System and method for producing hydrogen and methyl alcohol by utilizing residual electricity and residual heat of coal-fired generating unit

A generator set and generator technology, which is applied in the field of hydrogen and methanol production systems, can solve problems such as high cost and low efficiency, and achieve the effects of reducing installation difficulty and complexity, reducing carbon emissions, and reducing carbon dioxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

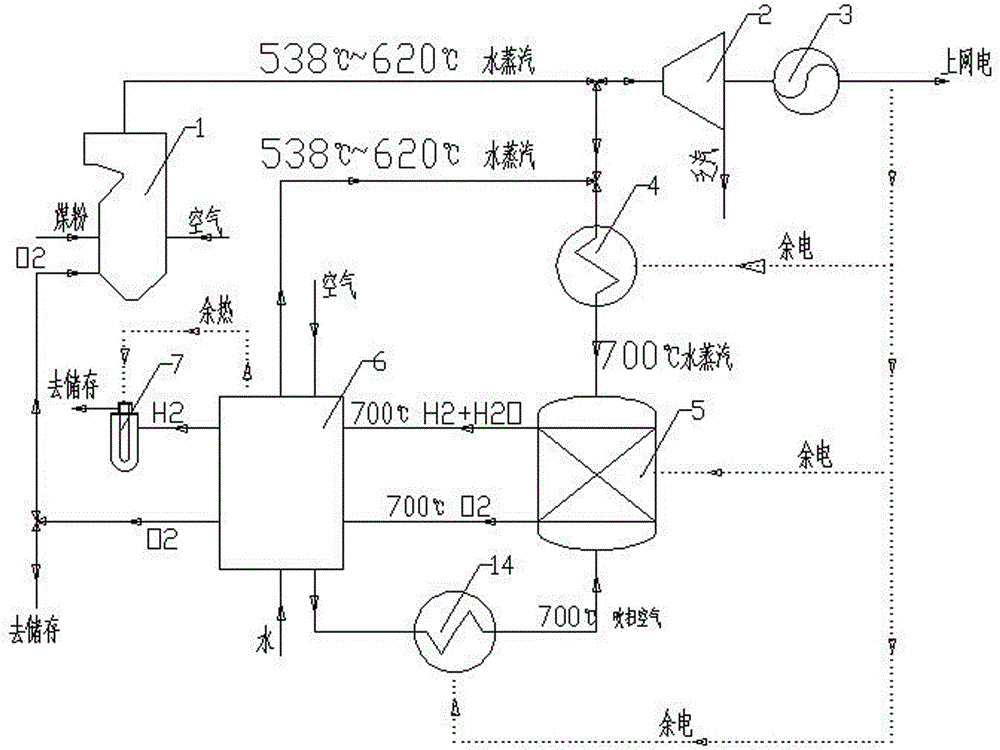

Embodiment 1

[0037] In this example, the method of hydrogen production is hydrogen production by electrolysis of high-temperature steam, and the main product is hydrogen. Such asfigure 1 Shown, this embodiment consists of supercritical / ultra-supercritical boiler 1, steam turbine 2, generator 3, steam auxiliary electric heater 4, high-temperature steam electrolytic cell 5, waste heat recovery device 6, hydrogen dryer 7, purge air Auxiliary electric heating device 14 is formed.

[0038] The main steam outlet of supercritical / ultra-supercritical boiler 1 is divided into two ways through the three-way valve: one way enters the steam turbine 2 to do work to drive the generator 3 to generate electricity, and the other way enters the water steam to assist the electric heater 4 to heat up to the high-temperature water steam electrolysis working temperature and then enters High-temperature steam electrolysis cell 5 electrolyzes, the outlet of the cathode side of the electrolysis cell is a high-temp...

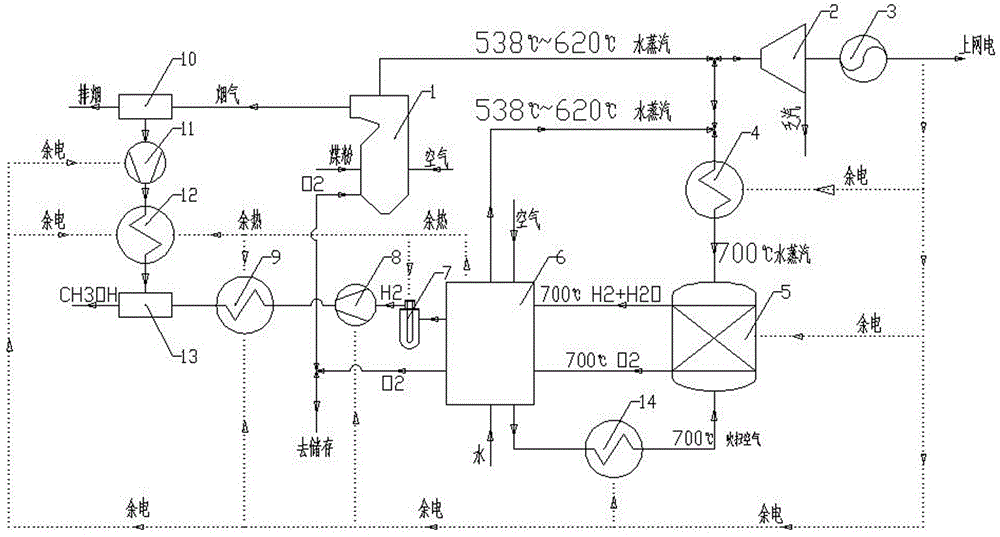

Embodiment 2

[0046] In this example, the method of hydrogen production is electrolysis of high-temperature steam to produce hydrogen, and the main product is methanol. Such as figure 2 As shown, this embodiment consists of a supercritical / ultra-supercritical boiler 1, a steam turbine 2, a generator 3, a steam auxiliary electric heater 4, a high-temperature steam electrolyzer 5, a waste heat recovery device 6, a hydrogen dryer 7, and a hydrogen compressor Machine 8, hydrogen heating device 9, carbon dioxide capture device 10, carbon dioxide compressor 11, carbon dioxide heating device 12, methanol synthesis device 13, purge air auxiliary electric heating device 14.

[0047] The main steam outlet of supercritical / ultra-supercritical boiler 1 is divided into two ways through the three-way valve: one way enters the steam turbine 2 to do work to drive the generator 3 to generate electricity, and the other way enters the water steam to assist the electric heater 4 to heat up to the high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com