Machining process method for hardware fittings of medical products

A technology of mechanical processing and process methods, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as inconvenient quality control, and achieve the effect of convenient traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

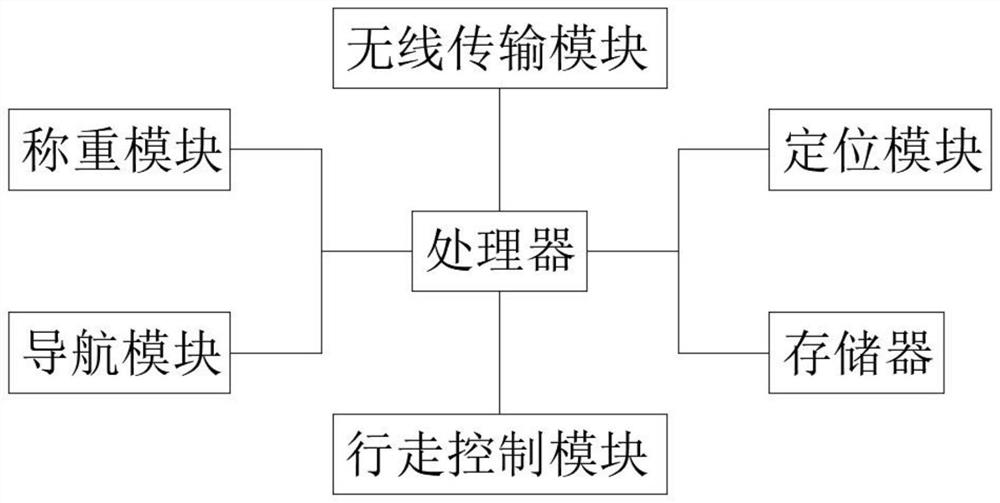

[0038] like figure 1 The shown machining process method for hardware accessories of medical products includes the following steps:

[0039] S1. Raw material inspection: inspection, registration and recording of raw material quality;

[0040] S2. Material cutting record: open the raw materials to form semi-finished products, place the semi-finished products in a recording disc according to a certain quantity, save the records of the raw materials used in the chip of the recording disc, and the recording disc weighs the weight of the semi-finished products. And compare it with the reference value, so as to judge whether the quantity and quality of the semi-finished products put in are qualified, if quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com