An antibacterial and anti-wrinkle antistatic knitted fabric

A knitted fabric and anti-static technology, applied in the field of knitted fabrics, can solve problems such as damage to gloves, knockdown by operators, affecting the anti-static effect of gloves, etc., and achieve the effect of improving the use effect and improving the detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

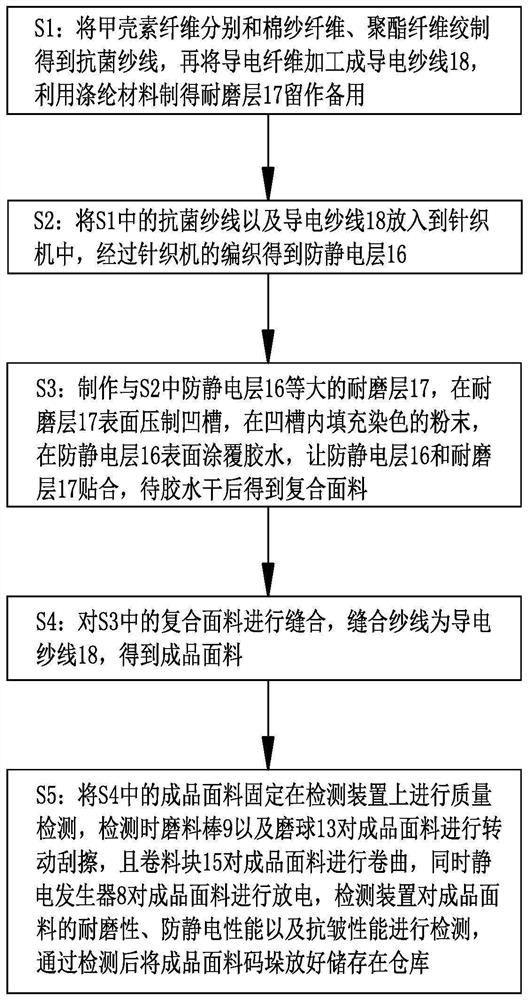

[0045] The preparation process of the knitted fabric is as follows:

[0046] S1: twist chitin fiber with cotton yarn fiber and polyester fiber to obtain antibacterial yarn, then process conductive fiber into conductive yarn 18, and use polyester material to make wear-resistant layer 17 for later use; chitin has natural antibacterial Antibacterial effect, so that the fabric can sterilize the absorbed sweat, so that the fabric has antibacterial effect; polyester fabric has high strength and elastic recovery ability, and the biggest advantage of polyester fiber is wrinkle resistance and shape retention. The joint action of the grinding layer 17 and the polyester fiber makes the fabric have good anti-wrinkle performance;

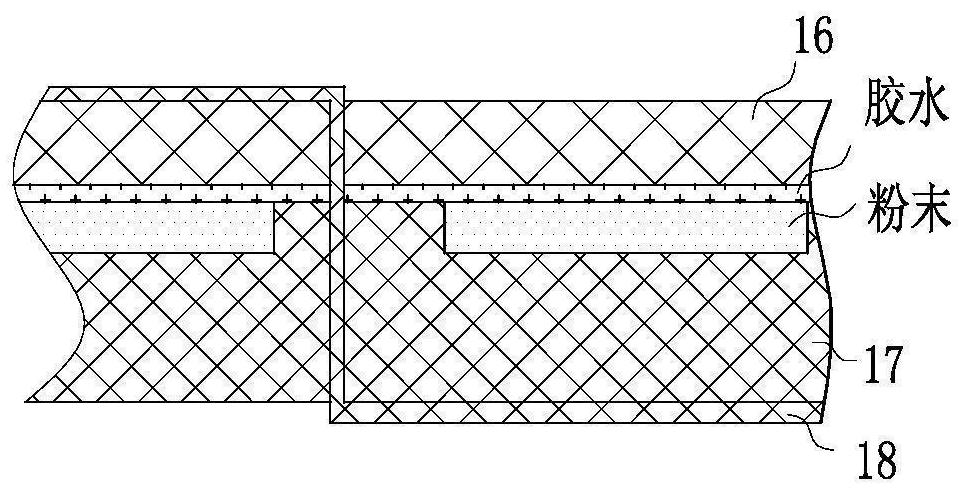

[0047] S2: put the antibacterial yarn and conductive yarn 18 in S1 into the knitting machine, obtain the antistatic layer 16 through weaving on the knitting machine, and weave the conductive fiber into the fabric so that the fabric has good conductivity, so that...

Embodiment approach

[0052] As a specific embodiment of the present invention, the conductive yarn 18 in the antistatic layer 16 is a weft thread, and the distance between adjacent conductive yarns 18 in the antistatic layer 16 is 1-3 cm; The fiber is used as both warp and weft to improve the wrinkle resistance and wear resistance of the fabric, avoiding the wrinkle of the fabric during use, which affects the use of the fabric; polyester fiber occupies a higher mass ratio to further ensure the wrinkle resistance of the fabric Performance; The distance between the conductive fibers not only ensures the conductive performance of the fabric, but also reduces the production cost.

specific Embodiment approach

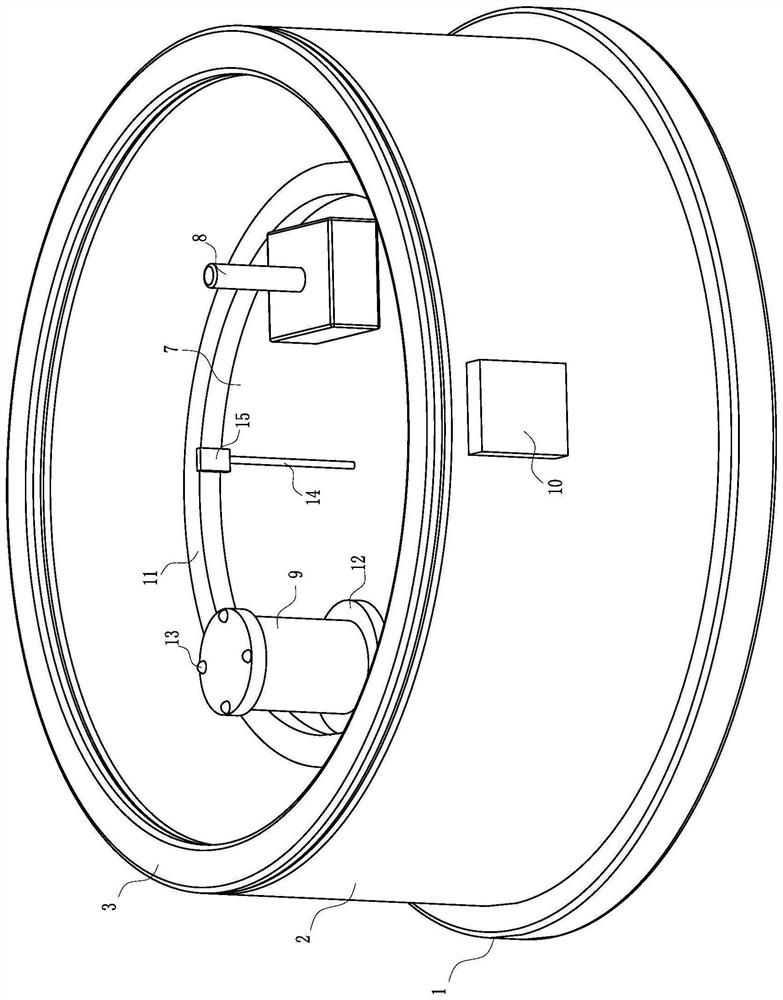

[0053] As a specific embodiment of the present invention, the detection device includes a chassis 1, a No. Two or more blocks 4 are fixed equidistantly along its circumference, and the top of the first ring 2 is correspondingly provided with two or more card slots 5, and the first ring 2 and the second ring 3 are used to fix the material , the top center of the chassis 1 is fixed with a drive motor 6, the output shaft end of the drive motor 6 is fixed with a turntable 7, the top of the turntable 7 is fixed with an electrostatic generator 8, and the top of the turntable 7 is rotatably equipped with abrasive rods 9. The abrasive rod 9 is made of insulating material, the side wall of the first ring 2 is provided with an electrostatic meter 10, and the electrostatic meter 10 is used to measure the voltage on the fabric, and the chassis 1 is provided with a controller , the controller is used to control the work of the detection device; when in use, pick up the second ring 3, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com