High-temperature, high-pressure and high-flow-rate moisture environment corrosion simulation loop system

A high-temperature, high-pressure, environmental corrosion technology, which is applied in the fields of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problem of inability to realize the simulation of corrosion on the top of submarine pipelines, difficulty in ensuring the same flow state, and increase the power consumption of air pumps, etc. Problems, to achieve the effect of uniform flow state, reduce temperature rise, and reduce flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

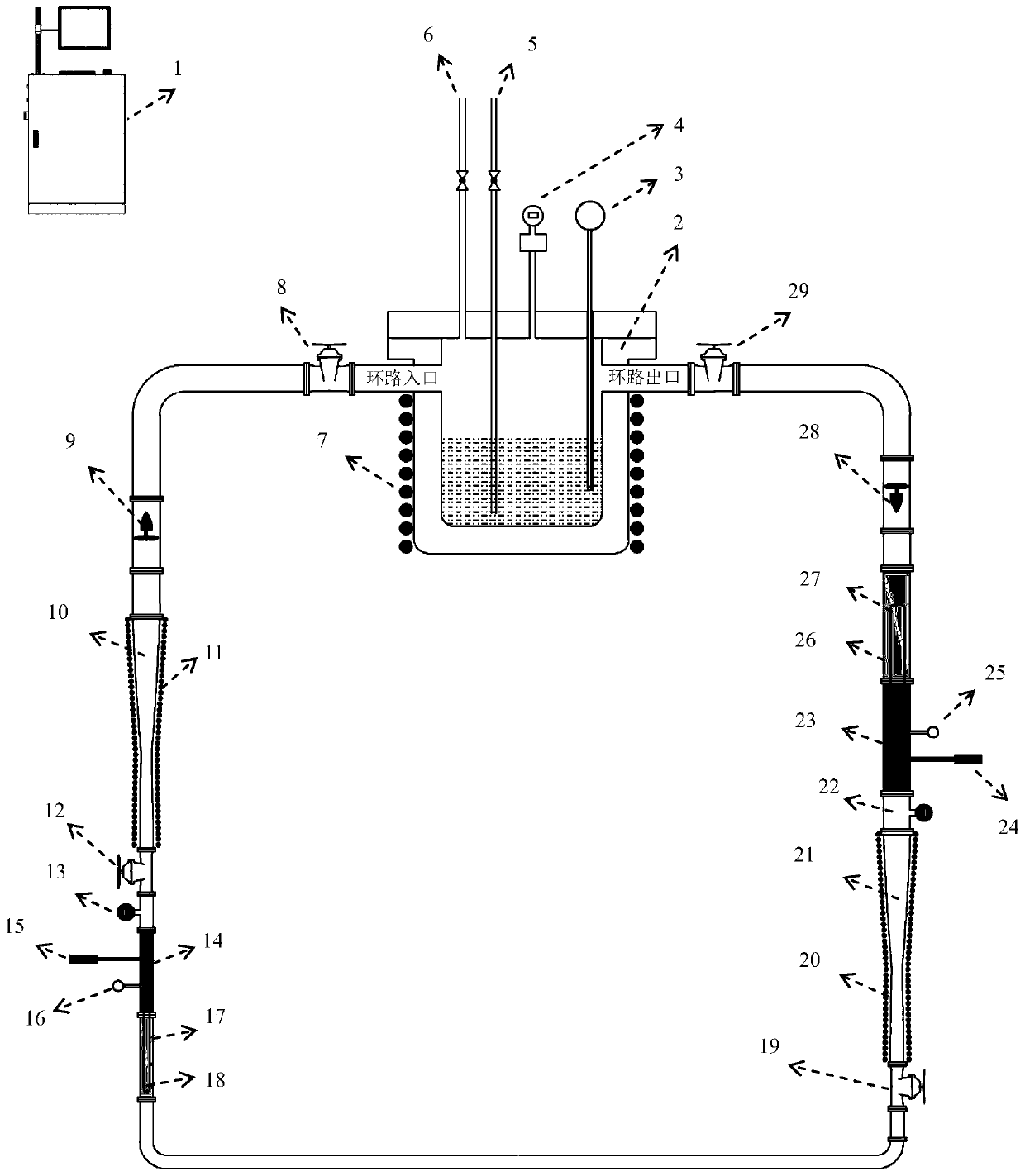

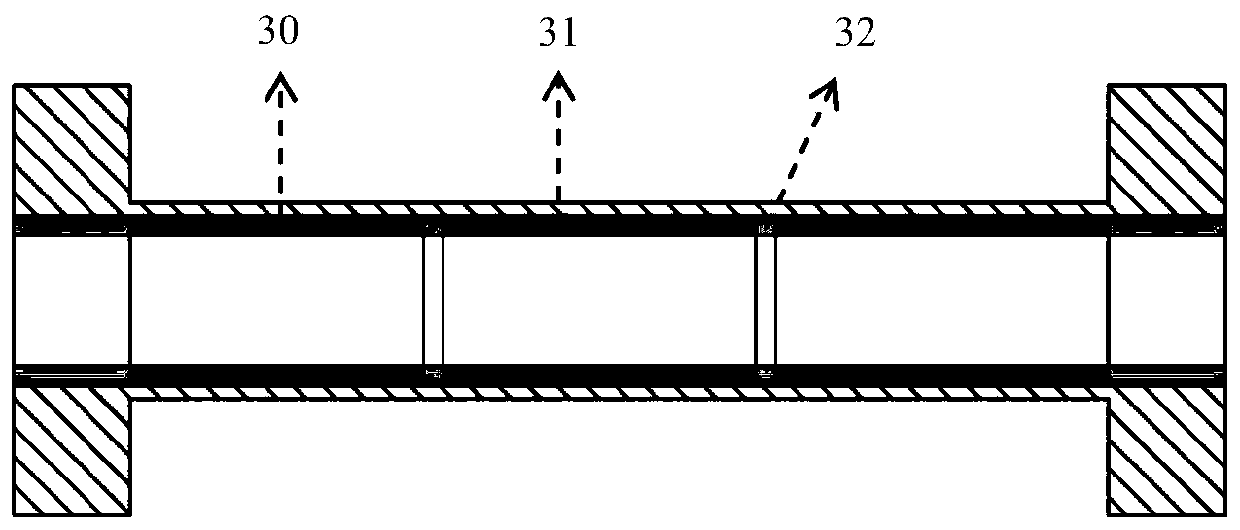

[0039] Such as figure 1 As shown, the temperature, high pressure and high flow rate H provided by the present invention 2 S / CO 2 Schematic diagram of the structure of the corrosion simulation loop system in a wet environment, including: control cabinet 1, high-temperature autoclave 2, thermocouple a3, pressure variable device 4, air inlet 5, exhaust port 6, heating coil a7, valve a8, The first axial fan 9, the first Laval tube 10, the heating coil b11, the valve b12, the gas flow meter a13, the first corrosion monitoring section 14, the corrosion probe a15, the thermocouple b16, the first sample mounting section 17. Thermoelectric refrigeration device a18, valve c19, heating coil c20, second Laval tube 21, gas flow meter b22, second corrosion monitoring section 23, corrosion probe b24, thermocoupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com