Detachable high-precision continuous sediment-taking bed load sediment discharge measuring device

A measuring device and bedding technology, which is applied in the direction of measuring device, particle size analysis, testing of machine/structural components, etc., can solve the problems of disturbed water flow field, insufficiency of sand extraction from the funnel, etc., and achieves the effect of facilitating the stuck

Pending Publication Date: 2017-08-25

ZHEJIANG UNIV

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to solve the problems of disturbed water flow field and endless sand taken by the funnel during the sand taking experiment, the present invention provides a deta

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

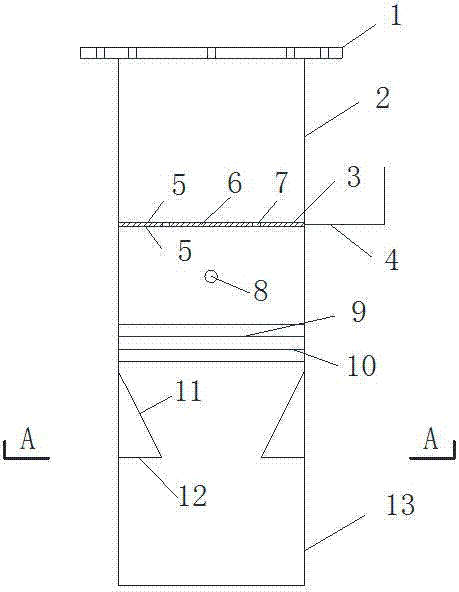

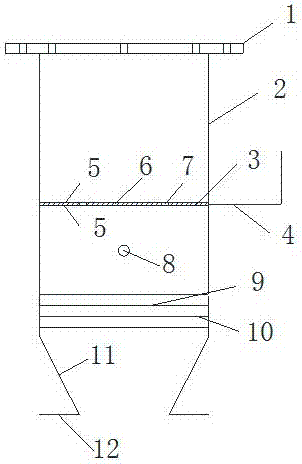

The invention discloses a detachable high-precision continuous sediment-taking bed load sediment discharge measuring device. The device mainly comprises a sediment collection inner cylinder and a sediment collection outer cylinder, wherein the sediment collection outer cylinder is positioned below the sediment collection inner cylinder; a circular turning plate is arranged inside the sediment collection inner cylinder; the sediment collection inner cylinder is divided into an upper sediment collection layer and a lower sediment taking layer; the circular turning plate is connected with a rotating shaft outside the sediment collection inner cylinder; the circular turning plate is turned by the rotating shaft; a water inlet and air outlet guide pipe is arranged on the cylindrical wall of the sediment collection inner cylinder, positioned below the circular turning plate and connected with the tail of a water tank through a connecting rubber hose; the lower part of the sediment taking layer of the sediment collection inner cylinder stretches into the sediment collection outer cylinder; the sediment collection outer cylinder is gradually closed so as to form an inverted cone frustum; a circular baffle is further arranged at the bottom of the inverted cone frustum. According to the device, the bed load sediment discharge of uniform/non-uniform sediments can be accurately measured.

Description

technical field [0001] The invention relates to a test device for the discipline of river sediment dynamics, in particular to a measuring device for studying the sediment transport rate of moving matter during the test of a sediment tank. Background technique [0002] River dynamics is a subject that studies the transport process of sediment in water flow and the movement law of sand-carrying water flow. Due to the unstable sampling of the drift mass in the field, there are large errors, and the engineering has to rely on the formula of the drift mass sediment transport rate derived from the actual measurement and deduction in the laboratory. important means. At present, the sand funnel, the measuring device used in the laboratory to measure the sand transport rate of the transported mass, has the following disadvantages: [0003] Some sand funnels are only equipped with a valve. When collecting the moving sediment, in order to ensure that the sediment in the tank does not...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N15/02G01M10/00

CPCG01M10/00G01N15/0255

Inventor 祝丽丽郭立恒孙志林黄赛花章军军

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com