Super large discharge lever float ball type steam drain valve

A floating ball and steam trap technology, used in steam traps, mechanical equipment, etc., to achieve the effects of reliable action, elimination of steam lock, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

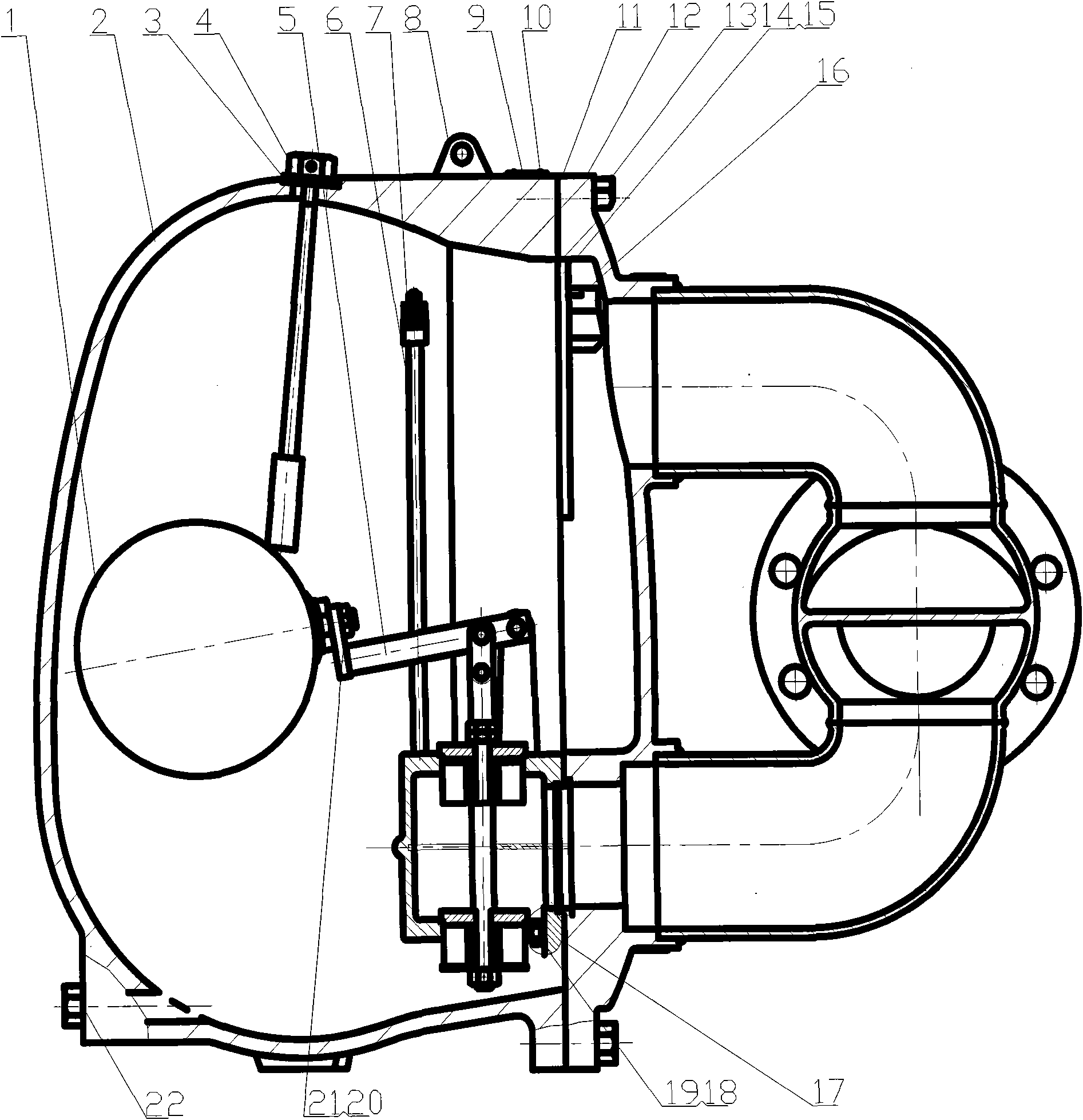

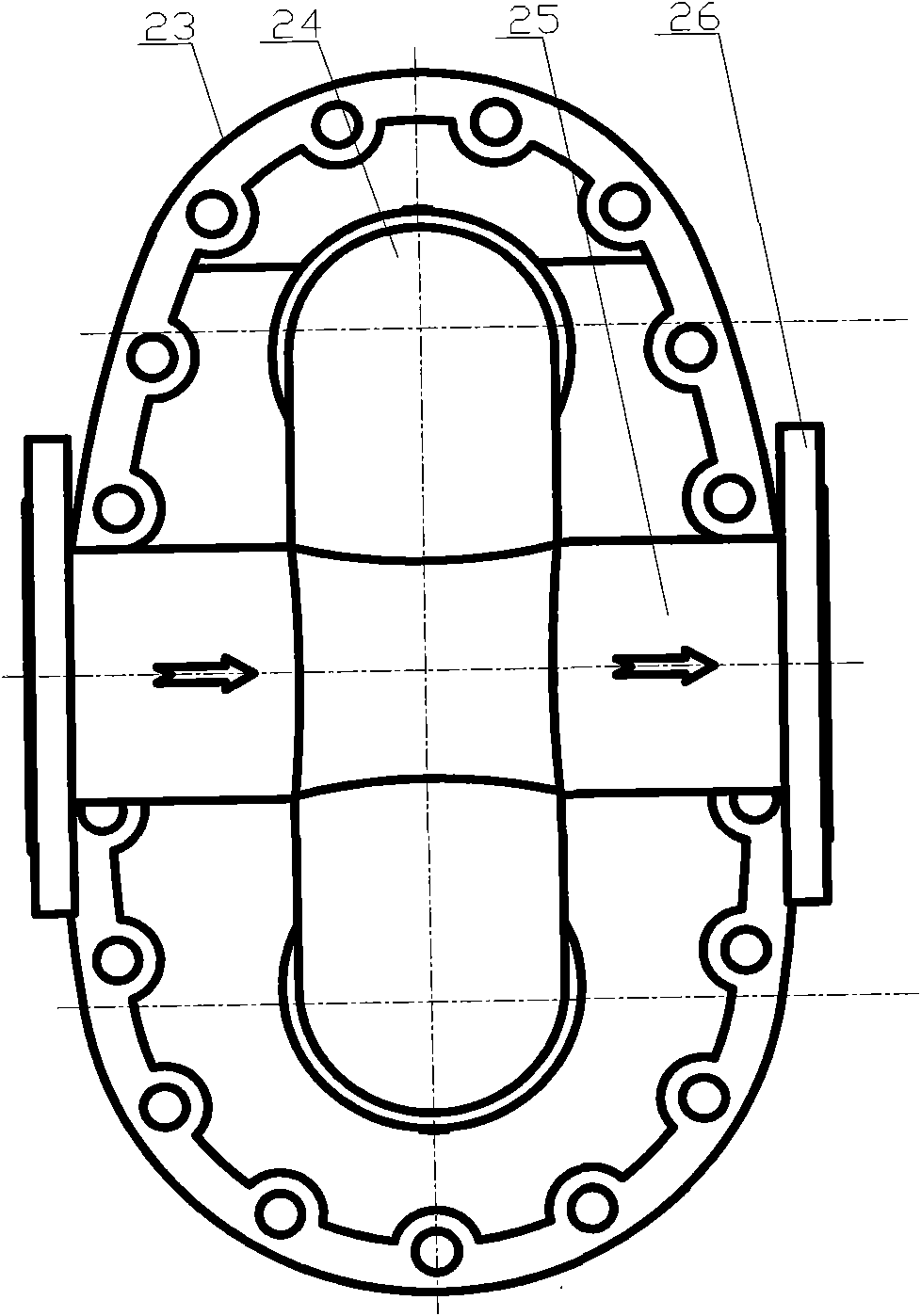

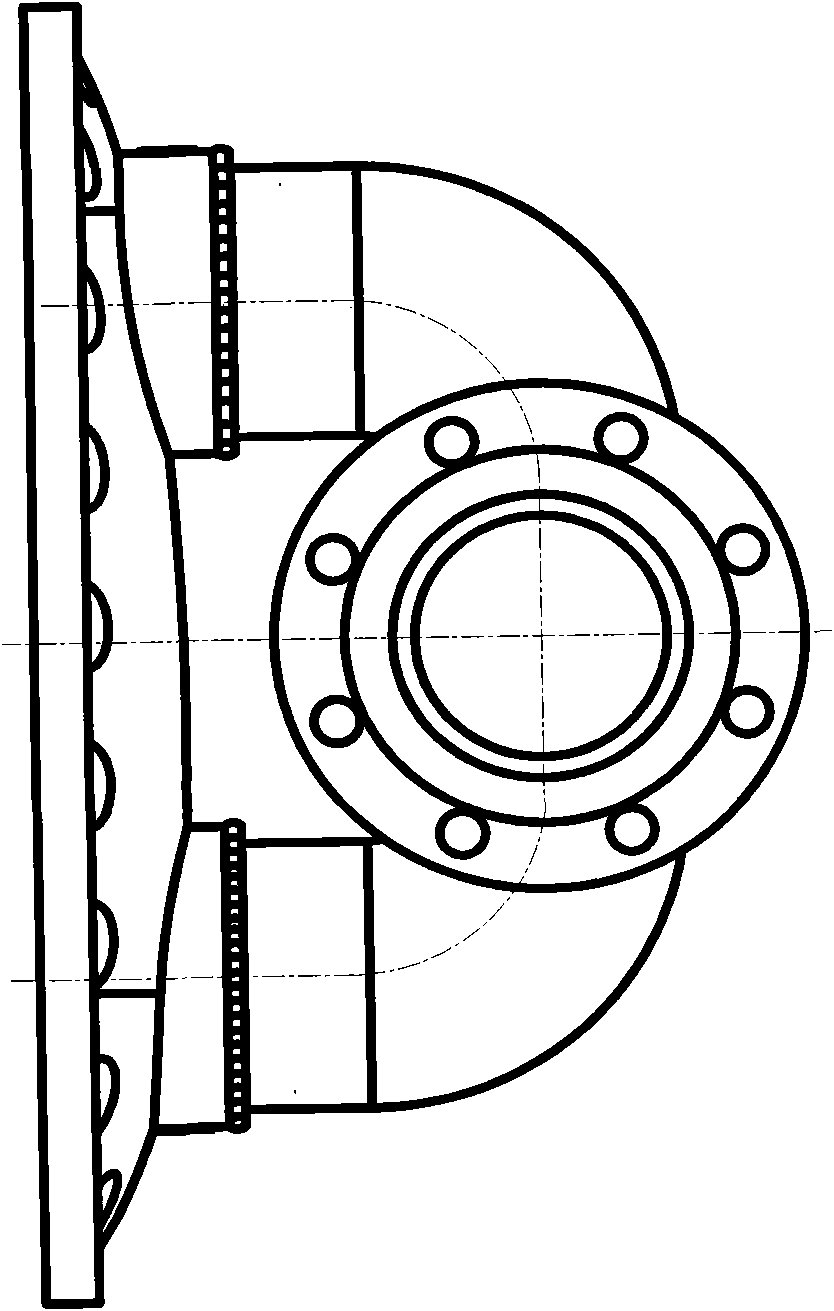

[0021] exist figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10: the right end of the valve body 2 is equipped with a large gasket 11 to connect with the valve cover assembly 12, and is fastened by the hex head bolt 13. Valve body 2 and bonnet 23 are designed according to PN16, and WCB castings are used. The wall thickness and pressure and temperature grade of the valve body meet the requirements of GB / T12224-2005 "General Requirements for Steel Valves". The steering joint 25 and the 90° elbow 24 in the valve cover assembly 12 are vertically welded on the valve cover 23 and communicate with each other, and the flanges 26 are horizontally welded on both sides of the steering joint 25 respectively. The steering joint 25 is made of 304 castings, which is resistant to cavitation and water hammer, and can increase the service life of the trap. It is connected horizontally from left to right, and the structural length is only 480mm, so the medium flow is very smooth, and the user's horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com