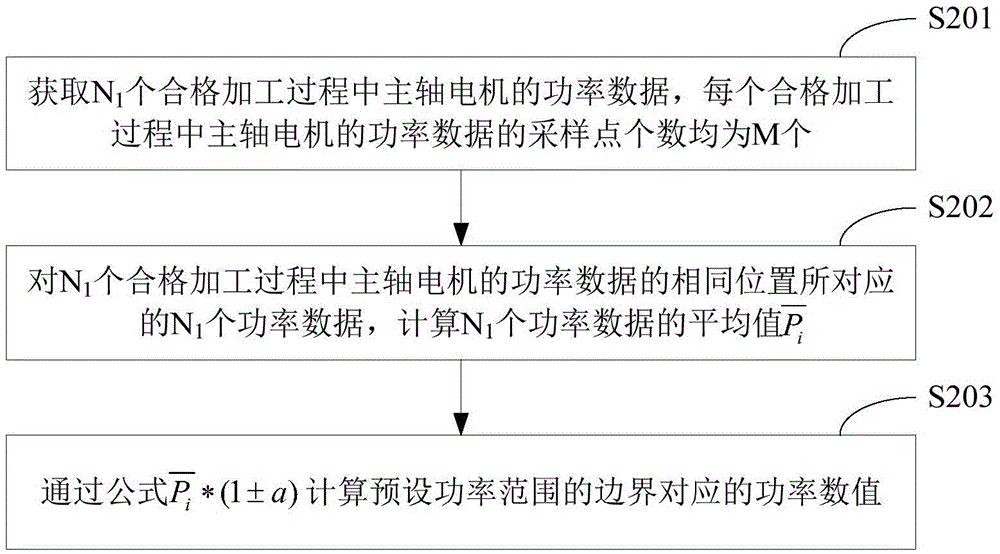

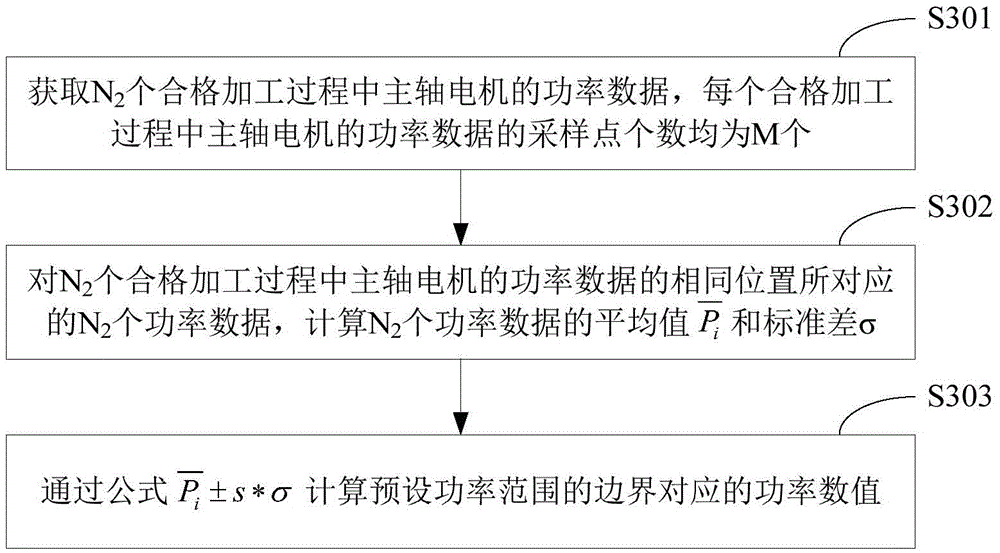

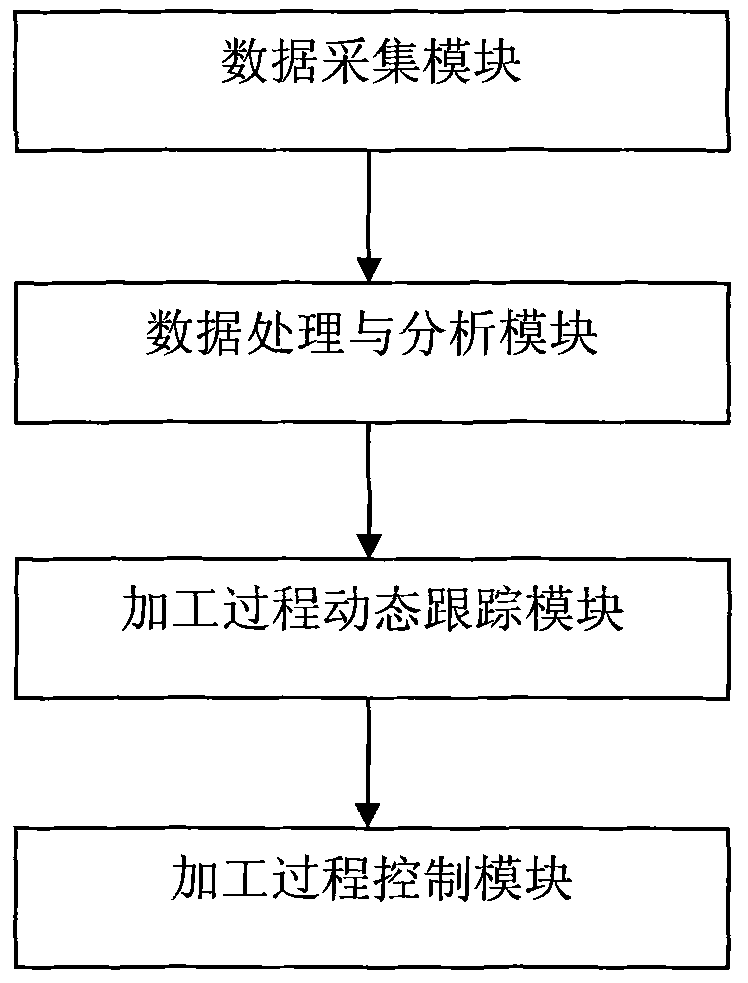

On-line quality control method and system for machining, and processing machine tool

ActiveCN105573250AAvoid bad batchesTimely detection of quality problemsProgramme controlComputer controlQuality control systemQuality control

The invention discloses an on-line quality control method for machining. The on-line quality control method for machining includes the steps: acquiring the real time physical quantity during the machining process of a processing machine tool; and comparing the real time physical quantity with a preset range, and determining that a machined workpiece is abnormal in quality and controlling the processing machine tool to perform a first operation if the real time physical quantity exceeds the boundary of the preset range, wherein the first operation includes closing down the machine tool immediately, closing down the machine tool after finishing the current process, or keeping on machining and giving an alarm. The on-line quality control method for machining can timely discover the quality problem during the machining process and realize quality control during the production process, and can prevent occurrence of reject batch for the machined products. The invention also discloses an on-line quality control system for machining, and a processing machine tool.

Owner:INTELLIGENT GRINDOCTOR TECH SHENZHEN CO LTD

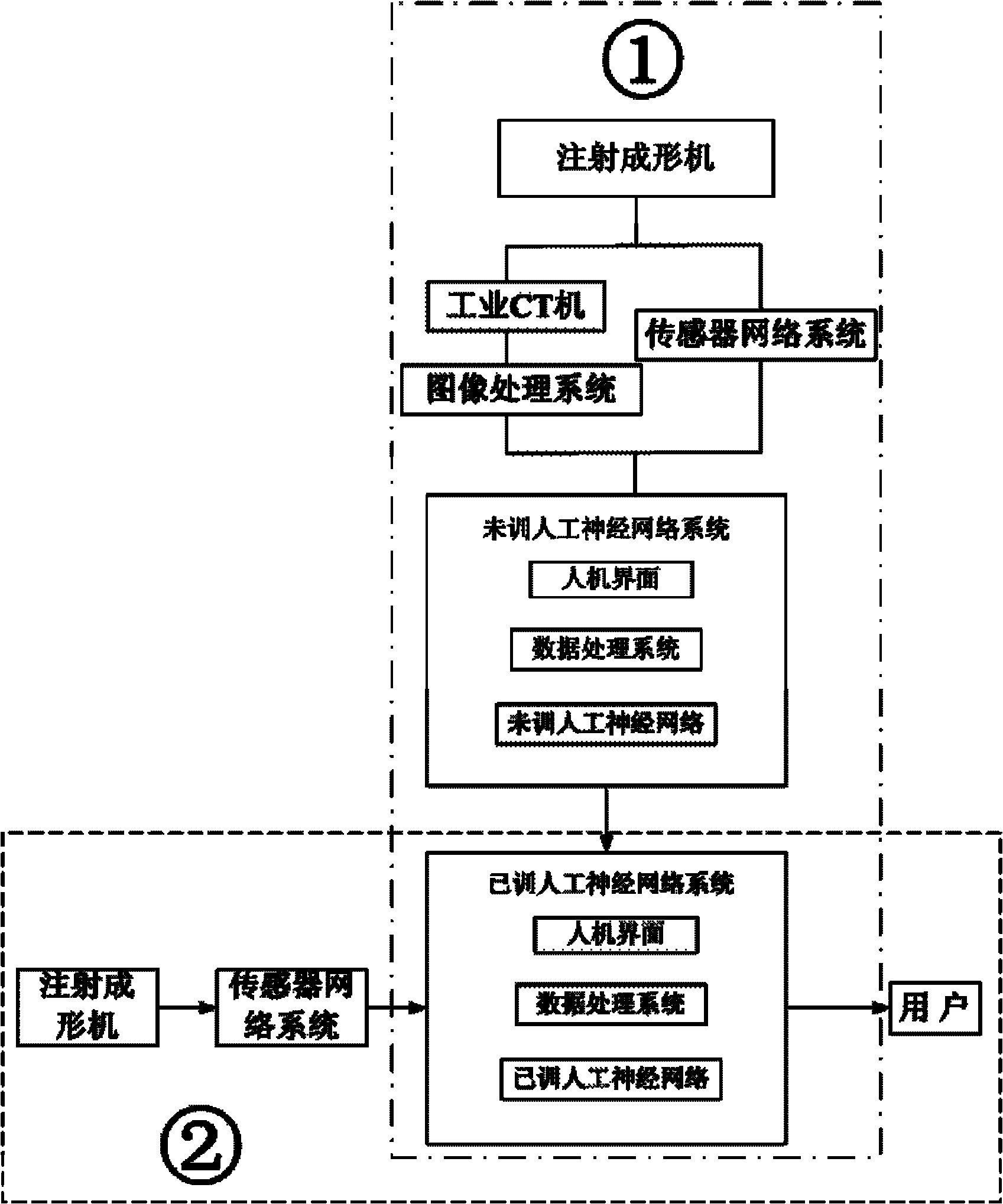

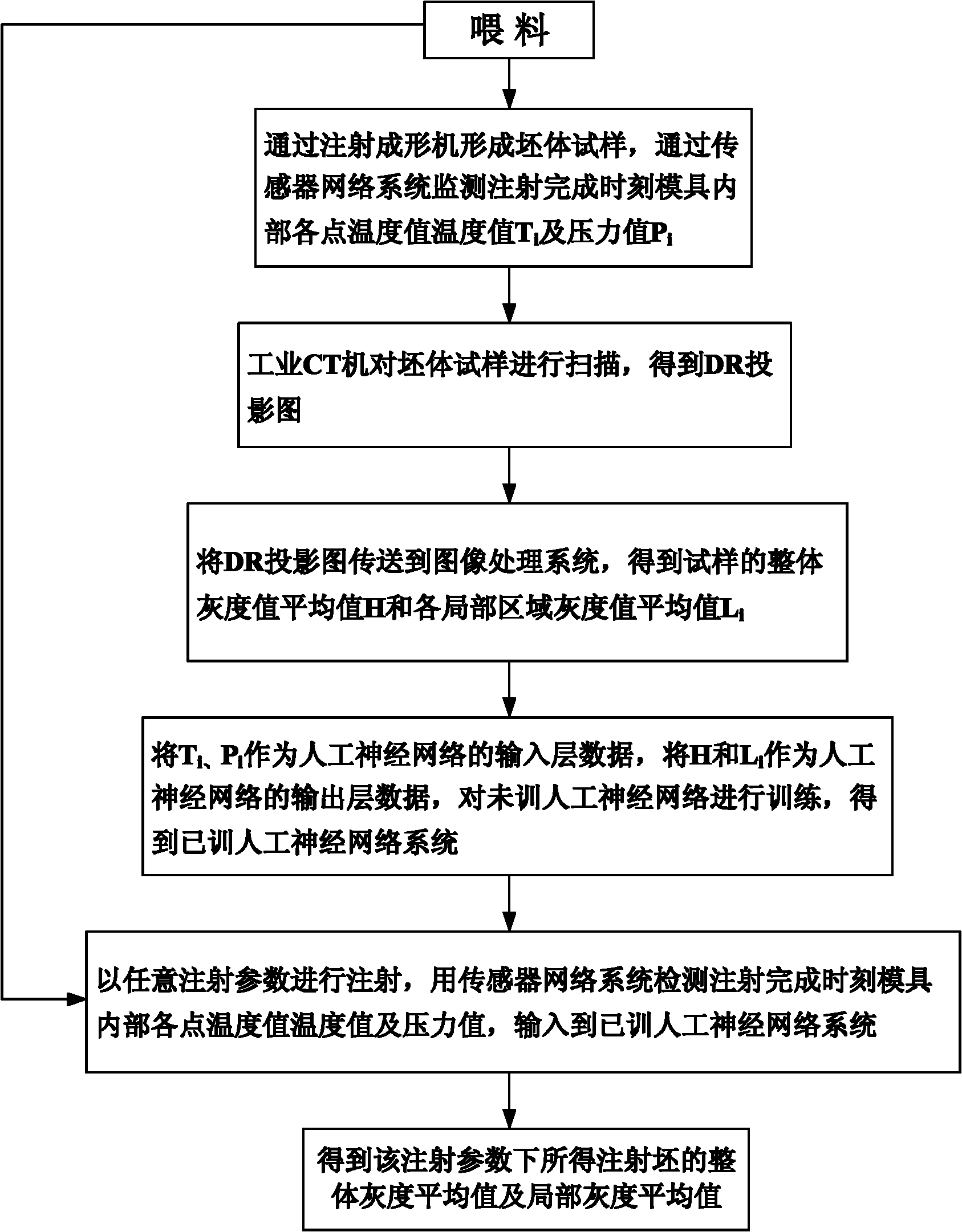

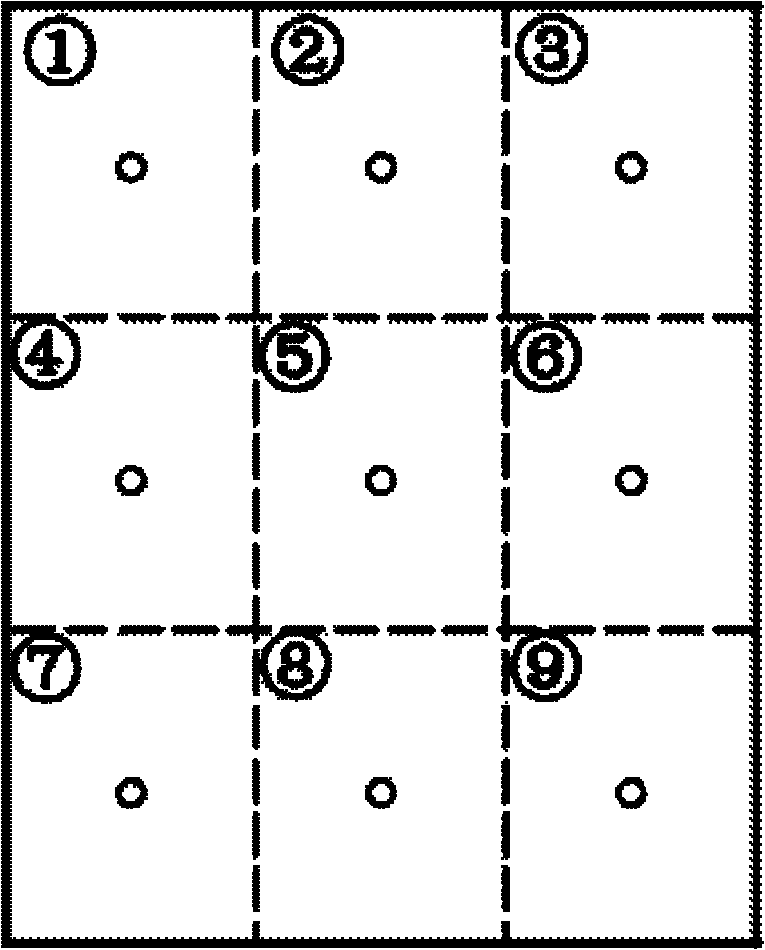

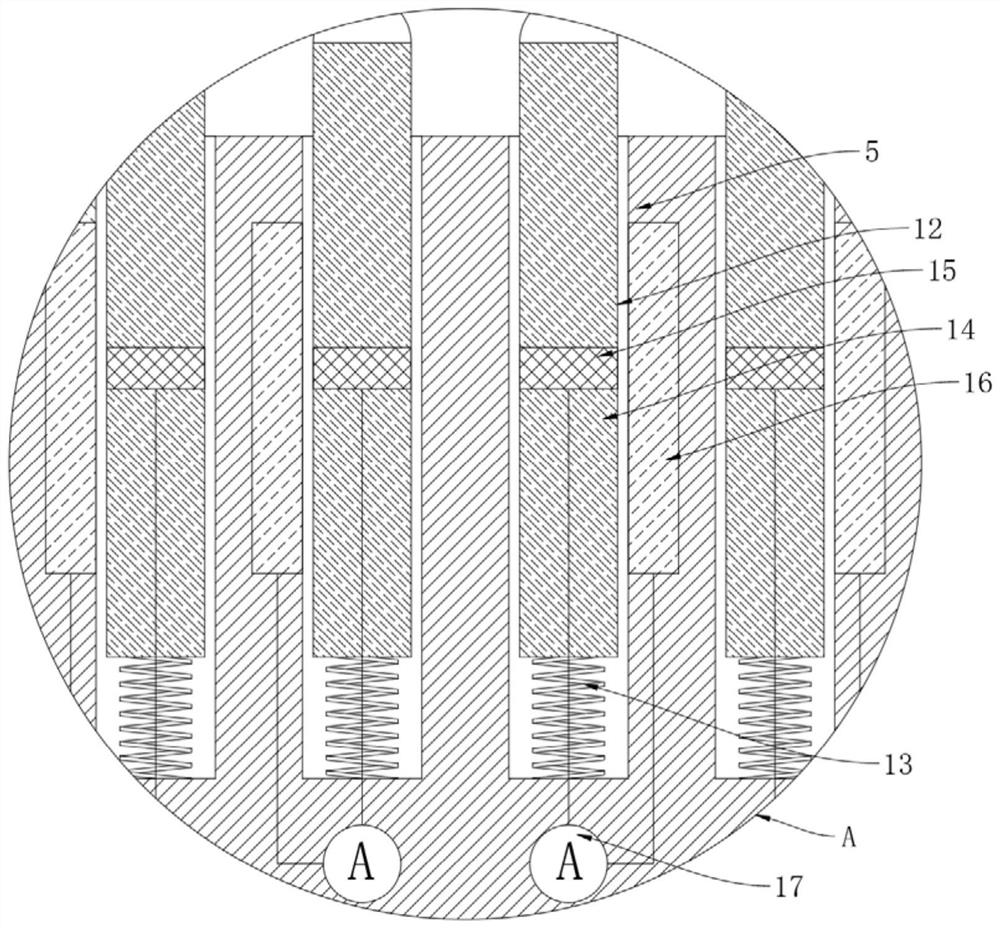

Online prediction system and method for density of powder injection molded blank

The invention belongs to the technical field of powder injection molding and particularly provides an online prediction system and a method for a powder injection molded injection blank. The system comprises an injection molding machine, an industrial CT (computed tomography) machine, an image processing system, a sensor network system and an artificial neural network system. The method comprises the steps as follows: uniform powder feed is conveyed into the injection molding machine and is injected according to a random group of technological parameters to form a blank body sample; at the moment that the injection process is finished, the sensor network system automatically detects temperature values T and pressure values P of all points inside an injection mould; and the temperature values T and the pressure values P are automatically conveyed to the artificial neural network system, and the neural network system automatically gives predictive values of overall grey scale H and local grey scale Li of the injection blank body sample. The online prediction system and the method have the advantages as follows: 1, the injection blank density distribution can be automatically predicted, and the efficiency is improved; 2, the sample is not damaged during the detection process, and qualified samples still can be used, so that the cost is saved; and 3, the quality of injection products can be monitored real timely, so that the quality problems of the injection blanks can be found out timely.

Owner:UNIV OF SCI & TECH BEIJING

Concrete stirring robot with automatic sampling function

ActiveCN111844444AQuality improvementTimely detection of quality problemsDischarging apparatusWithdrawing sample devicesConstruction engineeringStructural engineering

Provided is a concrete stirring robot with an automatic sampling function. The concrete stirring root comprises a sampling module, a conveying mechanism and a stirring tank. The sampling robot is usedfor sampling mixed concrete, and placing a sample in a sampling cup to be stored. The conveying mechanism is used for conveying concrete raw materials into a mixing pipe. The stirring tank is used for mixing the raw materials conveyed from the mixing pipe, and therefore concrete is obtained. According to the concrete stirring robot, the input proportion of all components of the concrete is strictly controlled, and therefore the concrete quality can be effectively controlled to meet construction and design needs. The sampling module can carry out sampling and stores the sample according to theset period and standards and randomly, and the sample is adopted as an evidence later to be sealed up or randomly inspected and detected; on one hand, the evidence can be kept, and later responsibility claiming is convenient; and on the other hand, a deterring effect can be achieved on the construction side, and therefore the construction quality is guaranteed, everyone directly has responsibility, the concrete quality problem can be found in time, reworking can be carried out in time, and bigger losses are avoided.

Owner:合肥名龙电子科技有限公司

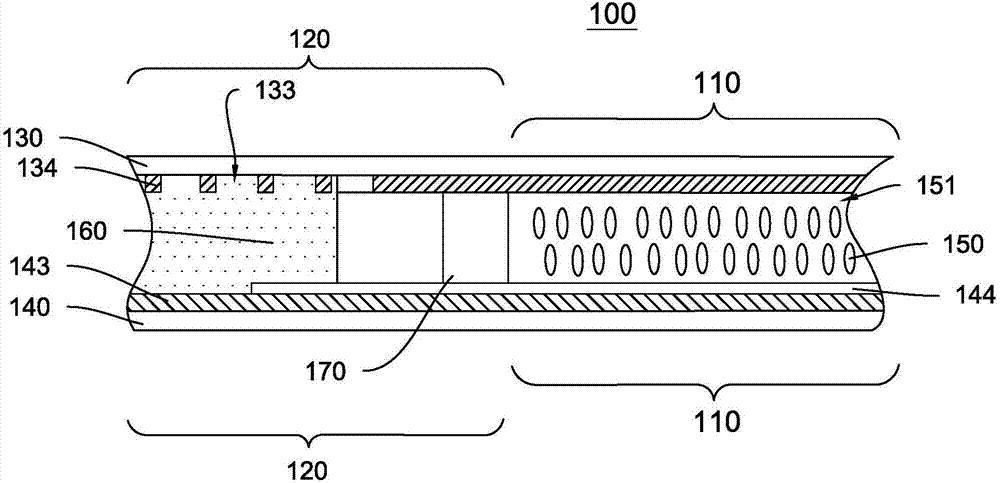

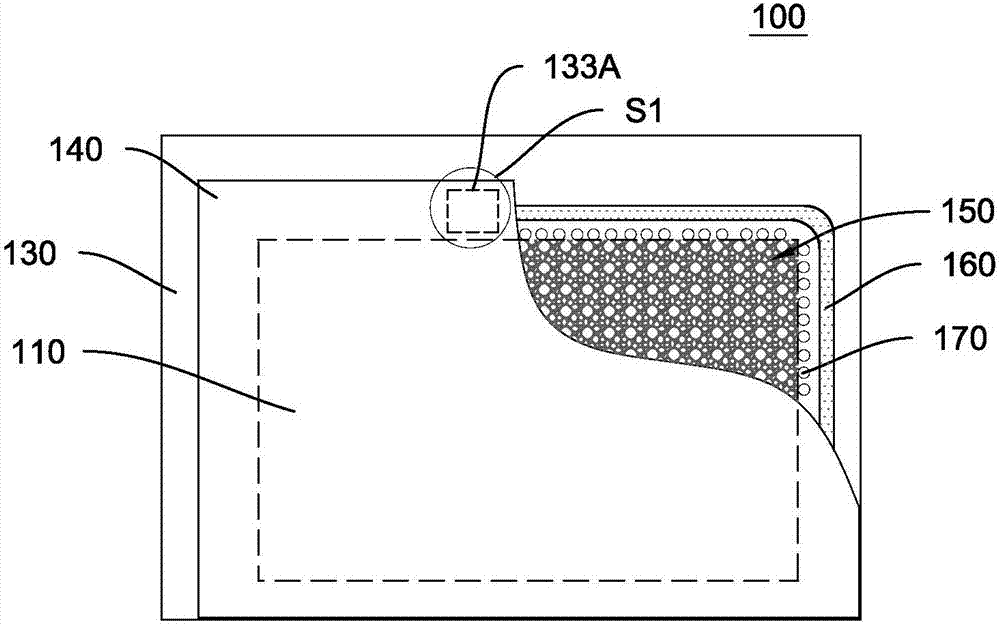

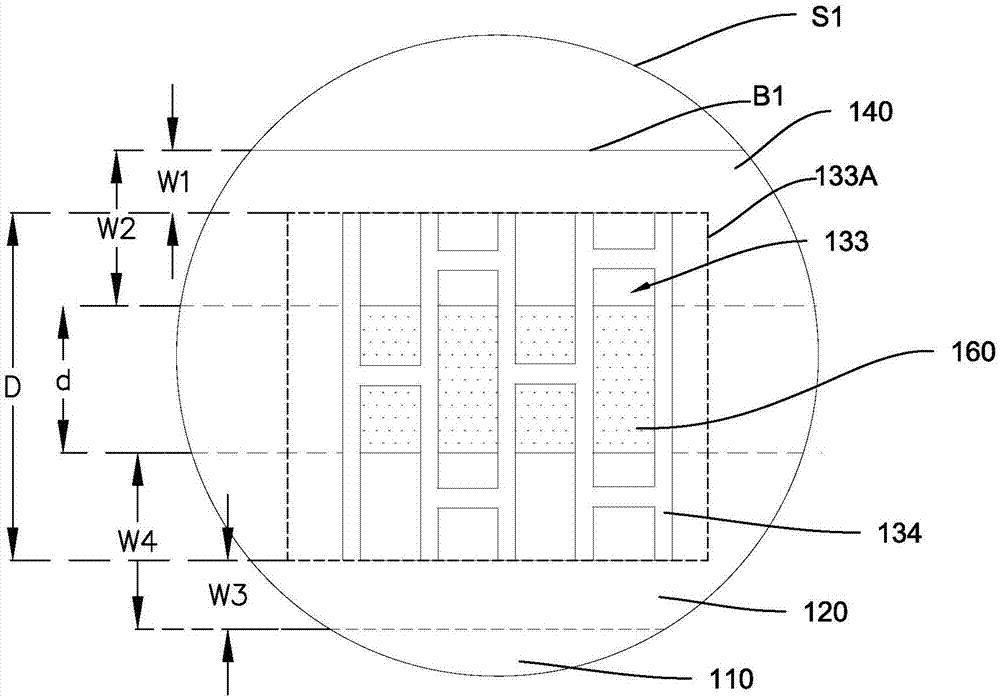

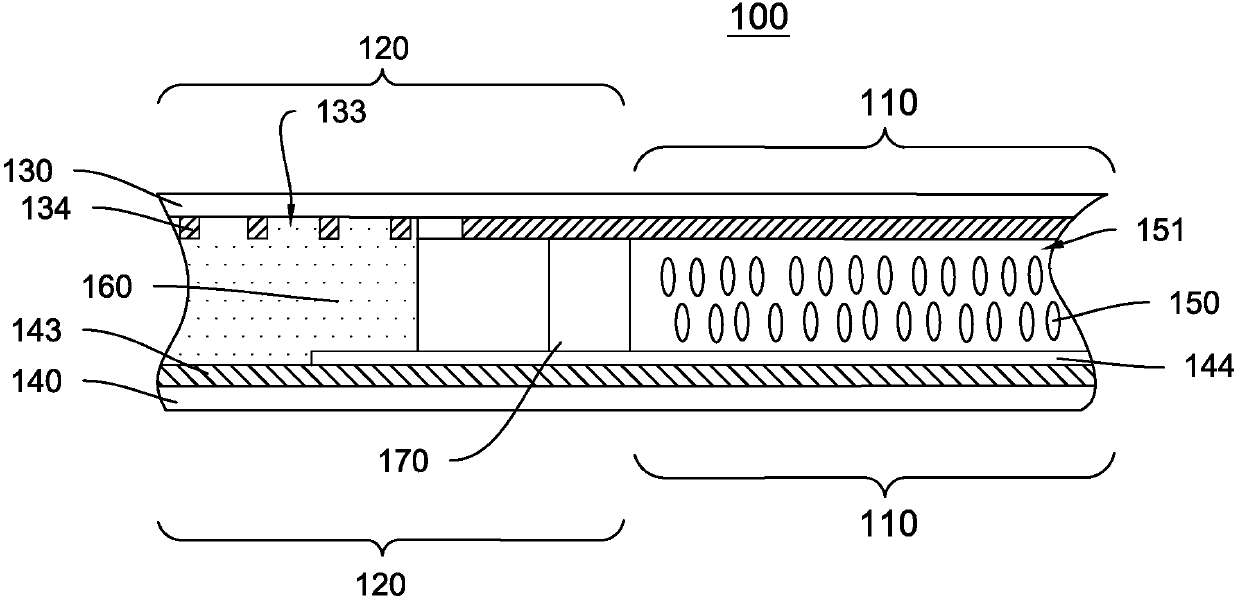

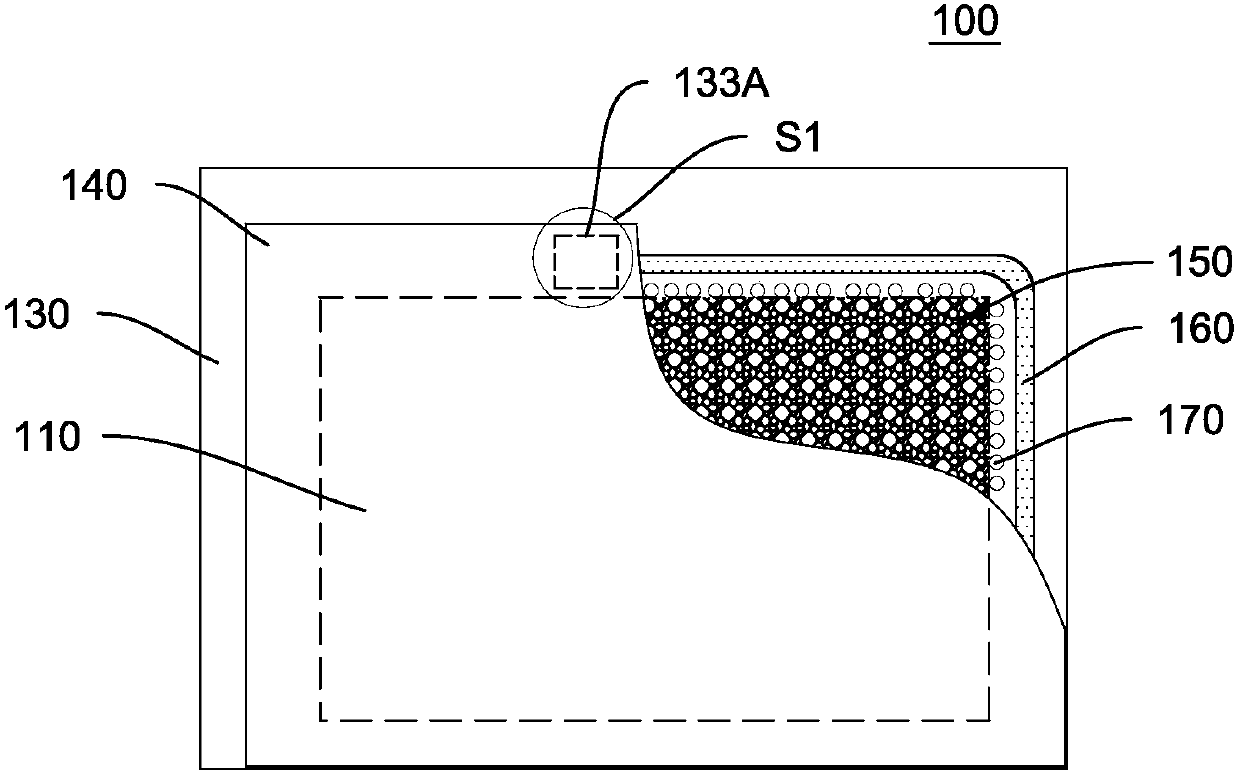

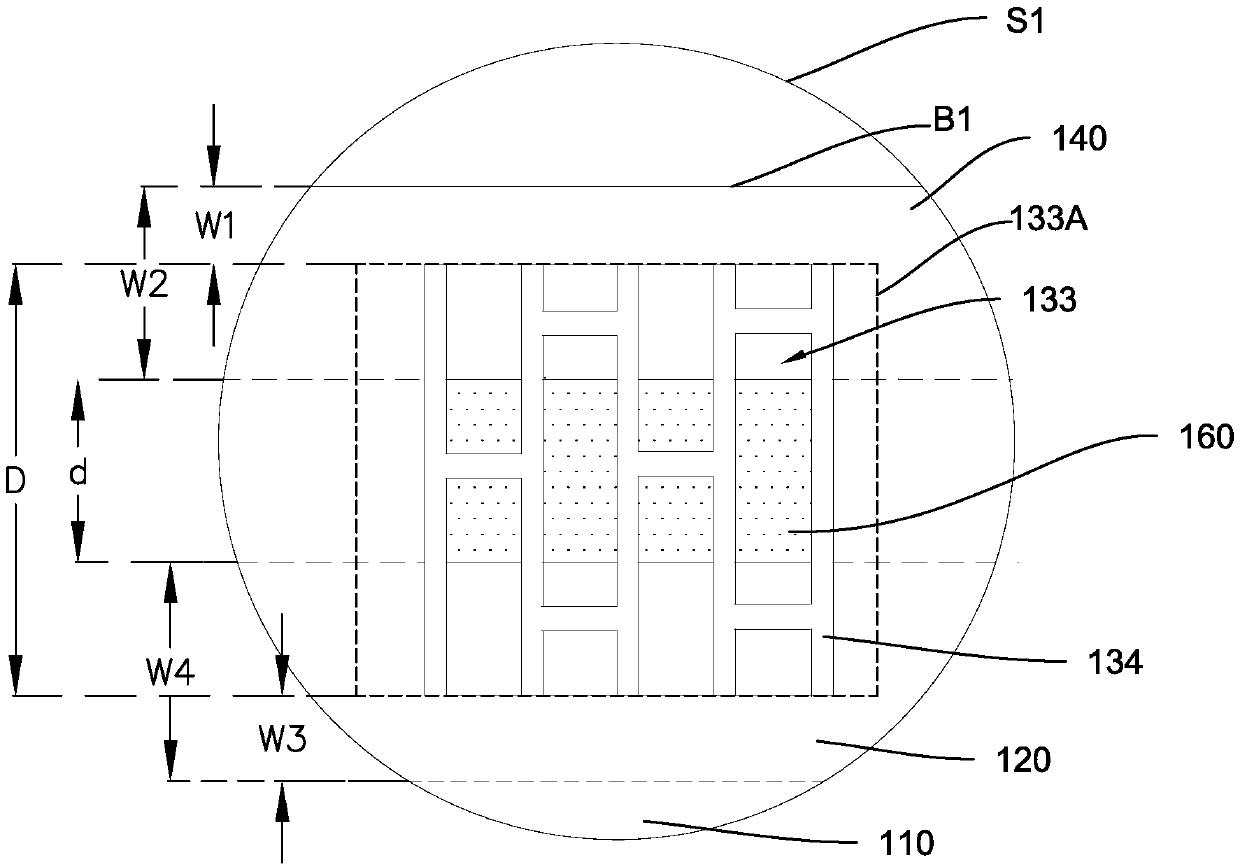

Liquid crystal display panel

InactiveCN107529628ATimely detection of quality problemsImprove pass rateNon-linear opticsColor gelActive switch

The invention relates to the technical field of liquid crystal displays and particularly relates to a liquid crystal display panel. The liquid crystal display panel comprises an active switch array substrate, a colored filter substrate, a liquid crystal layer and frame glue, wherein the active switch array substrate is provided with a display region and a non-display region located around the display region, a first frame glue observation region is arranged on the non-display region, and the first frame glue observation region comprises a plurality of first observation windows; the colored filter substrate is opposite to the active switch array substrate; the liquid crystal layer is arranged between the active switch array substrate and the colored filter substrate and is located on the display region; the frame glue is arranged between the active switch array substrate and the colored filter substrate and is located on the non-display region; and the frame glue partially covers the first observation windows. By arranging the glue frame observation region on the active switch array substrate, the coating condition of the frame glue can be observed accurately.

Owner:HKC CORP LTD

Liquid crystal display panel

InactiveCN107688257ATimely detection of quality problemsImprove pass rateNon-linear opticsColor gelEngineering

The invention relates to the technical field of liquid crystal display, in particular to a liquid crystal display panel. The liquid crystal display panel comprises a color filter substrate, an activeswitch array substrate, a liquid crystal layer and frame glue. The color filter substrate is provided with a display area and a non-display area around the display area, a first frame glue observationarea is arranged on the non-display area, and the first frame glue observation area comprises a plurality of first observation windows. The active switch array substrate is opposite to the color filter substrate. The liquid crystal layer is arranged between the active switch array substrate and the color filter substrate and located on the display area. The frame glue is arranged between the active switch array substrate and the color filter substrate and located on the non-display area. The frame glue covers part of the first observation window. According to the liquid crystal display panel,the frame glue observation area is arranged on the color filter substrate, and therefore the coating condition of the frame glue can be accurately observed.

Owner:HKC CORP LTD

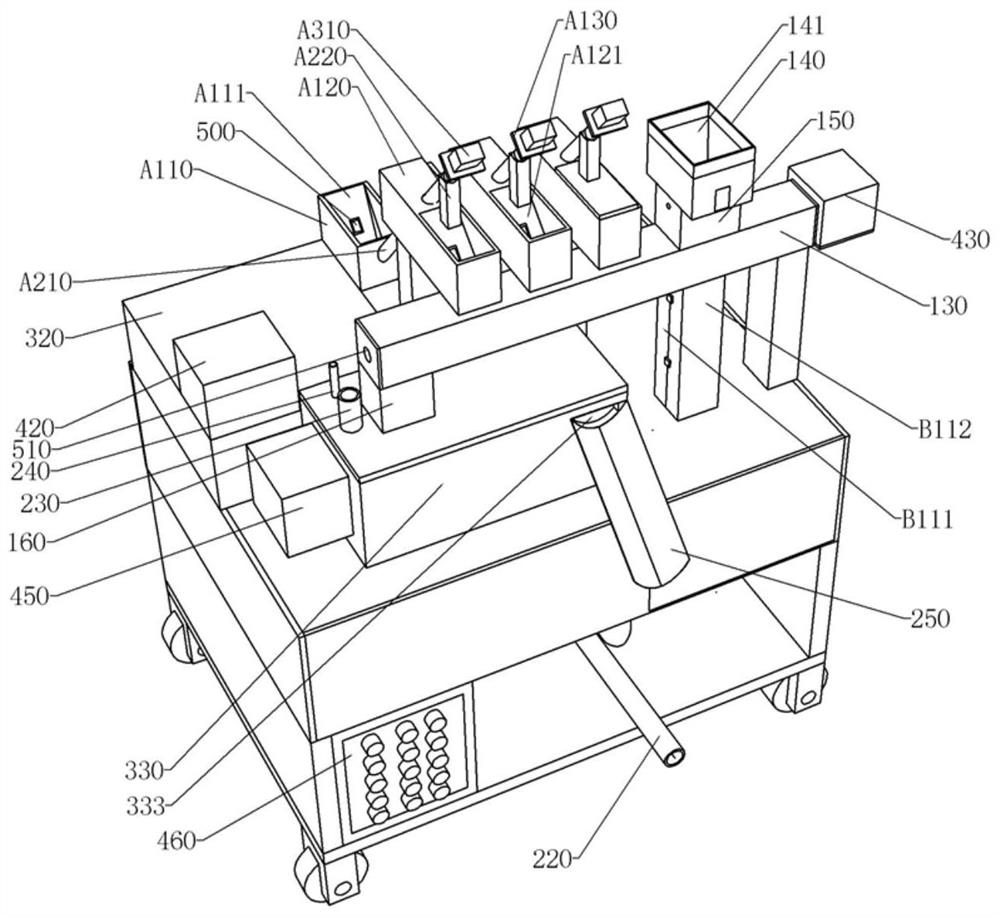

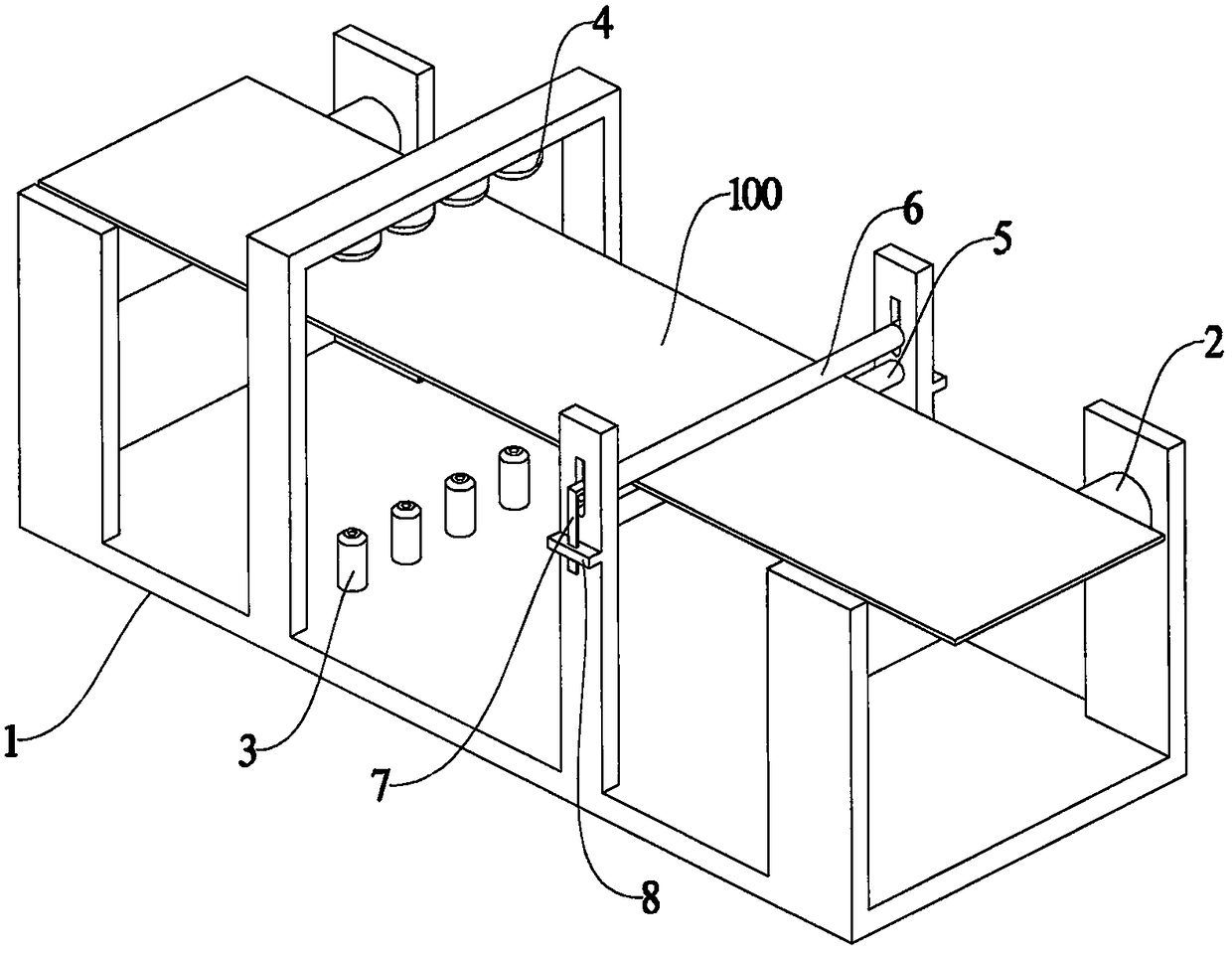

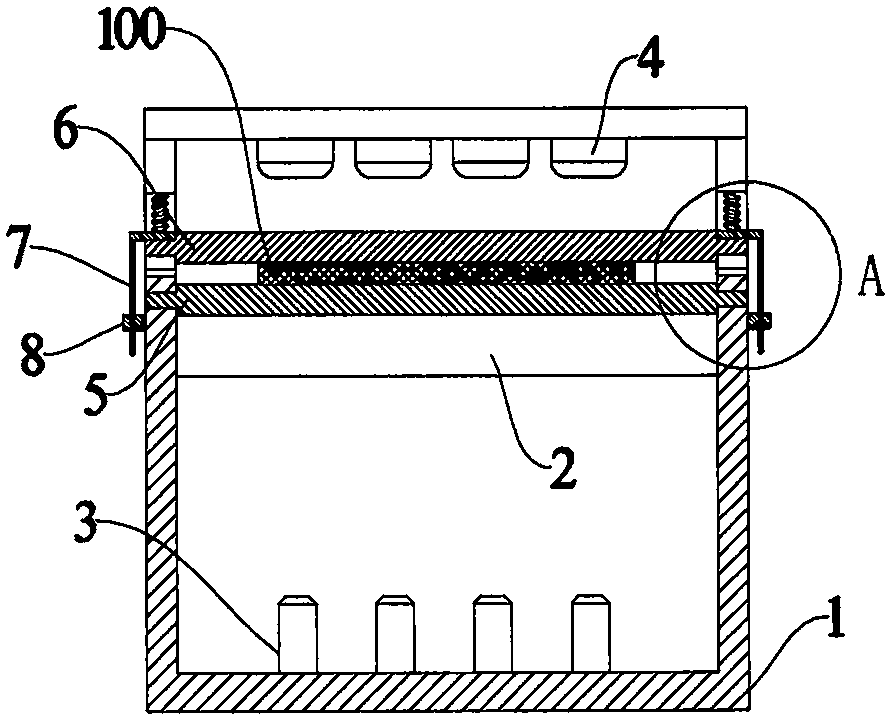

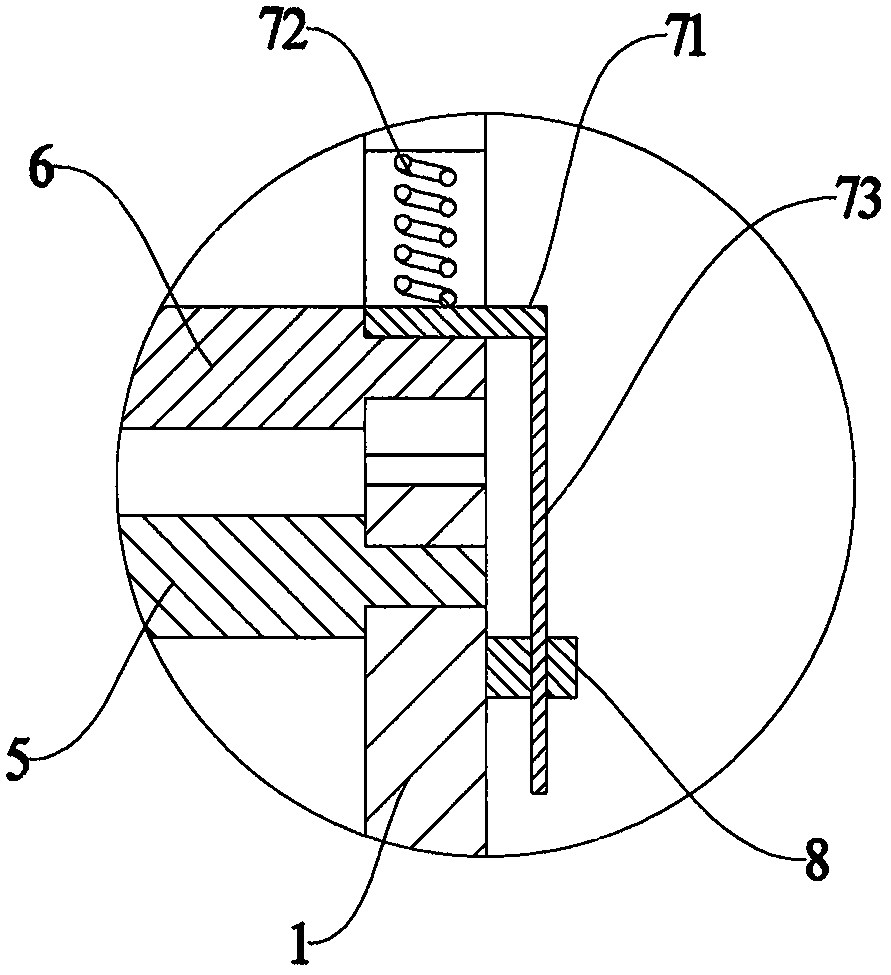

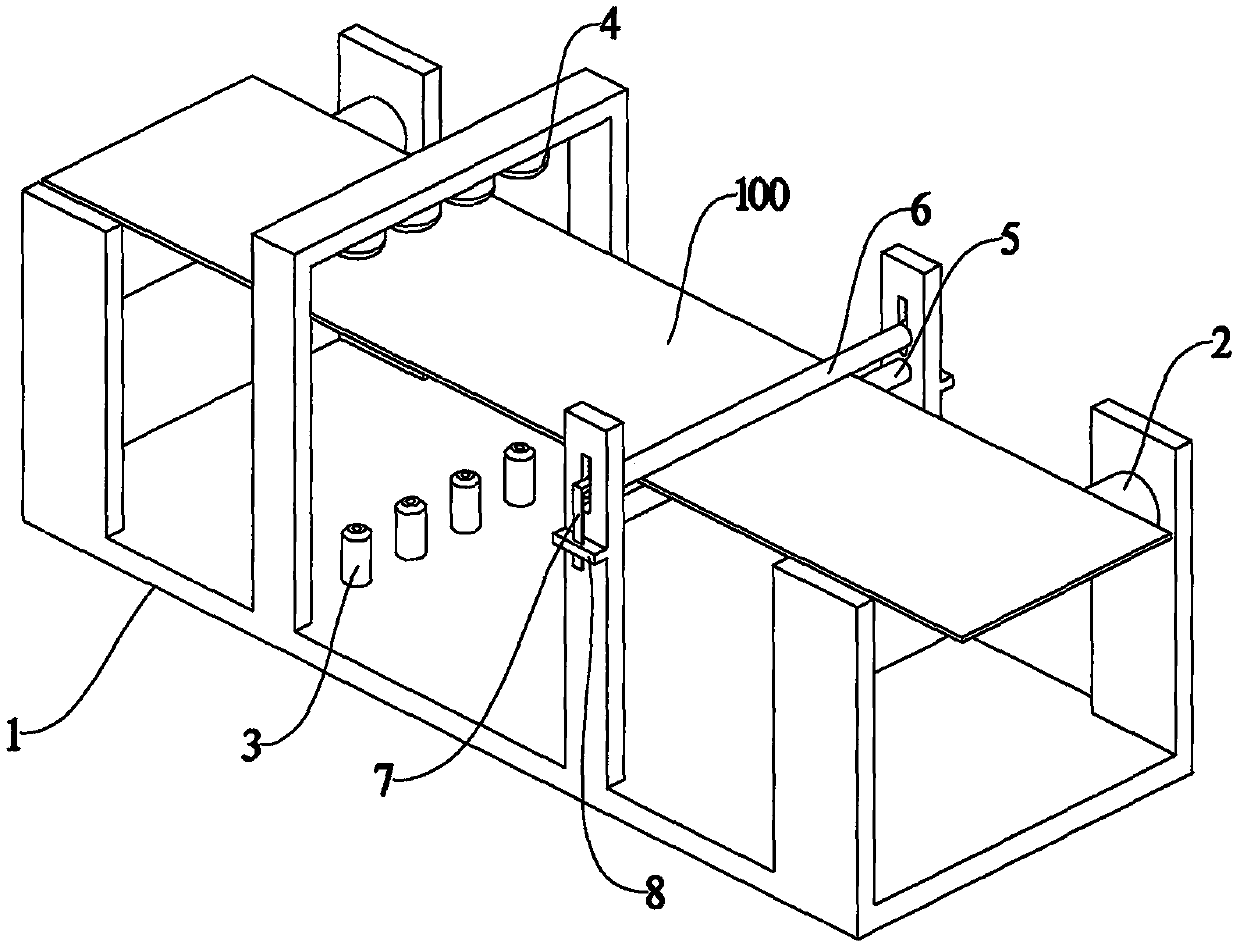

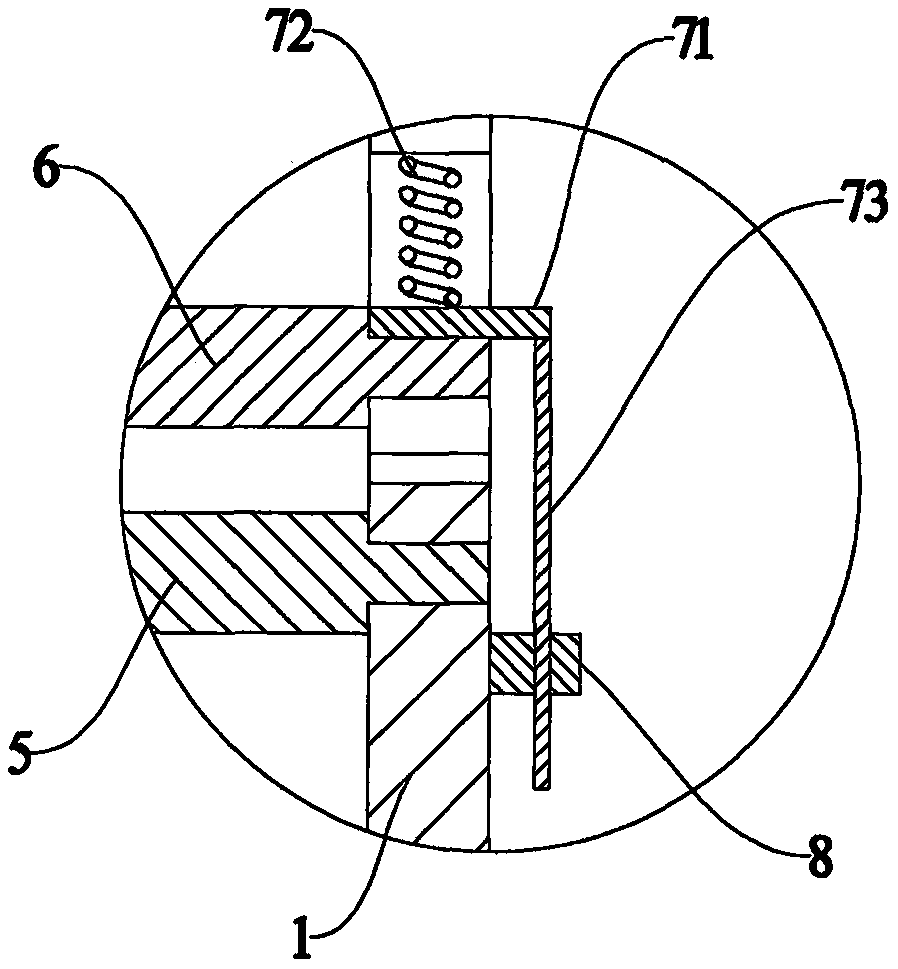

Thin film monitoring equipment

InactiveCN108151611ATimely detection of quality problemsIncrease productivityTransmissivity measurementsMechanical thickness measurementsLaser transmitterTransmittance

The invention provides thin film monitoring equipment. The equipment is characterized by comprising a machine frame, a conveying roller, a light transmittance measuring part and a thickness measuringpart. The conveying roller is rotationally connected to the machine frame and is used for conveying a thin film. The light transmittance measuring part comprises a laser emitter and a light intensitytester which are oppositely arranged on the two sides of the thin film. The thickness measuring part comprises a lower thickness measuring roller, an upper thickness measuring roller, a displacement assembly and a displacement sensor. The lower thickness measuring roller is rotationally connected to the machine frame. The upper thickness measuring roller is located above the lower thickness measuring roller. The upper thickness measuring roller can rotate on the machine frame and can also slide up and down along the machine frame. The thin film is located between the lower thickness measuringroller and the upper thickness measuring roller and is always tightly attached to the lower thickness measuring roller and the upper thickness measuring roller. The displacement assembly is arranged between the machine frame and the upper thickness measuring roller, and can slide up and down along with the upper thickness measuring roller. The displacement sensor is arranged on the machine frame and is used for measuring the sliding distance of the displacement assembly.

Owner:余姚敏宝卫浴洁具有限公司

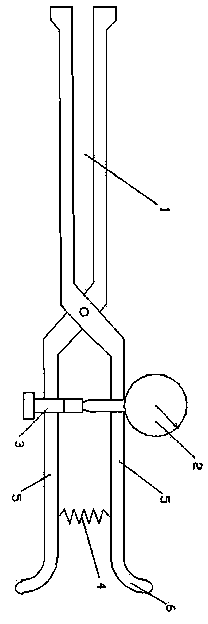

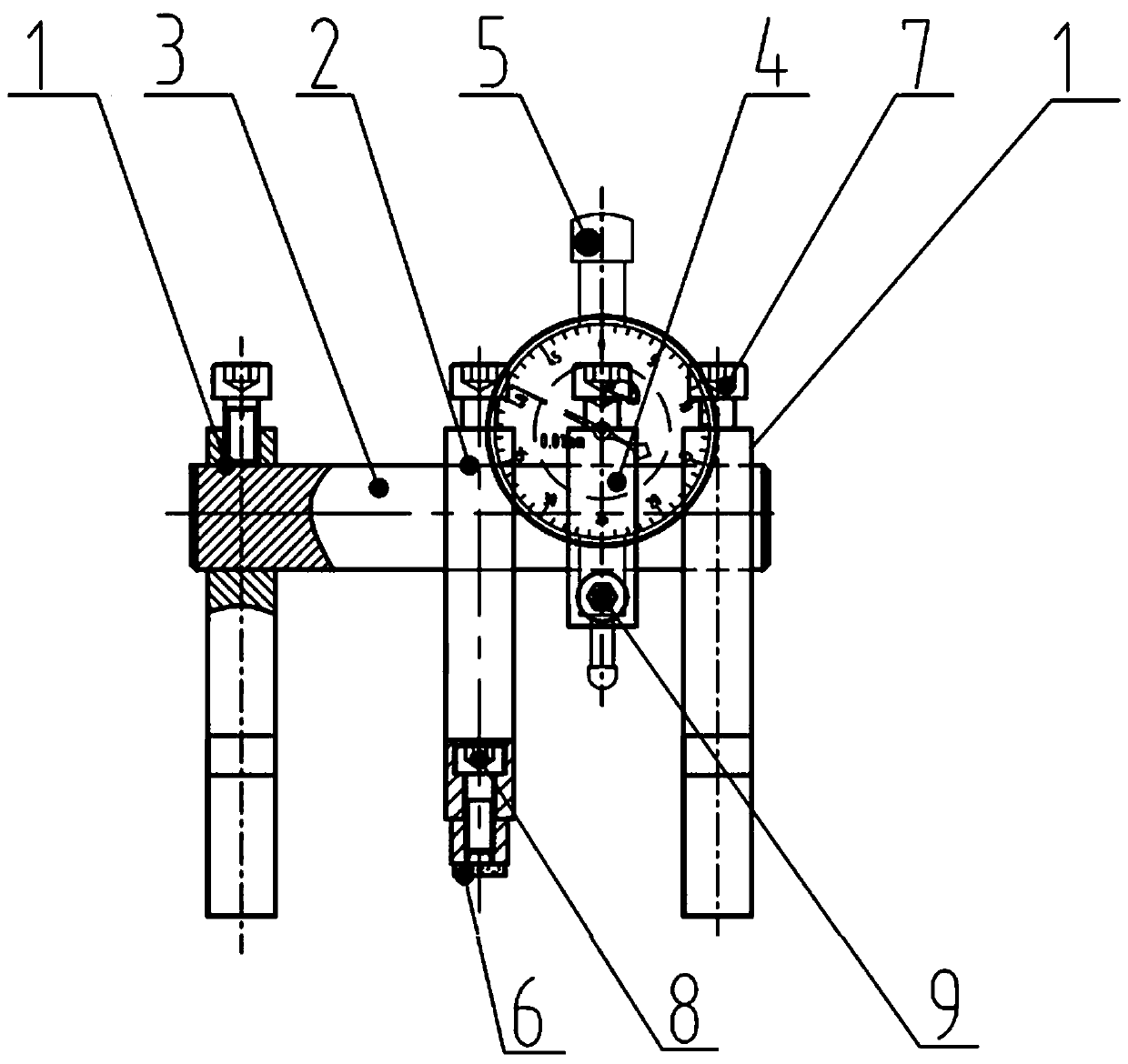

Gauge used for measuring inner groove diameter of elongated hole

InactiveCN105021107ASimple structureEasy to useMechanical diameter measurementsBiochemical engineeringCalipers

The invention relates to a gauge used for measuring the inner groove diameter of an elongated hole, which comprises a caliper gauge, a dial indictor, an adjustment lever and a spring, wherein the caliper gauge is of a pincer-shaped structure and formed by hinging two measuring rods, one of the measuring rods of the caliper gauge is fixedly provided with the dial indicator, the other measuring rod is fixedly provided with the adjustment lever, the adjustment lever corresponds to the dial indicator in position, the length of the adjustment lever relative to the measuring rods can be adjusted, and measuring ends of the two measuring rods are connected through the spring. The gauge provided by the invention is simple in structure, convenient to use, convenient for measurement at any time in processing at the production field, can improve the processing quality and reduce the processing rejection rate, and has the characteristics of high detection efficiency and high universality.

Owner:成都九龙柜业有限公司

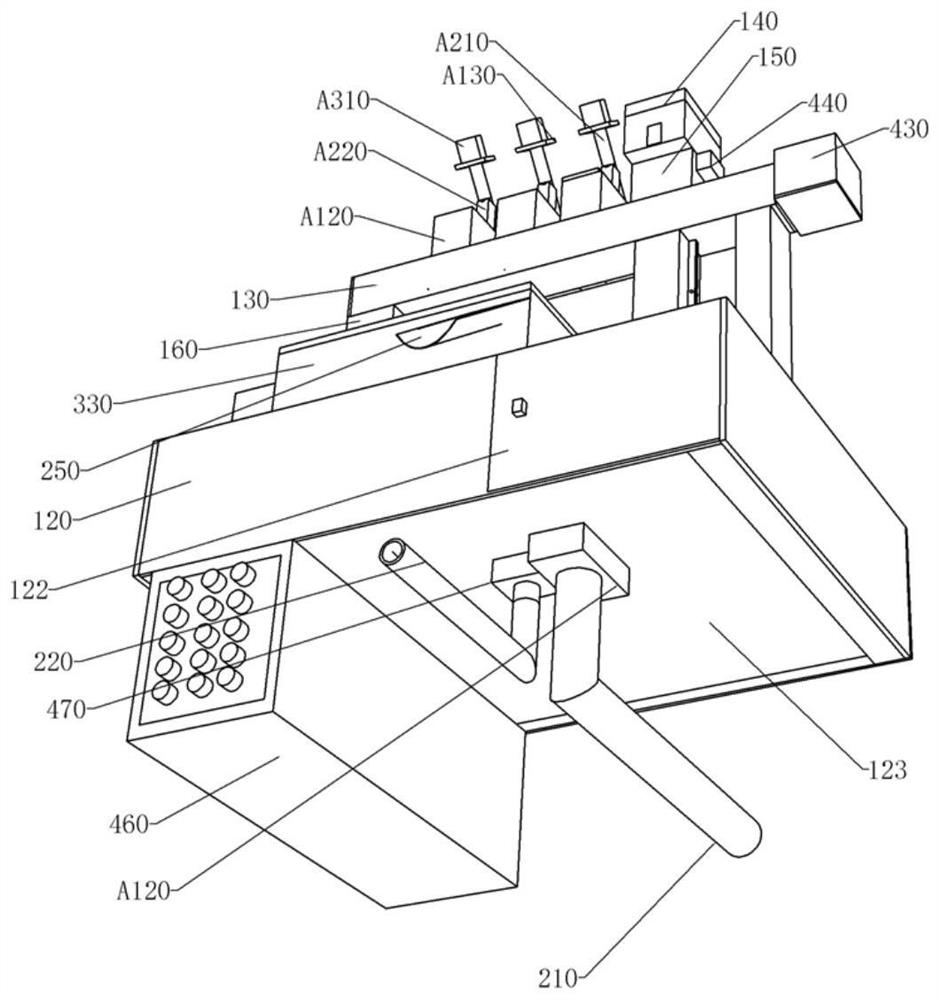

Novel film monitoring device

InactiveCN109540849AIncrease productivityGuarantee product qualityTransmissivity measurementsUsing optical meansTransmittanceLaser transmitter

The invention provides a novel film monitoring device. The device comprises: a frame, a conveying roller, a light transmittance measuring component and a thickness measuring component; the conveying roller is rotatably connected to the frame for conveying a film; the light transmittance measuring component comprises a laser emitter and a light-density tester which are oppositely arranged at two sides of the film; the thickness measuring component comprises a lower thickness measuring roller, an upper thickness measuring roller, a displacement component and a displacement sensor, the lower thickness measuring roller is rotationally connected with the frame, the upper thickness measuring roller is located at the upper portion of the lower thickness measuring roller and is capable of rotationon the frame and sliding on the frame up and down, the film is located between the lower thickness measuring roller and the upper thickness measuring roller and still clings to the lower thickness measuring roller and the upper thickness measuring roller, the displacement component is arranged between the frame and the upper thickness measuring roller and can slide up and down with the upper thickness measuring roller, and the displacement sensor is arranged on the frame and is configured to measurement the sliding distance of the displacement component.

Owner:NINGBO CHENYU ENERGY TECH CO LTD

Immortalized quality-control cell bank for chromosome karyotype analysis and construction method thereof

InactiveCN104060329AIncrease the difficultyIncreased complexityMicrobiological testing/measurementMicroorganism librariesBiologyDifferential diagnosis

The invention relates to an immortalized quality-control cell bank for chromosome karyotype analysis in the medicine field and a construction method thereof. The invention is mainly characterized in that the construction method comprises: taking residual attached primary or sub-culture living cells which are used for chromosomal disease diagnosis as needed by clinical diagnosis and treatment and are definitely diagnosed to have difficult chromosome abnormalities, introducing, through transgenosis technology, SV40LTag-pcDNA3.1(-) recombinant plasmid constructed by pcDNA3.1(-) connected by T4DNA ligase and digested by BamHI, and SV40LTag DNA amplified by PCR and separated by agarose gel electrophoresis, allowing recon to integrate with the cell DNA, screening immortalized cells integrated with recons by G418, performing subculture amplification and living cell cryopreservation, then extracting several respectively-prepared cells with different diseases, mixing the cells according to a required ratio for quality control so as to convert each original cell with a single chromosome abnormality into a cell with a plurality of easy-to-misdiagnose chromosome abnormalities with different ratios. Therefore, the difficulty and complexity for differential diagnosis and chromosome chimera diagnosis are increased; samples are easily available; and waste residual cells are converted into effective quality-control materials.

Owner:翁炳焕

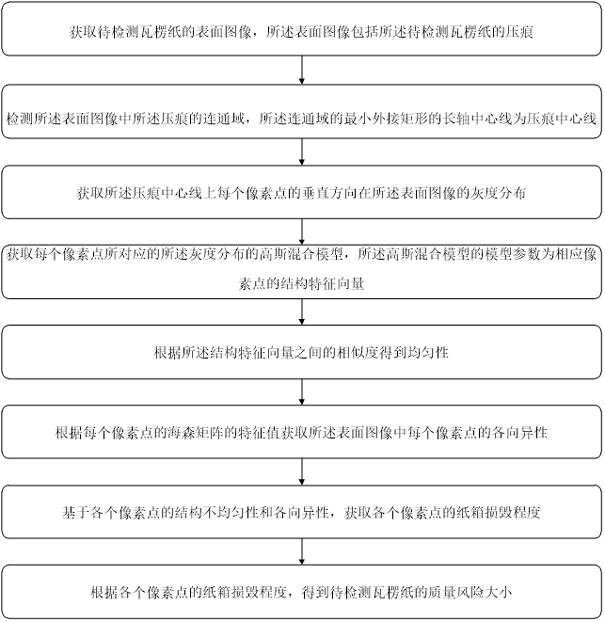

Carton indentation quality detection method and system based on computer vision

ActiveCN114549529AAvoid putting into useTimely detection of quality problemsImage enhancementPackage recyclingFeature vectorImaging processing

The invention relates to the technical field of image processing, in particular to a carton indentation quality detection method and system based on computer vision, and the method comprises the steps: obtaining a surface image of to-be-detected corrugated paper, and detecting an indentation center line of an indentation in the surface image, a Gaussian mixture model of gray distribution of each pixel point on the indentation center line in the vertical direction on the surface image is obtained, model parameters of the Gaussian mixture model are structural feature vectors of the corresponding pixel points, and uniformity is obtained according to the similarity between the structural feature vectors; and obtaining the anisotropy of each pixel point in the surface image according to the characteristic value of each pixel point, obtaining the carton damage degree of each pixel point, and obtaining the quality risk of the to-be-detected corrugated paper. According to the method, the carton damage degree and the tearing expansion risk of the indentation structure of the corrugated paper are sequentially detected through the image, so that the quality problem possibly occurring when the carton is folded along the indentation is accurately evaluated.

Owner:武汉福旺家包装有限公司

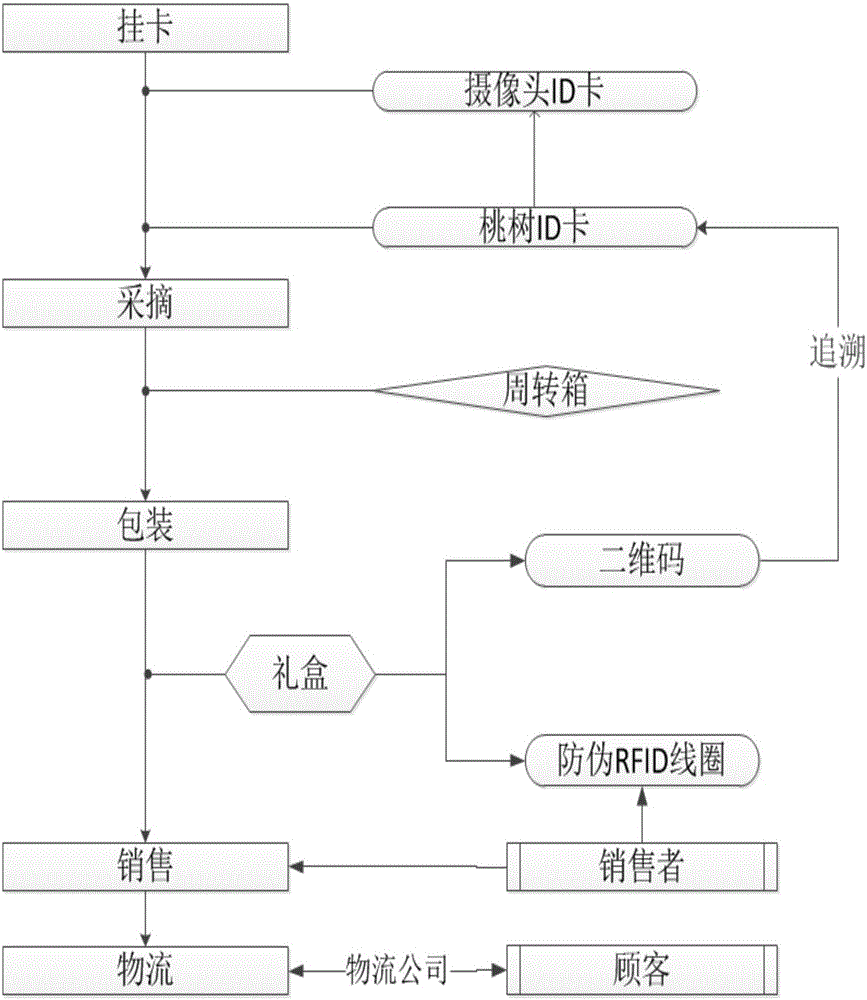

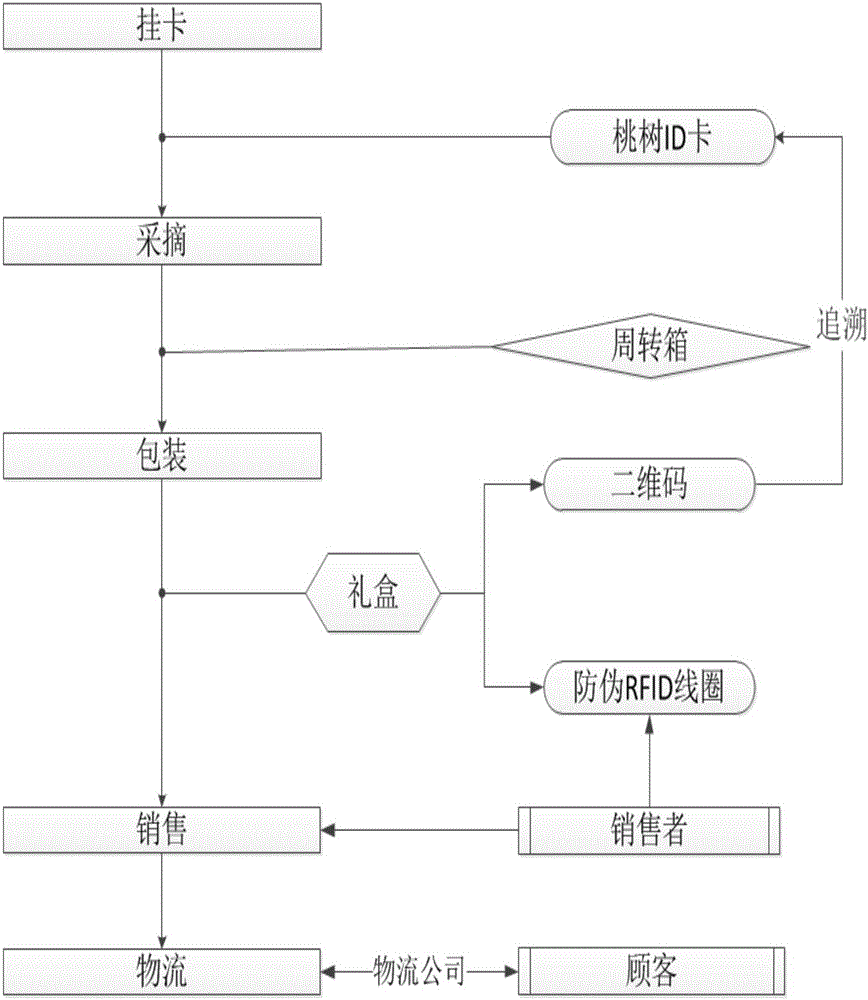

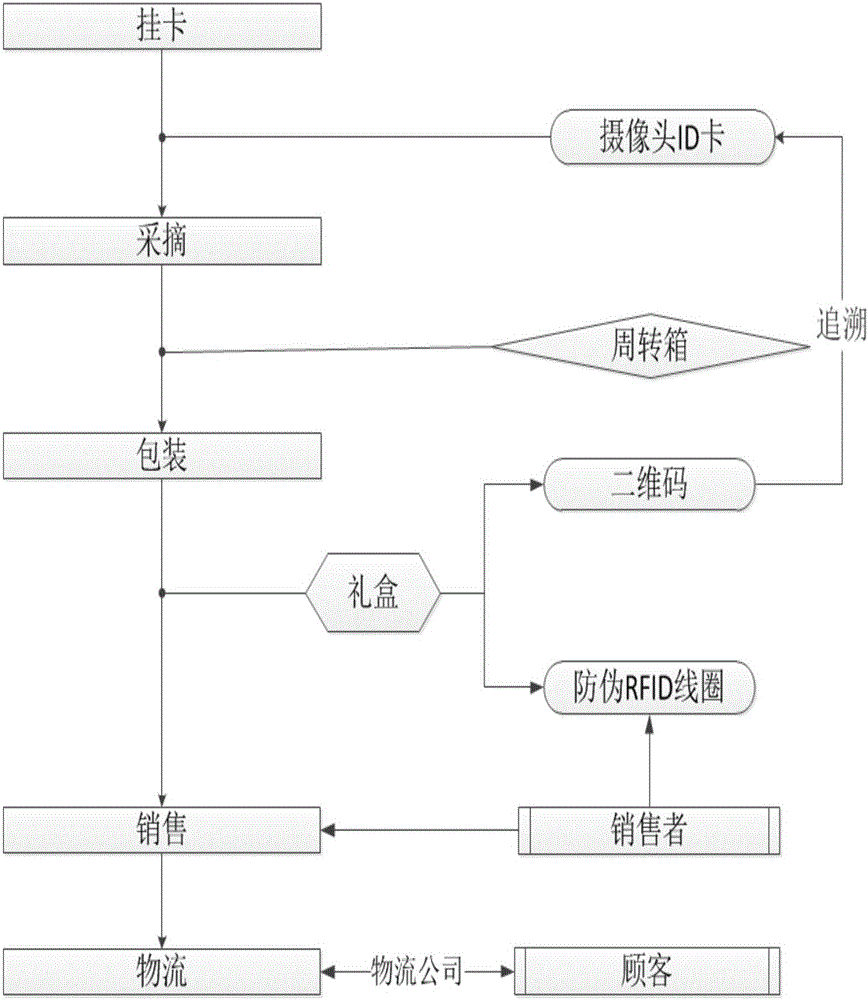

Intelligent agriculture tracing method

InactiveCN105139207AWith retrospective functionTimely detection of quality problemsCommerceLogistics managementHand held

The invention provides an intelligent agriculture tracing method. The objects of intelligent agriculture tracing are honey peaches. The tracing method comprises a peach tree tracing process, a peach garden tracking process and a producing area tracing process, wherein the peach tree tracing process comprises the following steps of: 1.1, hanging a card on each camera, giving a fixed ID to each camera, including peach trees within a visual range of each camera in a monitoring range, hanging a card on each peach tree, namely giving a fixed and unique ID to each peach tree, then using a hand-held machine to scan ID cards and taking photos, and placing the ID of the cameras and the peach trees into a database; 1.2, picking; 1.3, packaging; 1.4, marketing; and 1.5, logistics. Through the peach tree tracking process, the information of the producing area of the honey peaches, the peach garden and the peach tree of the honey peaches can be precisely traced. According to the invention, the intelligent agriculture tracing method with a tracing function and capable of discovering quality problems is provided.

Owner:杭州策望科技有限公司

Detection device of distance between crankshaft locating surface and axis, and usage method thereof

PendingCN110345844AReduce weightEasy accessMechanical clearance measurementsMeasurement deviceEngineering

The invention discloses a detection device of distance between crankshaft locating surface and axis, and usage method thereof. The detection device comprises a joint lever, and a locating device and ameasuring device both arranged on the joint lever; the locating device comprises a connecting rod locating frame, a connecting rod locating block, and two main shaft locating blocks in the form of areversed Y; the measuring device comprises a dial indicator and a L-shaped dial indicator frame; the main shaft locating blocks, the connecting rod locating frame and the dial indicator frame are connected on the joint lever serially through connection holes. The detection device provided by the invention is light in weight and convenient to take and operate quickly, and reduces fatigue strength of carrying a crankshaft in the conventional platform detection method. Detection can be completed quickly within 10 seconds, time for adjusting the crankshaft to a horizontal plane in the conventionalplatform detection method is reduced, and product detection efficiency is improved. The detection device can perform online real-time detection, can discover quality problems in production, and reduces risks of failure in quickly discovering the quality problems in production of the conventional platform detection method. The detection device and the usage method thereof provided by the inventionare suitable for being generalized and used in mass industrial production.

Owner:桂林福达曲轴有限公司

A steel coil segmented multi-dimensional online quality determination system and method

ActiveCN104751288BAchieve integrationImplementation checkResourcesManufacturing computing systemsQuality levelProgram planning

The invention belongs to the technical field of metallurgical industry manufacturing and informationization of the metallurgical industry and relates to a segment-based multi-dimensional online quality evaluation system and method for steel coils. production process data and surface detection data for use in quality evaluation are acquired through a data interface; when a steel coil is off a line, the steel coil is divided into a plurality of segments along the length; the acquired data are read; according to business rules and product quality standards, process and surface defect quality results are separately judged; comprehensive level of each segment and quality level of the steel coil are finally acquired. Primary secondary process parameters and instrument defect information are acquired, and the production process data is maximally integrated; the business quality standards and control plan operation procedures are quantitatively and systematically processed, segment-based dimensional evaluation is performed at the moment when products are off the line, comprehensive inspection of the steel coil is achieved, labor for data collection is freed, quality inspectors can be helped to find quality problems in time so as to make following treatment, and product quality and enterprise economic benefit are finally improved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

A Numerical Simulation Method for the Combination Process of Deep Drawing and Punching of High-strength Steel Wheel Spokes

InactiveCN104077439BTimely detection of quality problemsImproved process designSpecial data processing applicationsElement modelPunching

The invention discloses a numerical simulation method of a novel high-strength steel spoke drawing punching combined process. By means of establishment of an accurate finite element model, a forming process of a novel high strength steel plate for spoke production can be observed, distribution of wall thickness, stress, strain and damages in the spoke forming process can be obtained, possible forming defects such as excessively thinning and pull cracks of the plate in the spoke forming process can be discovered in time, forming properties of the plate can be evaluated in advance before the novel high strength steel plate is used for spoke actual production, thereby, the process design scheme can be effectively improved, mold parameters can be optimized, spoke product qualities are improved, rejection rate of products is reduced, large manpower and material inputs caused by trial and error can be avoided, the market competitiveness of the high-strength steel products is improved, application and development of novel high-strength steel wheels are facilitated, and the basis is provided for optimization of steel for high-strength wheels.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

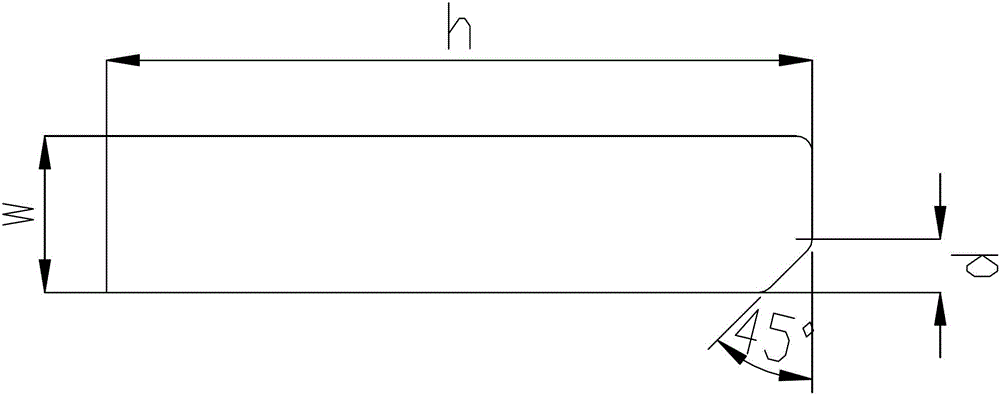

FDS bottom plate thickness judgment method and device, electronic equipment and storage medium

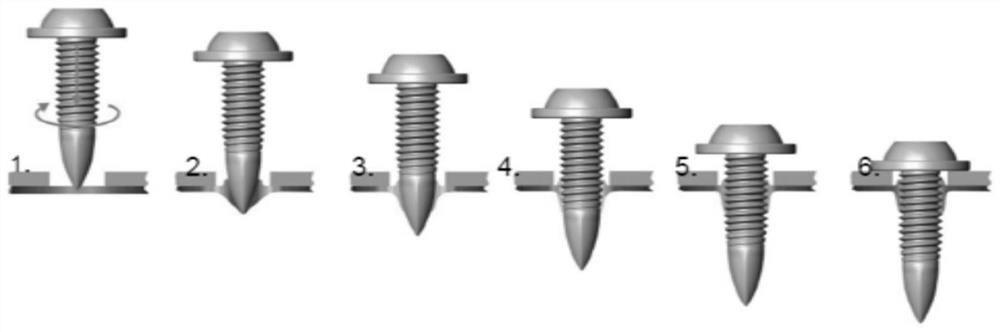

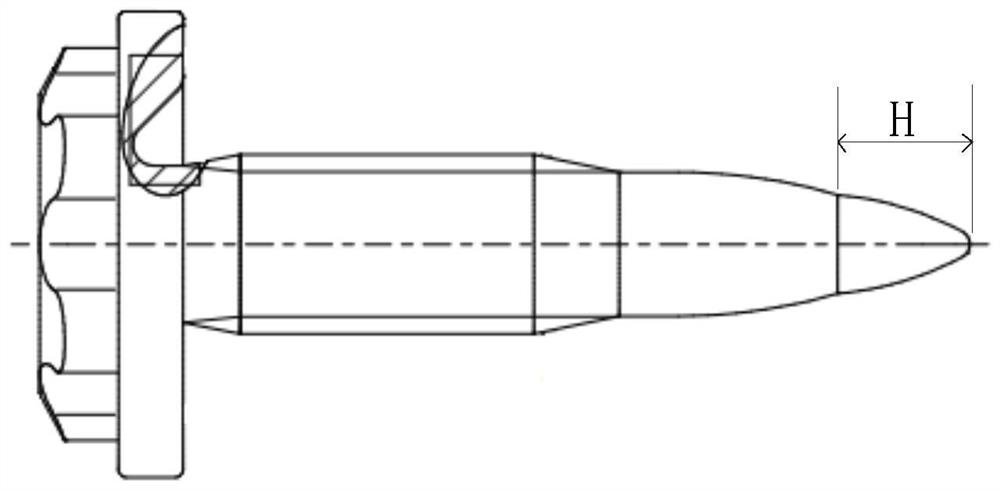

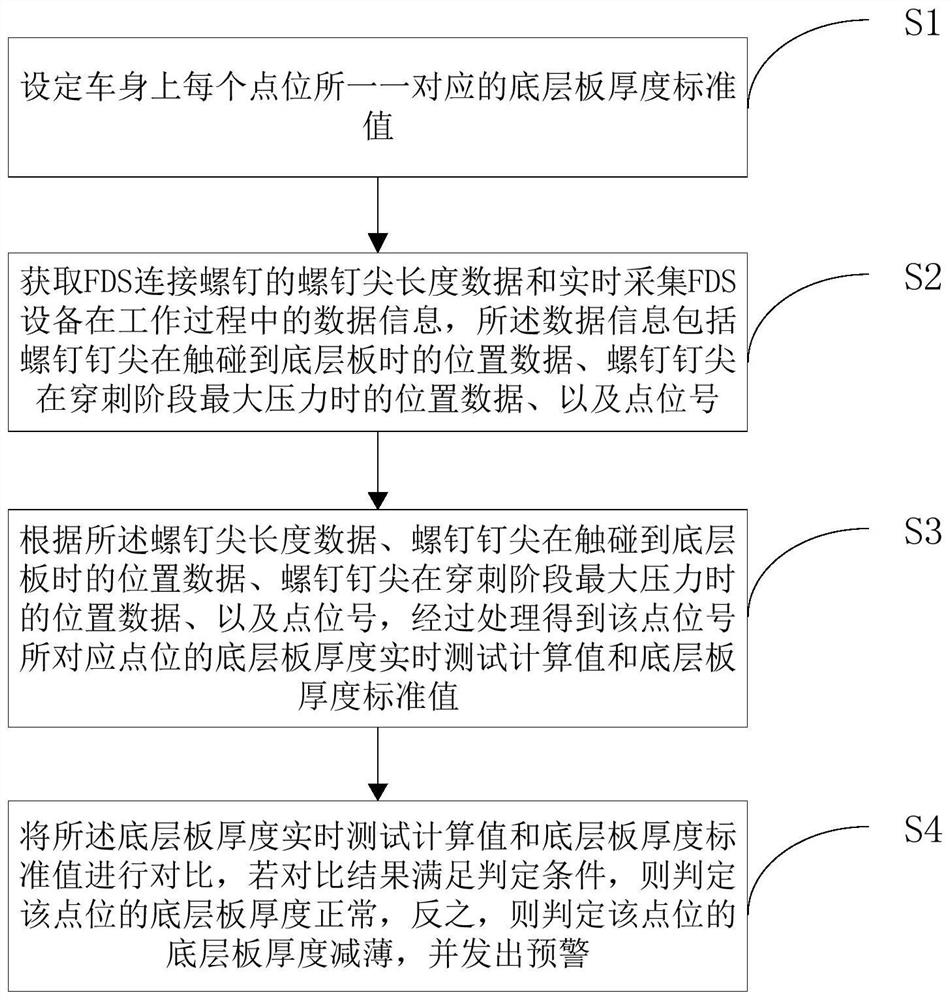

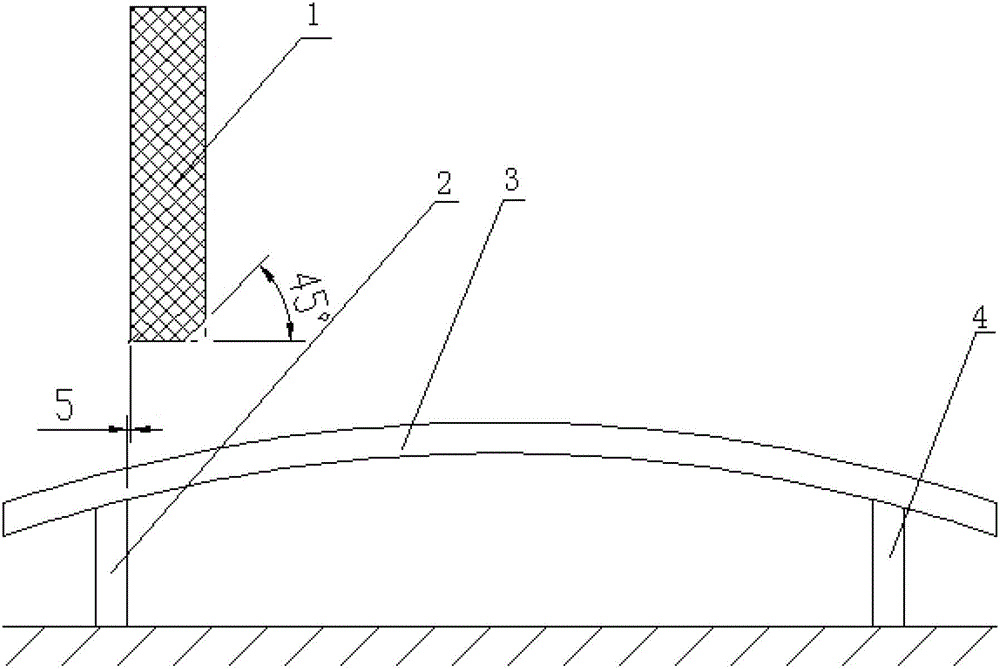

PendingCN112541707AReduce scrapReduce or even avoid scrappingOffice automationResourcesData informationEngineering

The invention discloses an FDS bottom plate thickness judgment method and device, electronic equipment and a storage medium. The judgment method comprises the following steps: a setting step: settinga bottom plate thickness standard value corresponding to each point location; an acquisition step: acquiring screw tip length data H and acquiring data information in the working process of the FDS equipment in real time, wherein the data information comprises position data L1 when the screw tip touches the bottom layer plate, position data L2 when the screw tip has the maximum pressure in the puncture stage, and a point position number; a processing step: according to the H, the L1, the L2 and the point location number, processing to obtain a real-time test calculation value and a standard value of the thickness of the bottom layer plate of the point location corresponding to the point location number; and a judgment step: comparing the real-time test calculation value with a standard value, if a judgment condition is met, judging that the thickness of the bottom plate of the point location is normal, and otherwise, judging that the thickness of the bottom plate of the point locationis reduced and giving an early warning. Whether the thickness of the bottom layer plate in the FDS process is reduced or not can be monitored in real time, and the quality problem in the production process can be found in time.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Detection method of automobile anti-collision beam based on safety performance

InactiveCN103175697BTimely detection of quality problemsImprove securityVehicle suspension/damping testingEnergy absorptionEngineering

The invention provides a car anti-collision beam detecting method based on safety performance. The method includes the steps of firstly, fixing two ends of a car anti-collision beam with an energy absorption box; secondly, impacting the two ends of the car anti-collision beam with a knocking hammer which is provided with two acceleration sensors, and acquiring acceleration variation curves of the knocking hammer during impacting through the two acceleration sensors; thirdly, acquiring average acceleration a according to the acceleration variation curves acquired in the second step; fourthly, calculating to obtain deformation of the car anti-collision beam according to the average acceleration a so as to judge whether deformation is smaller than 170mm or not; fifthly, calculating to obtain crossbeam bearing capacity of the car anti-collision beam according the average acceleration a so as to judge whether the crossbeam bearing capacity is larger than 40KN or not; and sixthly, if no breakage of the car anti-collision beam occurs, welding points are effective, deformation is smaller than 170mm and crossbeam bearing capacity is larger than 40KN, the car anti-collision beam is qualified. By the method which is a scientific testing method provided for car anti-collision beam part purchasers, quality and performance of the car anti-collision beam can be tested conveniently.

Owner:TONGJI UNIV +1

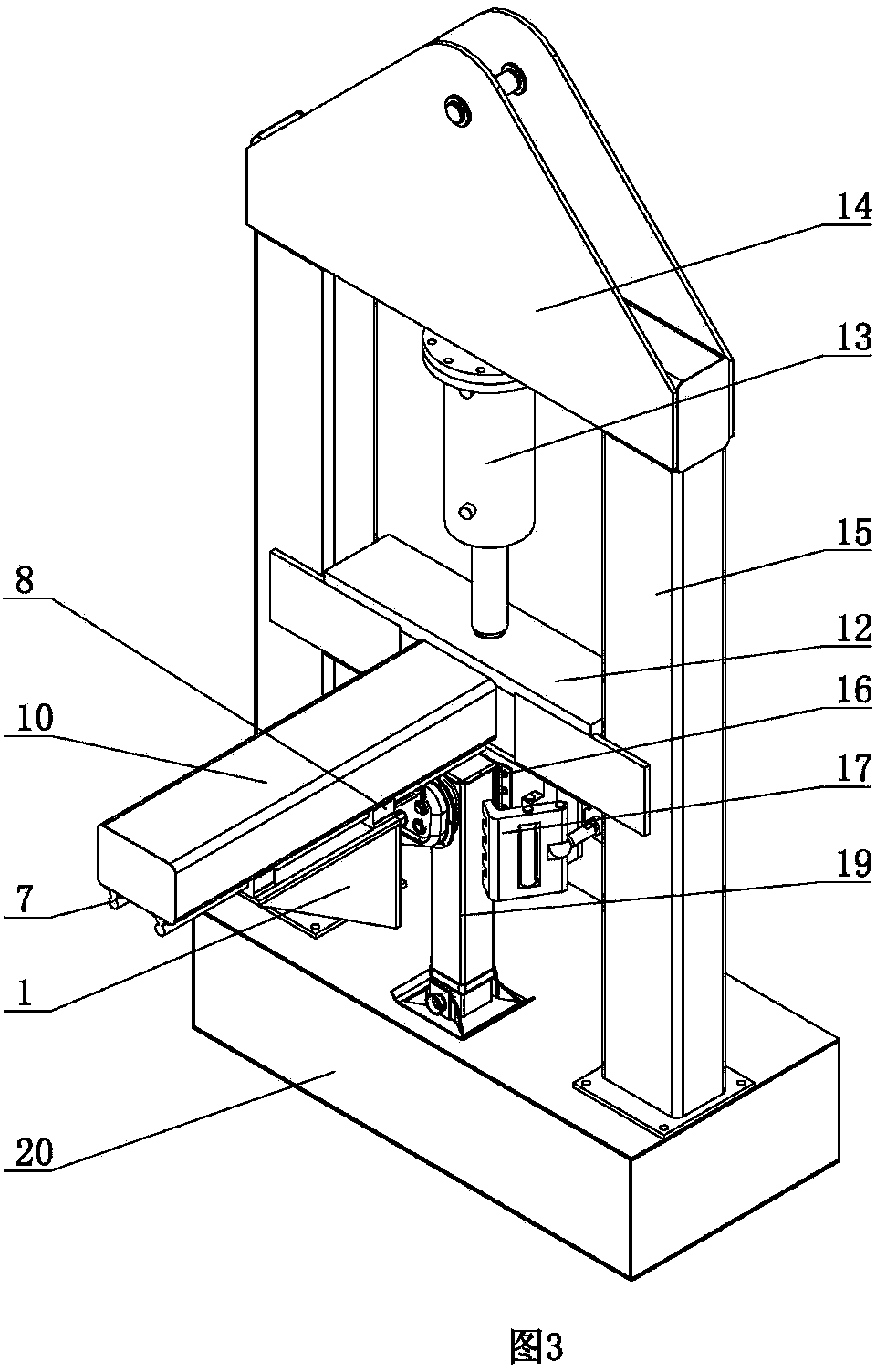

Supporting leg tester

ActiveCN102589902BTimely detection of quality problemsAffect accuracyVehicle testingOptimal testSupport plane

The invention discloses a supporting leg tester. The supporting leg tester comprises a supporting frame, wherein the supporting frame is provided with a down-pressing mechanism, the down-pressing mechanism is upwards connected with the supporting frame, an executive component of the down-pressing mechanism is downwards provided with a pressing block, the supporting frame is provided with a vertical guide mechanism, and the guide mechanism is matched with the pressing block. According to the supporting leg tester disclosed by the invention, the loading ability of each supporting leg can be accurately tested, the quality of supporting legs produced in the same batch can be truly reflected, and the potential quality problem of each supporting leg can be found in time so as to remove the potential safety hazard; since the supporting leg tester is provided with a supporting leg clamping mechanism, the test accuracy is prevented from being affected as the supporting legs are subjected to side bending in a test process; and in addition, the supporting leg tester is also provided with a supporting leg driving device, the extension and retraction of the supporting legs can be automatically driven, and the optimal test position of each supporting leg can be adjusted. The supporting leg tester disclosed by the invention also has the advantages of simple and compact structure, low manufacturing cost and convenience for using.

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

Machining process method for hardware fittings of medical products

PendingCN114536101AEasy to traceTimely detection of quality problemsMeasurement devicesMeasurement/indication equipmentsMedical productProcess engineering

The invention relates to the technical field of machining, in particular to a medical product hardware fitting machining process method which comprises the following steps: S1, raw material inspection: inspecting, registering and recording the quality of raw materials; s2, cutting and recording: cutting the raw materials to form semi-finished products, placing the semi-finished products in a recording disc according to a certain quantity, storing the records of the used raw materials in a chip of the recording disc, weighing the semi-finished products by the recording disc, comparing the semi-finished products with a reference value, and recording the semi-finished products; therefore, whether the number and quality of the placed semi-finished products are qualified or not is judged. S3, processing flow; s4, weighing and comparing; and S5, warehousing. The product quality can be conveniently controlled.

Owner:惠州市腾达科技有限公司

Multifunctional plastic film conveying and detecting equipment

InactiveCN112623836ATimely detection of quality problemsFind feedback in timeElectric/magnetic position measurementsUsing electrical meansBall screwGalvanometer

The invention discloses multifunctional plastic film conveying and detecting equipment which comprises a base plate. A mounting base and a driving motor are arranged on the upper end face of the base plate, an adjusting mechanism is arranged in the mounting base, and a rotating roller is horizontally and rotationally mounted between the output end of the adjusting mechanism and an output shaft of the driving motor. The adjusting mechanism comprises the mounting base and a placement groove formed in the side wall, opposite to the rotating roller, of the mounting base, a ball screw is rotatably mounted in the placement groove, a servo motor is mounted on the mounting base, and an output shaft of the servo motor is coaxially and fixedly connected with the input end of the ball screw. In the multifunctional plastic film conveying and detecting equipment, by arranging a detection element composed of a conductive block, a resistance plate and a galvanometer, the detection element can detect the pressure state of each part of the plastic film, so that various quality problems of the plastic film and whether the plastic film deviates or not during transmission can be found in time and fed back in time, and the functionality is strong.

Owner:武汉维卓科技咨询有限公司

A five-axis linkage numerical control manipulator polishing control system and method

InactiveCN111468989BAccurate and fast variable polishing force controlAccurate and fast track variable polishing force controlPolishing machinesAutomatic grinding controlNumerical controlRobot hand

The invention belongs to the technical field of mechanical processing, and discloses a five-axis linkage numerical control manipulator polishing control system and method, including a parameter configuration module, a monitoring module, a data acquisition module, a storage module, an angle adjustment module, a central control module, and pneumatic loading of polishing force module, a polishing parameter optimization module and a quality inspection module; the parameter configuration module includes: a numerical input unit, a mode setting unit, a mode selection unit, and an instruction generating unit. In the present invention, the monitoring module monitors the polishing process in real time through a camera; the data acquisition module detects and collects various data parameters in the polishing process through a plurality of sensors with different functions. The present invention can realize accurate and fast-tracking variable polishing force control during the polishing process, control the corresponding polishing force in real time, and can effectively meet the force control requirements of the polishing process; on the premise of ensuring the polishing quality, the present invention improves the working efficiency. efficiency.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

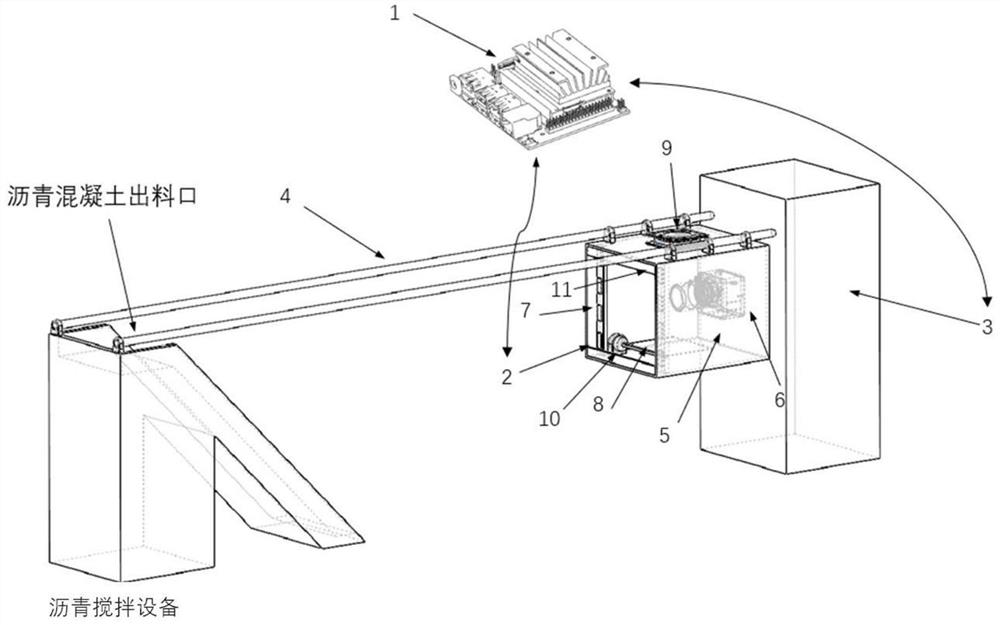

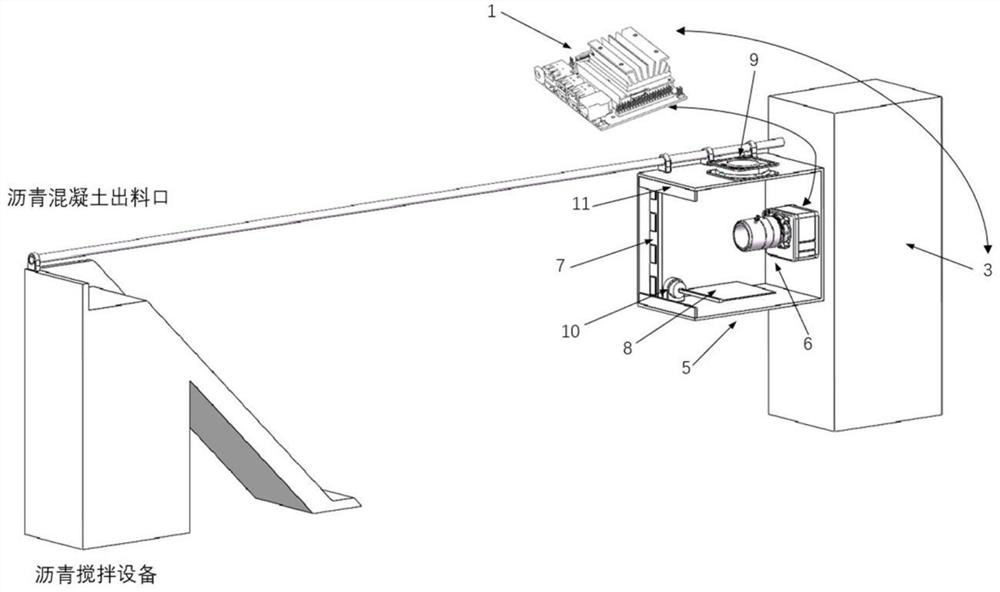

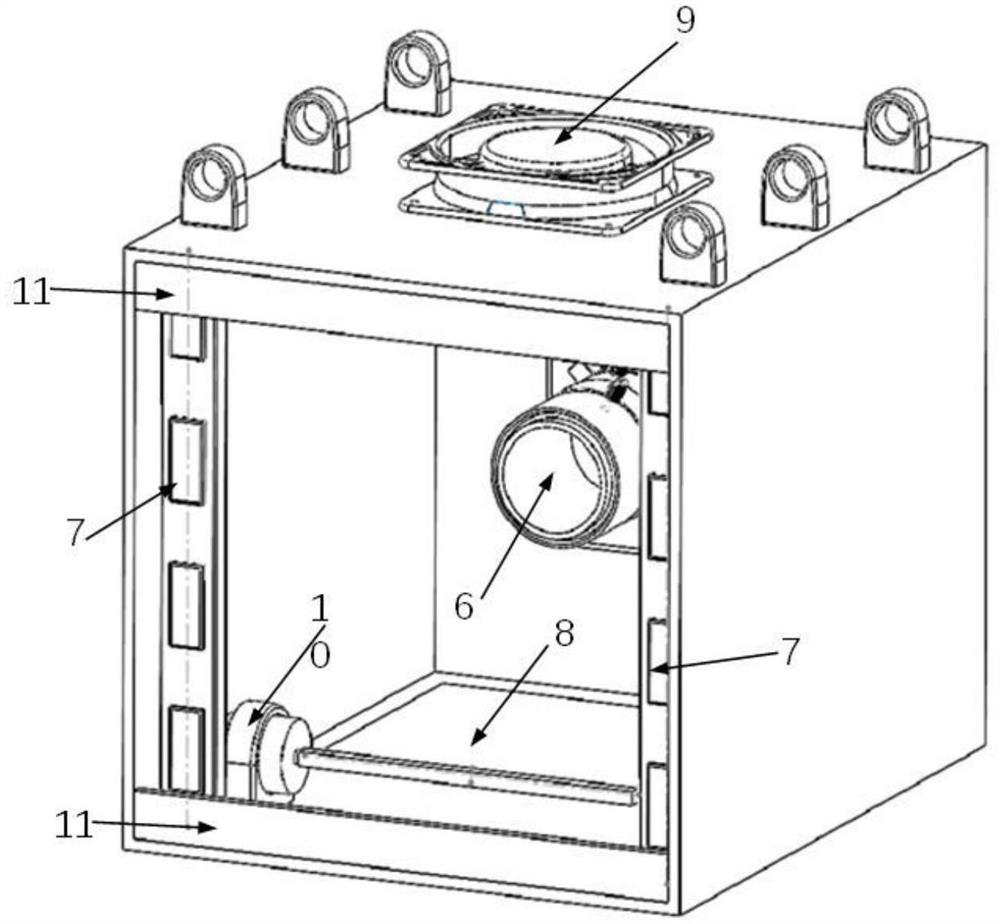

Asphalt concrete detection system and method based on fog generative adversarial neural network

ActiveCN113848216BEasy to identify and detectAvoid serious injuryImage enhancementImage analysisMachine visionMonitoring system

Owner:NANJING FORESTRY UNIV

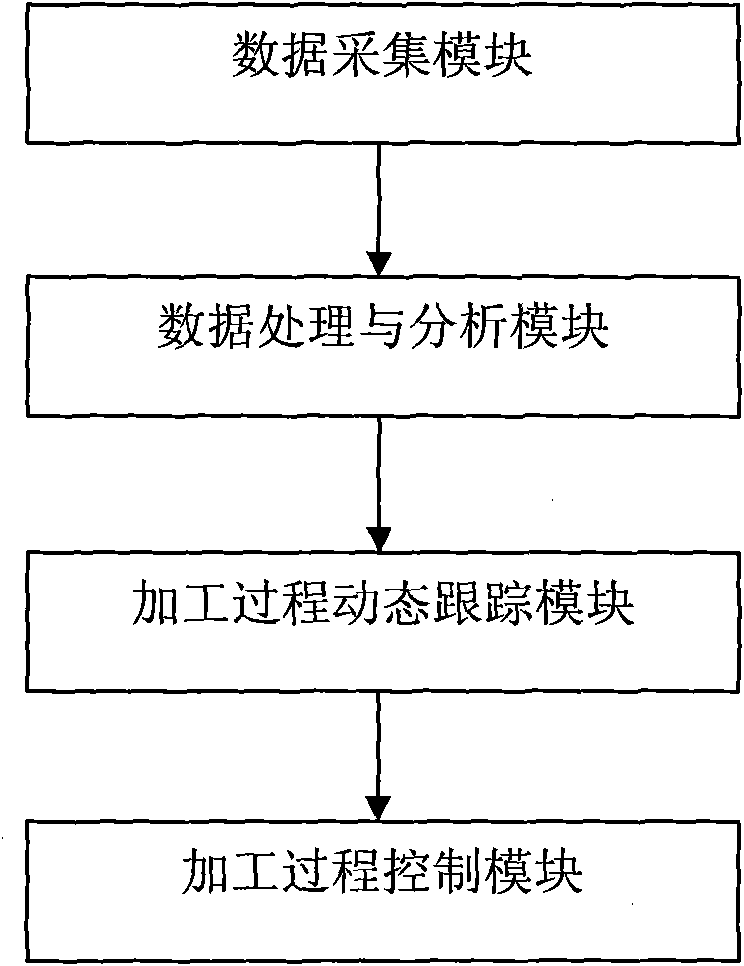

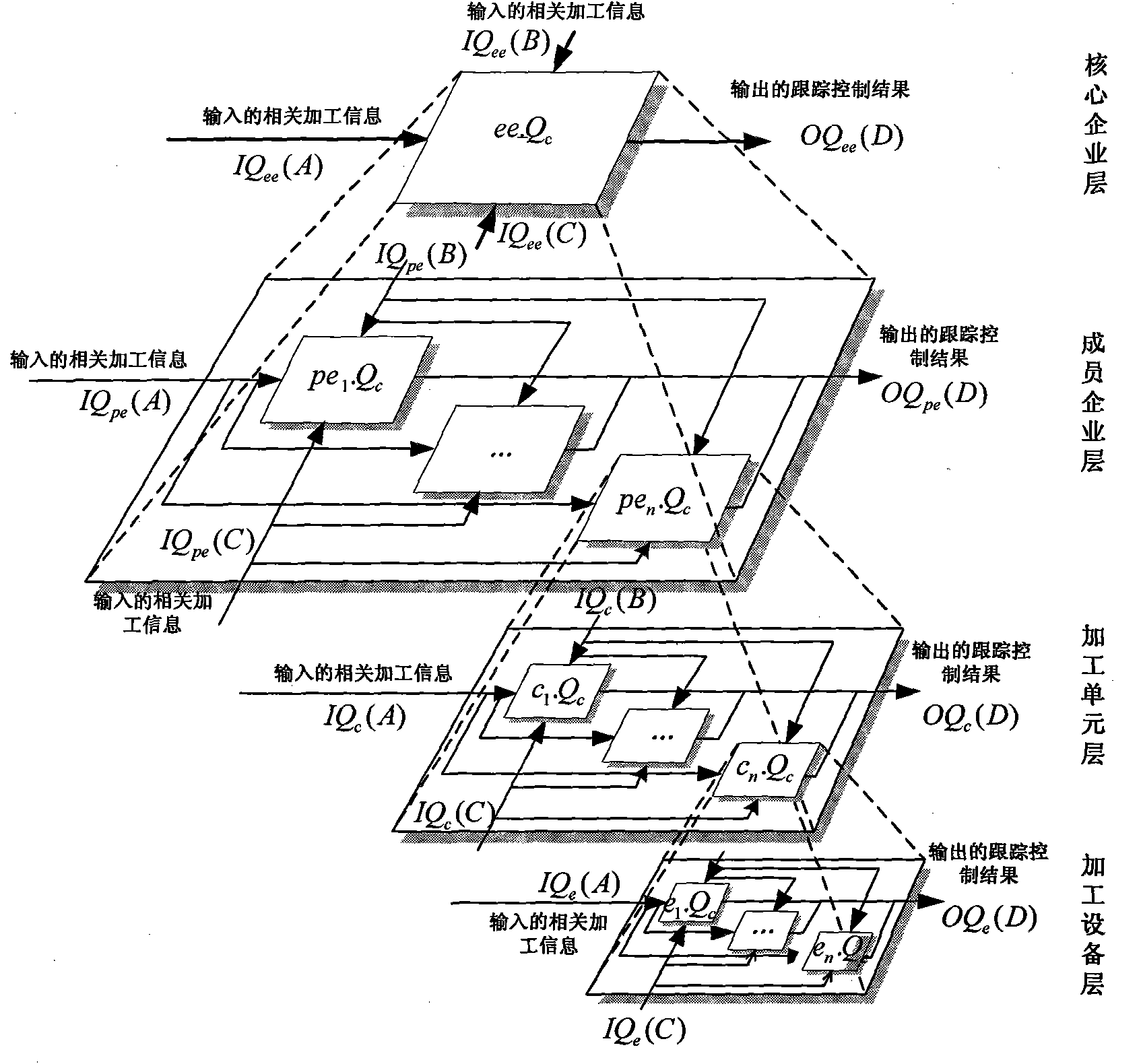

Multilayer dynamic tracking control method of processing process control system

InactiveCN101615026BRealize acquisitionLive UpdateTotal factory controlProgramme total factory controlProcess dynamicsControl system

Owner:XI AN JIAOTONG UNIV

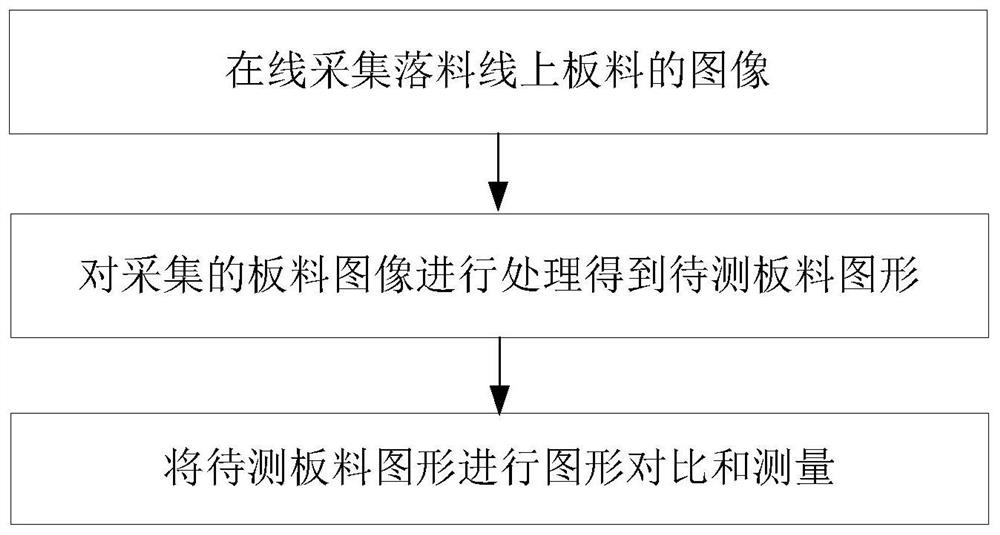

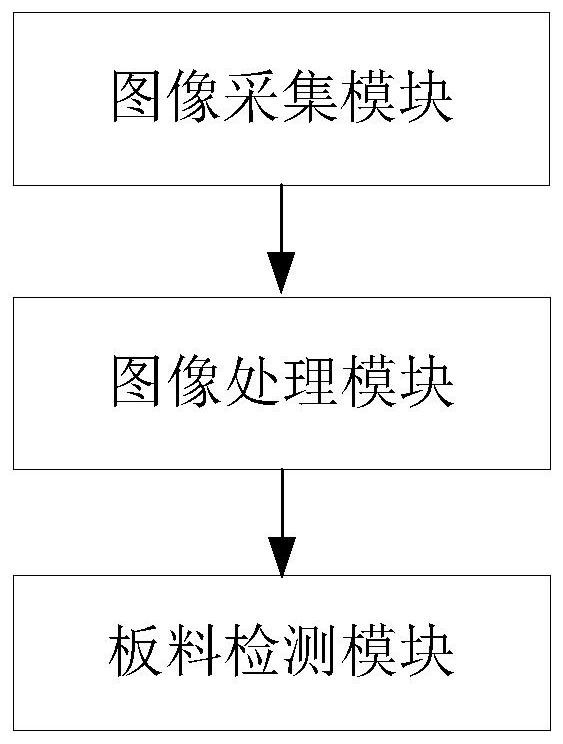

Plate detection method, device and system for blanking line

PendingCN113959334ASolve the problem that manual detection cannot be done onlineAvoid errorsImage analysisUsing optical meansEngineeringImage pair

The invention discloses a plate detection method, device and system for a blanking line, and aims to solve the problems of low speed, low efficiency and low accuracy of manual testing. The plate detection method for the blanking line comprises the following steps: acquiring an image of a plate on the blanking line on line; processing the acquired plate image to obtain a to-be-detected plate pattern; and performing pattern comparison and measurement on the pattern of the to-be-measured plate. The problems that time and labor are wasted, efficiency is low and complete detection cannot be achieved in manual detection are solved, errors existing in manual observation and judgment are avoided, the precision of plate detection of the laser blanking production line is improved, and the qualified rate of machining is increased.

Owner:JINAN AOTTO TECH

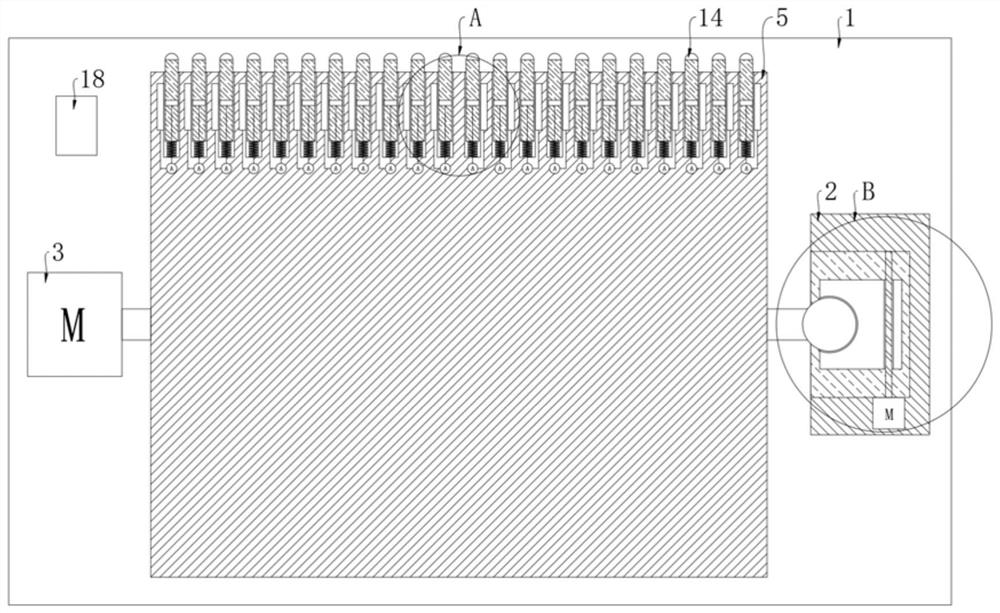

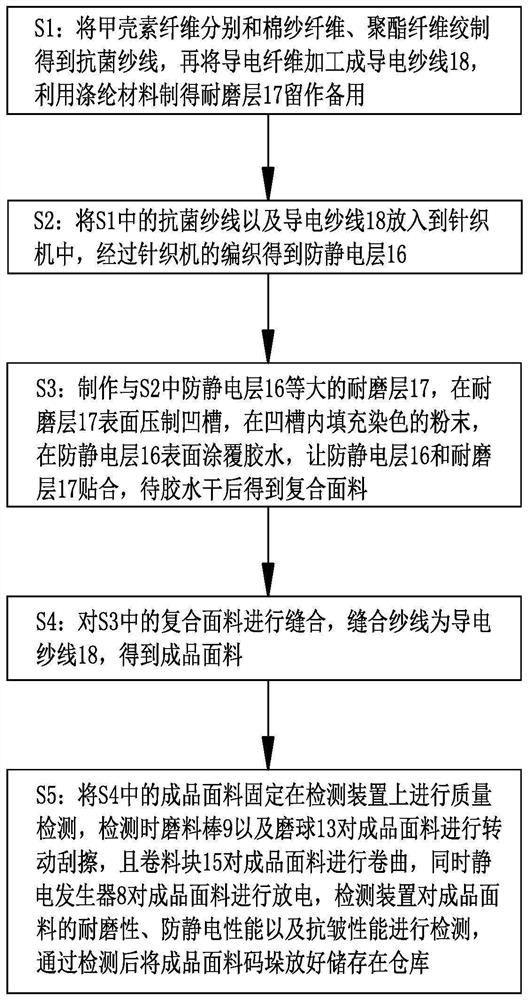

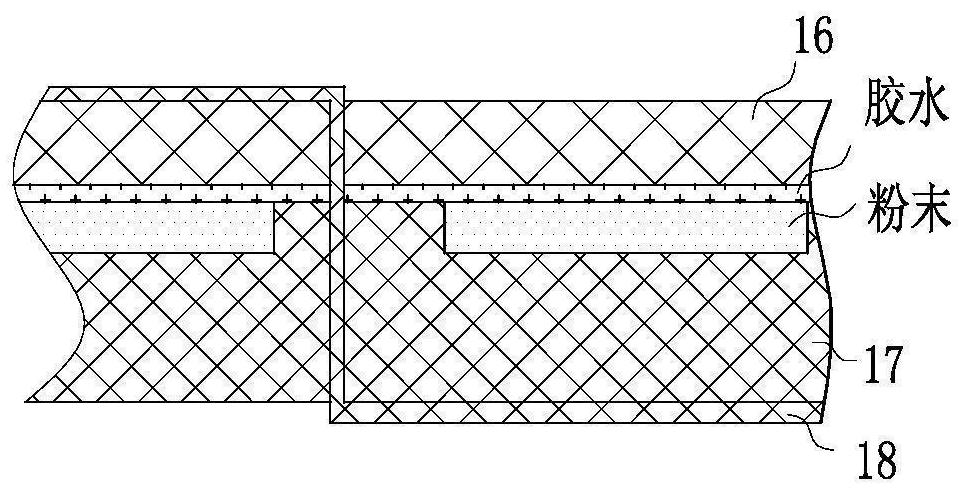

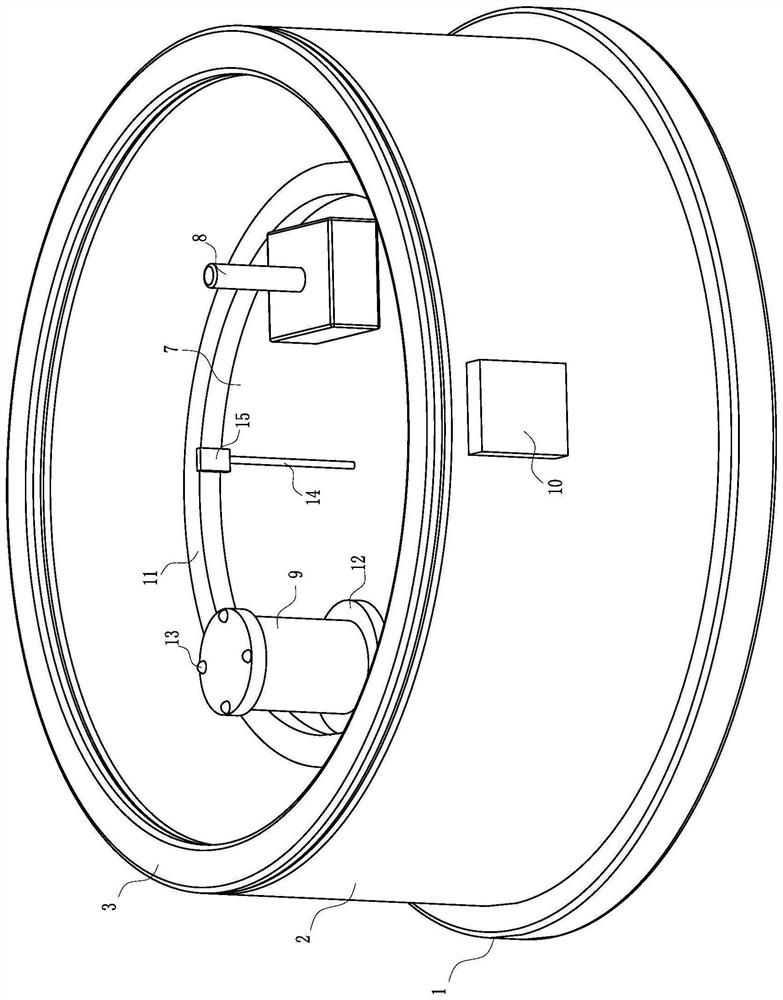

An antibacterial and anti-wrinkle antistatic knitted fabric

ActiveCN111703143BAnti-staticAnti-wrinkleFibre treatmentSynthetic resin layered productsFiberElectric machine

The invention belongs to the technical field of knitted fabrics, and specifically relates to antibacterial and wrinkle-resistant antistatic knitted fabrics. The detection device for fabric detection includes a chassis, and a number ring is fixed on the top of the chassis. No. 2 ring, the bottom end of the No. 2 ring is equidistantly fixed with more than two blocks along its circumference, and more than two snap slots are correspondingly arranged at the bottom of the No. 1 ring. The No. 1 ring and the No. 2 ring The number ring is used to fix the fabric, the top center of the chassis is fixed with a drive motor, the output shaft end of the drive motor is fixed with a turntable, the top of the turntable is fixed with an electrostatic generator, and the top of the turntable is rotated and installed with abrasive rods; The invention uses conductive fibers to sew the wear-resistant layer and the antistatic layer together, so that the fabric has the physical properties of antistatic, anti-wrinkle, antibacterial and wear-resistant, thereby improving the use effect of the fabric.

Owner:义乌市南吉针织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com