Patents

Literature

135results about How to "Improve parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

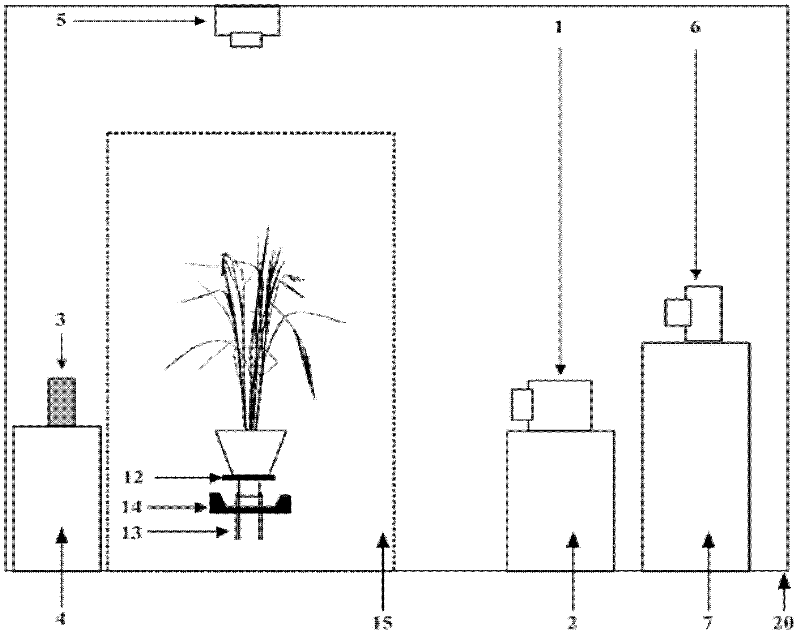

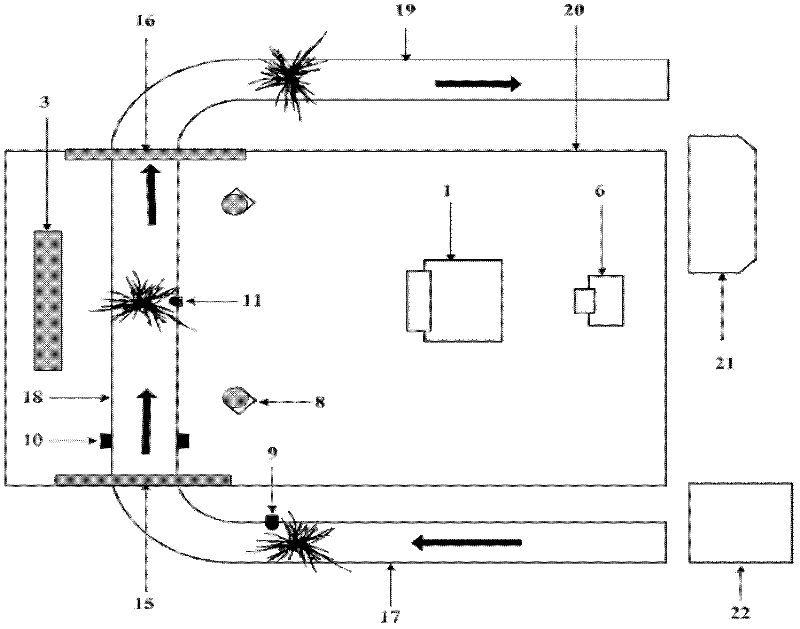

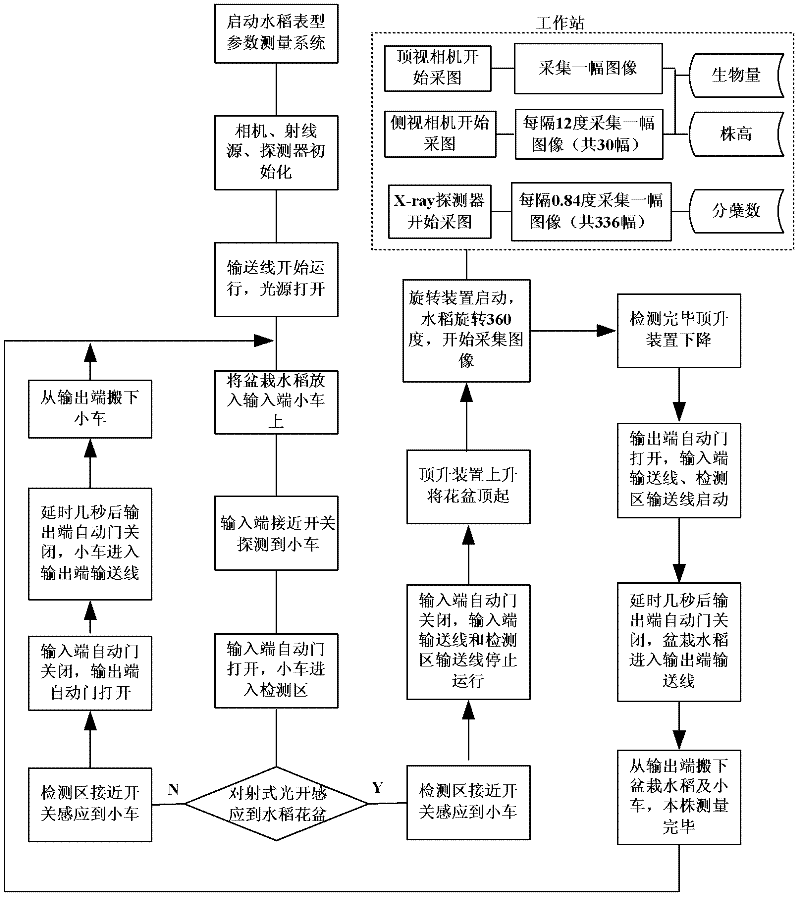

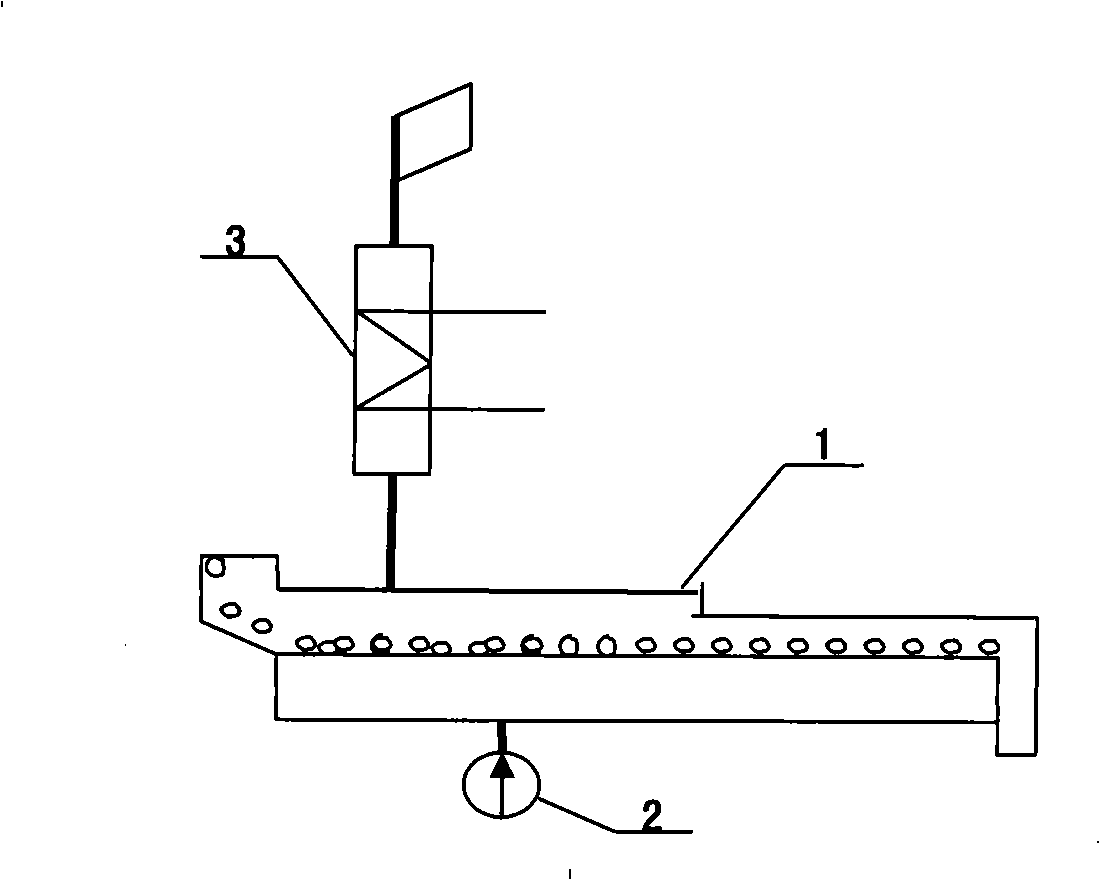

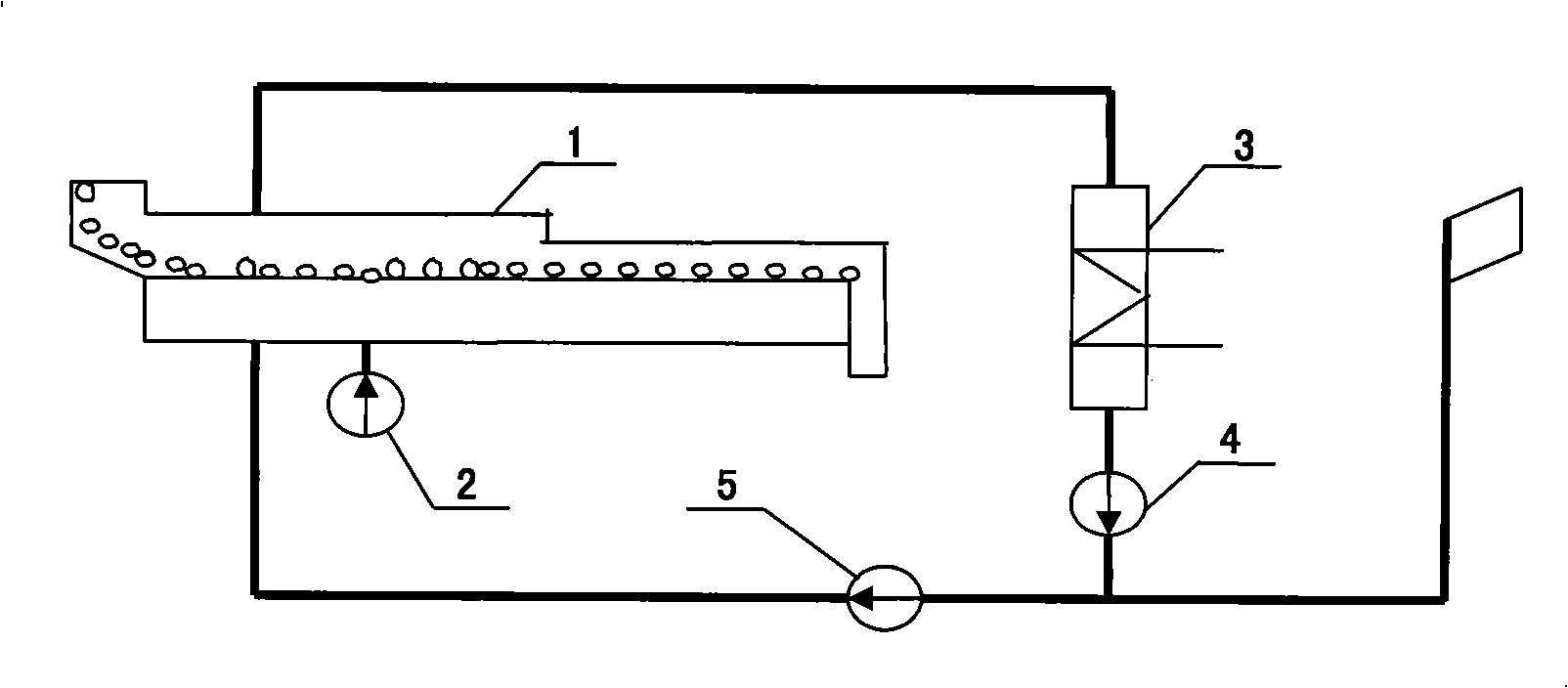

Fully-automatic nondestructive measurement system and measurement method for phenotype parameters of potted rice

InactiveCN102589441AImprove throughputHigh polyparameterMaterial analysis by optical meansUsing optical meansSoft x rayHigh flux

The invention relates to a fully-automatic nondestructive high-flux measurement system and a fully-automatic nondestructive high-flux measurement method for phenotype parameters of potted rice. The measurement system is controlled by a programmable controller, a conveying line conveys the potted rice, an X-ray imaging system shoots a rice tomography image, a three-dimensional visible light imaging system shoots a visible light image, a work station processes the obtained images, and all parameters of the rice are obtained. A new method for determining rice tiller number by X-ray tomography imaging is implemented, all parameters are extracted and integrated in a system, and a first set of fully-automatic, high-flux, multi-parameter and high-precision potted rice phenotype parameter automatic extraction system is successfully established.

Owner:HUAZHONG UNIV OF SCI & TECH

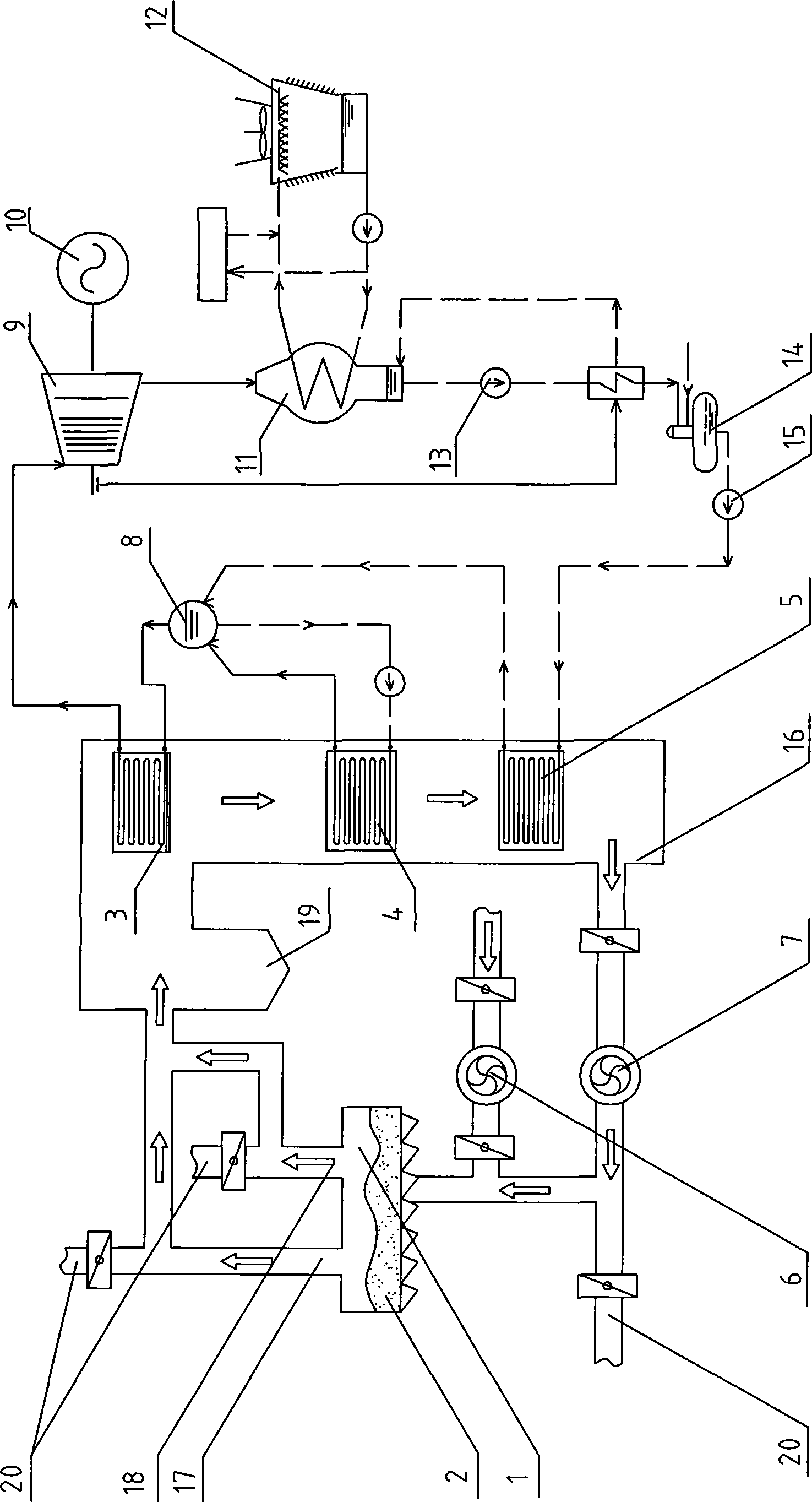

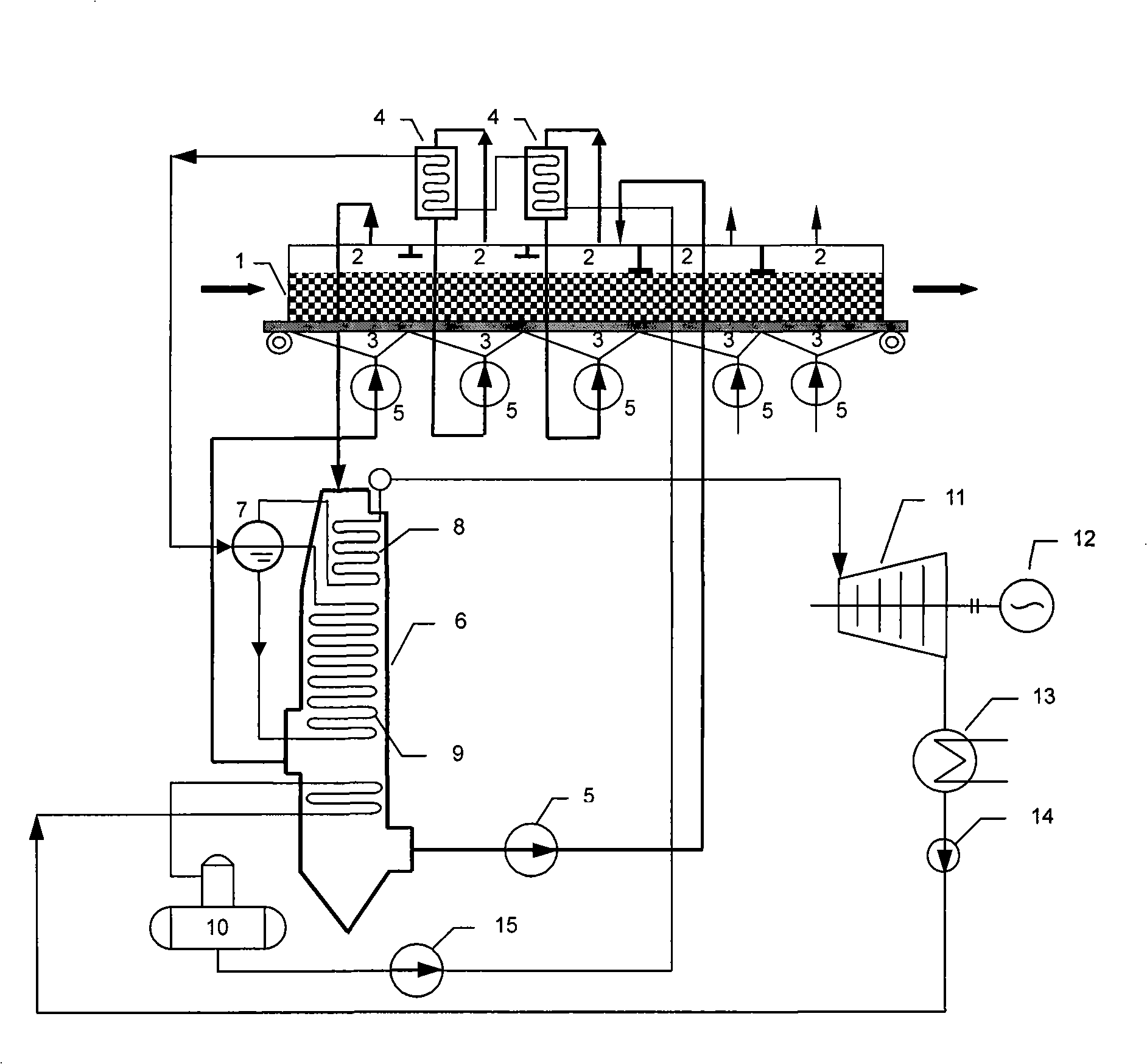

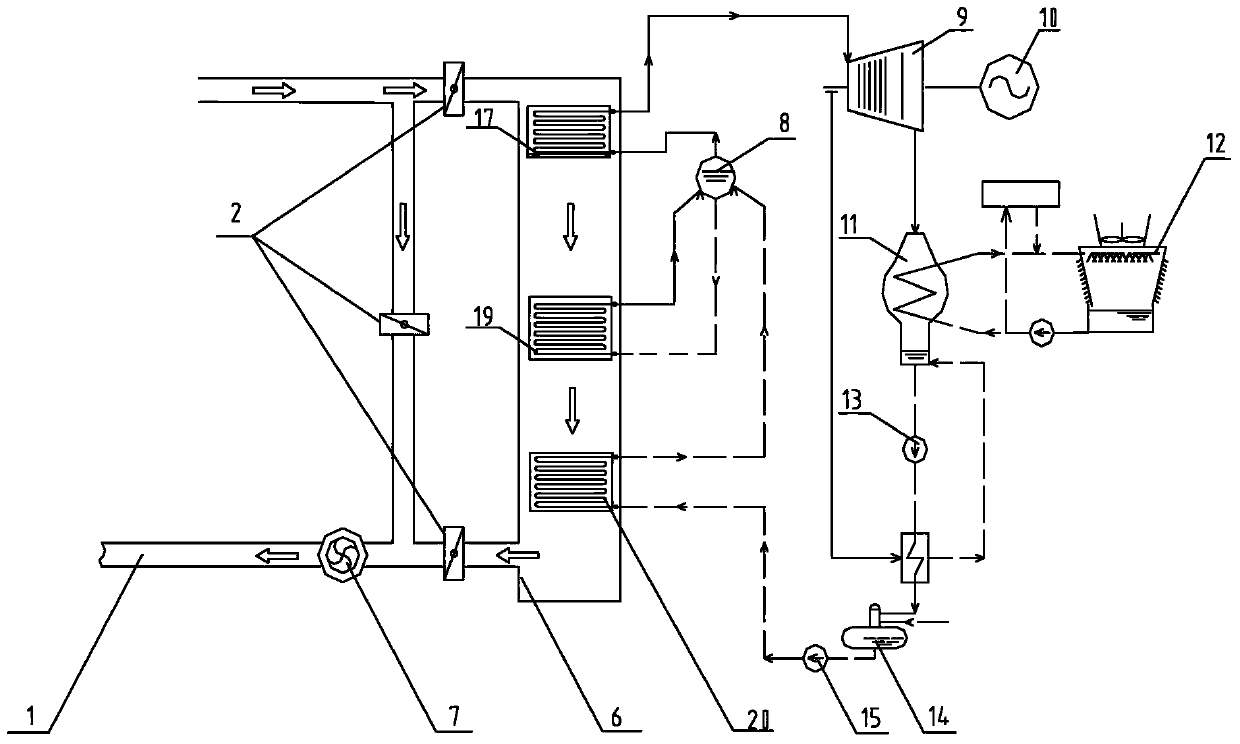

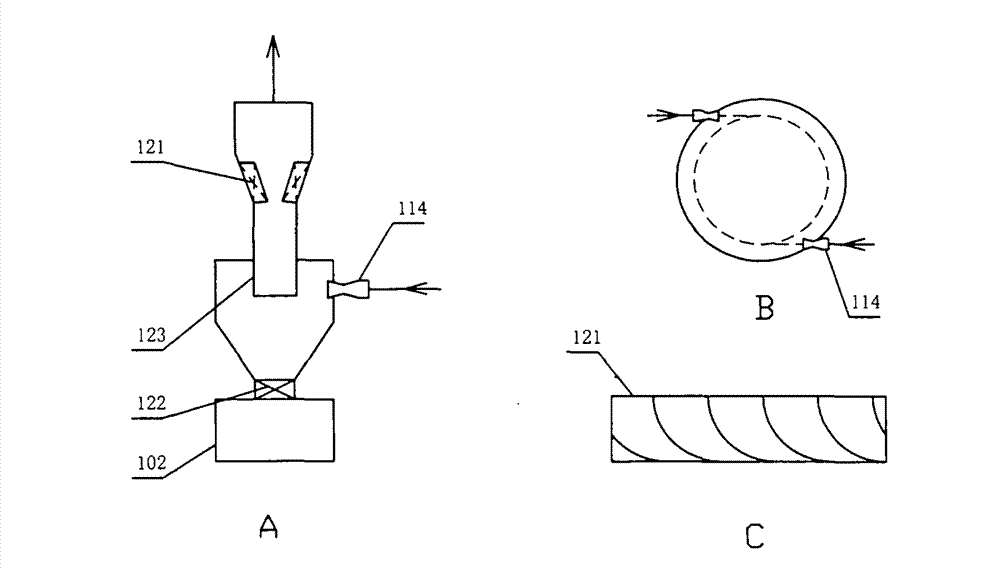

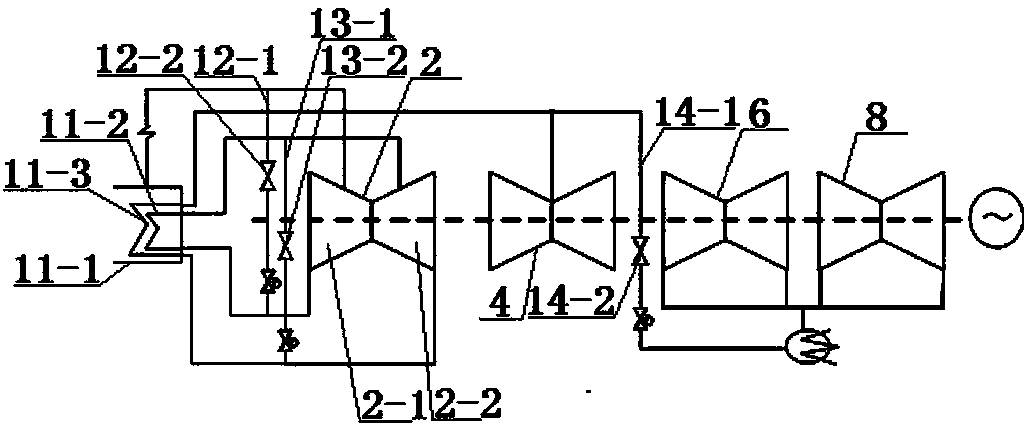

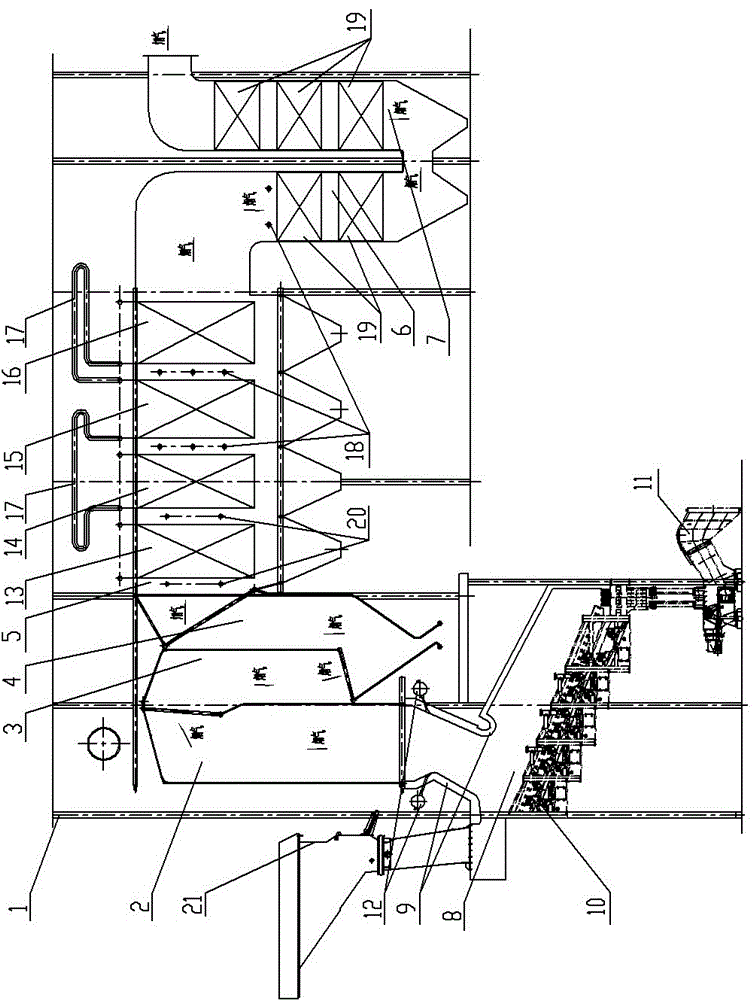

Sintered power generation by waste heat system with by-product gas afterburning

InactiveCN101509729AIncrease flue gas temperatureImprove steam parametersIncreasing energy efficiencySteam engine plantsSuperheaterEvaporator

The invention relates to a residual heat power generation system which is a power generation system with by-product gas supplemental combustion by sintering residual heat. The power generation system comprises a cooling machine, a waste heat boiler, a steam drum, a steam turbine, a boiler feed pump, an induced draft fan, an air blower and a chimney. A combustion hearth, a high-temperature superheater, a low-temperature superheater, an evaporator and an economizer are sequentially arranged on the waste heat boiler from top to bottom; the outlet of the high-temperature superheater and the steam inlet of the steam turbine are connected with each other by a pipeline; the waste heat boiler is provided with a sintering waste gas inlet and a by-product gas inlet; and the upper part of the cooling machine is provided with a high-temperature waste gas outlet, a middle-temperature waste gas outlet and a low-temperature waste gas outlet. The residual heat power generation system can greatly increase the temperature of the smoke and the temperature and the pressure of the overheated steam at the inlet of the steam turbine, and can improve the power generation capability.

Owner:江苏东能环保能源科技有限公司

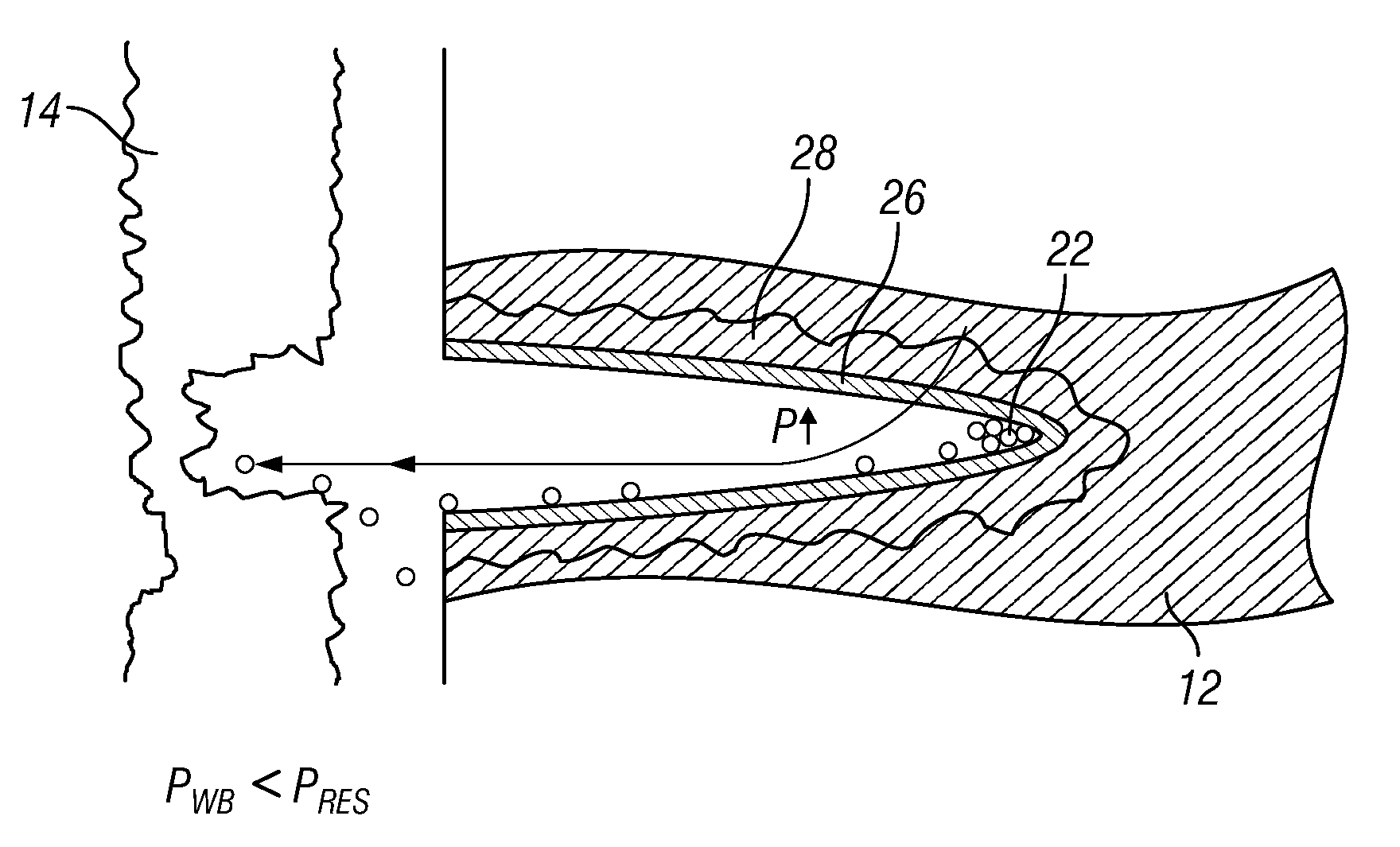

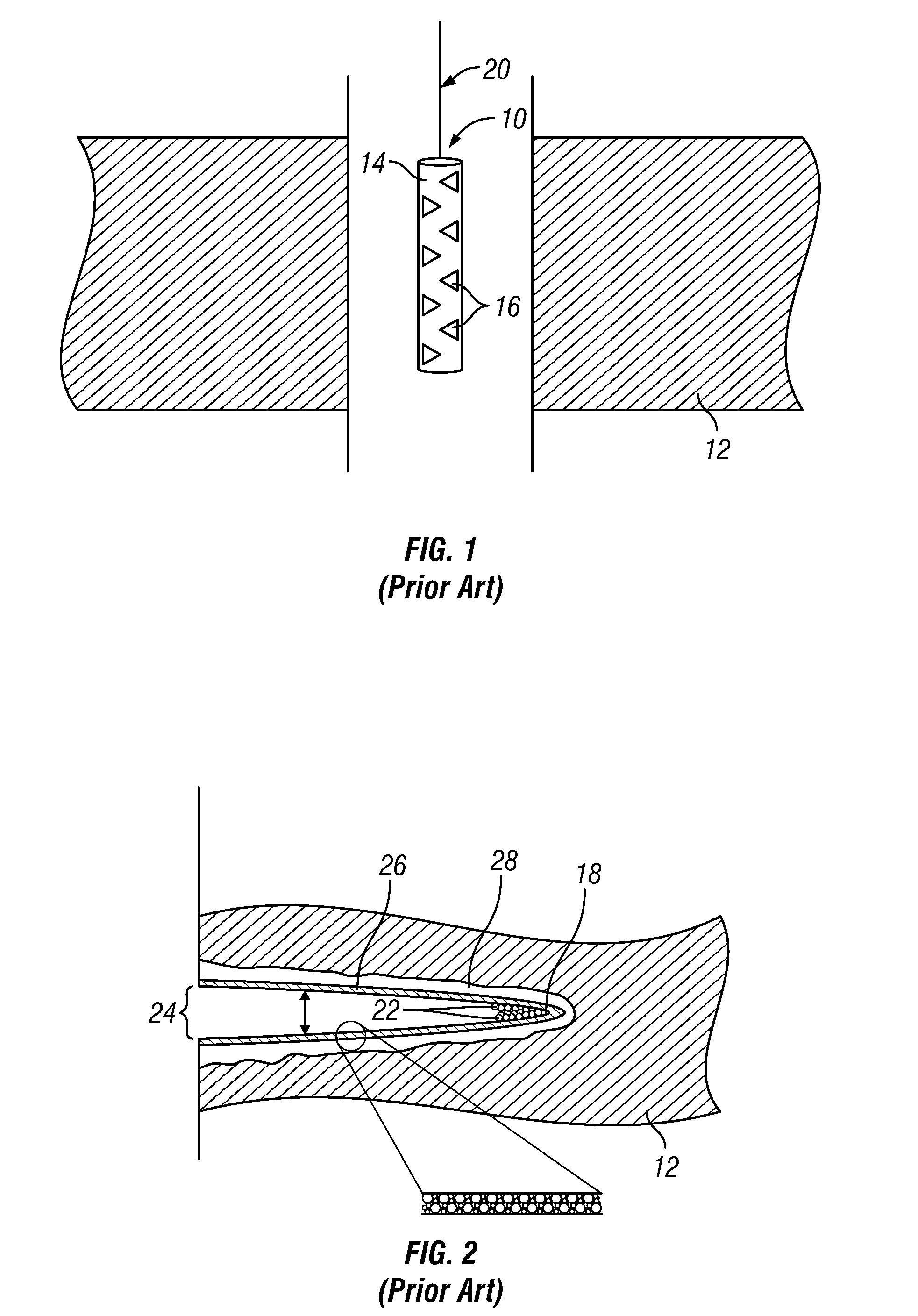

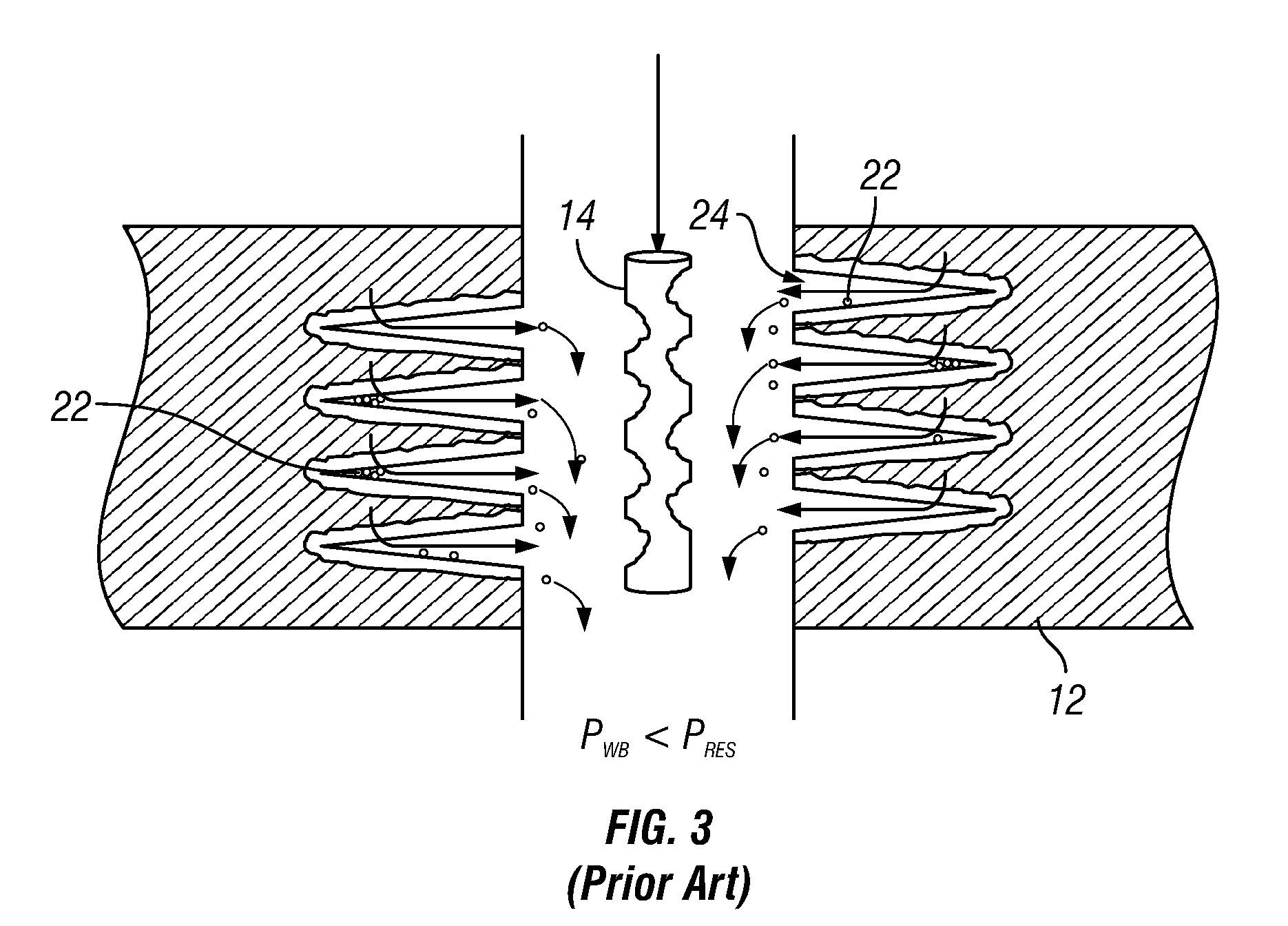

Method for the Enhancement of Dynamic Underbalanced Systems and Optimization of Gun Weight

By using reactive shaped charges, a dynamic underbalance effect associated with detonation of a perforating system is enhanced without compromising shot density. Fewer shaped charges can be loaded to achieve the same or better effective shot density as a gun fully loaded with conventional shaped charges, thereby increasing the free volume within the gun while creating debris-free tunnels with fractured tips and substantially eliminating the crushed zone surrounding each perforated tunnel. Further, the strength and grade of gun steel required to construct the gun can be reduced without compromising the amount the gun swells following detonation.

Owner:WELLS FARGO BANK NAT ASSOC +1

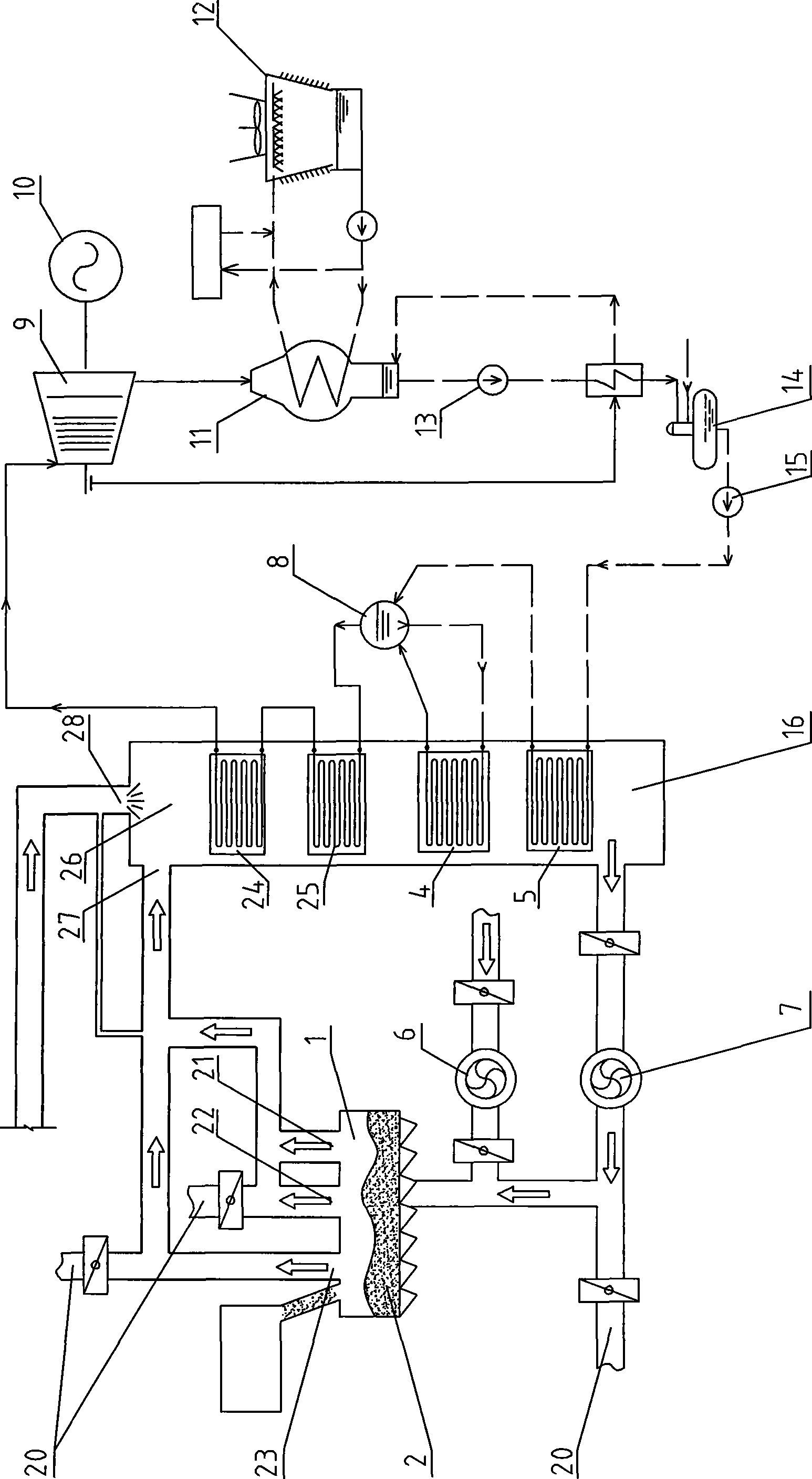

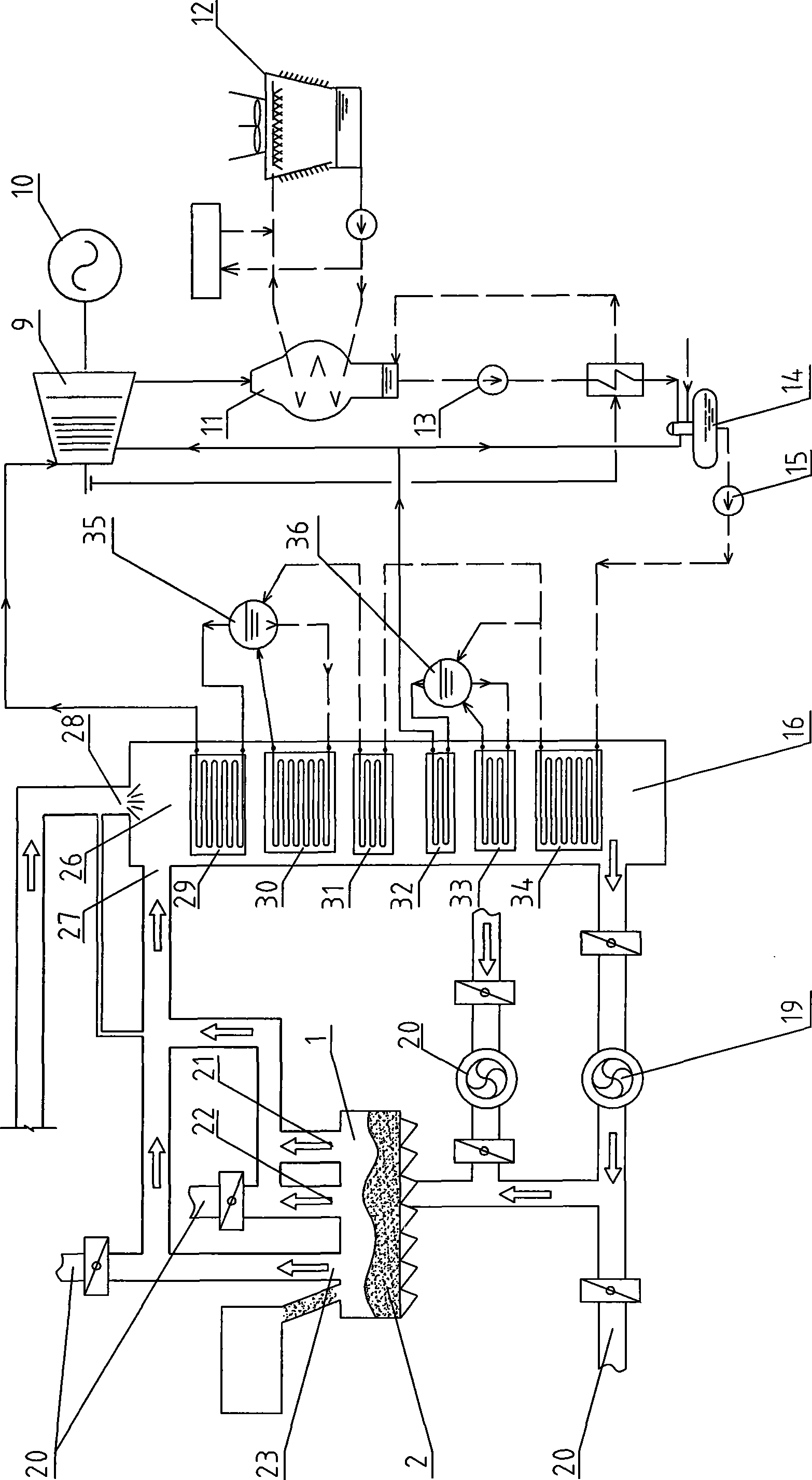

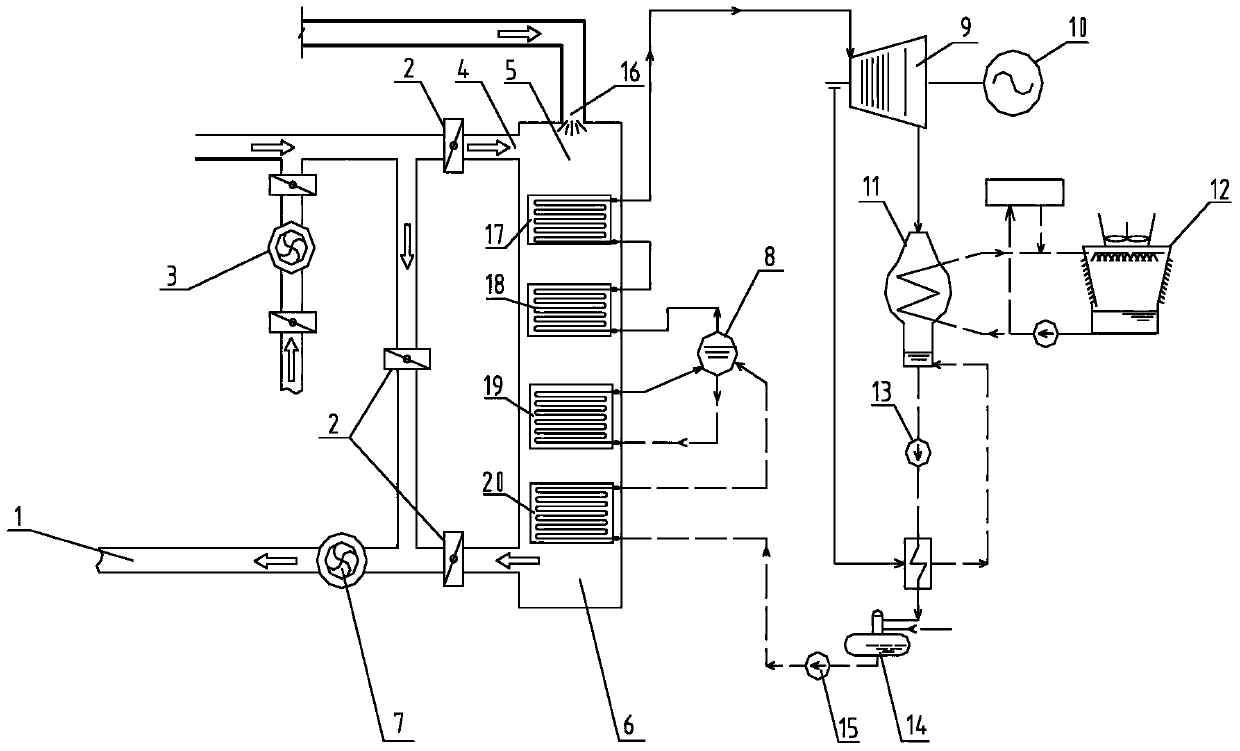

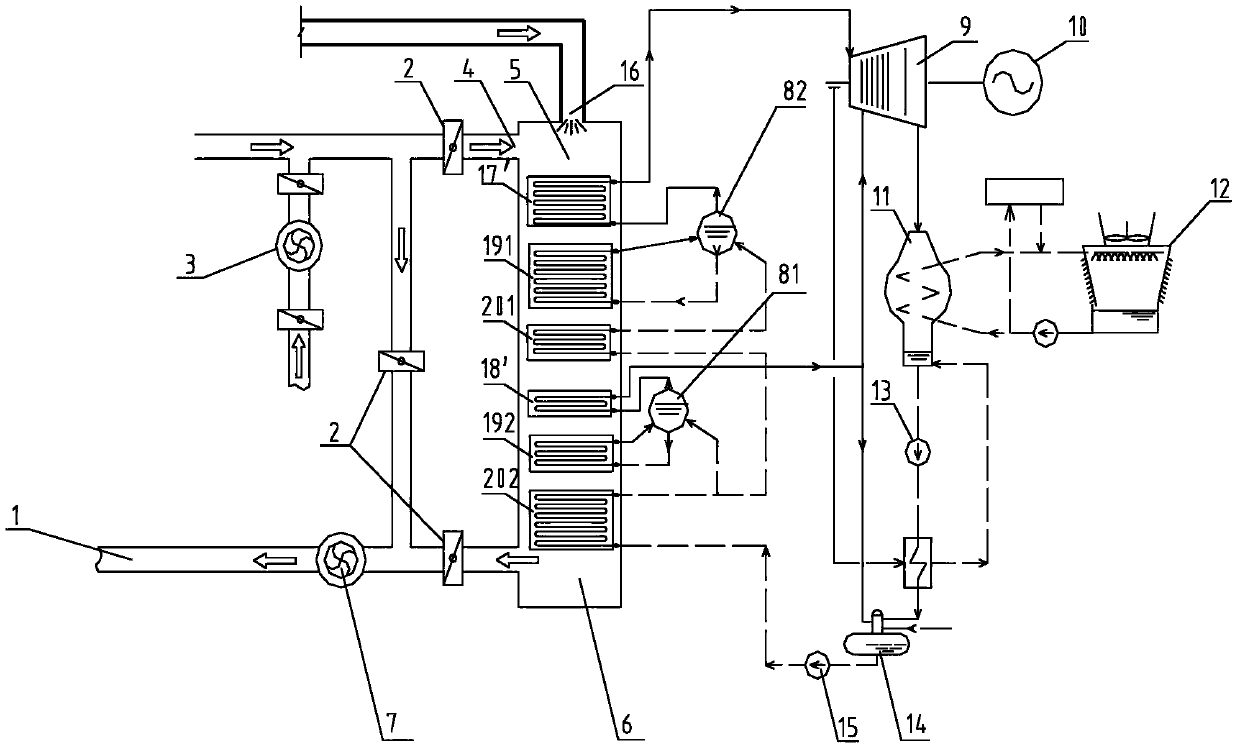

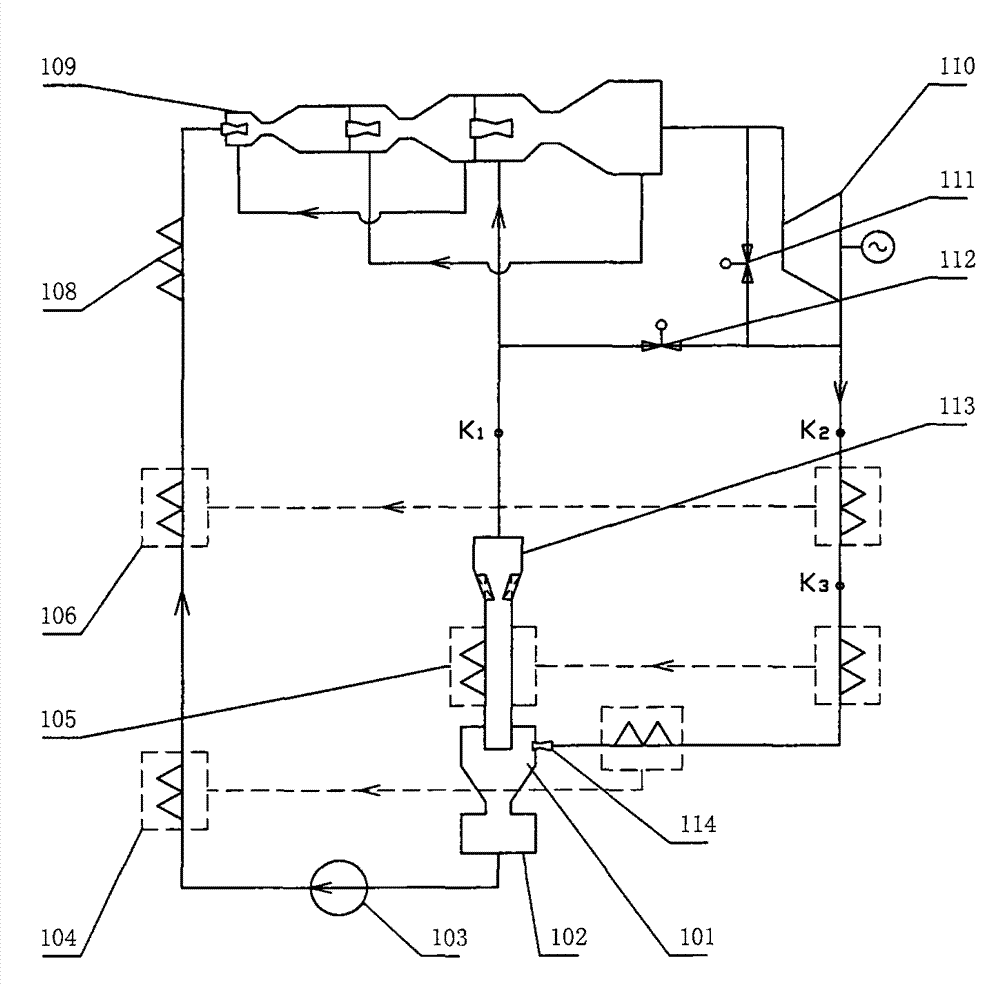

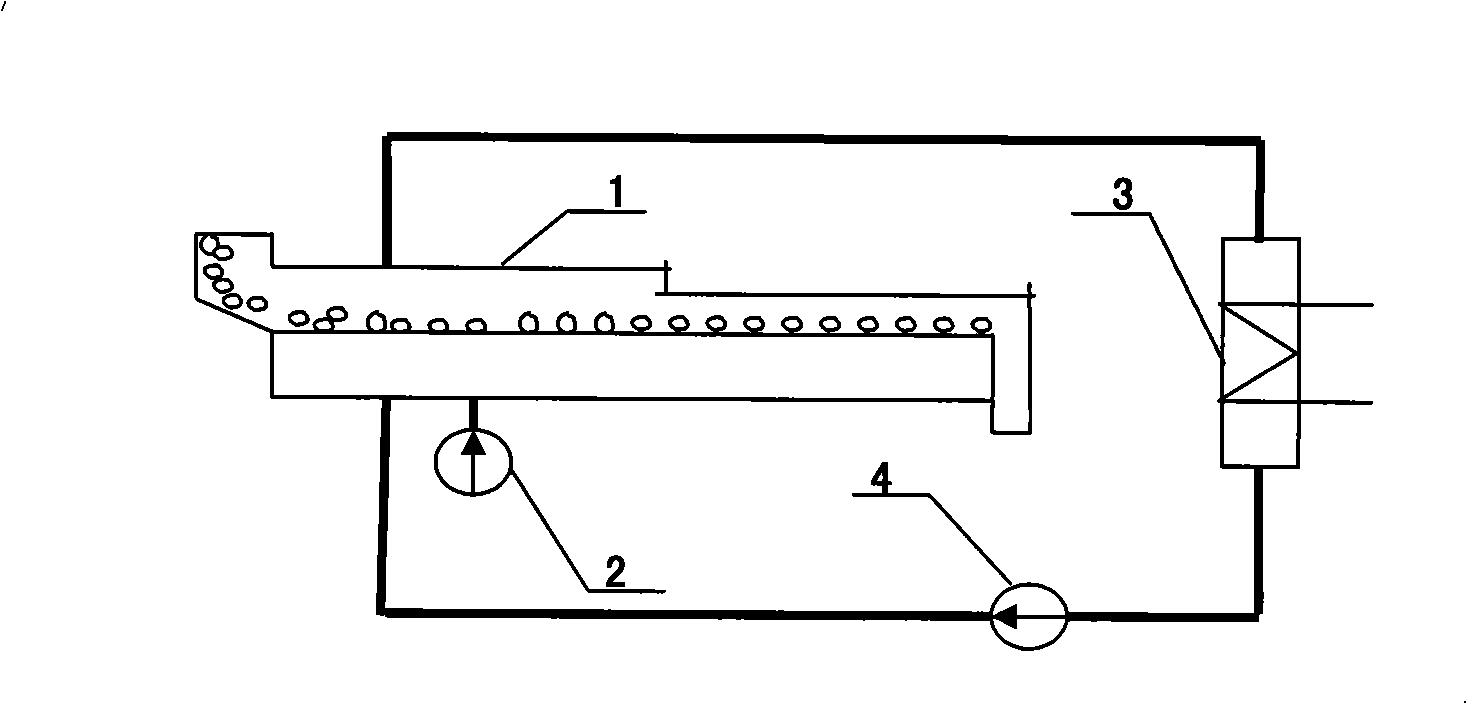

Sintered ring cold exhaust heat stepped recovery power generation system and technique

ActiveCN101344359AGuaranteed cycleImprove parametersFurnace typesIncreasing energy efficiencyAir volumeCooling effect

A sintering circulating cooling waste heat cascade recovery power generation system and a process thereof belong to the sintering waste heat utilization technology field. The system comprises a sintering circulating cooling machine, a windward chamber, a leeward chamber, a heat exchanger, a fan, a waste heat boiler, a steam bag, a superheater, an evaporator, an oxygen remover, a steam turbine, a generator, a condenser, a condensate pump and a water supply pump. The totally closed system is adopted to carry out subsection cooling and cascade recovery of waste heat of sinter, thereby recovering the sensible heat of the sinter to the maximum extent; the gradual increase of the temperature of cooling air can reduce the heat exchange temperature difference with the sinter; in order to not affect the cooling effect of the sinter, the system adopts the combined mode of the sub-cycle of the cooling air and the major cycle to absorb the sensible heat of the sinter, thereby improving the waste heat recovery efficiency. Compared with the prior art, the system and the process can extremely recover the waste heat of the sinter, improve the temperature of steam which is used for power generation under the premise of not increasing the total circulating air volume, increase the waste heat power generation amount and have great economic effects.

Owner:SHOUGANG CORPORATION +1

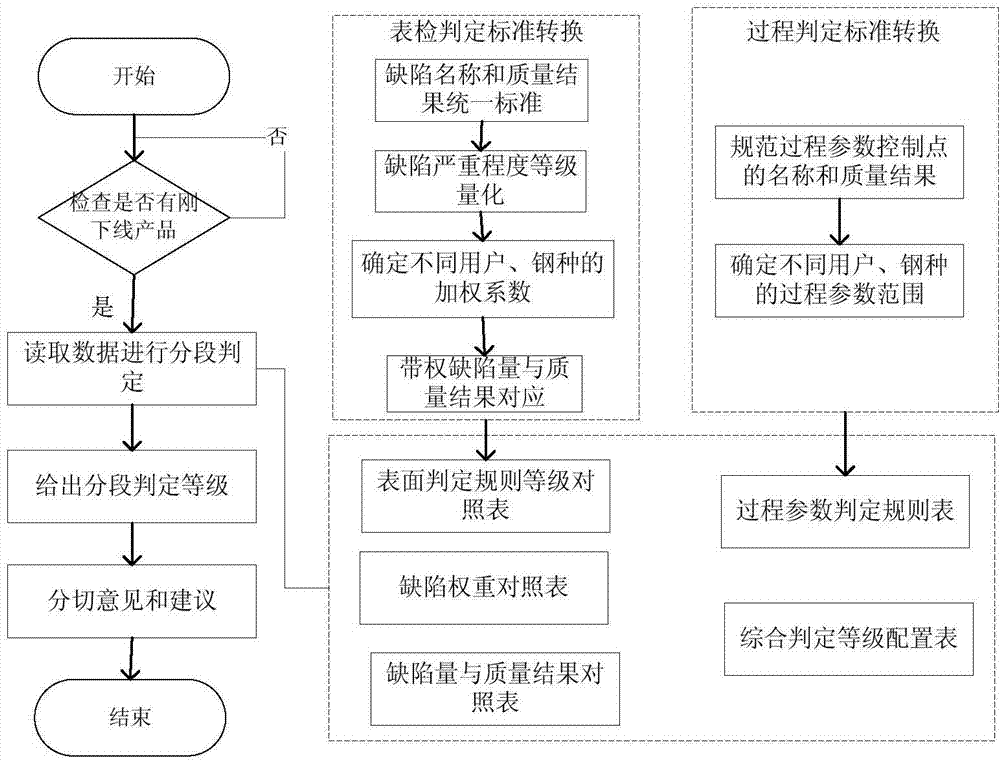

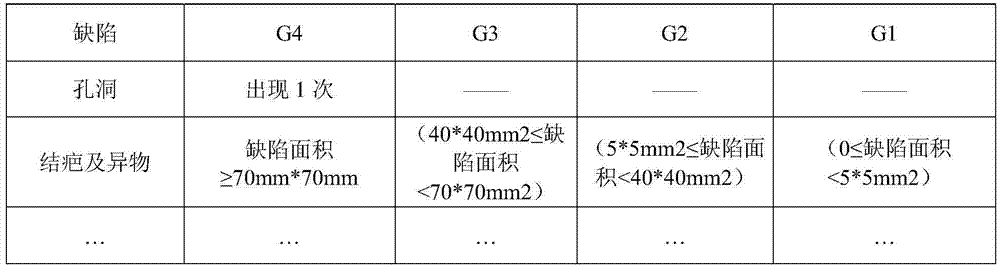

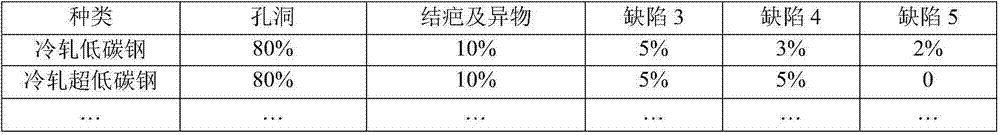

Segment-based multi-dimensional online quality evaluation system and method for steel coils

ActiveCN104751288AAchieve integrationImplementation checkResourcesManufacturing computing systemsQuality levelEconomic benefits

The invention belongs to the technical field of metallurgical industry manufacturing and informationization of the metallurgical industry and relates to a segment-based multi-dimensional online quality evaluation system and method for steel coils. production process data and surface detection data for use in quality evaluation are acquired through a data interface; when a steel coil is off a line, the steel coil is divided into a plurality of segments along the length; the acquired data are read; according to business rules and product quality standards, process and surface defect quality results are separately judged; comprehensive level of each segment and quality level of the steel coil are finally acquired. Primary secondary process parameters and instrument defect information are acquired, and the production process data is maximally integrated; the business quality standards and control plan operation procedures are quantitatively and systematically processed, segment-based dimensional evaluation is performed at the moment when products are off the line, comprehensive inspection of the steel coil is achieved, labor for data collection is freed, quality inspectors can be helped to find quality problems in time so as to make following treatment, and product quality and enterprise economic benefit are finally improved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

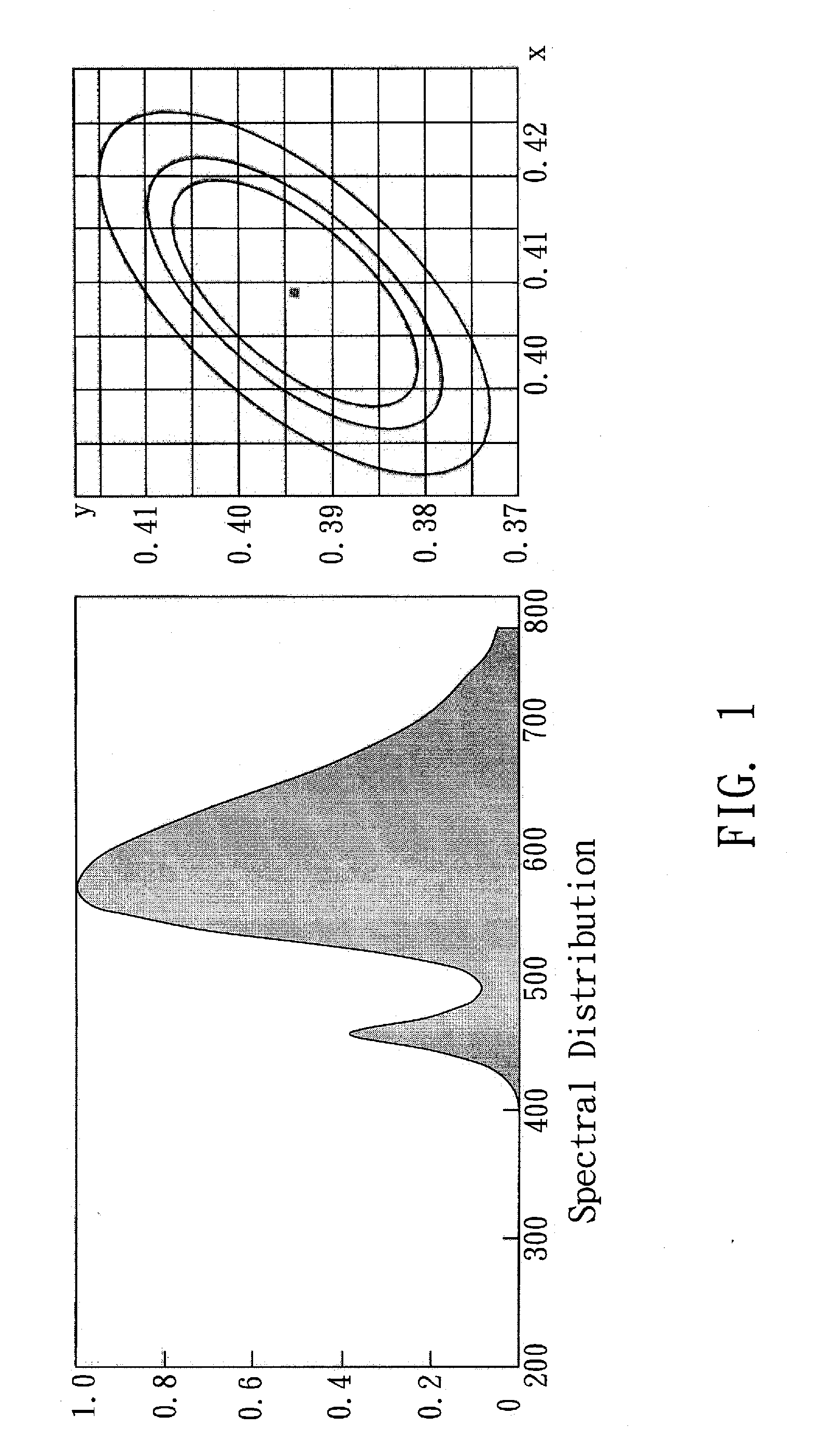

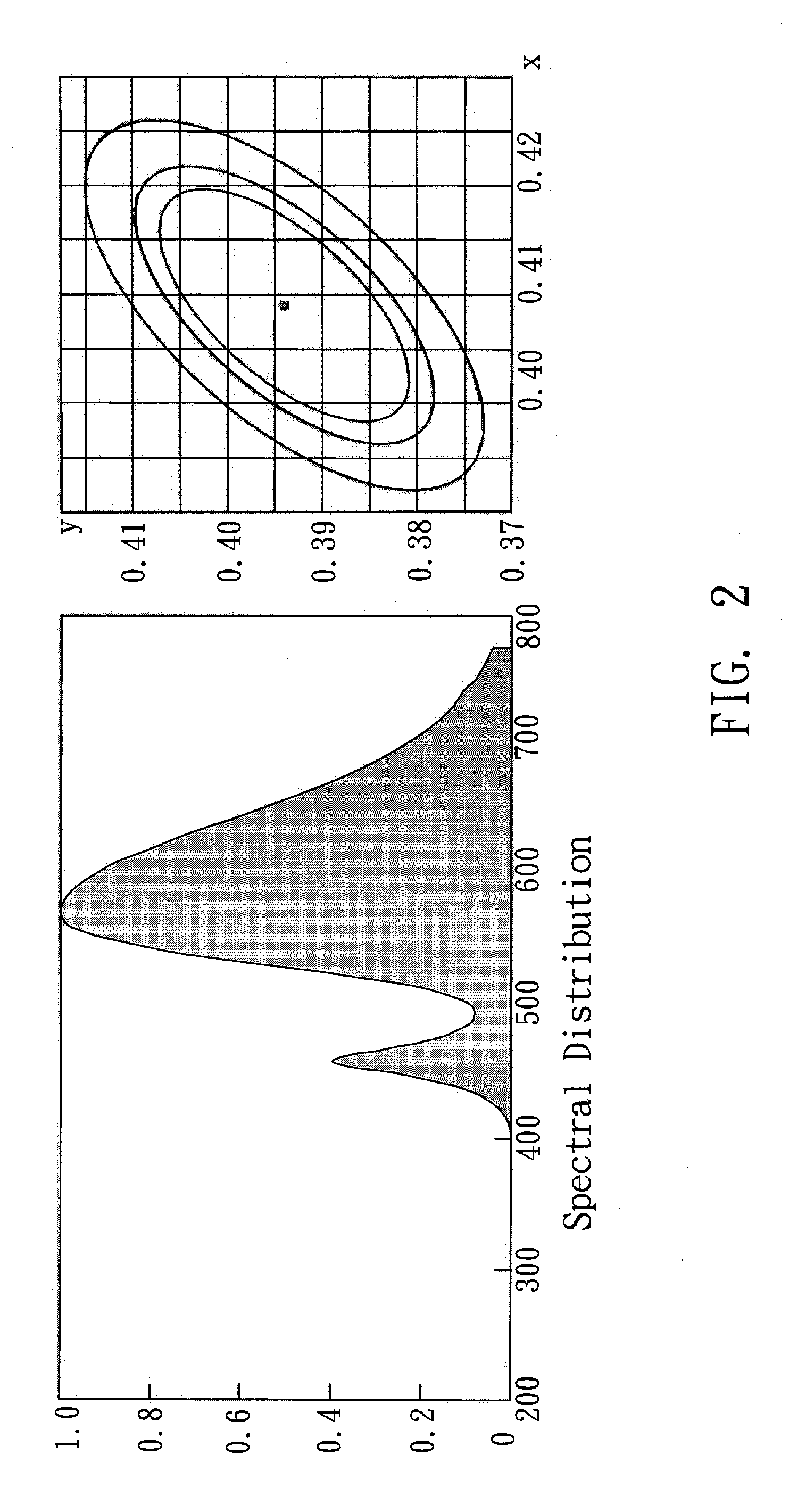

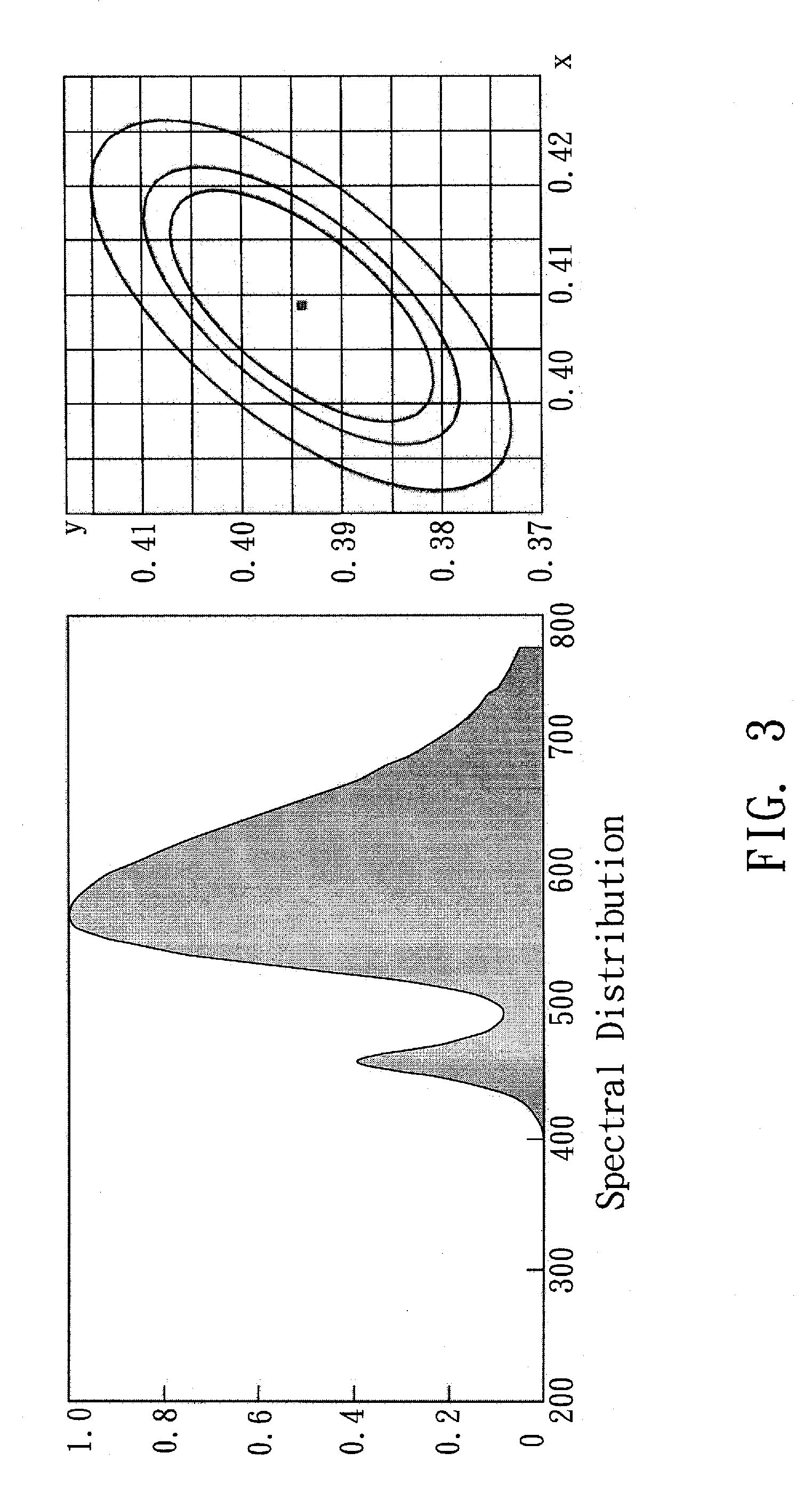

Warm-white light emtitting diode and its halide phosphor powder

InactiveUS20100044729A1Effective efficiencyEffective lightingDischarge tube luminescnet screensElectroluminescent light sourcesCeriumLight-emitting diode

The invention relates to a halide phosphor powder for warm-white light emitting diode, which is a kind of low-color-temperature phosphor powder of halide nitride based on garnet of rare earth oxides, uses cerium as activating agent and is characterized in that chloride (Cl−1) and nitrogen ion (N−3) are added to the composition of the phosphor powder and its stoichiometric relationship of the composition is (ΣLn+3)3Al2[(Al(O1-2pClpNp)4]3, wherein ΣLn is ΣLn=Y and / or Gd and / or Tb and / or Lu and / or Dy and / or Pr and / or Ce. In addition, the invention also discloses a use of a warm-white light emitting diode of the said phosphor powder with a weight ratio of 8 to 75%. The light emitting diode has a warm-red color temperature T≦3000 K when it has a power of 1 watt.

Owner:LO WEI HUNG

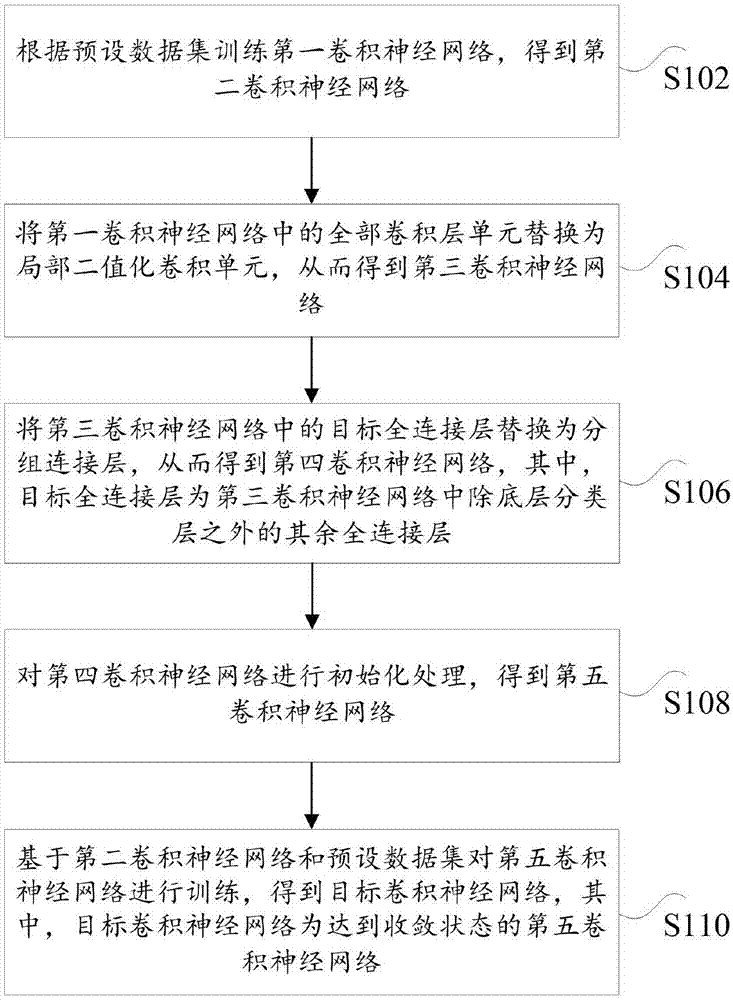

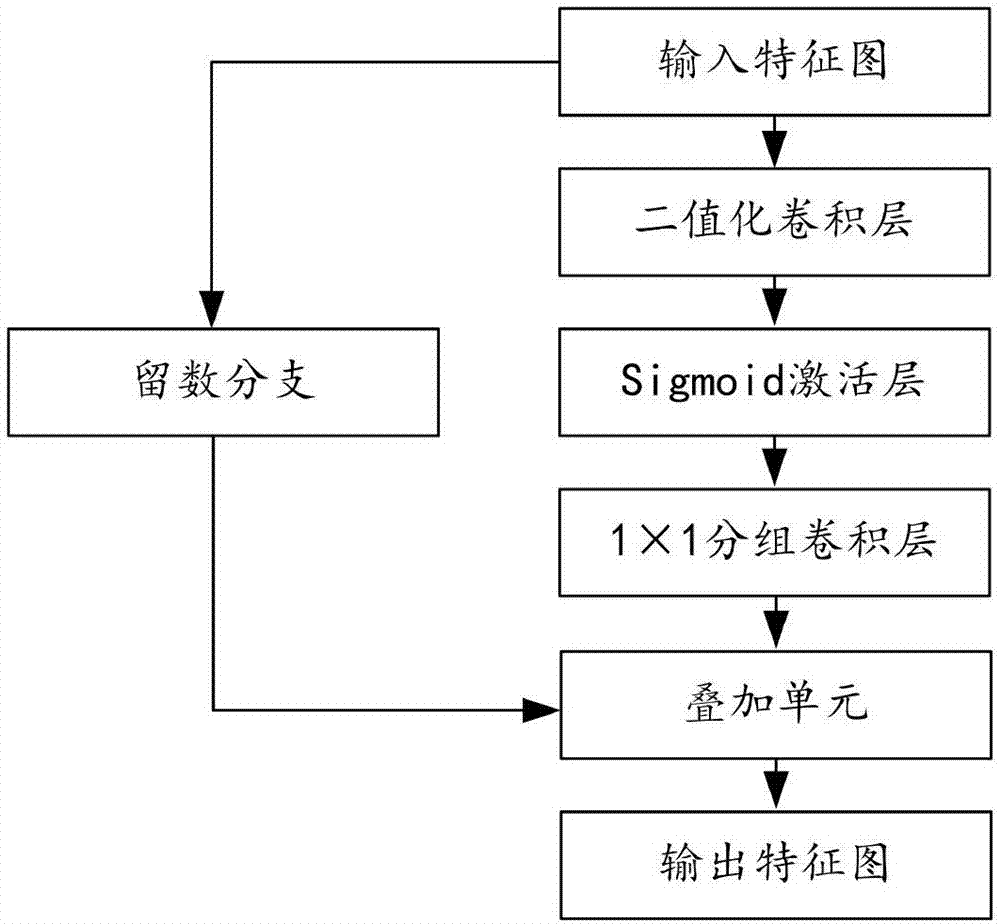

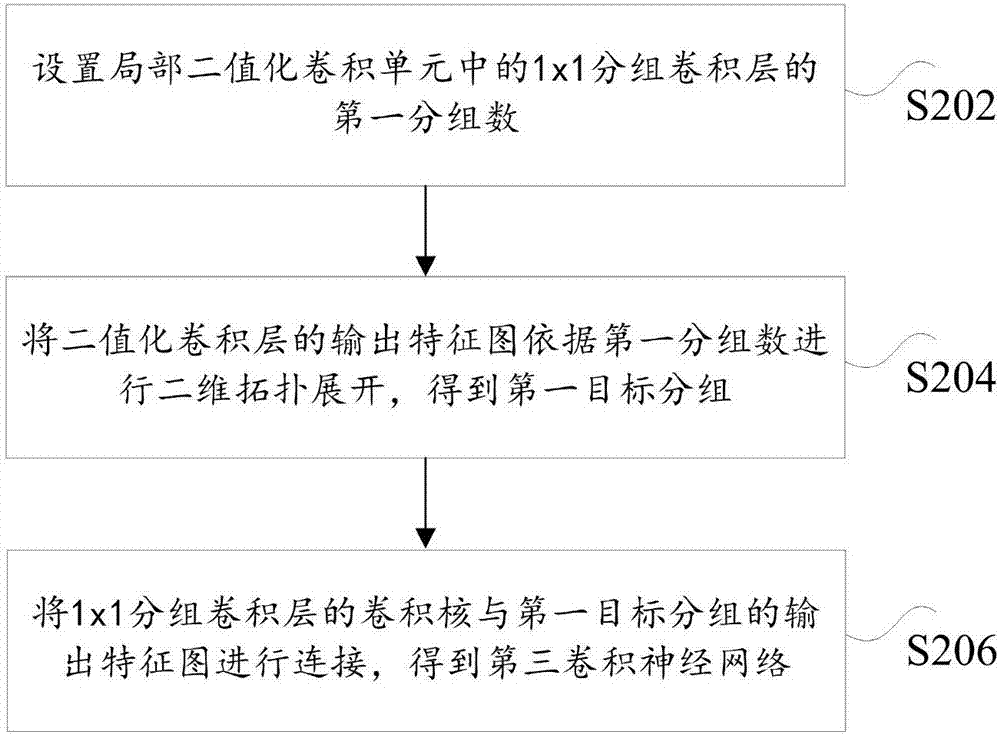

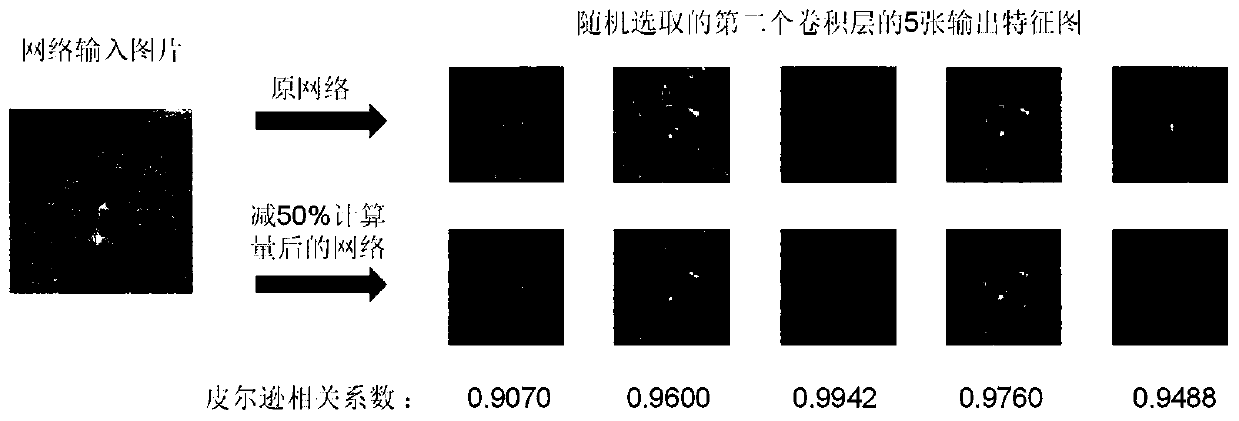

Local binary CNN processing method, device, storage medium and processor

InactiveCN107491787AAvoid the problem of excessive performance degradationImprove parametersCharacter and pattern recognitionNeural architecturesData setConvolution

The invention discloses a local binary CNN processing method, a device, a storage medium and a processor, wherein the method comprises the steps of training a first convolutional neural network according to a preset data set, and obtaining a second convolutional neural network; replacing all convolutional layer units in the first convolutional neural network by a local binary convolutional unit, thereby obtaining a third convolutional neural network; replacing objective total connecting layers in the third convolutional neural network by a grouping connecting layer, thereby obtaining a fourth convolutional neural network, wherein the objective total connecting layers are all total connecting layers except for a bottom classification layer in the third convolutional neural network; initializing the fourth convolutional neural network, thereby obtaining a fifth convolutional neural network; and training the fifth convolutional neural network based on the second convolutional network and a preset data set, thereby obtaining an objective convolutional neural network. The local binary CNN processing method, the device, the storage medium and the processor settle a technical problem of relatively low operation efficiency in the local binary convolutional neural network in prior art.

Owner:珠海习悦信息技术有限公司

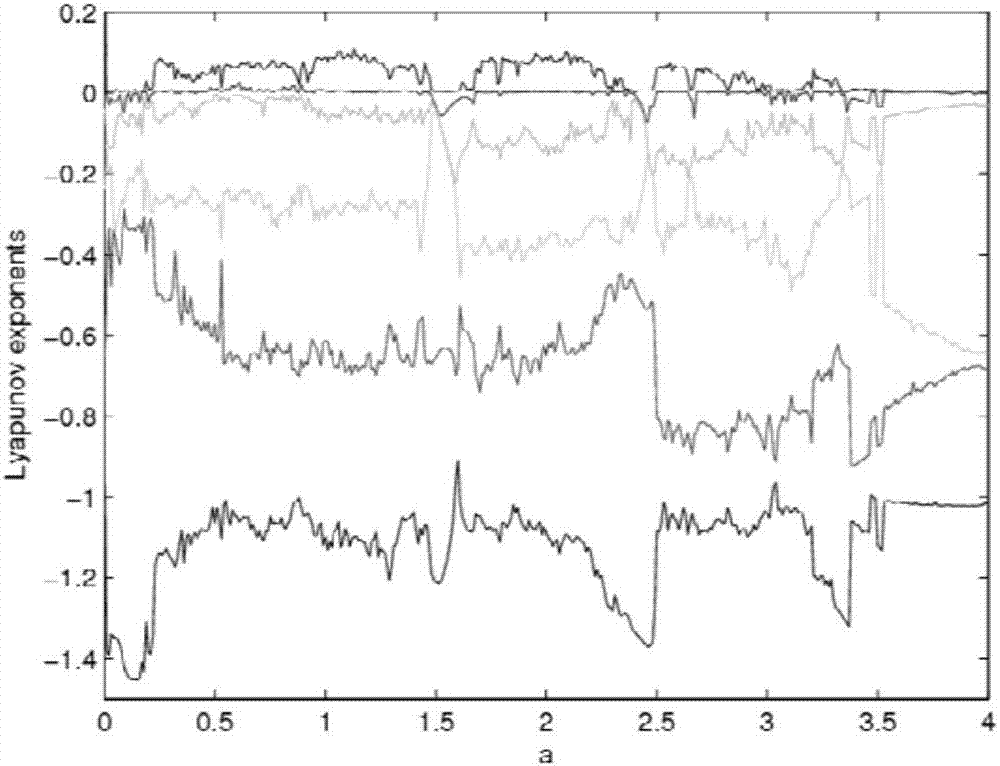

Hybrid memristor six-dimensional chaotic system and circuit

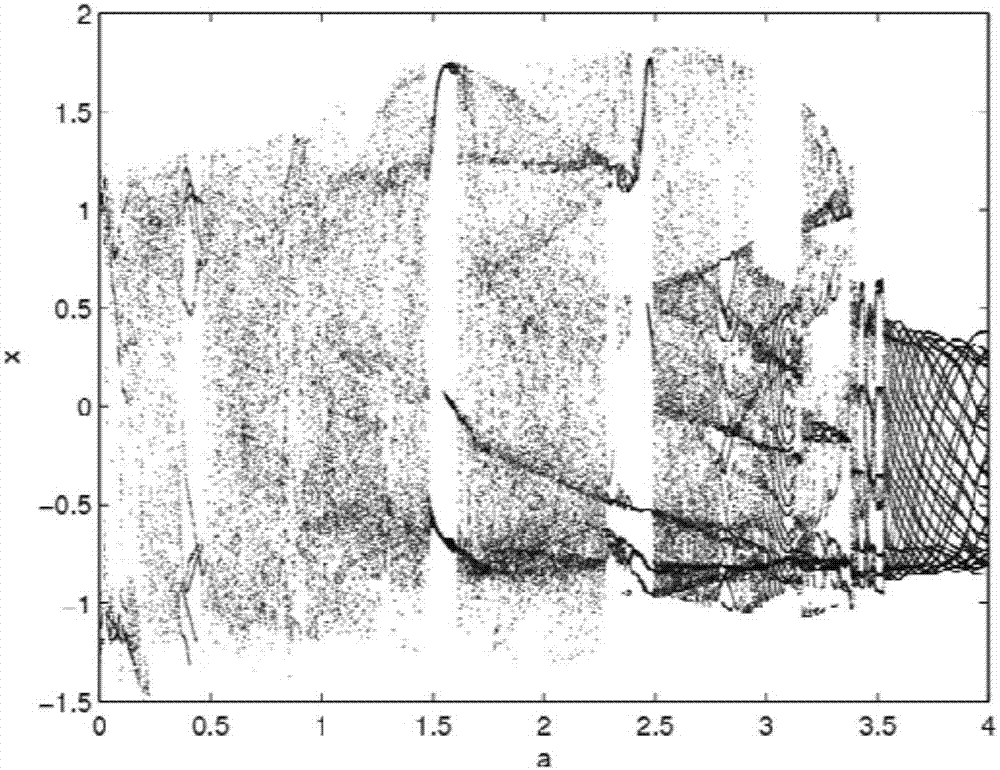

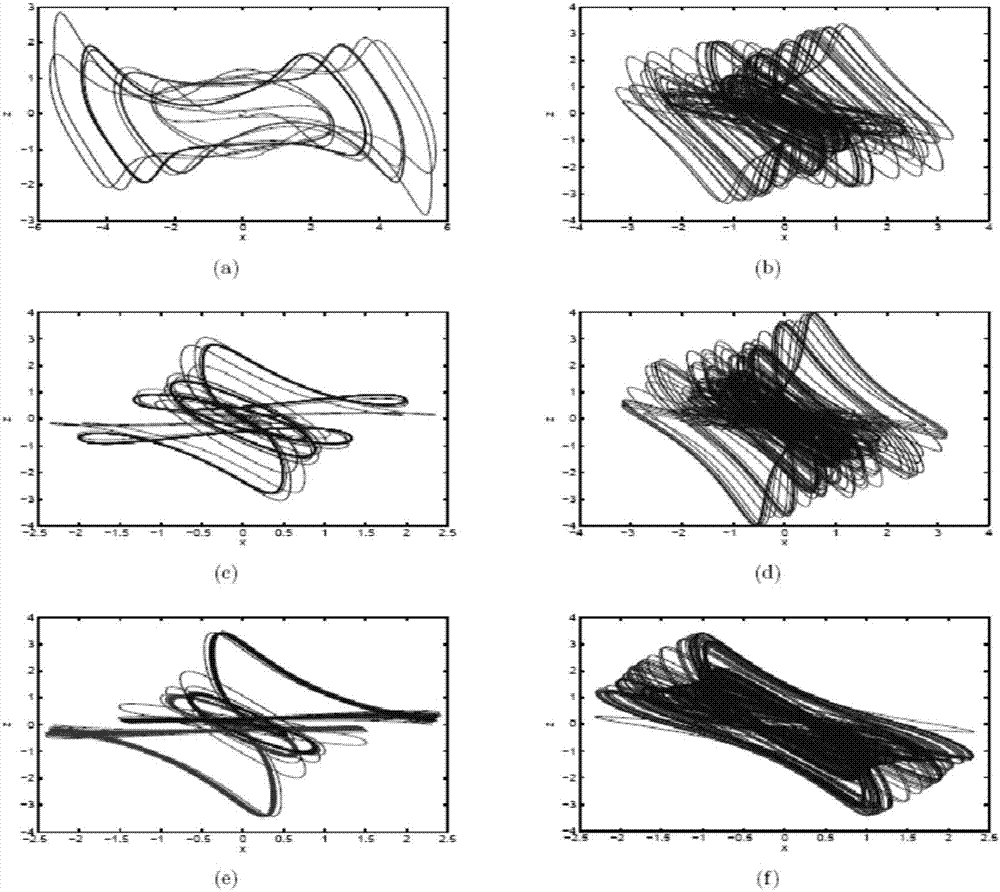

ActiveCN107147485AComplex topologyImprove securitySecuring communication by chaotic signalsCapacitanceElectrical resistance and conductance

The invention relates to a hybrid memristor six-dimensional chaotic system and a circuit, aiming to solve a problem that a topological structure of a low-dimensional memristor chaotic system is simple. The hybrid memristor six-dimensional chaotic system is built on a three-dimensional simplest memristor chaotic system, MATLAB software is used to verify bifurcation and Lyapunov indicator property, and a complex dynamic behavior of the hybrid memristor six-dimensional chaotic system is analyzed. A Multisim simulation software-based hybrid memristor six-dimensional chaotic circuit is built by using an inverting integral circuit formed by a resistor, a capacitor, a multiplier and an amplifier, a multiplication circuit and an inverting amplification circuit, the dynamic behavior of the circuit is verified, and experimental results prove that simulation results of Matlab and Multisim are consistent. Due to increase of variables and parameters, the hybrid memristor six-dimensional chaotic system has a more complex topological structure and the dynamic behavior thereof is hard to predict, so that confidential communication is safer and more reliable.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

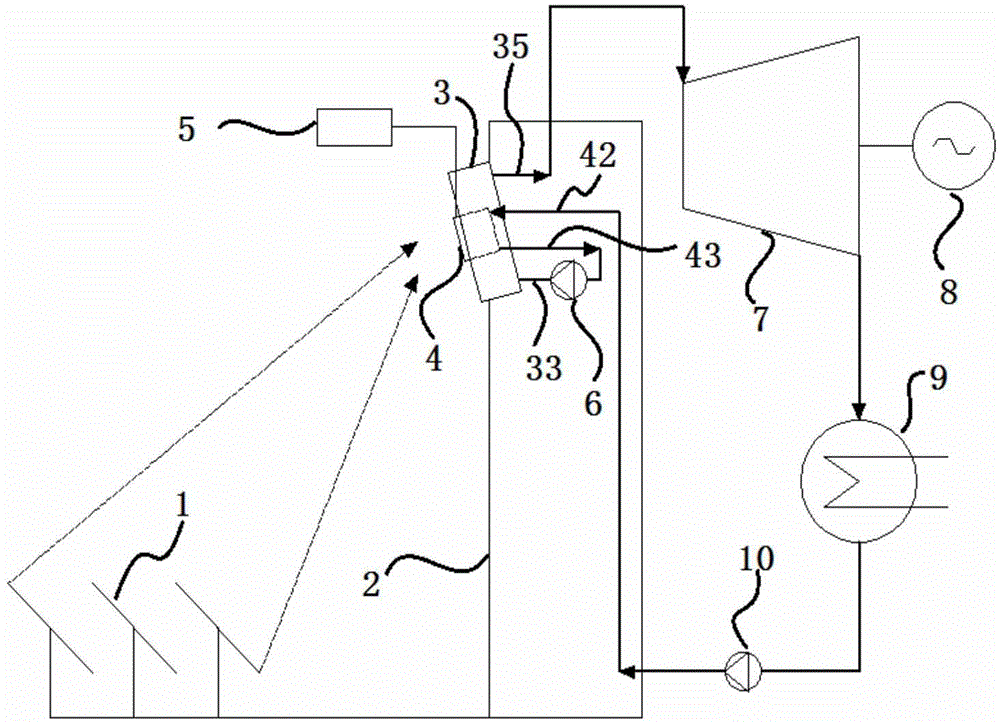

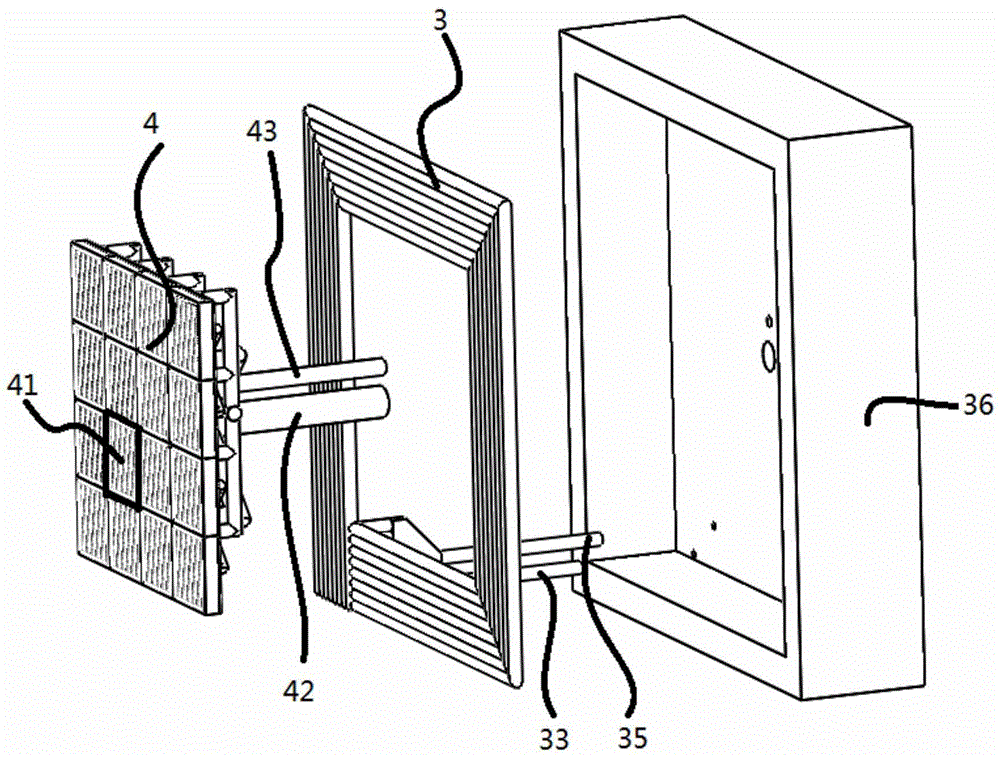

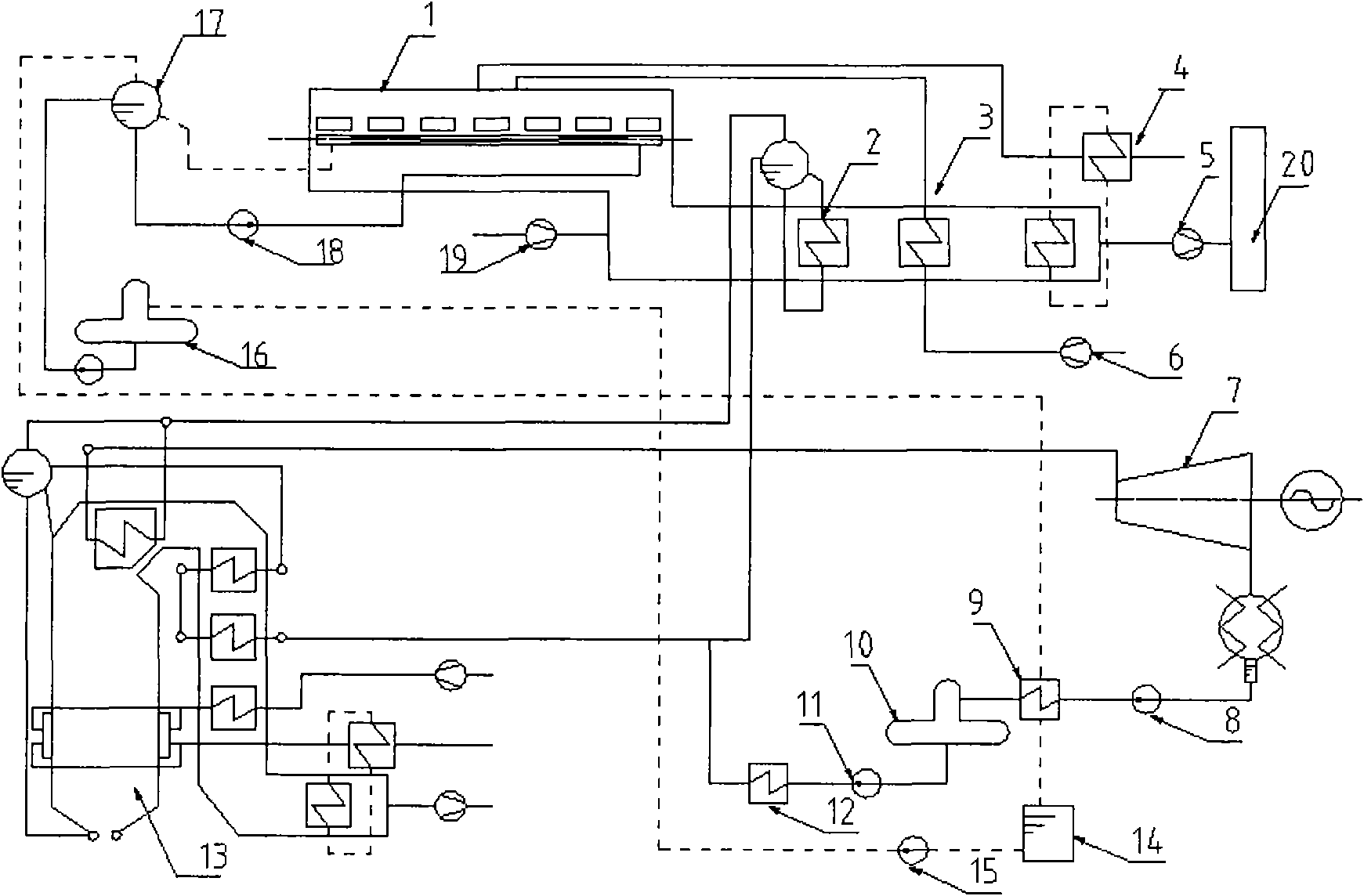

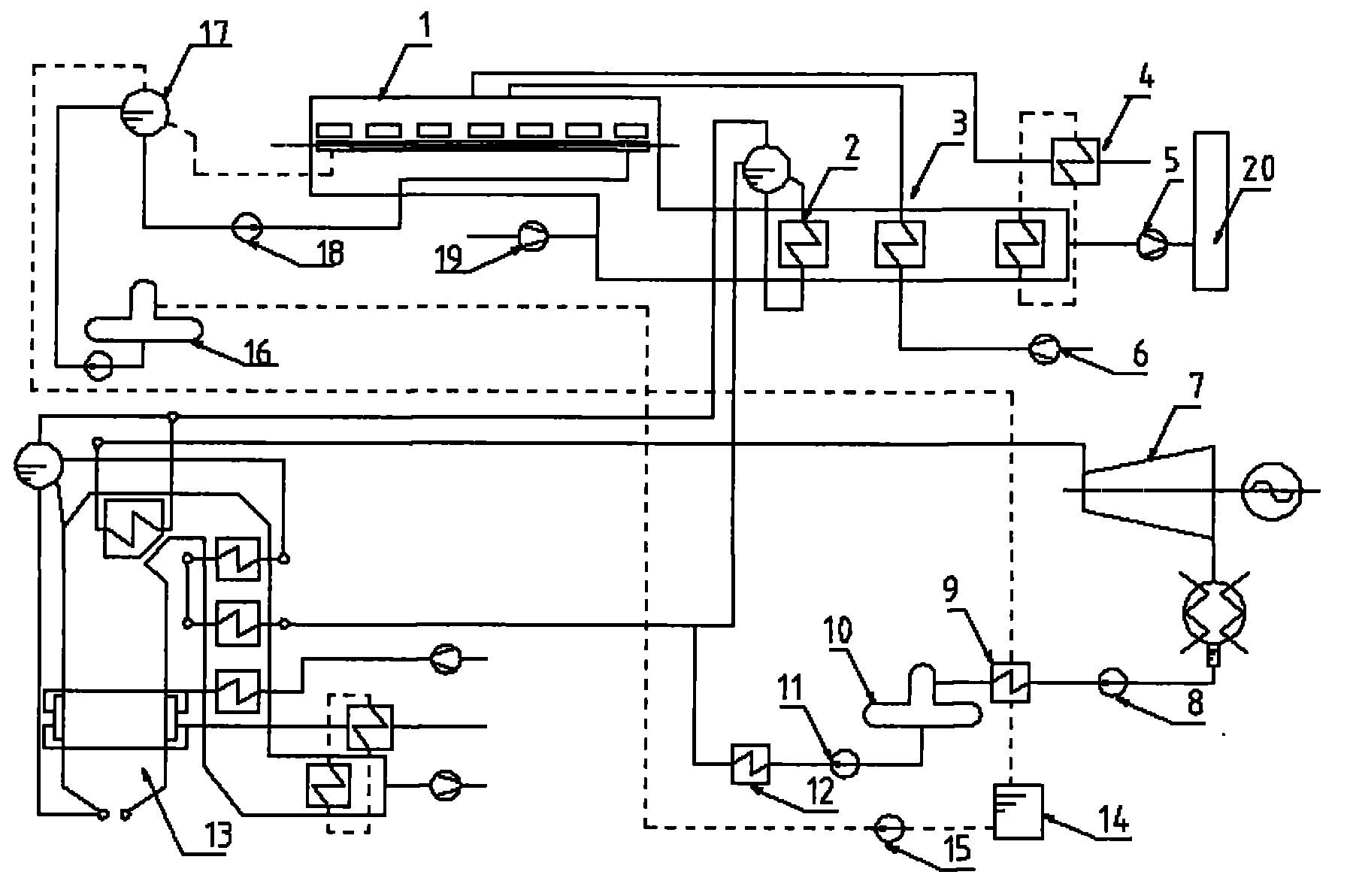

Concentrating photovoltaic and photo-thermal composite power generation system

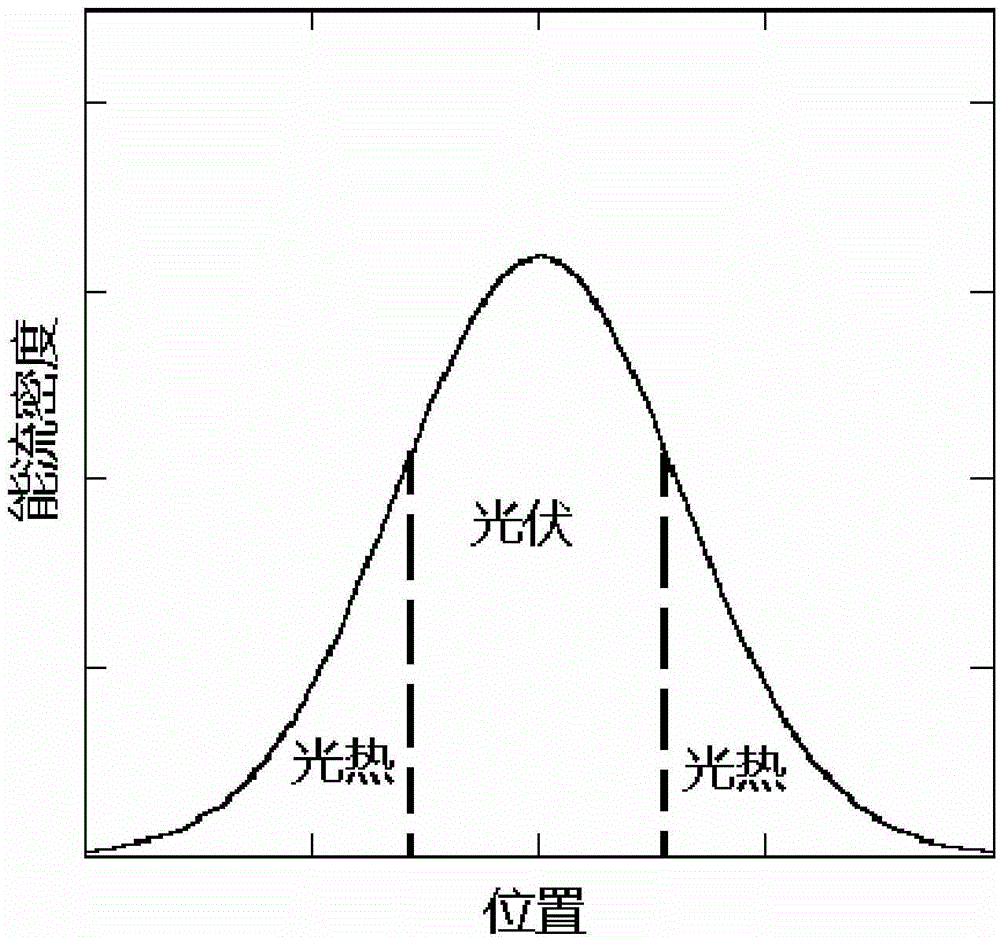

ActiveCN103607166AImprove parametersImprove efficiencyFrom solar energyPV power plantsHigh energyEnergy flux

The invention discloses a concentrating photovoltaic and photo-thermal composite power generation system, and belongs to the technical field of solar energy utilization. The system comprises a tracking concentrating system, a photovoltaic and photo-thermal module and a thermal cycle portion. The photovoltaic and photo-thermal module comprises a dense array battery module, a heat absorber module, a heat preservation layer, a connecting loop and a supporting structure. The heat absorber module is arranged on the periphery of the dense array battery module. The portion with the higher energy flux density in the center of a concentrating facula is projected to the surface of the dense array battery module, and the other portions are projected to the surface of the heat absorber module. After cooling liquid cools the dense array battery module, the temperature of the cooling liquid rises, the cooling liquid is used as a heat absorption working medium to be pumped into the heat absorber module to continuously absorb energy, steam with the certain temperature is generated, and electricity is generated through a thermal cycle. A secondary concentrator module can also be arranged on the periphery of the photovoltaic and photo-thermal module, and the optical characteristics of the system can be further improved by means of the secondary concentrator module. According to the concentrating photovoltaic and photo-thermal composite power generation system, the efficiency and economical performance of photovoltaic and photo-thermal power generation can be improved, and impact, caused by photovoltaic power generation, on a power grid can also be weakened.

Owner:恒基能脉新能源科技有限公司

Heating-furnace cogeneration system and method thereof

ActiveCN101788233AImprove steam parametersImprove power generation efficiencySteam useEnergy industryAir preheaterElectricity

The invention relates to a heating-furnace cogeneration system and a method thereof, and belongs to the field of waste energy and heat recovery. The cogeneration system comprises a heating furnace, a heating-furnace waste heat boiler, a heating-furnace air preheater, a heating-furnace heat-pipe coal gas preheater, a heating-furnace tail suction fan, a superheated steam boiler, a turbogenerator set and a chemical water system, wherein the heating-furnace tail is orderly provided with the heating-furnace waste heat boiler, the heating-furnace air preheater, the heating-furnace heat-pipe coal gas preheater and the heating-furnace tail suction fan along the fume flow direction, and used for recovering the fume waste heat of the heating furnace; the heating-furnace waste heat boiler is used for generating electricity; and the chemical water system is used for providing supplementary water for the heating-furnace waste heat boiler and the superheated steam boiler. The invention enables the superheated steam boiler to still ensure the low-load stable operation of the cogeneration system when heating furnace is to be rolled, increases the steam parameter of the heating-furnace waste heat generating equipment by utilizing the superheated steam boiler, and enhances the generating efficiency. The invention maximally recovers the waste heat of the heating furnace, thereby having favorable economic and environmental benefits and high values for application and popularization.

Owner:SHOUGANG CORPORATION

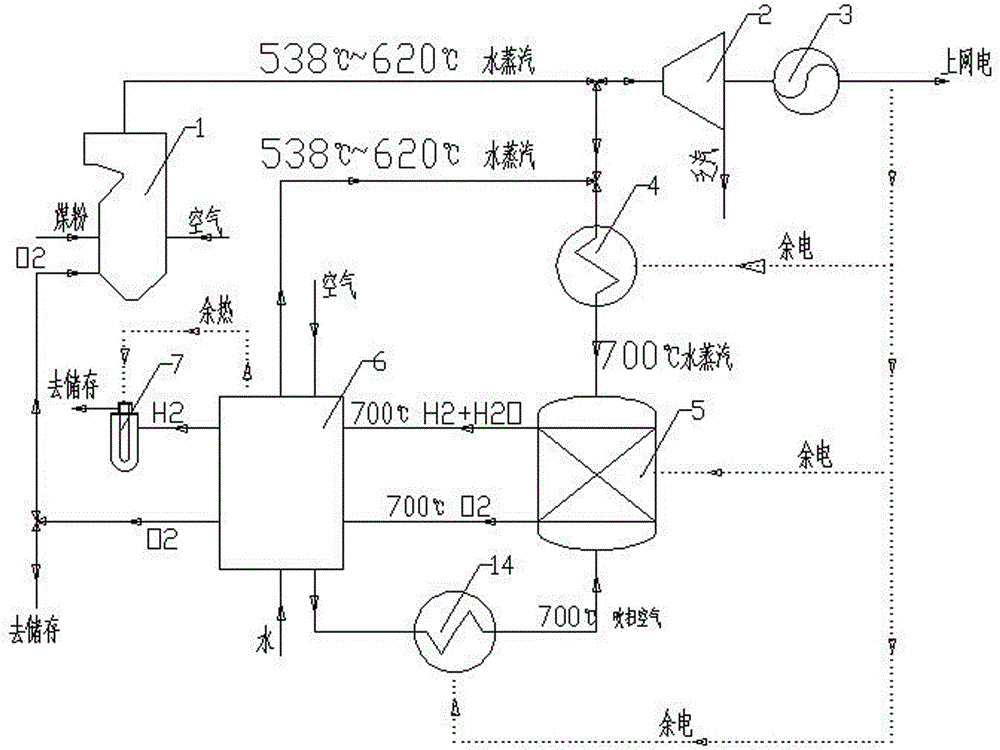

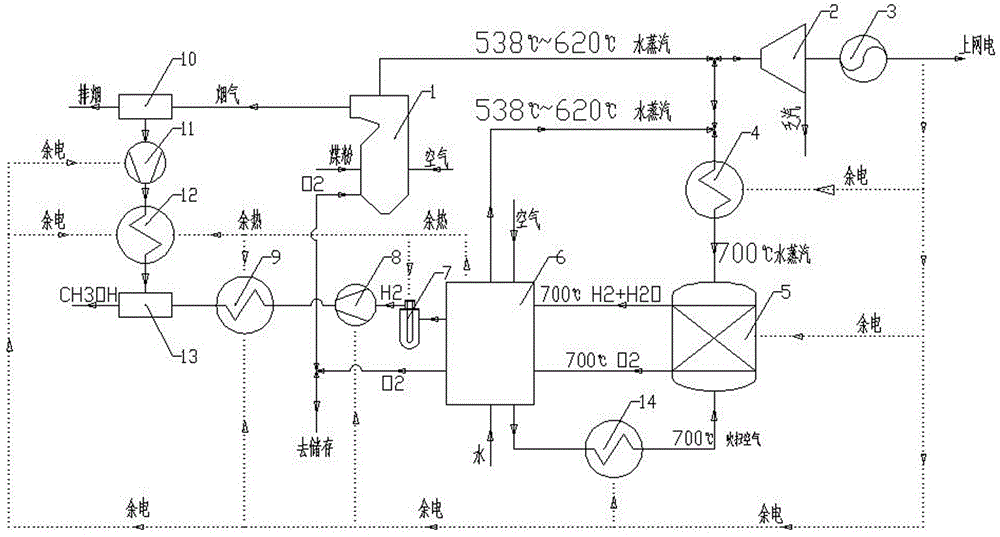

System and method for producing hydrogen and methyl alcohol by utilizing residual electricity and residual heat of coal-fired generating unit

The invention relates to a system and a method for producing hydrogen and methyl alcohol by utilizing residual electricity and residual heat of a coal-fired generating unit. The system comprises a boiler, a steam turbine and an electric generator, wherein the boiler produces water steam to drive the electric generator through the steam turbine to generate electricity. The system also comprises a water steam auxiliary electric heater, a high-temperature water steam electrolytic bath, a residual heat recovery device, a scavenging air auxiliary electric heater, a hydrogen compressor, a hydrogen heating device, a carbon dioxide collecting device, a carbon dioxide compressor, a carbon dioxide heating device and a methanol synthesis device. According to the method, a boiler main steam outlet is divided into two paths, wherein one path of steam enters the steam turbine for work to drive the electric generator to generate electricity; the other path of steam enters the water steam auxiliary electric heater so as to be heated to achieve the water steam electrolysis working temperature, and then enters the high-temperature water steam electrolytic bath to electrolyse; and a high-temperature hydrogen / water steam mixture is formed on an outlet at the cathode side of the electrolytic bath. The system and the method provided by the invention are reasonable in procedure, and efficiently utilize the residual electricity / the residual heat of the coal-fired generating unit to produce fuels such as the hydrogen and the methyl alcohol.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Lime kiln waste gas waste heat electricity generating system with by-product coal gas afterburning function

InactiveCN103344124AIncrease temperatureImprove working abilityIncreasing energy efficiencyMachines/enginesCooling towerSuperheater

The invention discloses a lime kiln waste gas waste heat electricity generating system with a by-product coal gas afterburning function. The lime kiln waste gas waste heat electricity generating system comprises a smoke valve, a waste heat boiler, a steam pocket, a turbine, a boiler water feeding pump, a condenser, a condensate water pump, a cooling tower, a deaerator, an electricity generator, an induced draft fan, an air blower, and a chimney. A combustion hearth, a high temperature super-heater, a low temperature super-heater, an evaporator and a coal economizer are sequentially arranged in the waste heat boiler from top to bottom, an outlet of the high temperature super-heater is connected with a steam inlet of the turbine through a pipeline, the waste heat boiler is provided with a lime kiln waste gas inlet and a by-product coal gas inlet, and an air blowing opening is additionally formed in an air inlet smoke pipe so as to provide oxygen needed by coal gas burning. The lime kiln waste gas waste heat electricity generating system with the by-product coal gas afterburning function can greatly increase smoke temperature, so that the temperature and the pressure of superheated steam at the inlet of the turbine are increased, and electricity generating capacity is improved.

Owner:广州智光节能环保有限公司

Self-cooled thermal power acting method

InactiveCN103775148AHigh thermal efficiencyUniversal useHeat pumpsJet pumpsThermal energyCyclic process

The invention relates to a self-cooled thermal power acting method and belongs to the field of thermal energy power. A working medium of a thermal power system absorbs heat from a heat source to act. The self-cooled thermal power acting method includes the temperature rising process in which after the pressure of the working medium which is in a low temperature state is boosted and the working medium is heated, the working medium becomes a power air source, the expansion acting process carried out after the power air source enters an expansion acting system and the heat releasing process in which heat of the low-temperature gas working medium which carried out expansion acting is further released. The thermal power system achieves the thermal power circulating process from the temperature rising process, the expansion acting process, the heat releasing process and the temperature rising process. A thermal pump process is used for cooling or liquefying the gas working medium which carried out expansion acting. When heat is released in the thermal pump process, the temperature or the pressure parameter of the working medium is lower than the maximum parameter of the power air source. In the expansion acting process, partial or overall heat which is released in the thermal pump process is absorbed and common acting is carried out. A heat returning process is adopted, so that the heat released by the system is absorbed in the system heat absorbing process. An air energy engine with practicability is obtained, and high-efficiency thermal power circulation of all sorts is achieved. Meanwhile, the invention provides a novel jetting air ejector and a novel thermal pump optimizing system and cost is reduced.

Owner:张玉良

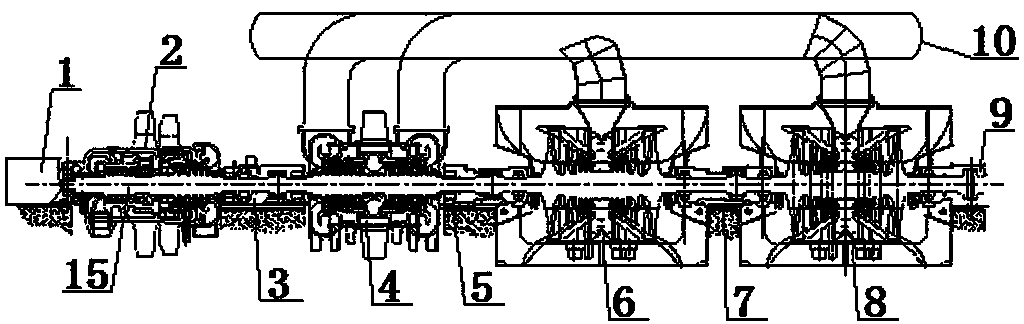

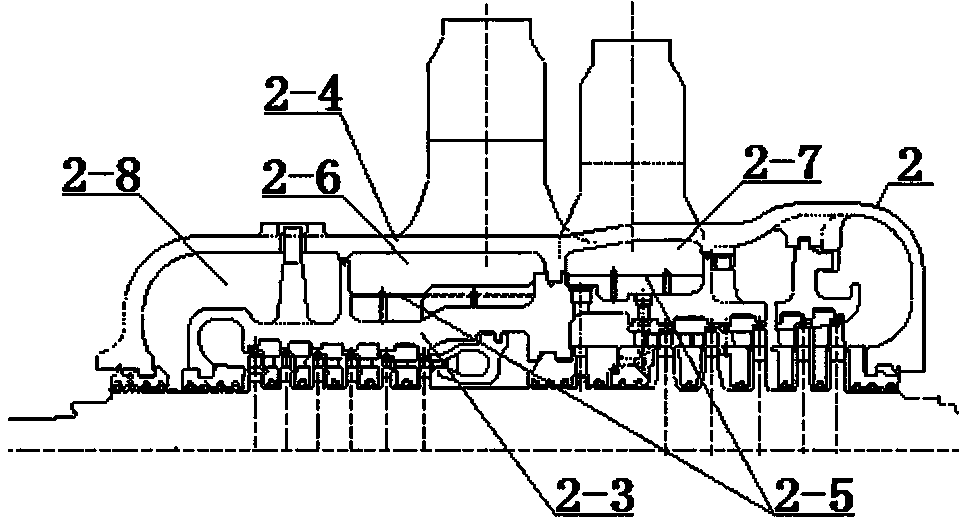

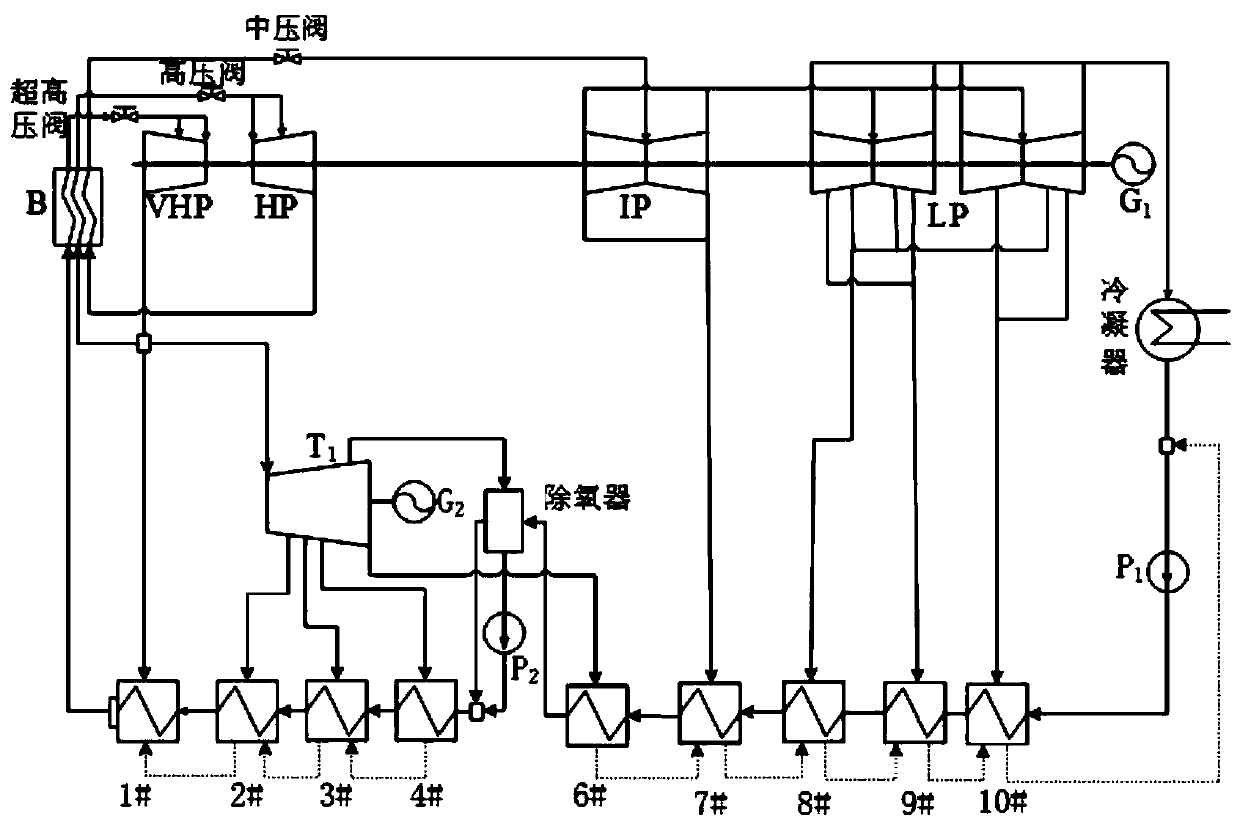

Ultra-supercritical secondary re-heating steam turbine set

InactiveCN103670550ADoes not affect safety and reliabilityDoes not affect runnabilityEngine componentsSteam engine plantsUltra high pressureEngineering

The invention discloses an ultra-supercritical secondary re-heating steam turbine set. The ultra-supercritical secondary re-heating steam turbine set comprises a first bearing box, an ultra high pressure-high pressure cylinder, a second bearing box, a medium-pressure cylinder, a third bearing box, a first low-pressure cylinder, a fourth bearing box, a second low-pressure cylinder and a turning gear box which are assembled on a rotor in sequence. The capacity of the steam turbine set is 1000-1300MW, the ultra high pressure-high pressure cylinder is of a cylinder combined structure, the pressure of a steam inlet of an ultra high pressure part is 30-35MPa, the temperature is 600 DEG C, the pressure of a primary re-heating steam inlet of a high pressure part is 10MPa, the temperature is 610-630 DEG C, the medium-pressure cylinder, the first low-pressure cylinder and the second low-pressure cylinder are respectively of a double-flow-division structure, the medium-pressure cylinder provides steam for the first low-pressure cylinder and the second low-pressure cylinder respectively through communication pipes, the pressure of a secondary re-heating steam inlet of the medium-pressure cylinder is 2.8MPa, and the temperature is 610-630 DEG C. The ultra-supercritical secondary re-heating steam turbine set has the advantages of being large in capacity, high in parameter, small in occupied space, low in investment cost, stable and reliable in operation and obvious in economical benefit, saving energy, reducing consumption and the like.

Owner:DONGFANG TURBINE CO LTD

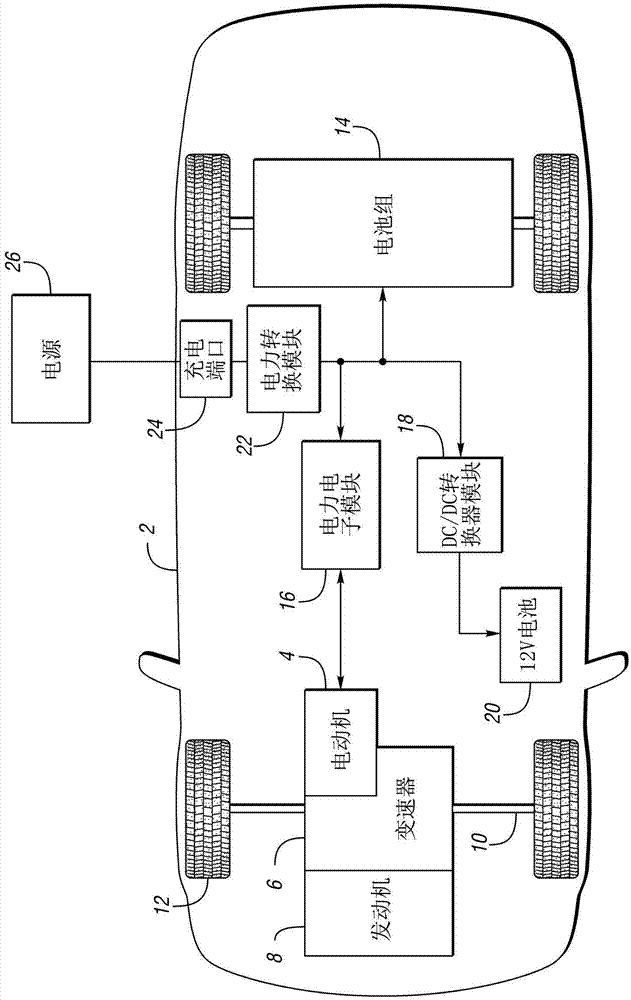

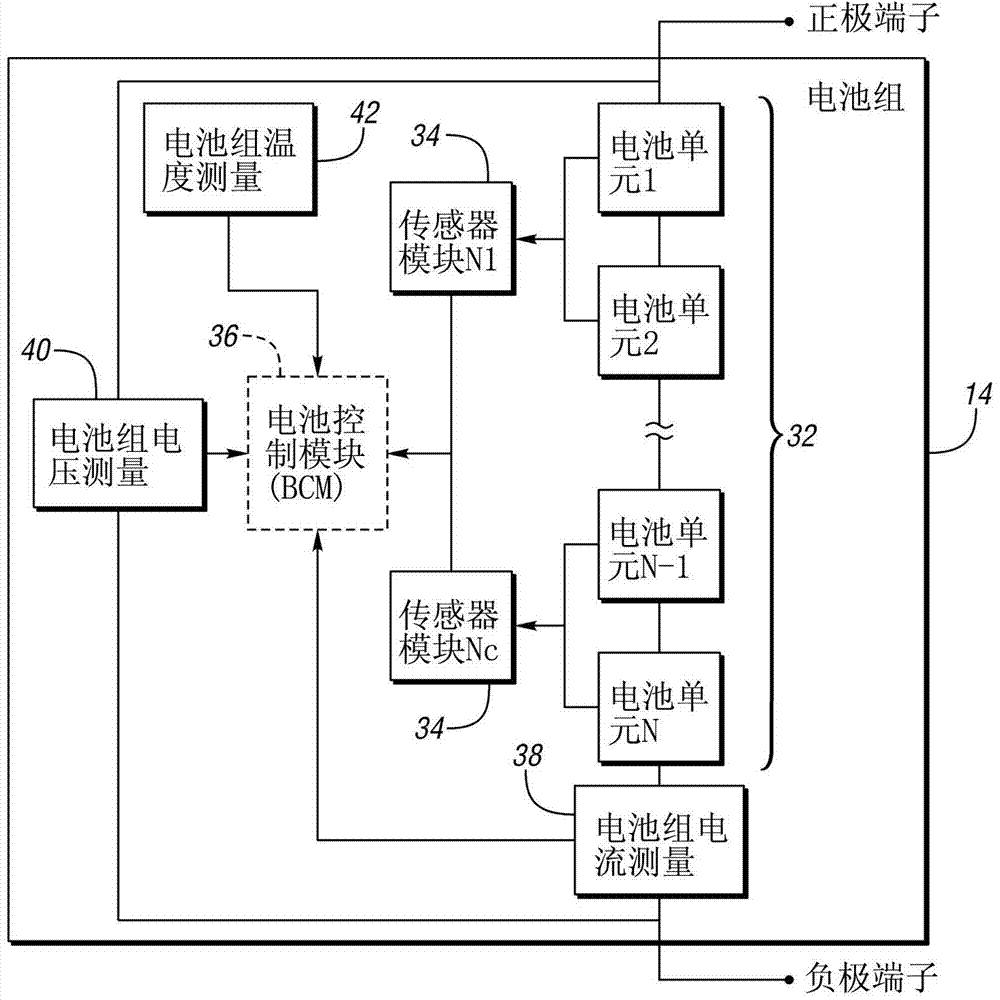

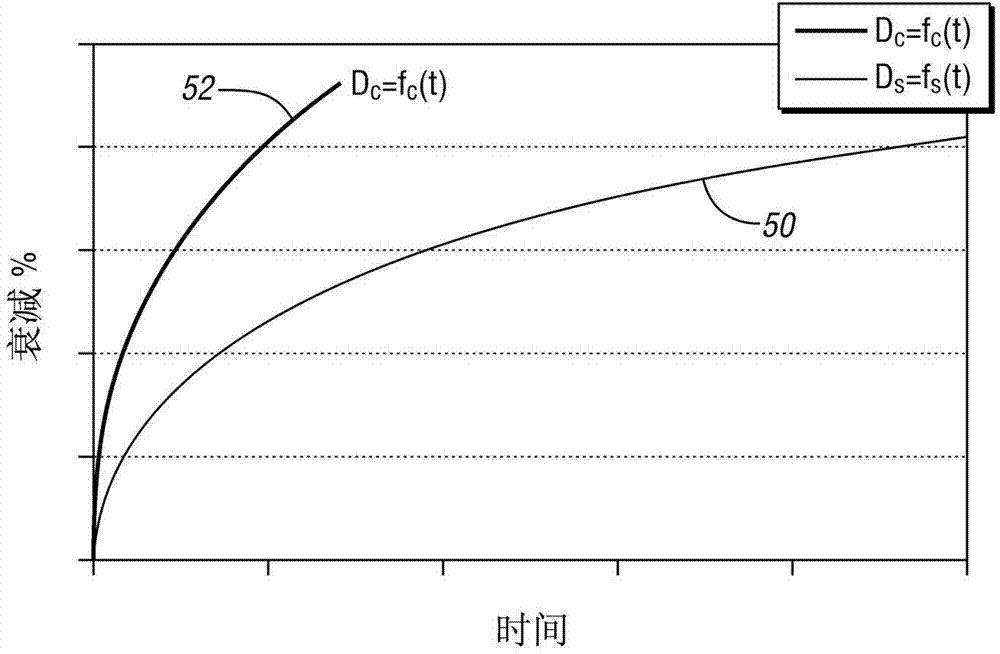

Vehicle and battery degradation accumulation methods

ActiveCN104723895AImprove parametersElectrical testingCells structural combinationBattery degradationEngineering

A vehicle includes a traction battery subject to alternating cycling and storage modes and a controller. The controller is programmed to calculate an accumulated degradation for the traction battery based on a degradation profile for the traction battery. The degradation profile defines degradation accumulated over time and may differ based on the mode and temperature. The initial degradation value includes the accumulated degradation for the present mode and at least a portion of the accumulated degradation for the other mode. Degradation is then accumulated according to the degradation profile starting from the initial degradation value. The amount of accumulated degradation from the other mode that is included may vary based on the mode and the accumulated degradation.

Owner:FORD GLOBAL TECH LLC

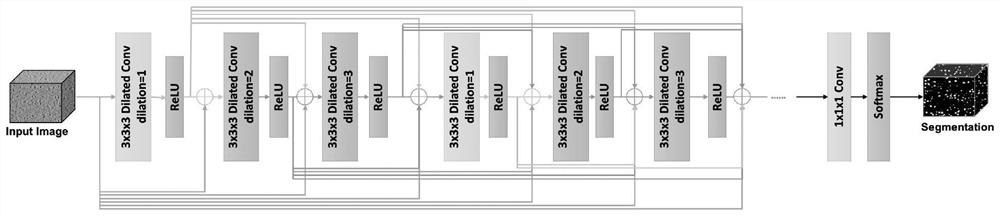

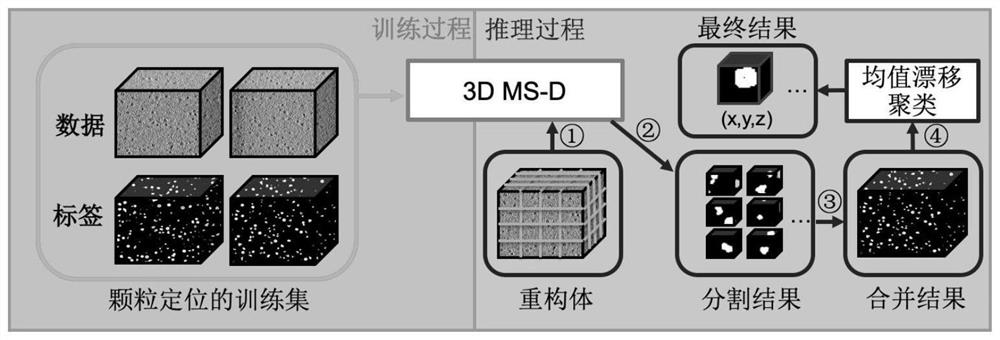

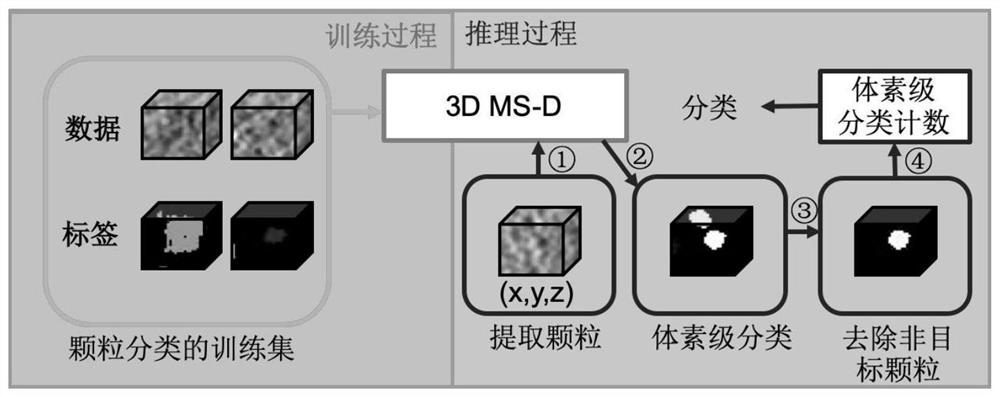

Three-dimensional particle category detection method and system based on convolutional neural network

ActiveCN112001218AFew parametersImprove parametersNeural architecturesICT adaptationAlgorithm3d image

The invention provides a three-dimensional particle category detection method and system based on a convolutional neural network. The method comprises the following steps: constructing a three-dimensional mixed-scale dense convolutional neural network comprising a mixed-scale three-dimensional extended convolutional layer, dense connection and a loss function, training the convolutional neural network by using a three-dimensional frozen electron tomography image marked with the particle coordinates to obtain a particle selection model, and training the convolutional neural network by using thethree-dimensional frozen electron tomography image marked with the particle category to obtain a particle classification model; acquiring the three-dimensional frozen electron tomography image through a sliding window to obtain to-be-detected three-dimensional reconstructed subareas, predicting each subarea through the particle selection model, and combining prediction results of the subareas toobtain coordinates of each particle in the three-dimensional frozen electron tomography image; and extracting a three-dimensional image of each particle according to the coordinate of each particle, and inputting the three-dimensional image of each particle into the particle classification model to obtain the category of each particle.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

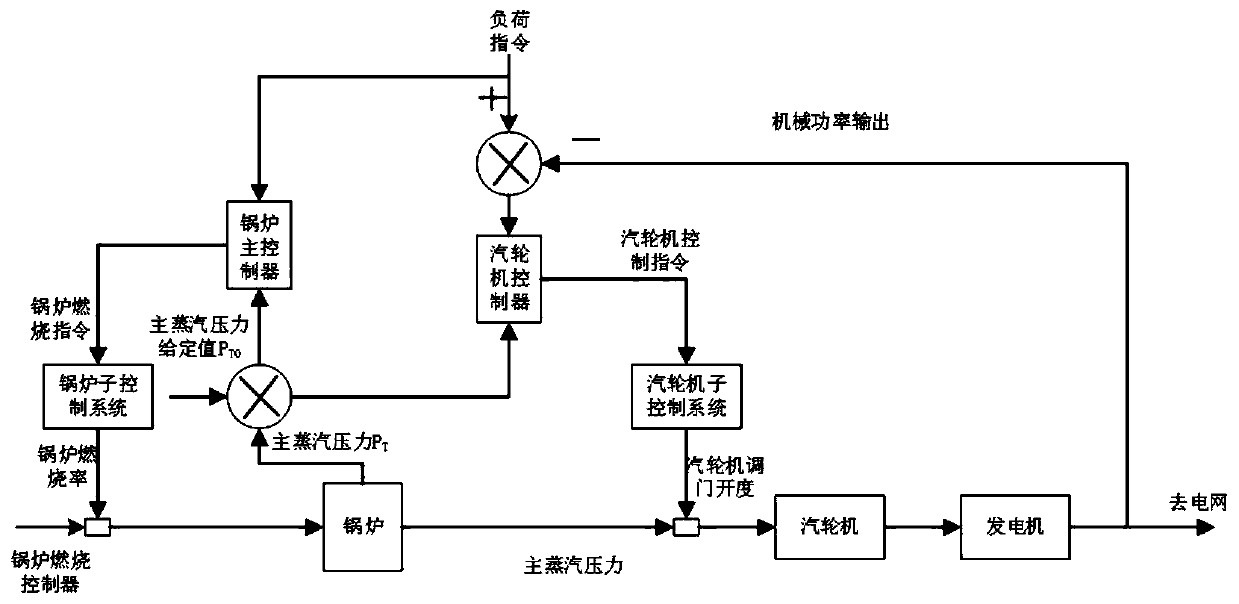

Control system and method for ultra-supercritical secondary reheating unit to participate in power grid primary frequency modulation

PendingCN110792482AAchieve a FMIncrease capacityBoiler controlEngine componentsUltra high pressureControl system

The invention discloses a control system and method for an ultra-supercritical secondary reheating unit to participate in power grid primary frequency modulation. The system comprises an ultrahigh-pressure cylinder regulation valve, a high-pressure cylinder regulation valve, a medium-pressure cylinder regulation valve, a first steam supplementing valve and a second steam supplementing valve; ultrahigh-pressure cylinder regulation valve, the high-pressure cylinder regulation valve and the medium-pressure cylinder regulation valve of a secondary reheating unit can be controlled to simultaneouslyparticipate in power grid primary frequency modulation in a steam supplementing regulation mode. When the practical load of a power grid is higher or lower than a rated load, the frequency of the power grid deflects for 50 HZ; the deflection change of the frequency of the power grid is received by the control system; the opening amplitudes of the ultrahigh-pressure cylinder regulation valve, thehigh-pressure cylinder regulation valve and the medium-pressure cylinder regulation valve are controlled, and the steam inlet flow of each cylinder is changed, so that the mechanical power output of asecondary reheating turbine is changed; and practical power output is matched with the load of the power grid, so that primary frequency modulation of the power grid is realized.

Owner:XI AN JIAOTONG UNIV

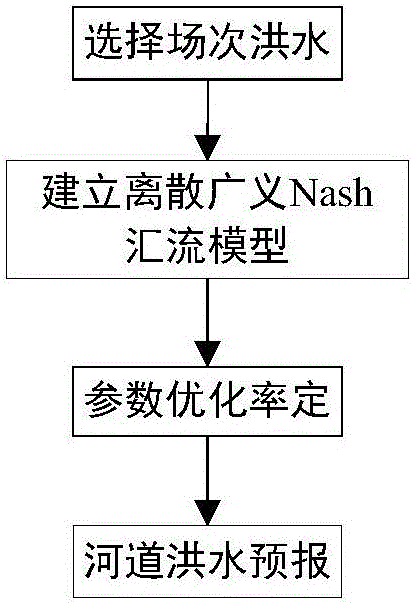

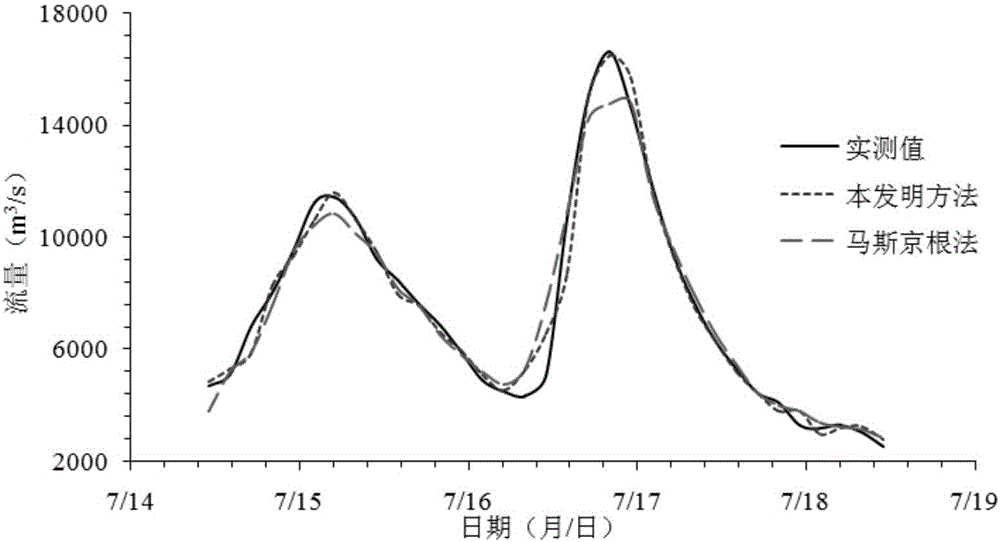

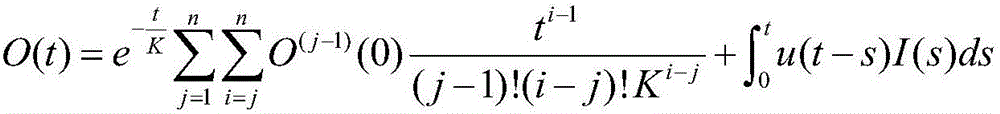

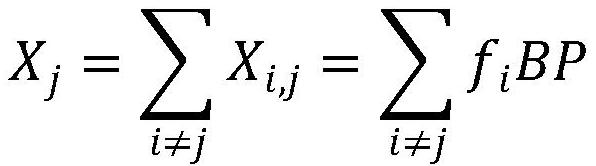

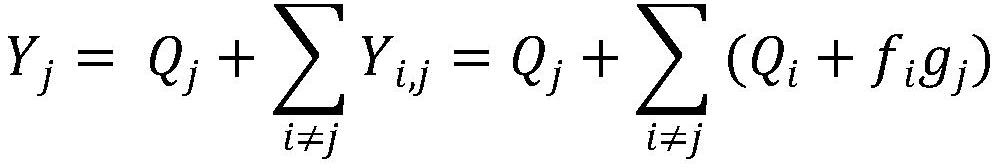

River flood forecasting method based on discrete generalized Nash routing model

ActiveCN106803131AImprove forecast accuracyImprove parametersClimate change adaptationForecastingRouting modelWeight coefficient

The invention discloses a river flood forecasting method based on a discrete generalized Nash routing model. By introducing the detention storage curve, simplifying a generalized Nash routing model, and establishing a discrete generalized Nash routing model, a river flood forecasting method is provided based on this model. The method expresses the outflow process of a river lower section as a linear combination of the inflow at the beginning and the end of a period and the outflow of the current time and a plurality of previous time moments, and obtains a weight coefficient according to the detention storage curve. The river flood forecasting method based on a discrete generalized Nash routing model, because integrating some historical effective information, can improve forecasting accuracy, is simple and visual, and can be easily popularized and applied in engineering practice.

Owner:HUAZHONG UNIV OF SCI & TECH

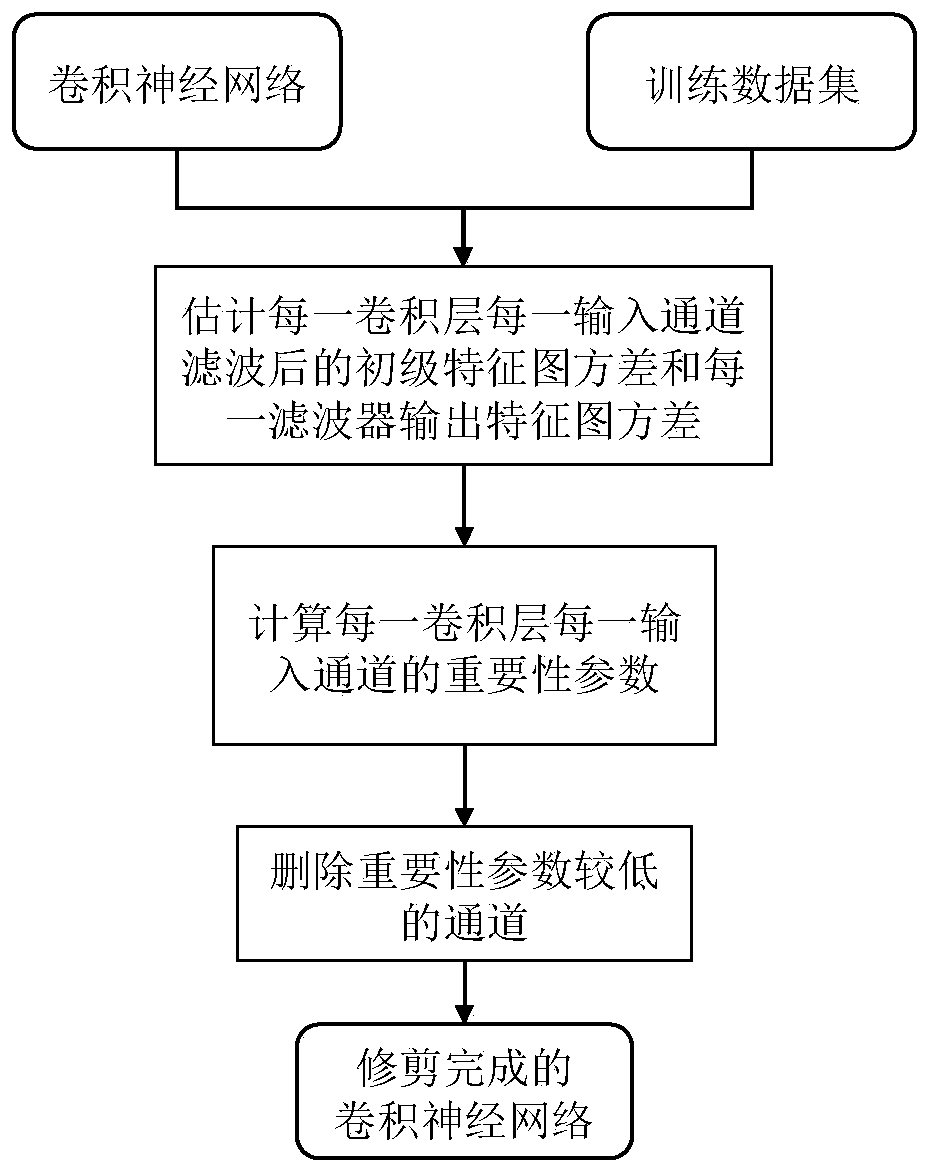

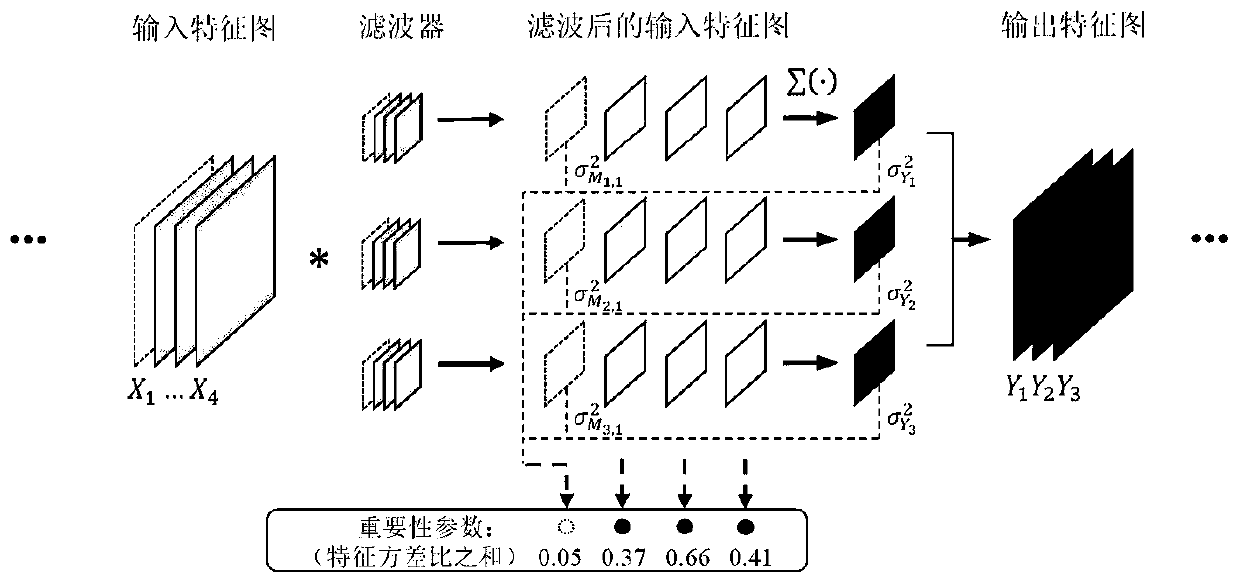

Convolutional neural network channel pruning method based on characteristic variance ratio

InactiveCN111144551AInterpretableImprove pruning efficiencyNeural architecturesData setNetwork structure

The invention relates to a convolutional neural network channel pruning method based on a characteristic variance ratio. Firstly, a data set is trained; estimating the variance of the primary featuremap of each input channel in each layer after being filtered by the convolution kernel corresponding to the input channel in each filter and the variance of the output feature map corresponding to each filter; according to the sum of the ratio of the variance of each primary characteristic pattern of each input channel in each layer after being filtered by different filters to the variance of theoutput characteristic pattern of the filter corresponding to the primary characteristic pattern; and finally, performing global channel pruning on the convolutional neural network according to the importance parameter of each input channel of each layer. Compared with a traditional channel pruning method, the method has the advantages that interpretability is achieved, extra hyper-parameters are not introduced, and the pruned network structure does not need to be defined manually.

Owner:ZHEJIANG UNIV

High-parameter waste incineration boiler with reheating function

ActiveCN105953231AImprove sealingHigh thermal efficiencyCasings/liningsSteam superheatersSpray coatingEconomic benefits

The invention relates to waste incineration boilers used for power generation and steam supply, in particular to a high-parameter waste incineration boiler with a reheating function. According to the high-parameter waste incineration boiler with the reheating function, the heat efficiency of the boiler and the overall power generation efficiency of a power plant can be effectively improved, so that the economic benefits of the power plant are greatly increased. The high-parameter waste incineration boiler comprises a hearth. The hearth sequentially communicates with a first perpendicular channel, two perpendicular reburning chambers, a horizontal flue and tail perpendicular flues. A reheater, a high-temperature superheater, a medium-temperature superheater and a low-temperature superheater are sequentially arranged in the horizontal flue. The reheater is provided with a spraying coating or is made of an anti-corrosion material. The tail perpendicular flues are each internally provided with coal economizers.

Owner:WUXI HUAGUANG BOILER

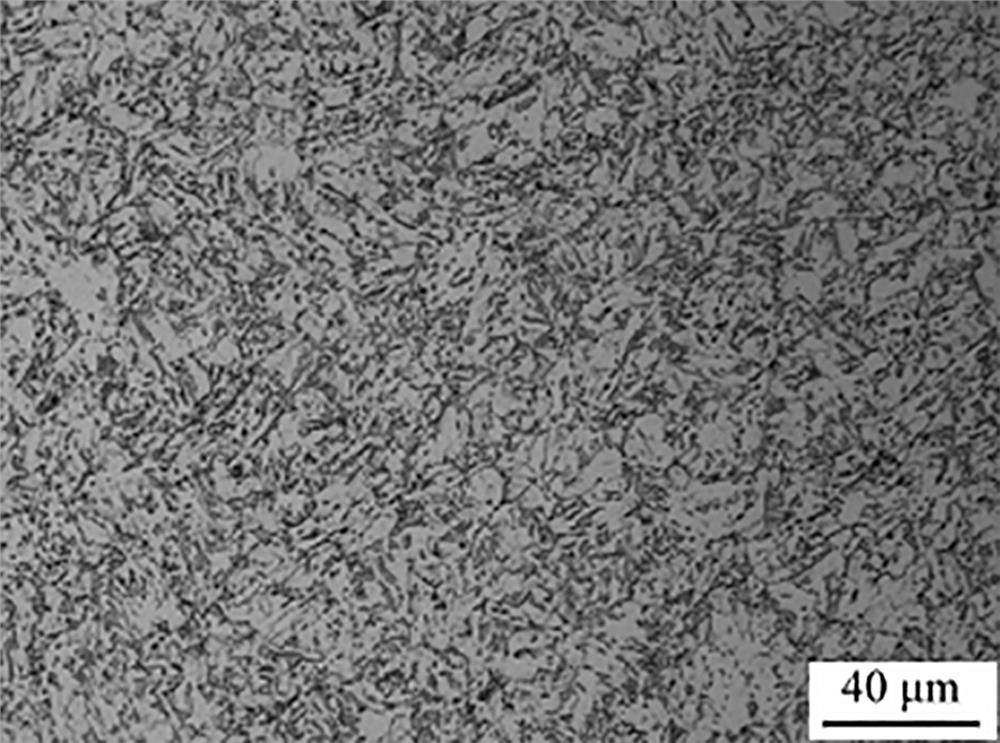

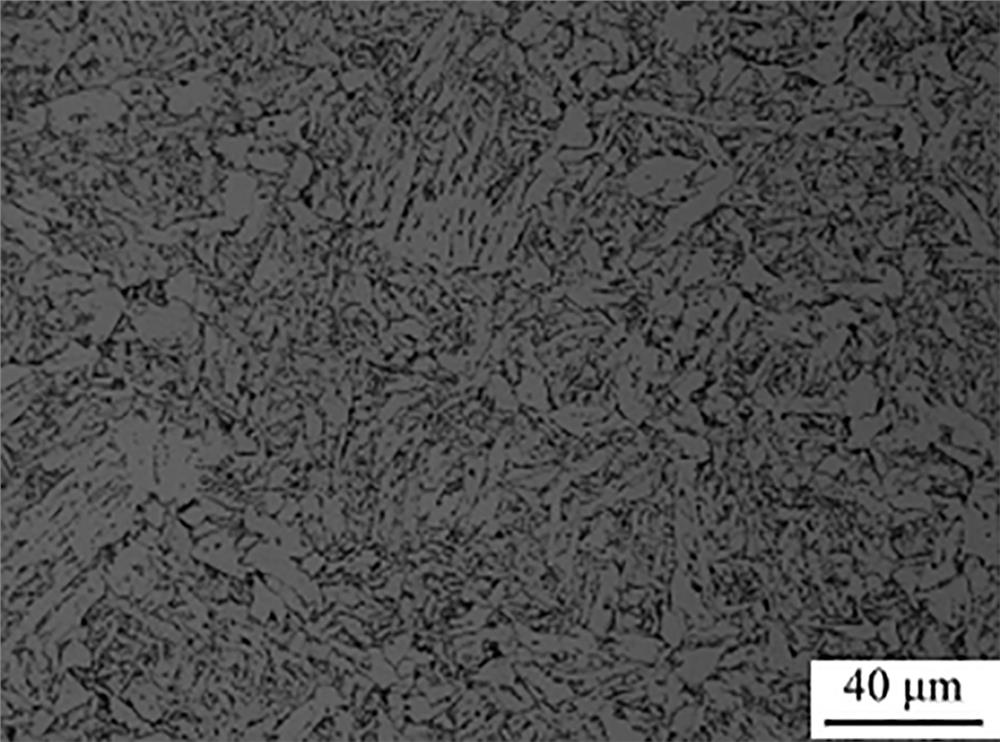

500MPa-class weather-resistant bridge steel with impact power being not lower than 54J in welded heat-affected zone at minus 40 DEG C

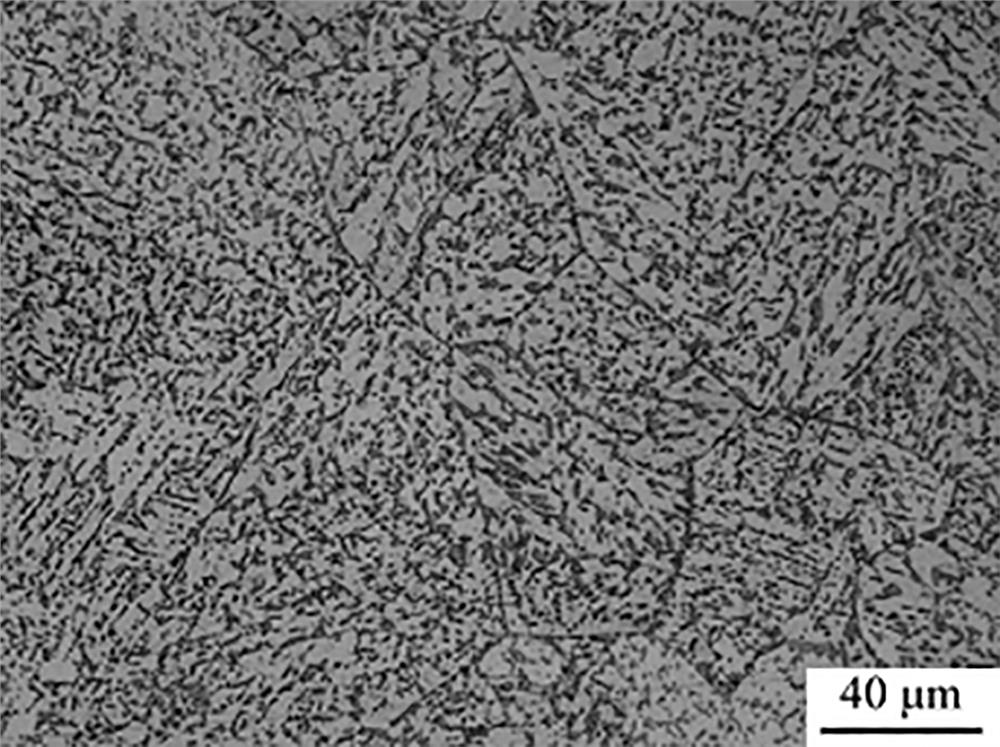

ActiveCN111996460AEasy to implementThe production process is simple and easy to controlFurnace typesHeat treatment furnacesHeat-affected zoneChemical composition

The invention discloses a 500MPa-class weather-resistant bridge steel with impact power being not lower than 54J in a welded heat-affected zone at minus 40 DEG C. The weather-resistant bridge steel isprepared from the chemical components in percentage by weight: 0.04 to 0.08 percent of C, 0.20 to 0.40 percent of Si, 1.35 to 1.70 percent of Mn, 0.40 to 0.70 percent of Cr, 0.25 to 0.65 percent of Ni, 0.25 to 0.40 percent of Cu, 0.05 to 0.20 percent of Mo, 0.010 to 0.050 percent of Nb, 0.010 to 0.030 percent of V, 0.010 to 0.040 percent of Ti, 0.020 to 0.035 percent of Al, 0.0012 to 0.0050 percent of Ca, 0.0035 to 0.0080 percent of N, less than or equal to 0.0040 percent of O, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, and the balance Fe and inevitable impurities. According to the weather-resistant bridge steel provided by the invention, under the condition that the conventional electric-arc welding heat input ranges from 15 to 40Kj / cm, a structure of the welded heat-affected zone is formed by acicular ferrite, granular bainite and M-A components, so that the impact power of the welded heat-affected zone at minus 40 DEG C is not lower than 54J, the 500MPa-class weather-resistant bridge steel is weather-resistant and easy to weld, and the stable industrial production can be realized.

Owner:YANSHAN UNIV

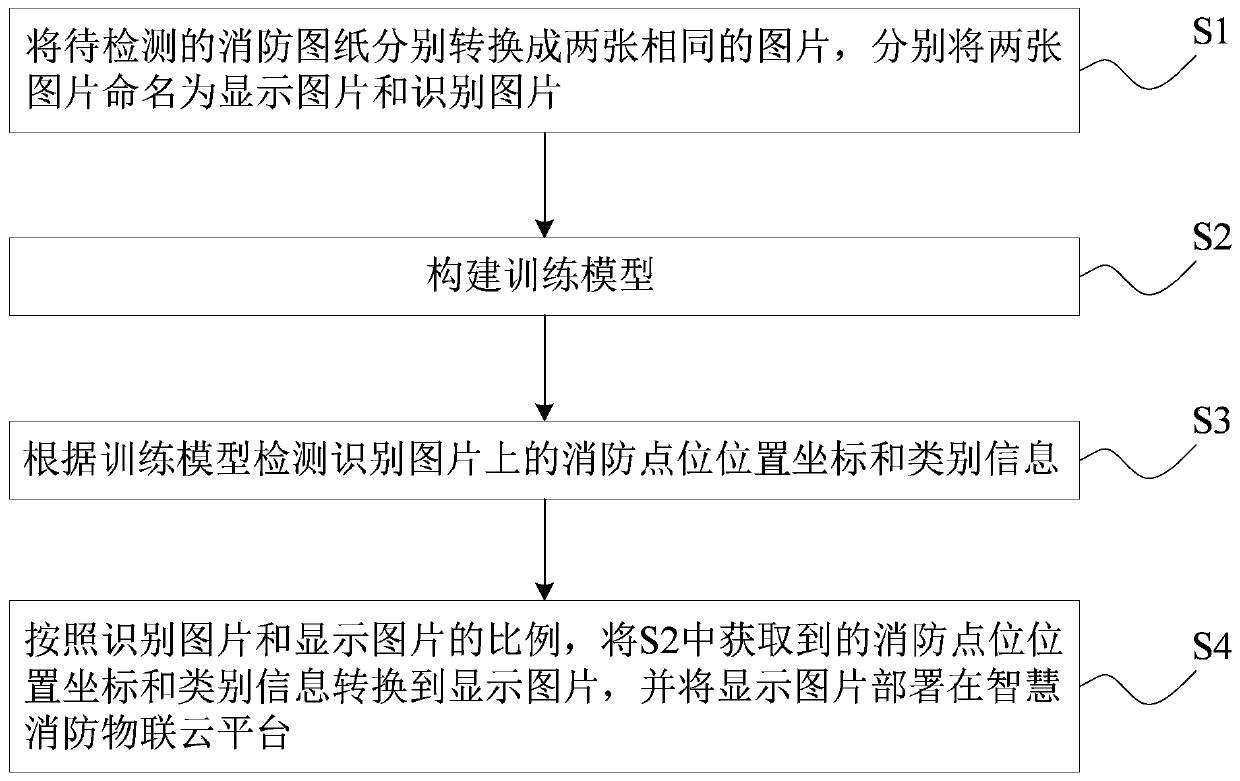

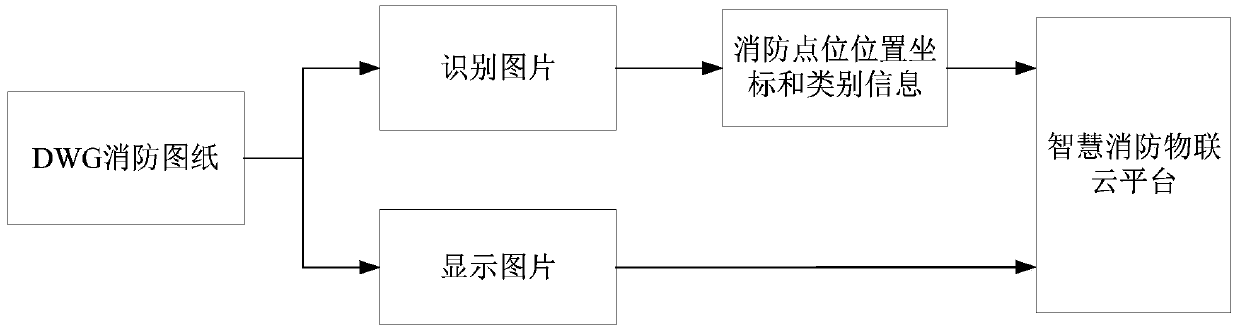

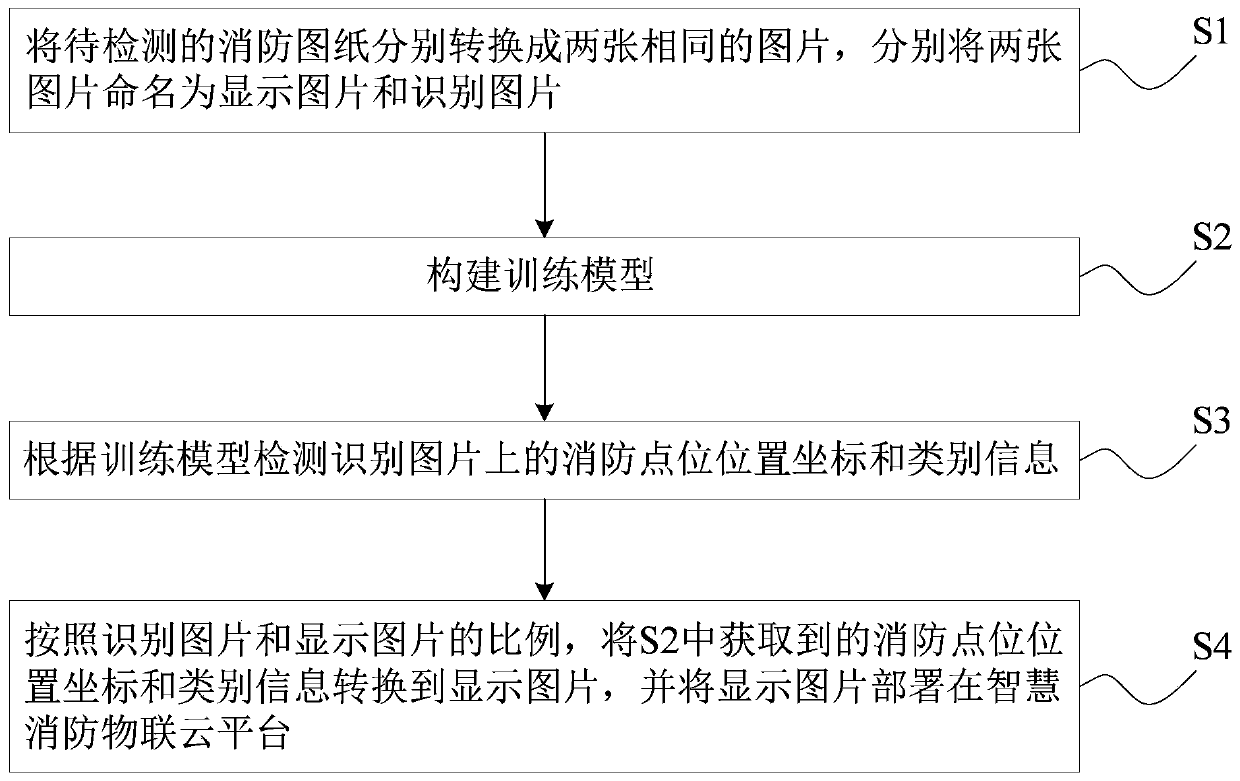

Fire-fighting point location automatic layout method applied to cloud platform

PendingCN111177811ADetection speedImprove efficiencyGeometric CADCharacter and pattern recognitionFirefightingEngineering

The invention provides a firefighting point location automatic layout method applied to a cloud platform. A plurality of types of firefighting point location training models are constructed, the firefighting point location training model of each type detects the position coordinates and type information of the firefighting point locations of the same type on the image to be identified, through multiple types of firefighting point location training models, position coordinates and type information of all firefighting point locations on an image to be identified can be detected, and the multipletypes of firefighting point location training models are high in detection speed, high in efficiency and high in accuracy; and on the basis of construction of a traditional SVM classification model,a difficult case processing step is added, the target image which is not detected and the non-target image which is detected to be wrong are intercepted again and expanded into the positive and negative sample set, the SVM classification model is retrained, and parameters of the SVM classification model are increased, so that the detection result error of the SVM classification model is small, andthe detection result is accurate.

Owner:WUHAN WUTOS

Intelligent gateway dynamic flow limiting implementation method

PendingCN113595925ASolve the problem of transmission securityEnsure safetyData switching networksExpiration TimeIntelligent Network

The invention discloses an intelligent gateway dynamic flow limiting implementation method, which comprises the following steps of: starting an intelligent gateway, receiving a service request, caching configuration information of the intelligent gateway and loading the configuration information into a memory; refreshing the memory cache automatically, and meanwhile recalculating the cache expiration time; reading configuration information; performing black and white list verification, performing login verification and permission verification, and if login succeeds, obtaining a request body rewriting mapping rule from the long-term cache, and executing request body rewriting; performing intelligent gateway distributed cluster flow limiting control, configuring the local flow limiting size of the gateway, and when the flow is too large, returning a flow limiting response code; performing local fusing control; and forwarding the service request to the intelligent gateway cluster, and processing the request to realize load balancing. According to the invention, the deployment architecture is simple, the database and the gateway are decoupled, personalized dynamic current limiting and fusing are realized, an intelligent gateway realization method with distributed deployment, high availability and high concurrency capability is provided, the error-tolerant rate of communication abnormity is increased, and the use scene is expanded.

Owner:中企云链(北京)金融信息服务有限公司

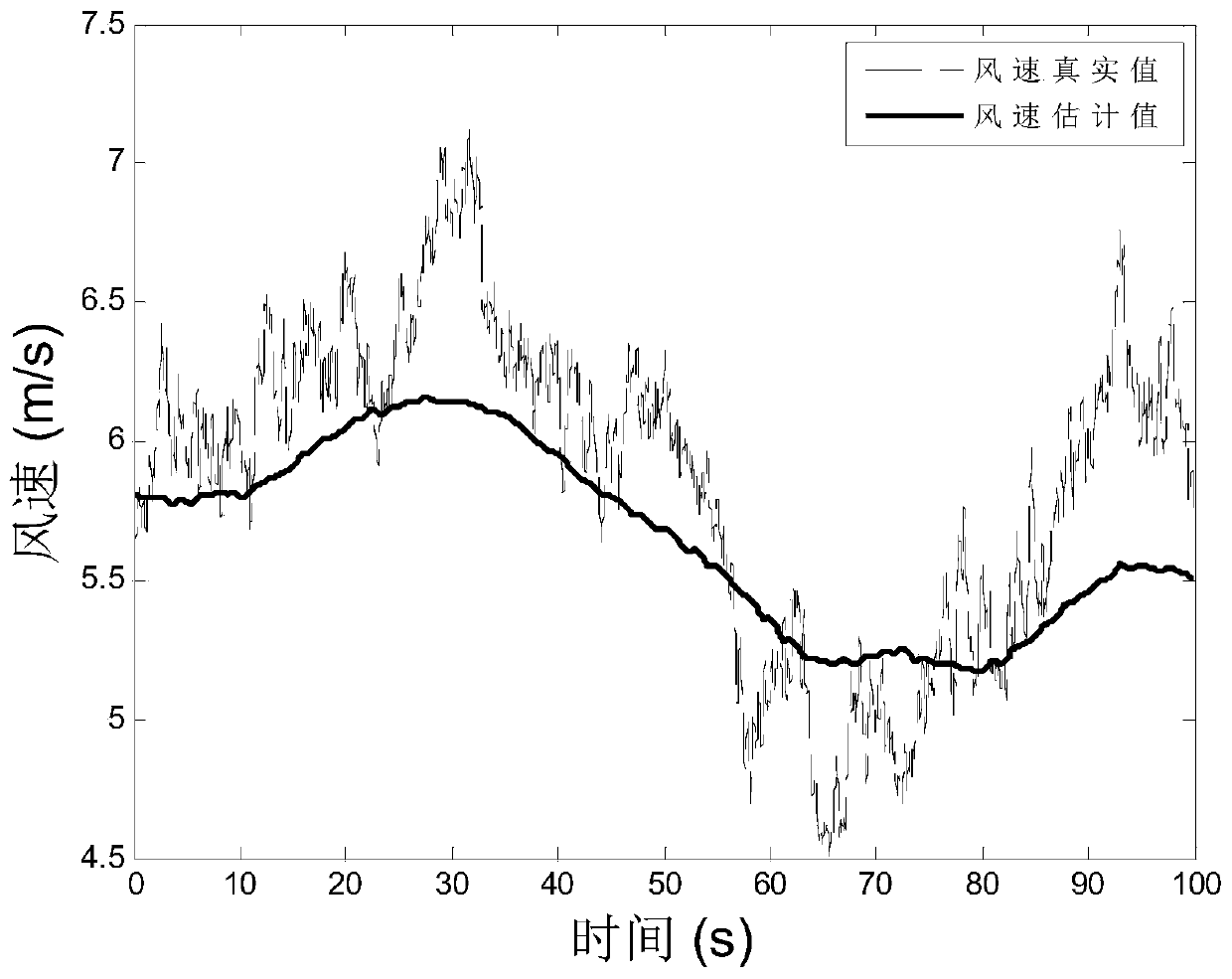

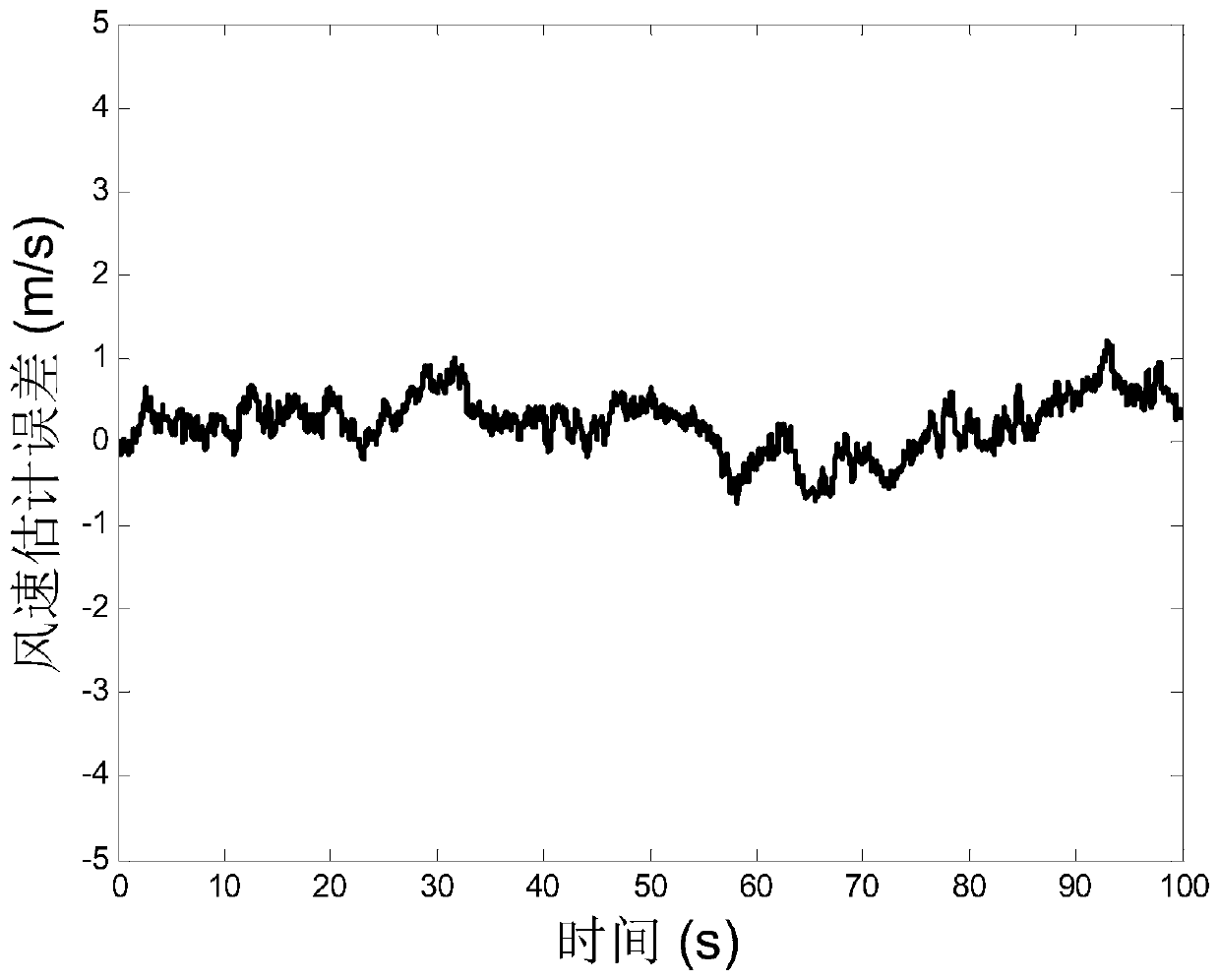

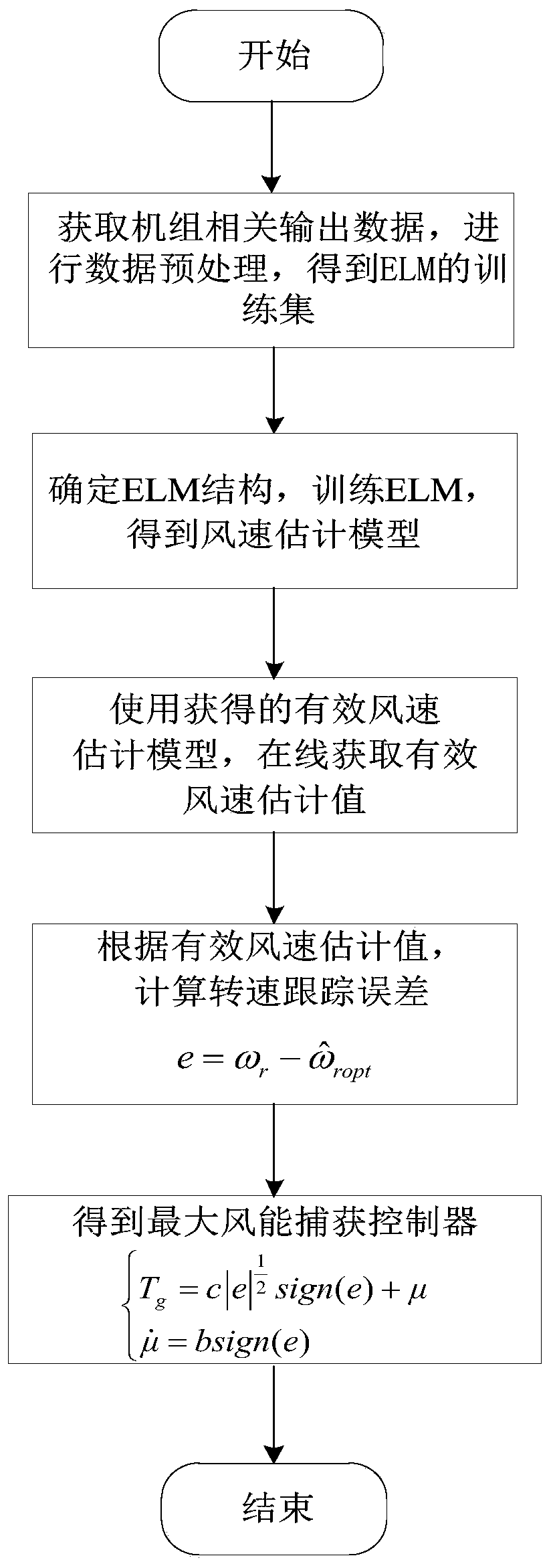

ELM based maximum wind energy capturing method of variable speed wind turbine

ActiveCN111075647AReduce usageReduce mechanical loadWind motor controlEngine fuctionsTime segmentEconomic benefits

The invention discloses an ELM based maximum wind energy capturing method which comprises the following steps: obtaining effective wind speed information of a unit within certain time segment and theunit output data related to the effective wind speed within a corresponding time segment, removing the correlation of the obtained unit output data, carrying out normalization operation, constructinga training set of ELM, adopting the training set to determine an ELM model to obtain a wind speed estimation model, giving an effective wind speed value on time by the model to further calculate the revolving speed tracking error, and giving a continuous and maximum wind energy capturing controller. According to the ELM based maximum wind energy capturing method, the obtained maximum wind energy capturing controller can eliminate the buffeting phenomenon, so that the load of a drive system is reduced, the service life of the unit is prolonged, the defect that the traditional optimal torque algorithm is lower in convergence rate is overcome, the wind energy capturing efficiency is improved, the method is simple and easy to do, the implementation cost is low, and the parameters to be debugged are fewer; and compared with the traditional optimal torque control algorithm, the unit productivity can be improved to improve the economic benefit of a wind farm.

Owner:ZHEJIANG UNIV

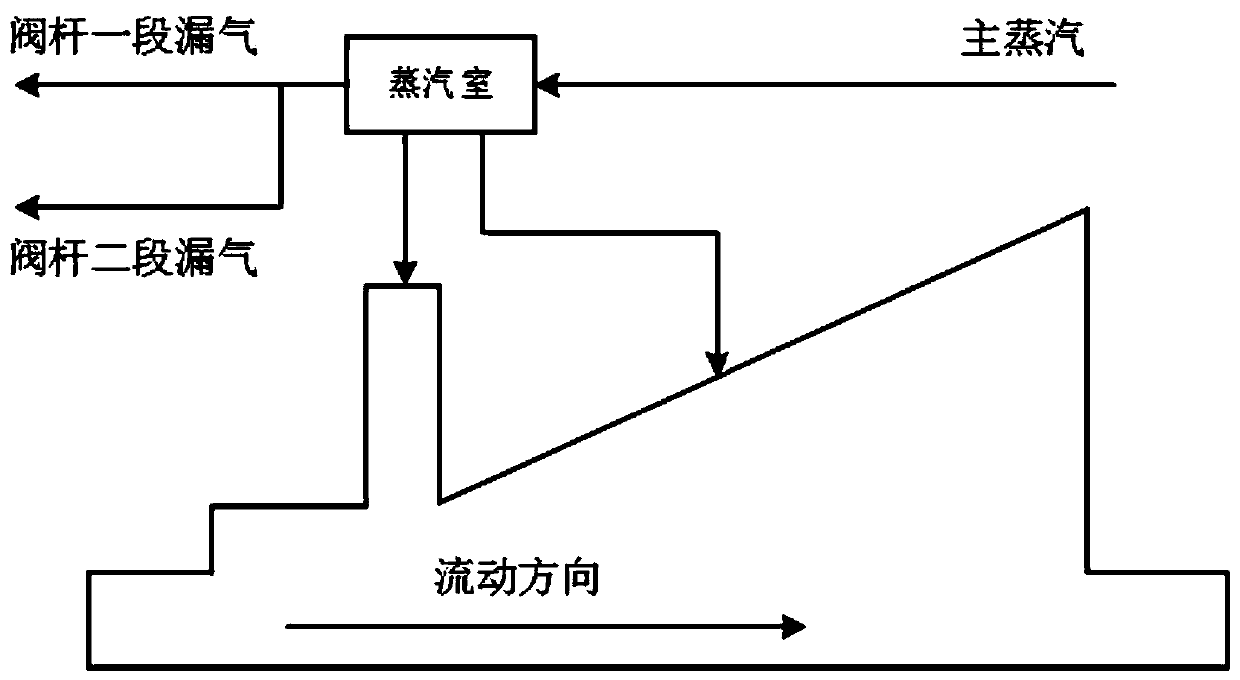

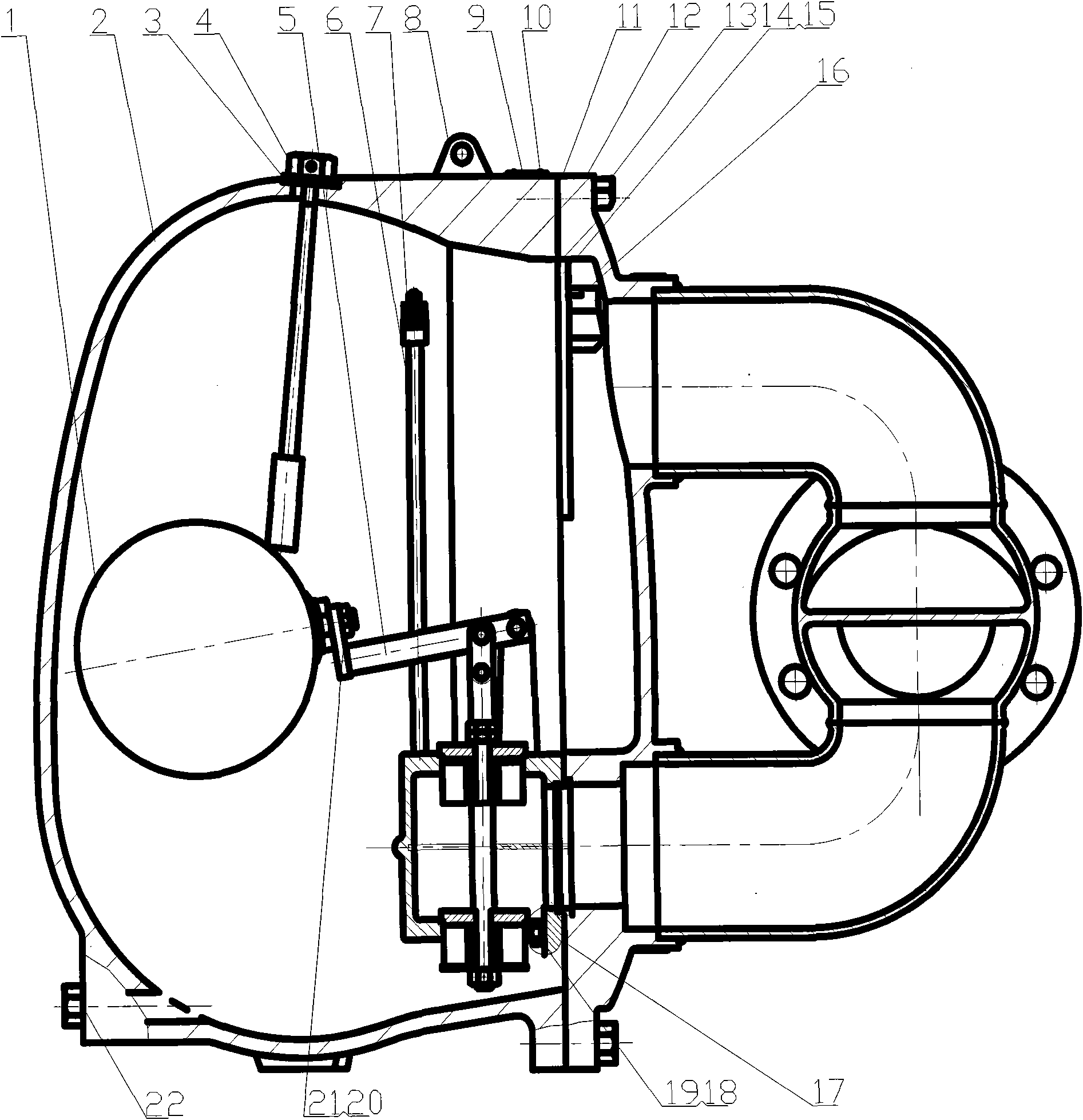

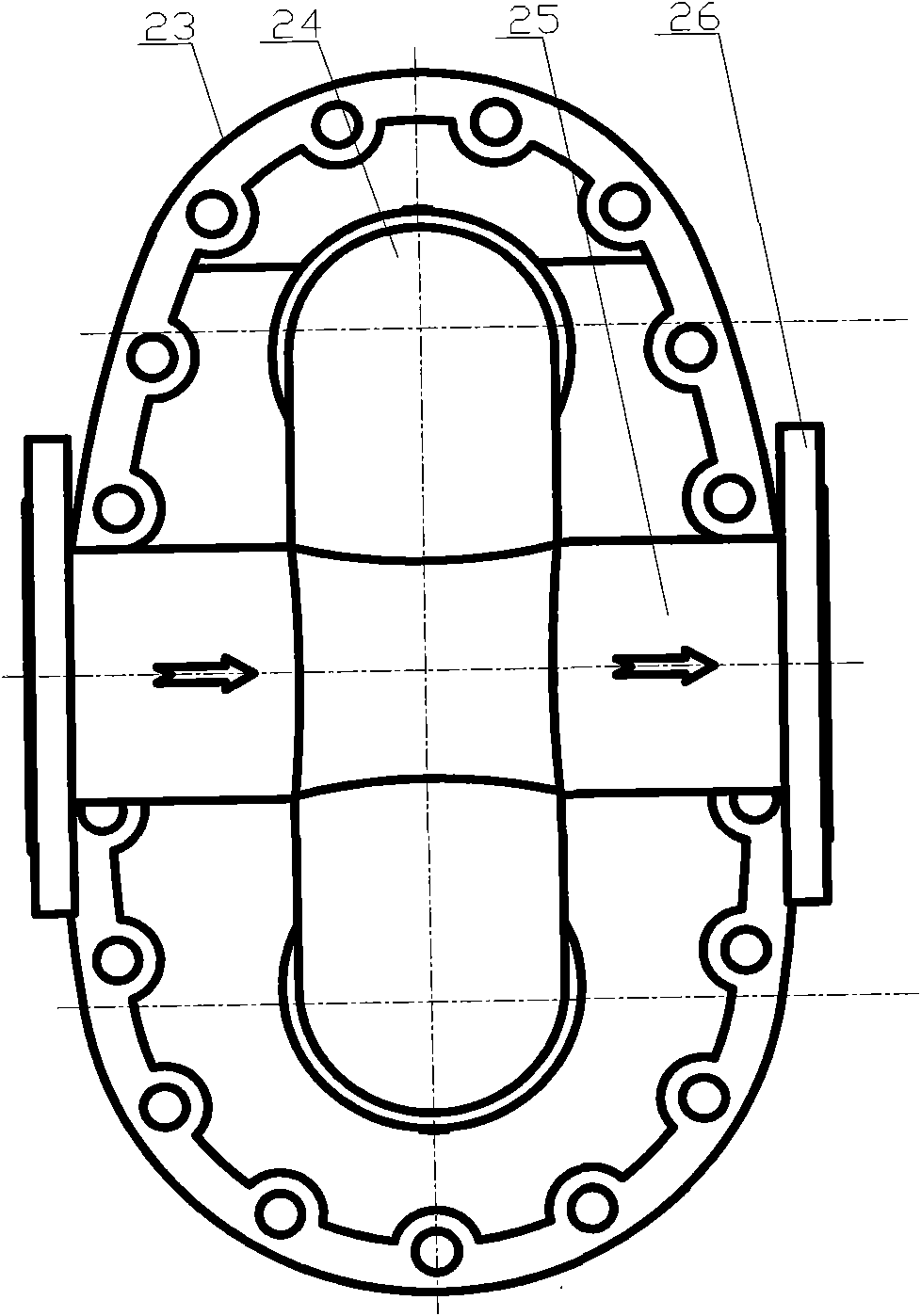

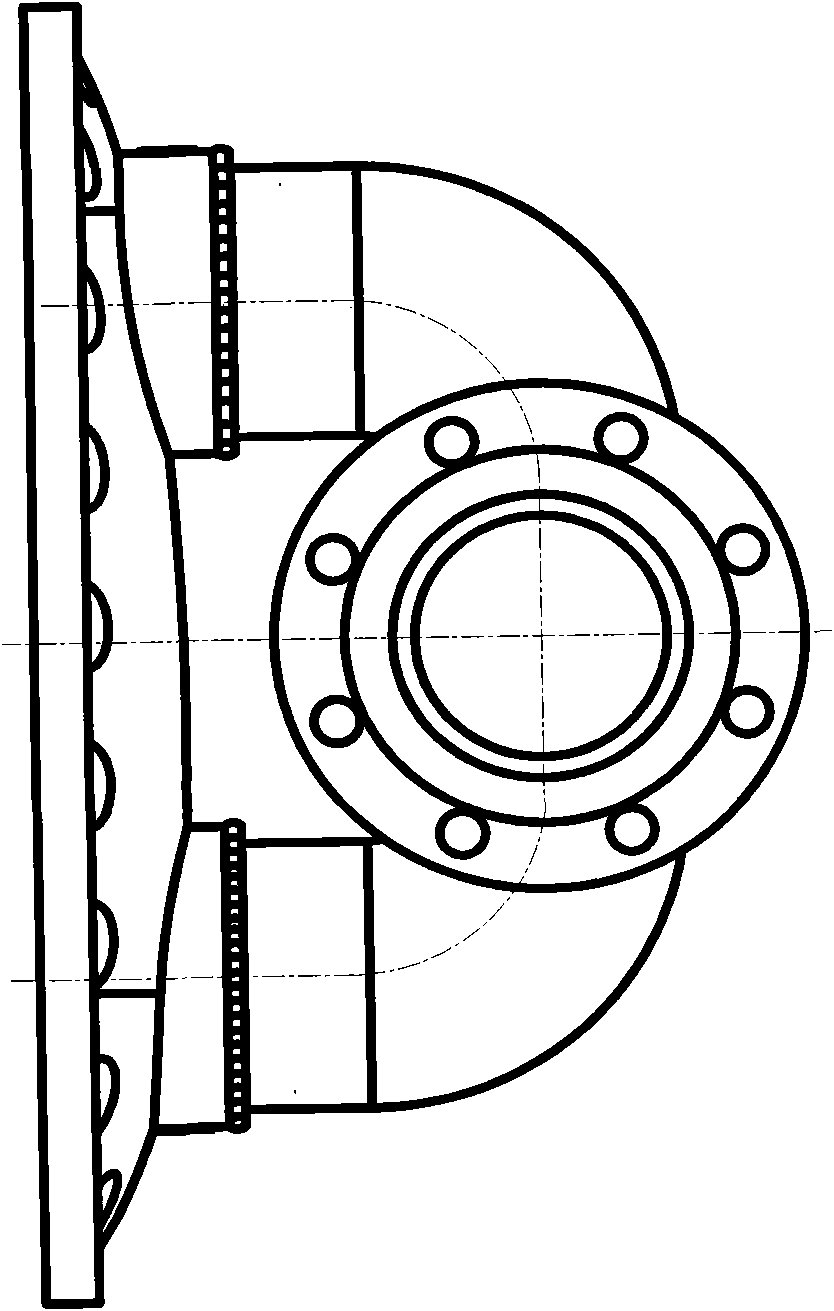

Super large discharge lever float ball type steam drain valve

The invention relates to a super large discharge lever float ball type steam drain valve. The invention is characterized in that: the right end of a valve body (2) is connected with a valve cover component (12), a retainer component (4) is arranged at the upper end of the valve body (2) through the valve body, a current plate (16) is fixed at a water inlet at the upper part of the valve cover component (12), the right end of a control frame (37) is connected with a water outlet at the lower part of the valve cover component (12), and a screw plug (22) is arranged at the left lower side of the valve body (2) by penetrating the valve body. A direction changing joint (25) of the valve cover component (12) and a 90 degree elbow (24) are vertical to each other and are welded at a vale cover (23). A bar frame (48) of a control frame component (5) is connected with a fixing plate (55), and the fixing plate (55) is connected with a float ball valve seat (35). An airway tube component (6) is arranged at the left upper side of the control frame (37), and the joint of the airway tube component (6) is internally connected with an automatic air discharge valve (7). With super large water drainage amount under lower operating differential pressure, the invention can replace a condensed water recycle pump, has reliable motion, long service life, low price and high parameter usage and can be maintained on pipelines.

Owner:刘金海

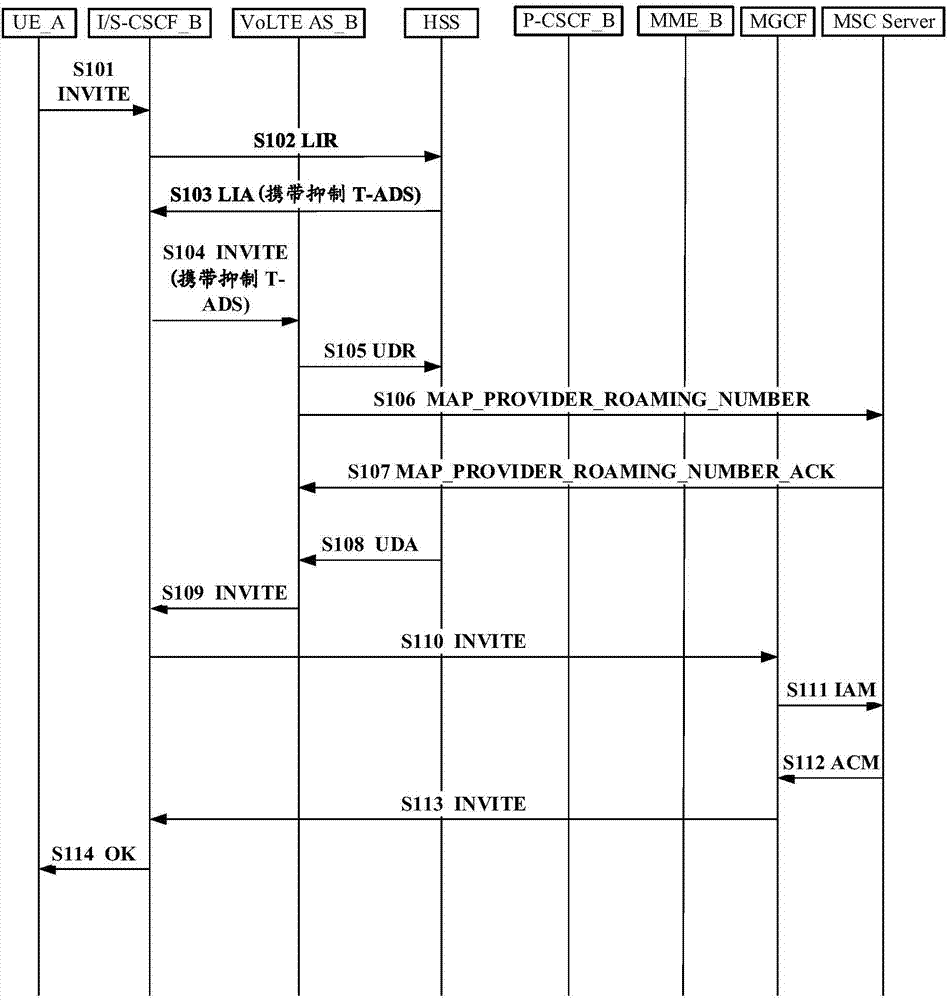

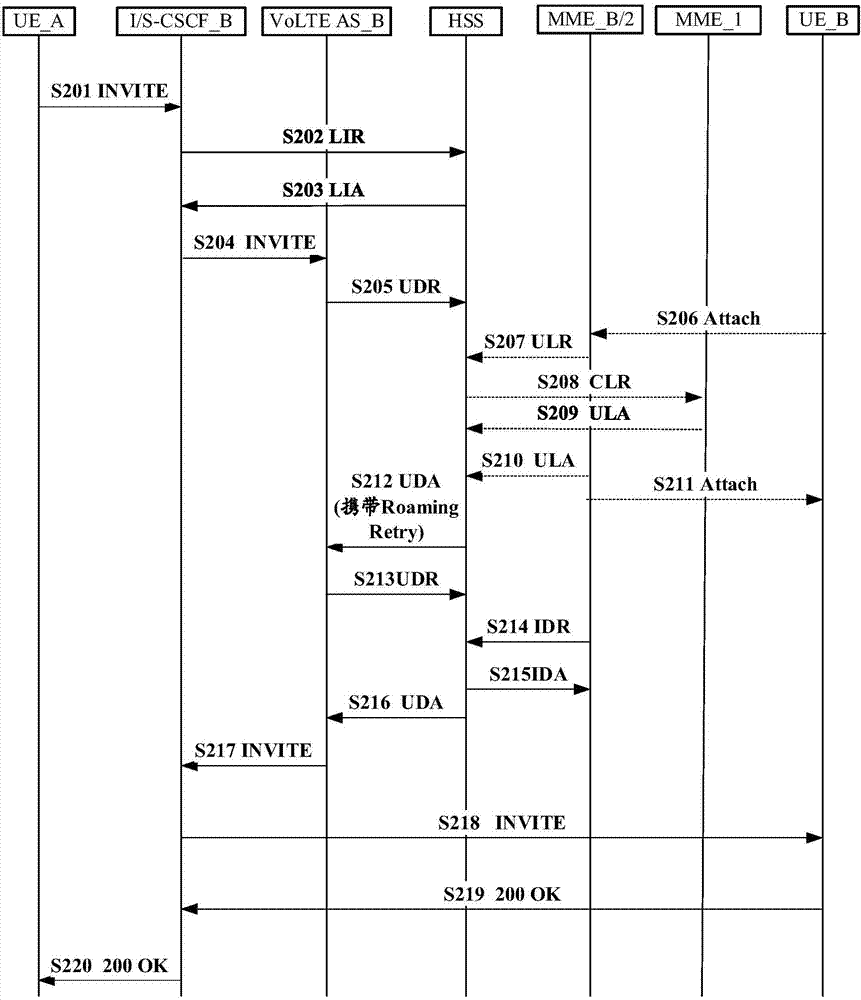

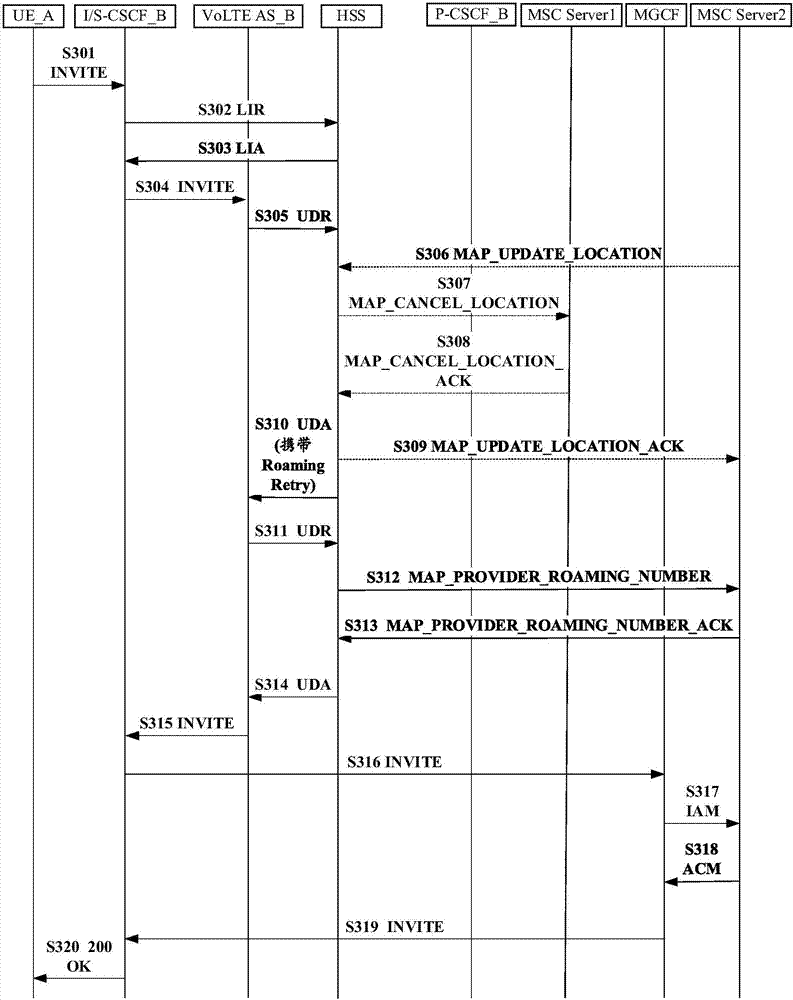

Decision-making voice over LTE (VoLTE) final call domain selection method and system

ActiveCN107548110AImprove parametersTroubleshoot call setup failuresConnection managementTransmissionTelecommunicationsSpeech sound

The invention provides a decision-making voice over LTE (VoLTE) call domain selection method and system, belonging to the field of communication technology. The method comprises the following steps: an HSS detects that a terminal has been registered in a CS network after receiving an LIR message, and sends an LIA message that carries suppression T-ADS parameters to I-CSCF_B; an S-CSCF_B receives aterminal INVITE message, and then sends the terminal INVITE message that carries the suppression T-ADS parameters to VoLTE AS_B according to IFC data of a called terminal; and the VoLTE AS_B receivesthe INVITE message, and then detects the suppression T-ADS parameters, and sends a UDR message to the HSS to acquire a CSRN. According to the method and system provided by the invention, the problemthat the call establishment fails due to signal coverage or user roaming in a VoLTE call establishment process can be solved, and the smooth communication can be guaranteed.

Owner:ZTE CORP

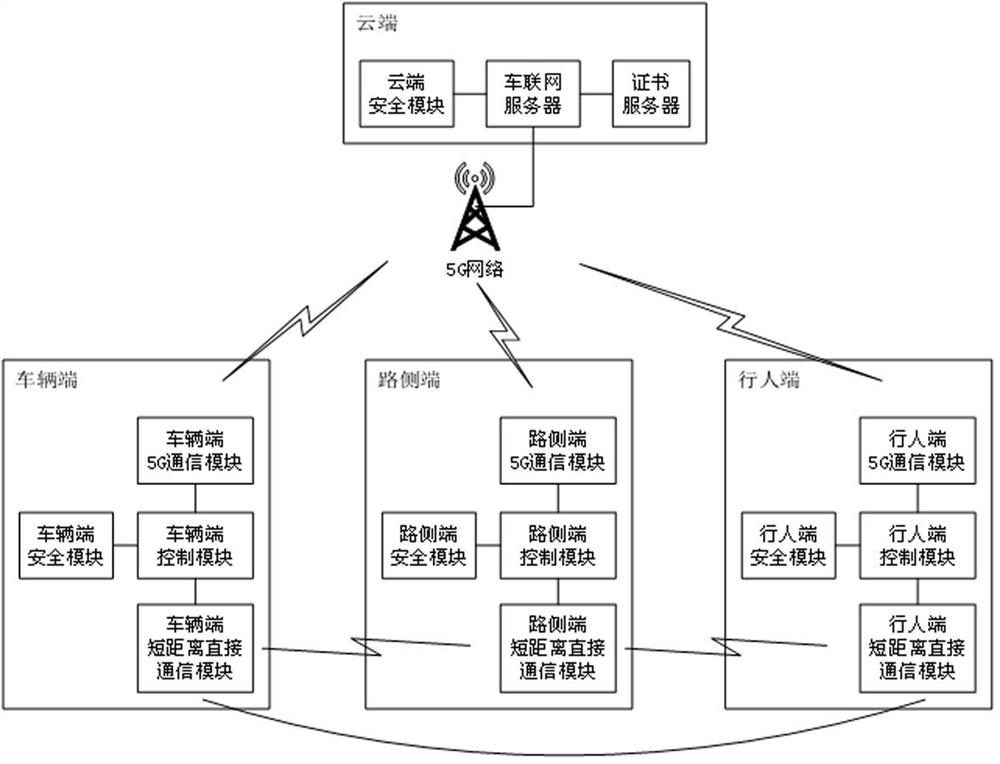

V2X Internet-of-vehicles safety communication system and method based on 5G

ActiveCN112055330AEasy to useImprove securityKey distribution for secure communicationPublic key for secure communicationEmbedded systemSecure communication

The invention relates to a V2X Internet-of-vehicles safety communication system and method based on 5G. The V2X Internet-of-vehicles safety communication system comprises a cloud terminal, a vehicle terminal, a road side terminal and at least two pedestrian terminals, wherein the sum of the number of the road side terminals and the number of the pedestrian terminals is at least two; the cloud terminal comprises a certificate server, a cloud security module and an Internet-of-vehicle server; the vehicle end comprises a vehicle end short-distance direct communication module, a vehicle end 5G communication module, a vehicle terminal safety module and a vehicle terminal control module; the roadside end comprises a roadside end short-distance direct communication module, a roadside end 5G communication module, a roadside terminal safety module and a roadside terminal control module; the pedestrian terminal comprises a pedestrian end short-distance direct communication module, a pedestrian end 5G communication module, a pedestrian end safety module and a pedestrian end control module; V2X Internet-of-vehicles identity authentication and group security encryption communication are realized according to the characteristics of 5G and V2X Internet-of-vehicles, so that the V2X Internet-of-vehicles identity authentication and group security encryption communication are safe, reliable, simple and efficient.

Owner:ZHENGZHOU XINDA JIEAN INFORMATION TECH

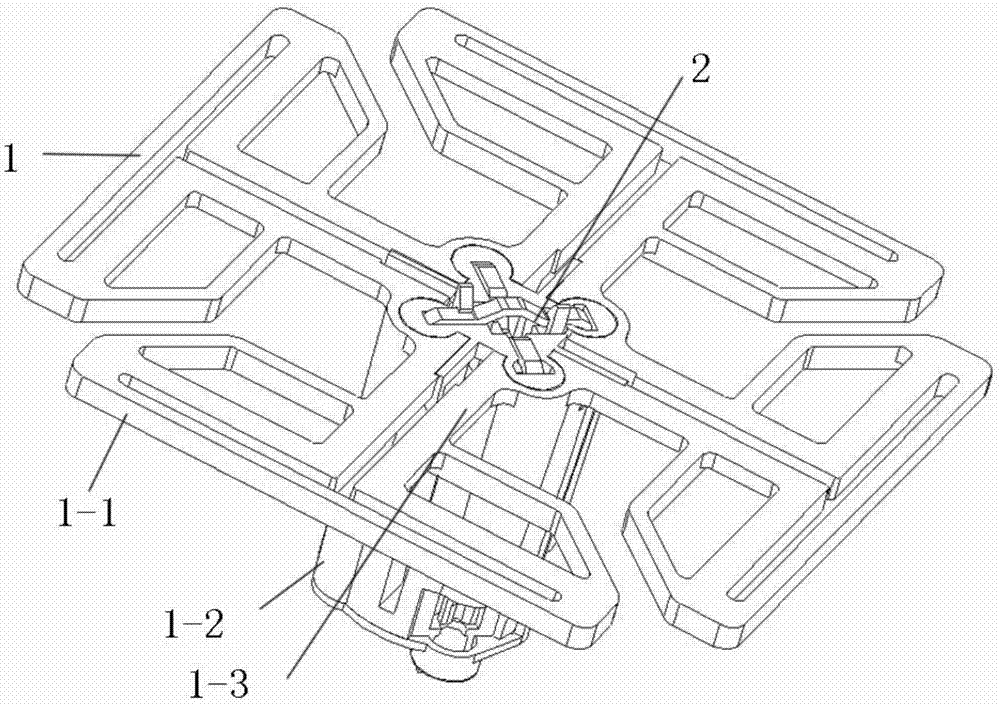

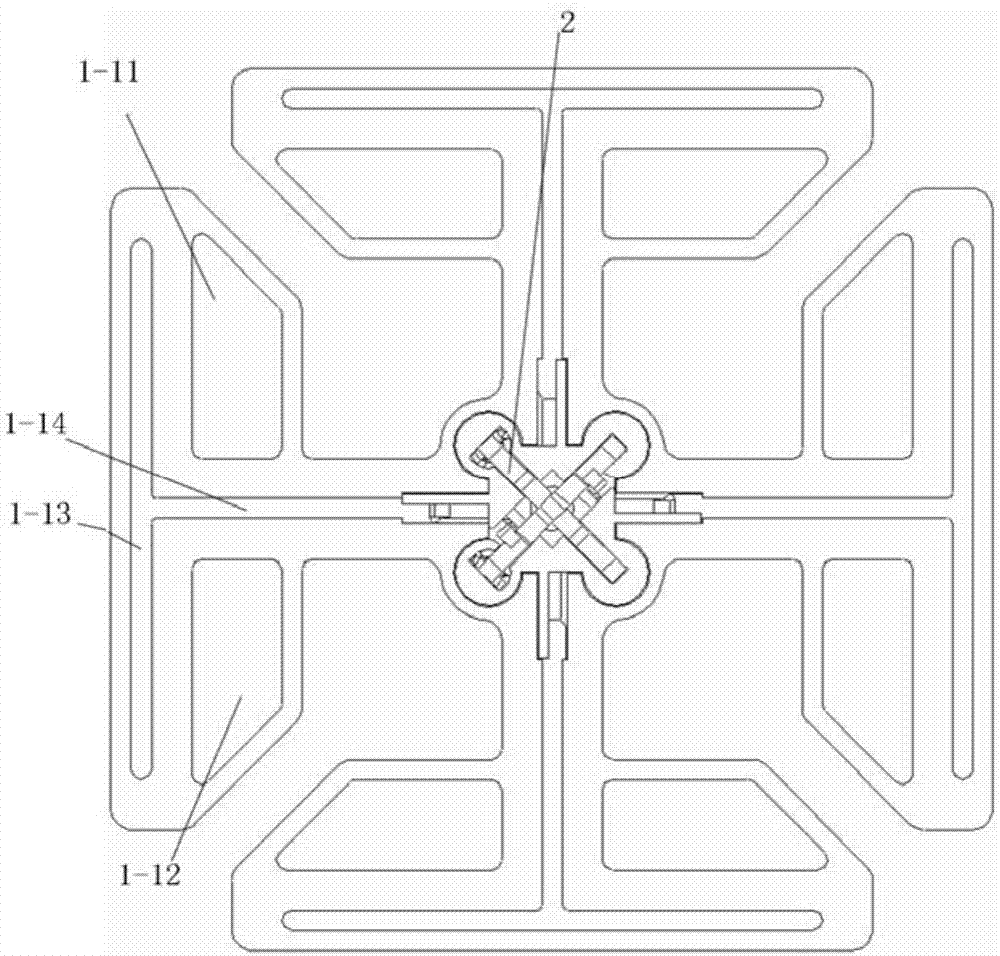

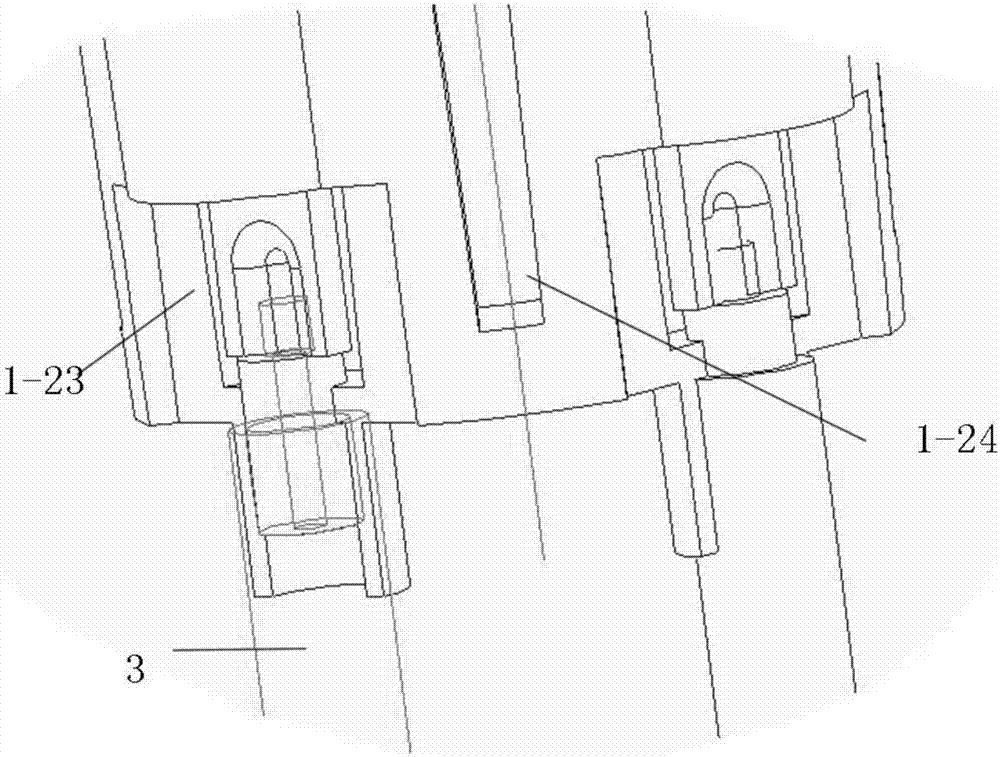

Antenna vibrator

PendingCN107968254AOptimization parametersHigh bandwidthAntenna supports/mountingsRadiating elements structural formsElectrical and Electronics engineeringRadiation

The invention discloses an antenna vibrator. The antenna vibrator is characterized in that the antenna vibrator comprises a vibrator body and a feeding slice; the vibrator body comprises four radiation slices and a balun fixing base; vibrator connecting arms are connected between the radiation slices and the balun fixing base; left and right hollow holes and a first bar-shaped hole are hollowed out in each radiation slice; a second bar-shaped hole which is vertically connected with a first bar-shaped hole is hollowed out in each vibrator connecting arm; and left and right hollow holes are symmetrically arranged on both sides of the second bar-shaped holes. According to the invention, the antenna vibrator has the advantages of simple structure, low cost, firm cable welding, increased bandwidth and enhanced structural strength.

Owner:GUANGDONG SHENGLU TELECOMM TECH

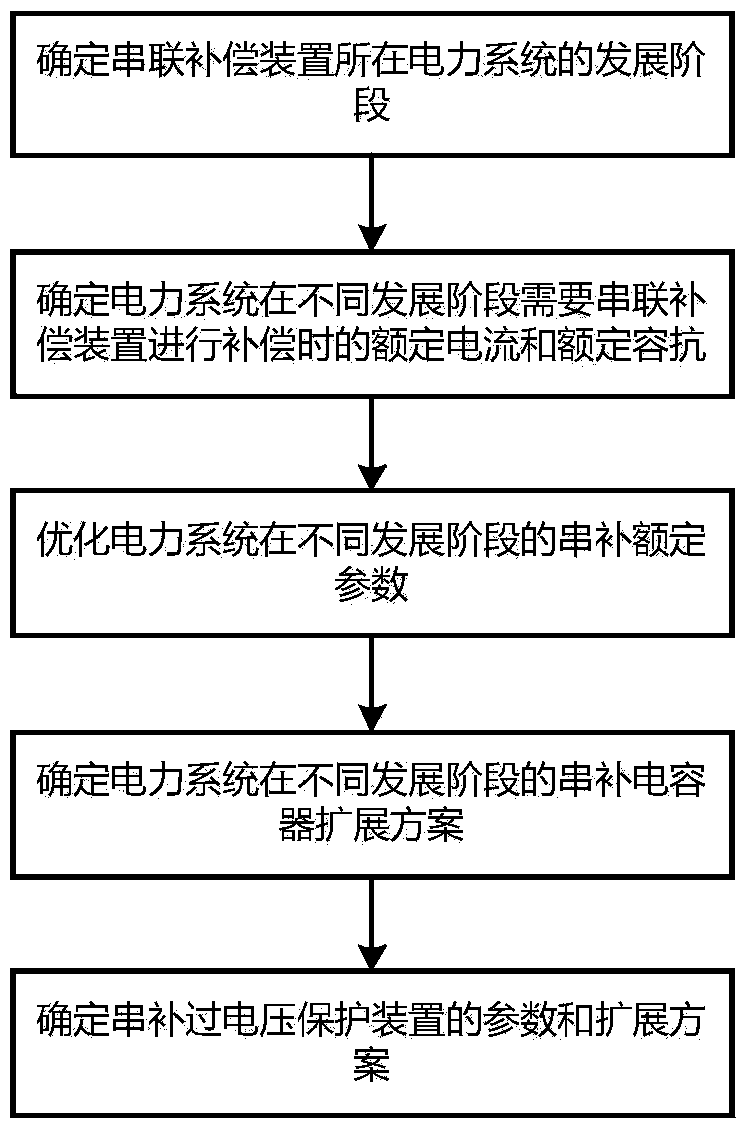

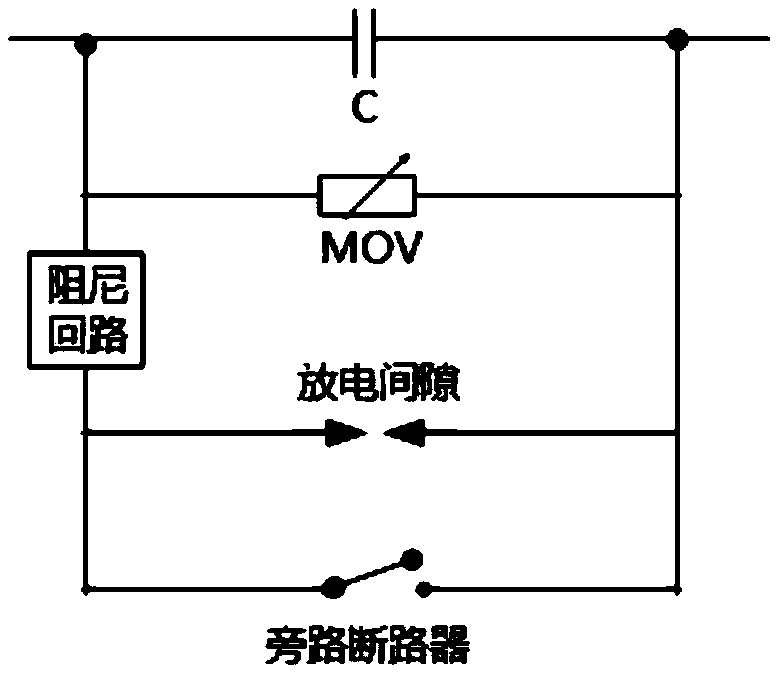

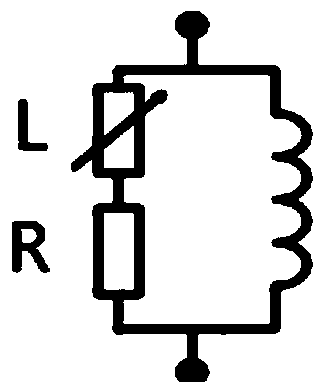

Rated parameter adjustable series compensation design method

ActiveCN105375493AExpansion of rated parametersImprove parametersReactive power adjustment/elimination/compensationReactive power compensationOvervoltageSeries compensation

The invention provides a rated parameter adjustable series compensation design method. The method comprises the following steps: step 1, determining the development stage of a power system, wherein a series compensation apparatus is in the power system; step 2, determining rated current and rate capacitive reactance of the power system in different development stages requiring compensation from the series compensation apparatus; step 3, optimizing the series compensation rated parameters of the power system in different development stages; step 4, determining series compensation capacitor expanding schemes of the power system in different development stages; and step 5, determining the parameters and expanding schemes of a series compensation overvoltage protection apparatus. According to the rated parameter adjustable series compensation design method, the parameters of the series compensation apparatus and the series compensation overvoltage protection apparatus are expanded in different stages according to the development stages of the power system, and the economical efficiency and the reliability of the series compensation apparatus are improved.

Owner:CHINA ELECTRIC POWER RES INST +2

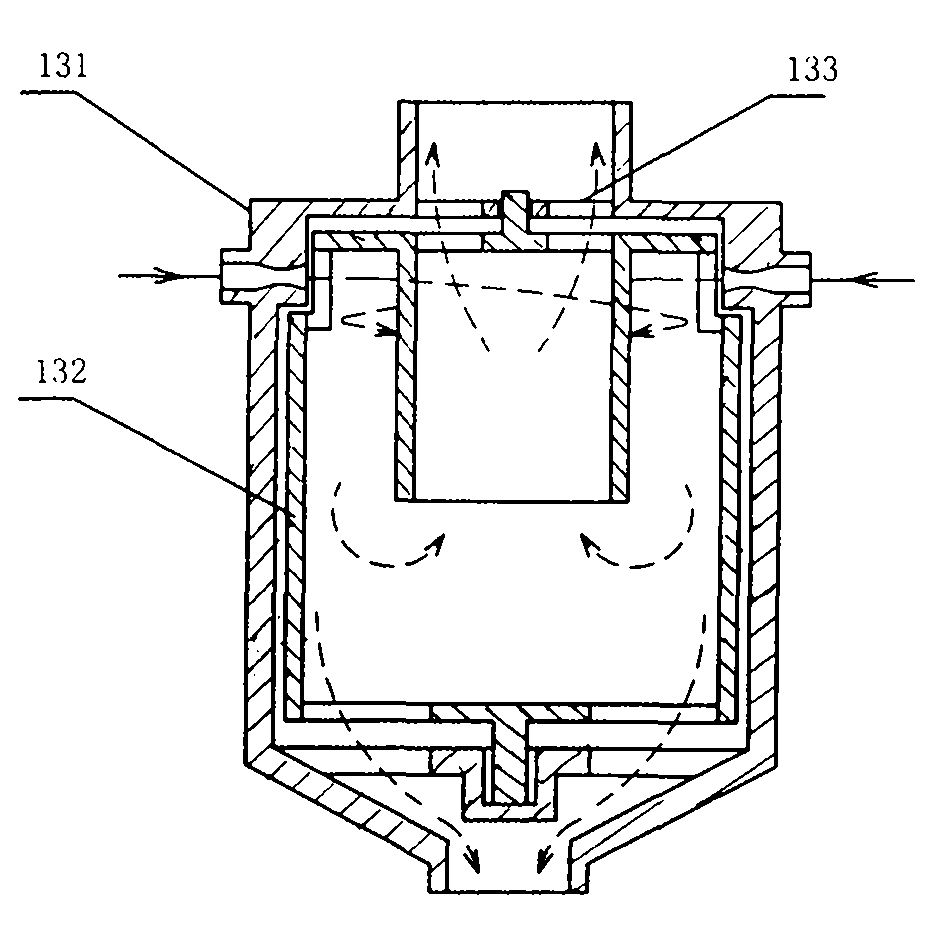

Steel works sintering cooling machine low-temperature flue gas residual heat utilization system

ActiveCN101338979AIncrease profitGuaranteed manufacturing quality and installation speedEnergy industryIncreasing energy efficiencyFlueEngineering

The invention discloses a system for utilizing the low temperature fume waste heat of a sintering cooling machine in steel works. The system comprises a sintering forced draft cooling machine, a waste heat boiler and a blower. The sintering forced draft-cooling machine is communicated with the waste heat boiler through a flue, and pumps fume to the waste heat boiler through the blower. The waste heat boiler comprises a moderate temperature waste heat boiler and a low temperature waste heat boiler which are arranged independently. Therefore, after high temperature fume of the hot section of the sintering forced draft cooling machine is directly taken into the moderate temperature waste heat boiler for heat exchange and pumped by a recirculating blower, and fume is conveyed back to a bellows arranged on the lower part of the sintering forced draft cooling machine; after the lower temperature fume at the moderate temperature section of the sintering forced draft cooling machine is taken into the low temperature waste heat boiler for heat exchange and is pumped by an induced draft fan, fume is discharged into the environment. As the independent fume complete circulation moderate temperature waste heat boiler system is provided, the working parameters of the waste heat boiler can be improved; the generated output, the pressure and temperature of the waste heat boiler can be stabilized; in addition, the heat of the low temperature fume at the moderate temperature section of the sintering forced draft cooling machine is effectively reclaimed.

Owner:BERIS ENG & RES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com