Flood-discharge tunnel-based combined energy dissipater synchronizing flood discharge and power generation

A technology of synchronous combination and flood discharge tunnel, which is applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of unsuitable flood discharge tunnels for power generation and energy dissipation, and increased project investment, so as to improve the downstream ecological environment, increase energy dissipation efficiency, Reduce the effect of surface tumbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

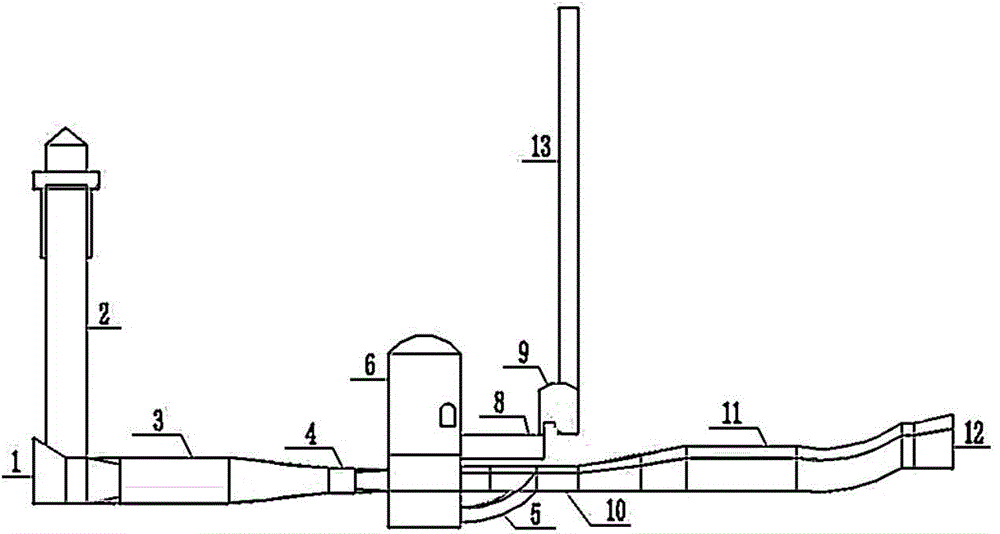

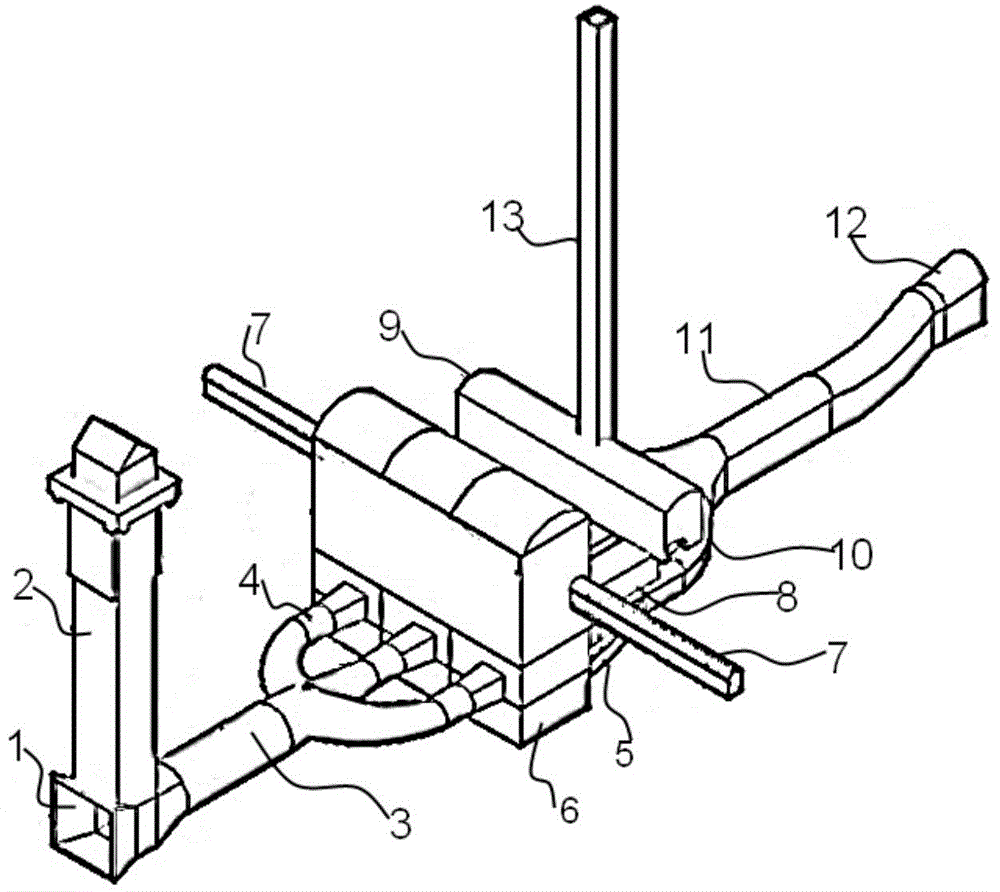

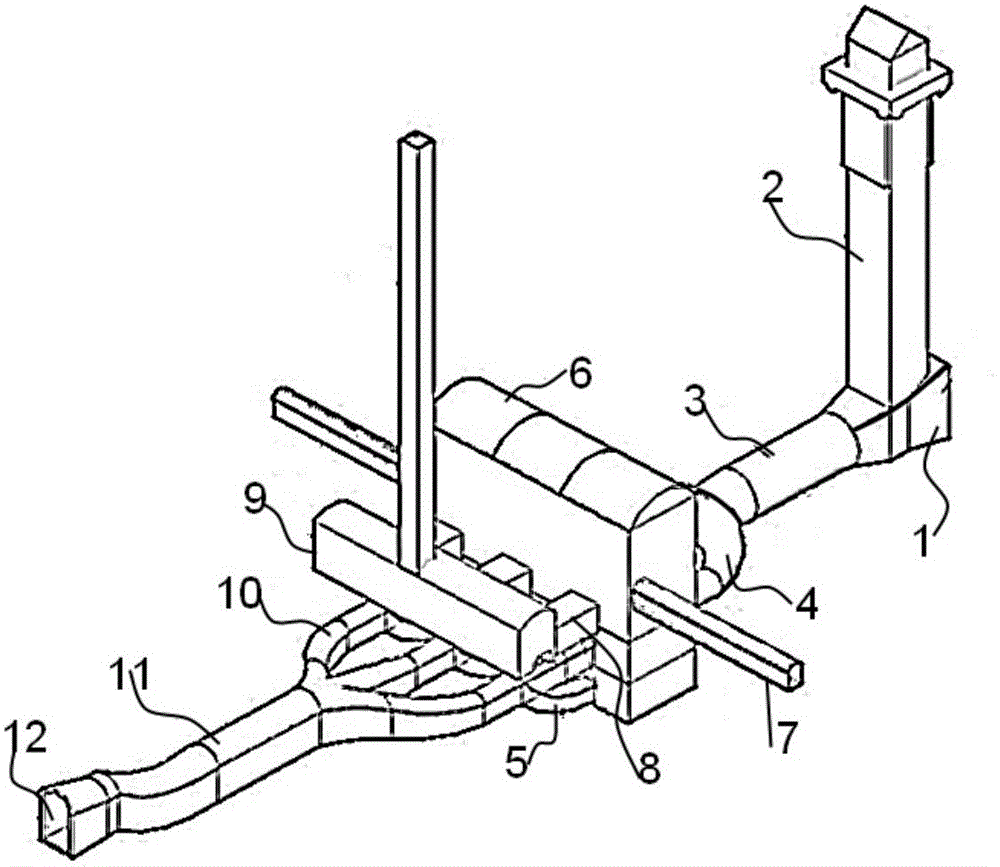

[0018] like Figure 1 to Figure 5 As shown, the present invention is based on the synchronous combination energy dissipation device for flood discharge power generation of flood discharge tunnel, which mainly includes sequentially arranged water inlet tower, underground main powerhouse, contact hole, main transformer room with transformer, shaft, draft pipe, tail water branch holes and tailwater holes. A water inlet is arranged under the water inlet tower, and is connected with the hydroelectric generator in the underground main powerhouse through a pressurized water flow tunnel and a diversion branch tunnel. The positional relationship and connection relationship of the above structures are shown in the figure, and the positional relationship can be adjusted according to the actual situation.

[0019] The water inlet tower 2 is provided with a water inlet 1, which leads the water in the flood discharge tunnel to the underground main powerhouse 6 through the pressurized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com