Segment-based multi-dimensional online quality evaluation system and method for steel coils

A technology for judging systems and quality, applied in manufacturing computing systems, instruments, data processing applications, etc., to achieve a wide range of data, ensure product quality, and save labor and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

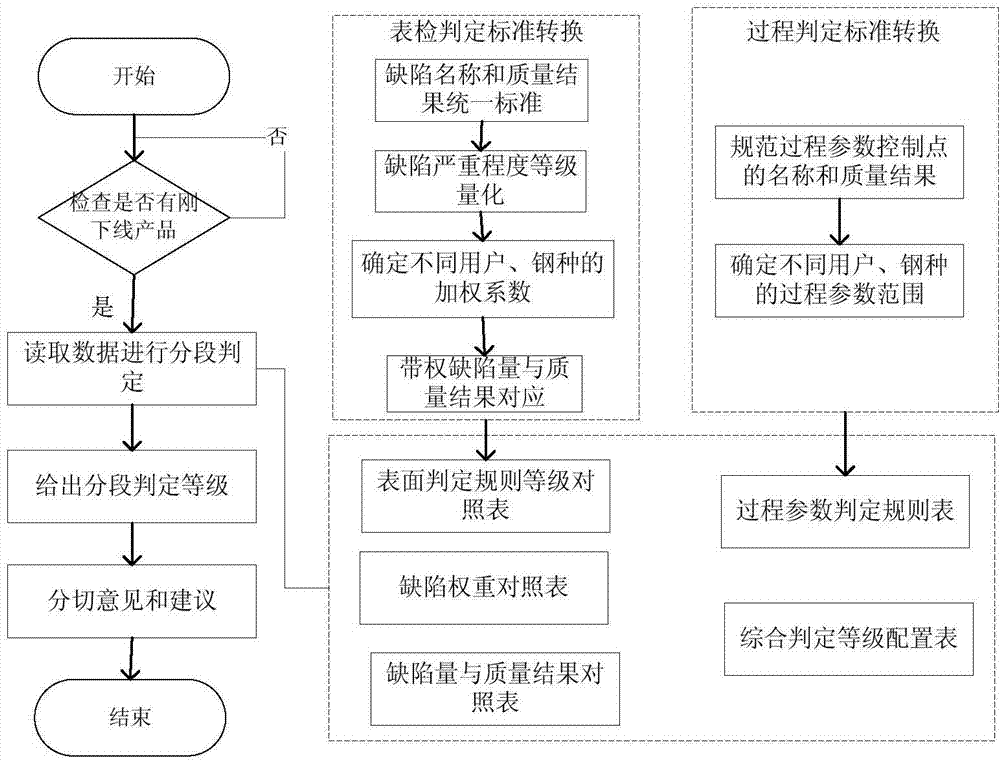

[0054] The present invention proposes a segmented multi-dimensional online quality judgment system and method for steel coils, combining figure 1 , 2 , 3, 4, 5 and examples are detailed as follows:

[0055] 1. Acquisition of quality parameters: Establish data interfaces with primary and secondary, MES, LIMS and surface inspection systems, and integrate data into the online quality judgment system through real-time triggering.

[0056] 2. Table inspection judgment standard conversion

[0057] ⑴ Surface judgment grades are divided into: G1, G2, G3, G4. Surface quality results are divided into S1, S2, S3, S4.

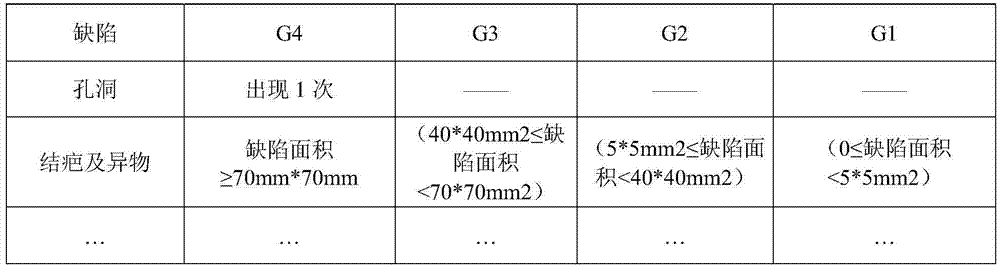

[0058] ⑵ Quantify the defect level according to the number and area of the defect according to the enterprise standard, and form a level comparison table. Take holes as an example: once a hole appears, the level is judged as G4. See figure 2 , all defects can be quantified according to actual needs.

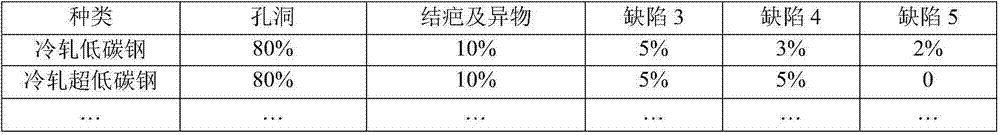

[0059] ⑶ Specify the weight of each defect according to differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com