Omnidirectional flow making pipeline system of underwater vibrating platform

A pipeline system and shaking table technology, applied in the field of pipeline system, can solve the problems of large building volume, difficult simulation, large difference in structure fluid-structure coupling characteristics and earthquake response effects, etc., to ensure the rectification length, efficient use, guarantee Fast and efficient loading effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

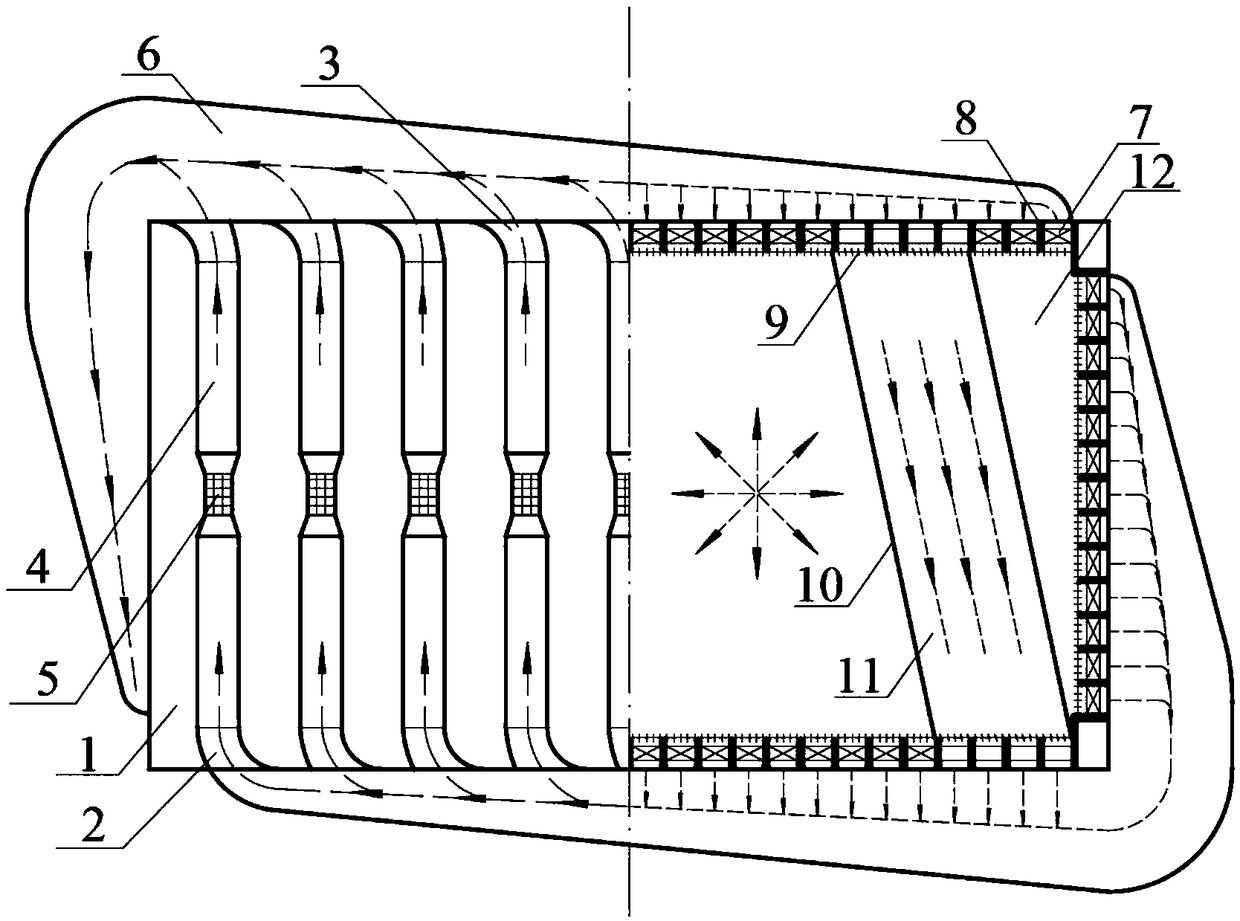

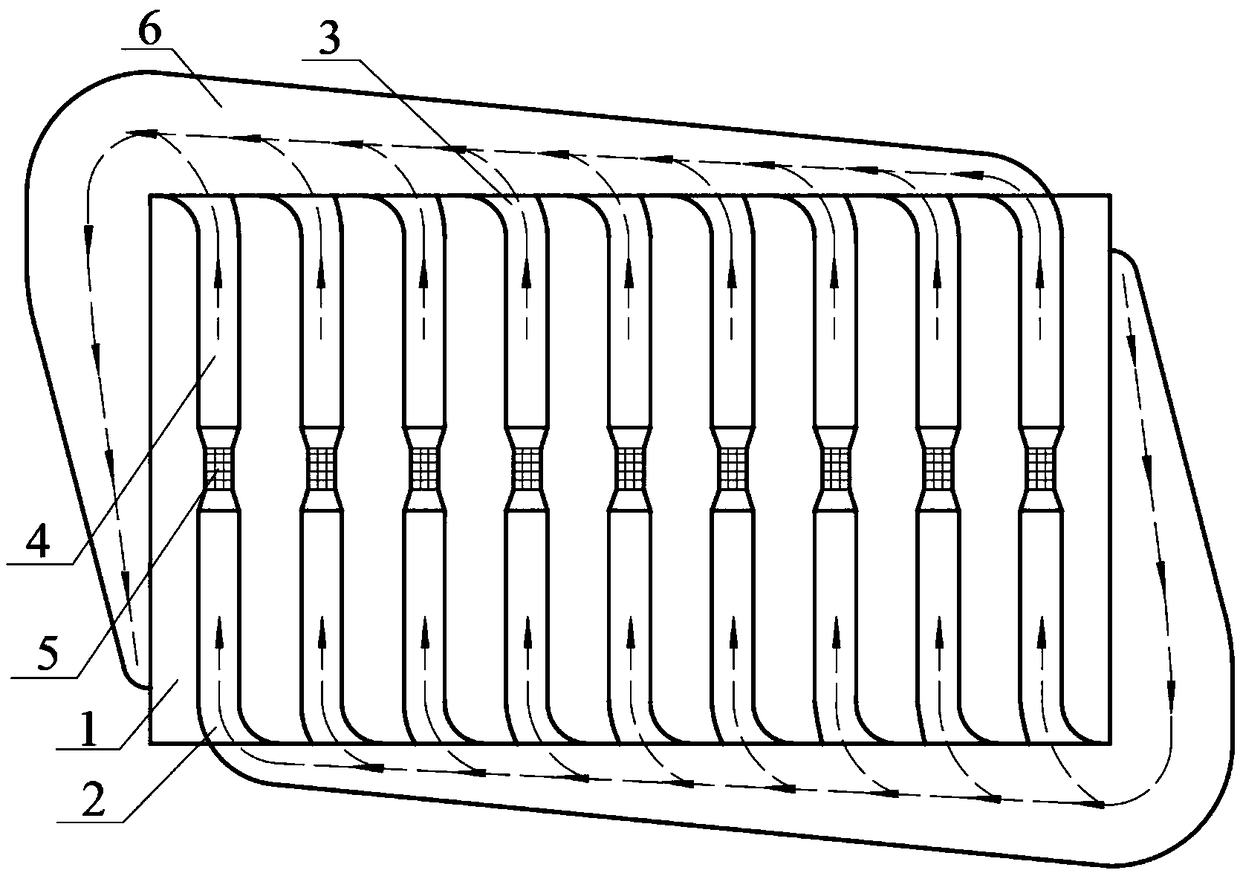

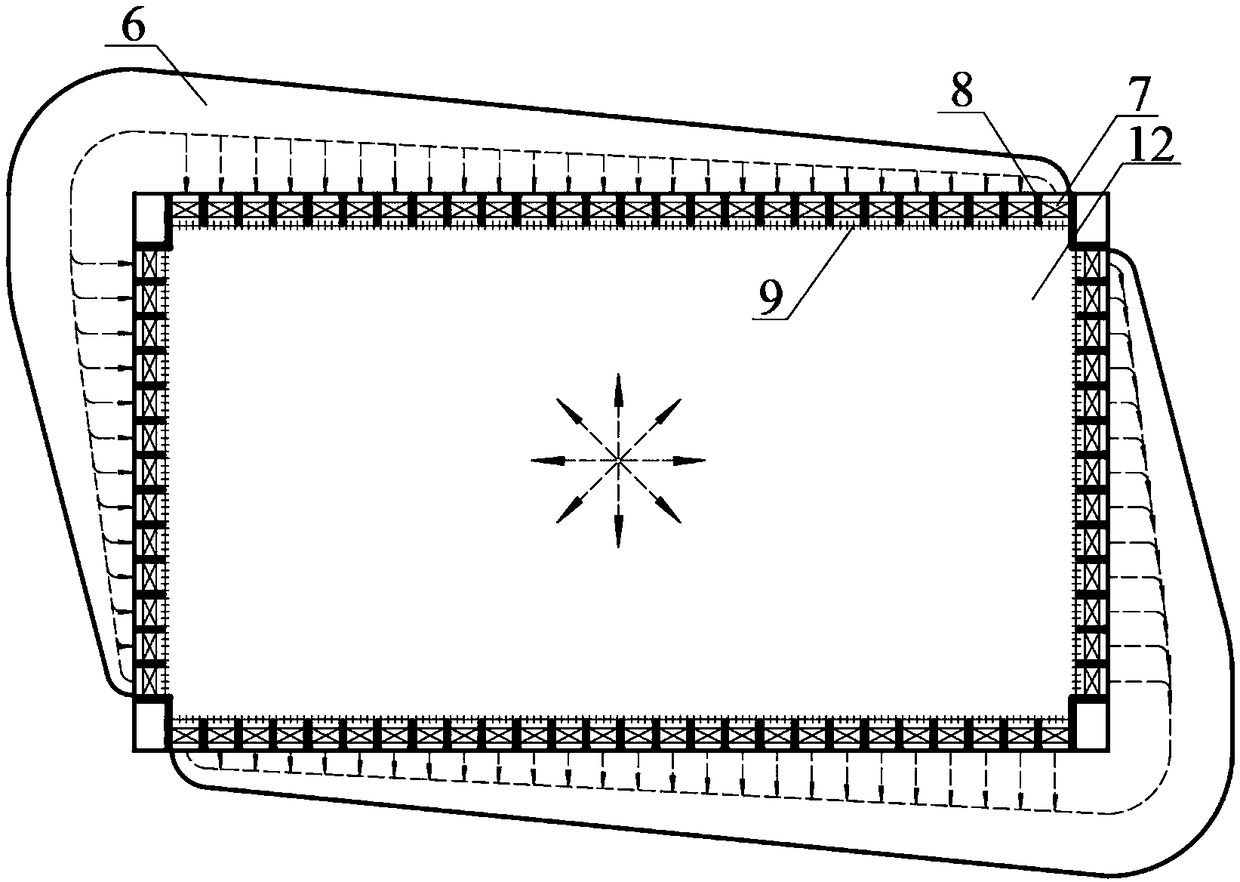

[0024] attached by figure 1 And attached figure 2 It can be seen that the omnidirectional flow-making pipeline system of the underwater vibrating table of the present invention consists of a flow-making pool 1, a return port 2, an outlet port 3, a return pipe 4, a two-way tubular pump 5, a confluence area 6, a gate 7, a gate pier 8, Guide vane 9, baffle plate 10 constitutes. Among them, the flow-making pool 1 is divided into two layers, which are made of reinforced concrete materials. The upper layer is the test area, and the lower layer is the return area.

[0025] See attached figure 2 , the return area of the lower layer of the flow-making pool 1 includes the return port 2, the outlet port 3, the return pipe 4, and the two-way flow pump 5; wherein, the return port 2 is connected to the return pipe 4, and the return pipe 4 is connected to the two-way flow pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com