Single-stage centrifugal pump with balanced axial force

A technology of axial force and centrifugal pumps, applied in pumps, components of pumping devices for elastic fluids, pump elements, etc., can solve problems such as large leakage losses, poor balance effects, and reduced efficiency, and achieve overall pressure Low, improved hydraulic performance, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

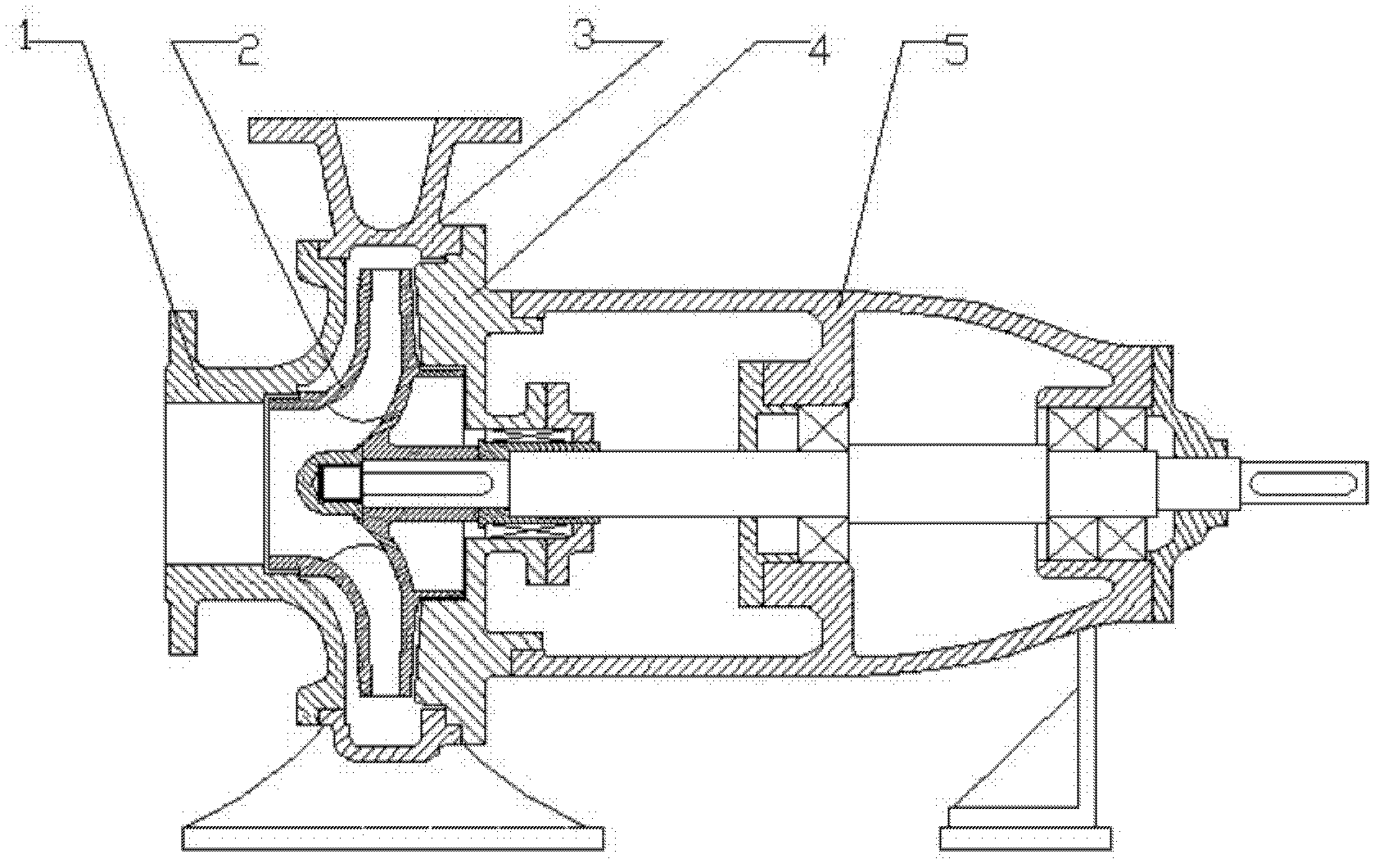

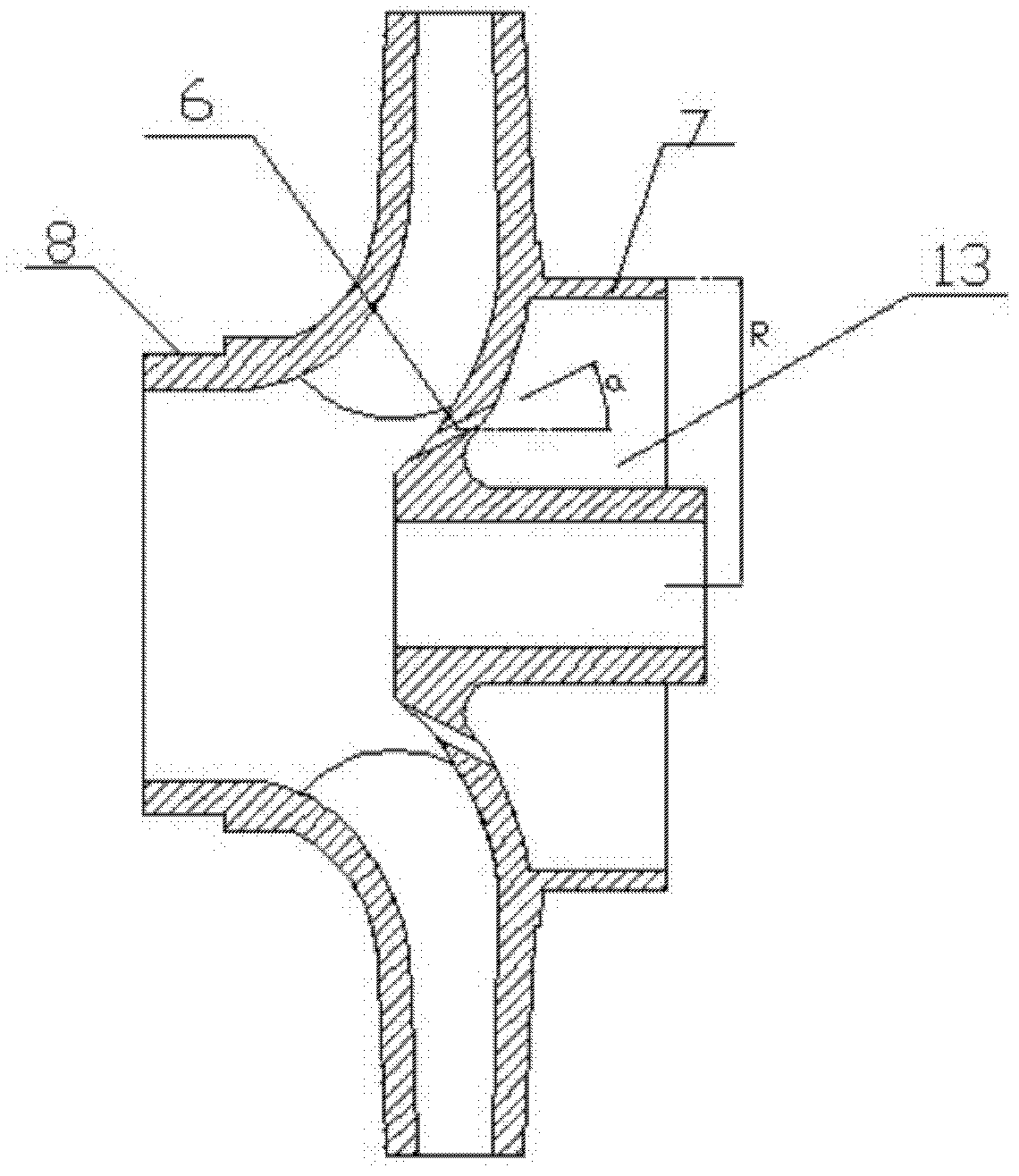

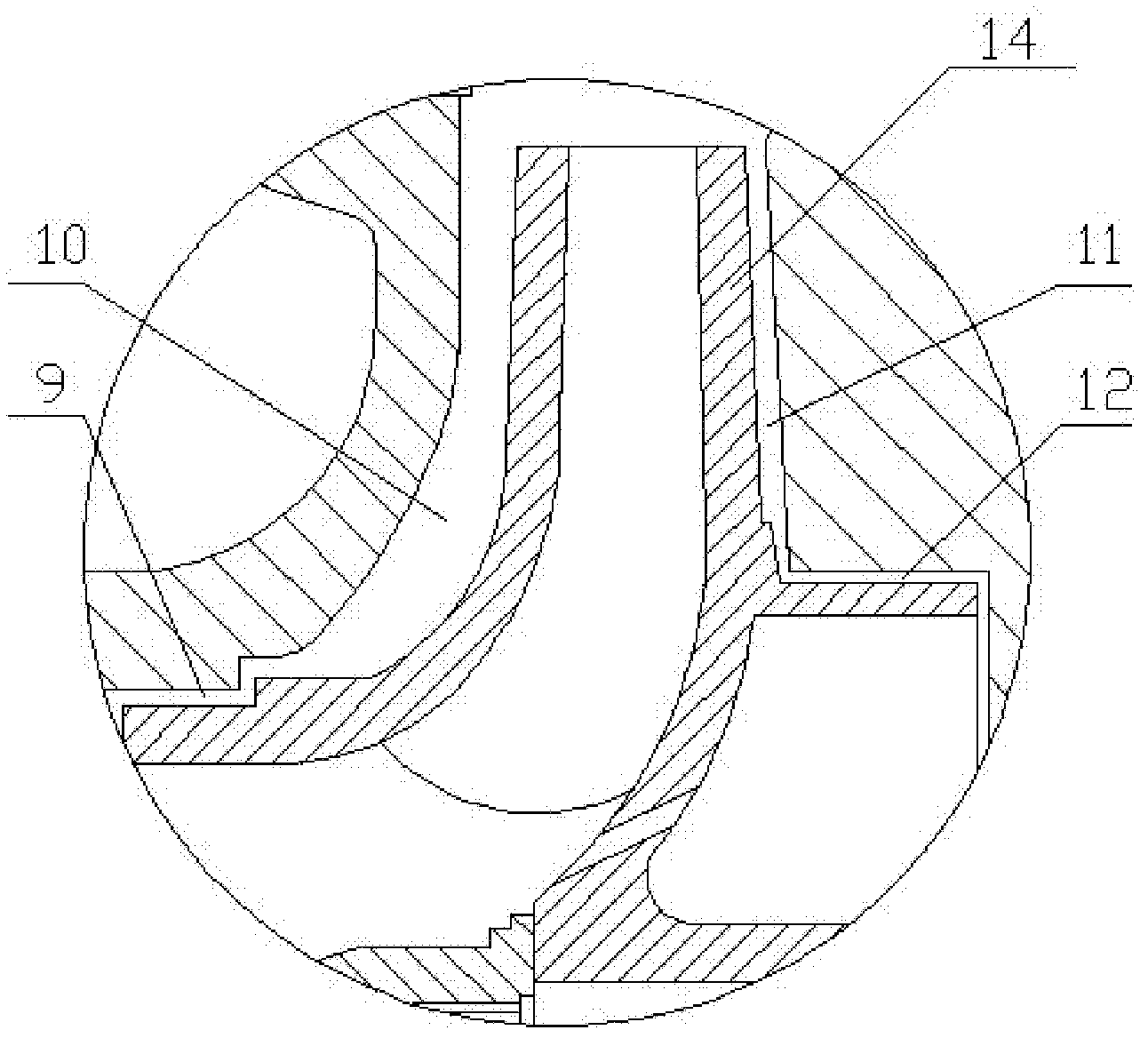

[0016] Refer to attached figure 1 , 2 , the one-way centrifugal pump with axial force balance in the present invention comprises a pump body 3, a front pump cover 1, an impeller 2, a rear pump cover 4, a rear cover plate mouth ring 7, a bearing body 5, and the rear part of the rear cover plate A balance chamber 13 is formed, and the balance chamber 13 of the rear cover communicates with the suction port of the impeller 2 . The impeller 2 has an inclined balance hole 6, the balance hole 6 is located near the hub at one end of the suction inlet of the impeller 2, and is located at the end of the balance chamber 13 away from the hub. The center line of the balance hole 6 is at an angle to the axis of the hub; the diameter of the impeller rear port ring 7 is larger than that of the front port ring 8 , and the length of the rear port ring 7 is longer than that of the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com