Apparatus for rapidly increasing sediment concentration of sand silo/thickener and improving fluidization property

A technology of thickener and sand bin, which is applied to the feeding/discharging device of the settling tank, sedimentation and separation, chemical instruments and methods, etc., to achieve the effects of increasing sand settling speed, reducing power consumption, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

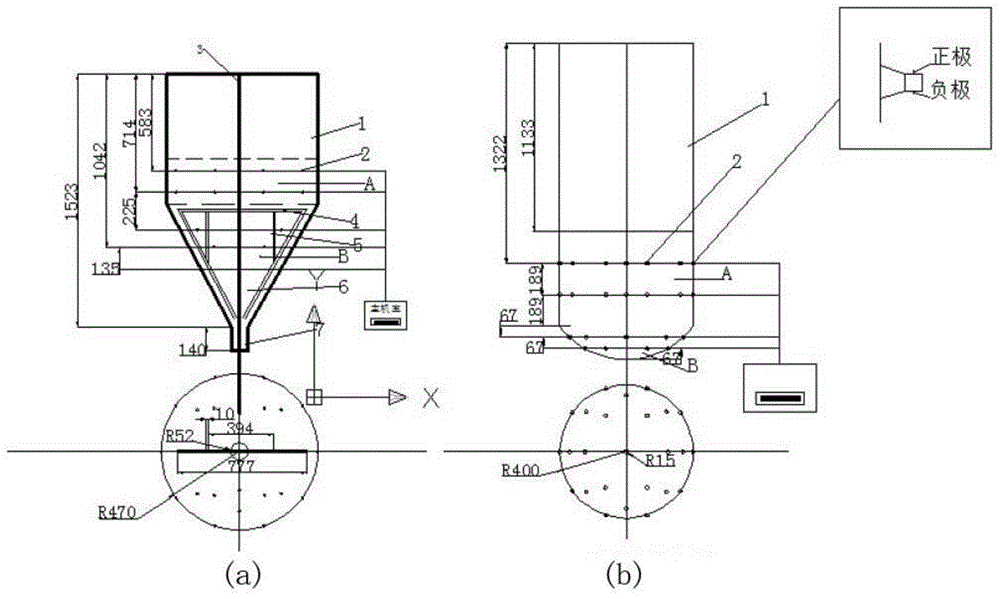

Image

Examples

Embodiment Construction

[0037] In the sand setting process, the ultrasonic generator in the settlement area is turned on to generate 20KHZ ultrasonic waves, which are converted into mechanical vibration through the transducer, and the mechanical vibration acts on the mortar to increase the sand setting speed; ensure proper "sand raising" time and ensure sand settling concentration (take a gold mine as an example, ensure that the concentration of sand settling is about 70%).

[0038] In the sand release process, the ultrasonic generator in the settlement area is turned on to generate 20KHZ ultrasonic waves, which are converted into mechanical vibration through the transducer to improve the fluidization of the mortar, increase the sand release rate, and ensure long-term stable sand discharge of the mortar (a gold mine is used as an example) For example, after slurry making, it is necessary to ensure that the sand concentration in the sand bin is continuously stable at about 68% for a long time).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com