Supporting leg tester

A technology of testing machine and support frame, which is applied in the direction of vehicle testing, machine/structural component testing, instruments, etc. It can solve problems such as difficult to guarantee safety, potential safety hazards, and inability to actually detect the quality of outriggers, achieving low manufacturing costs , accurate load capacity, and the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

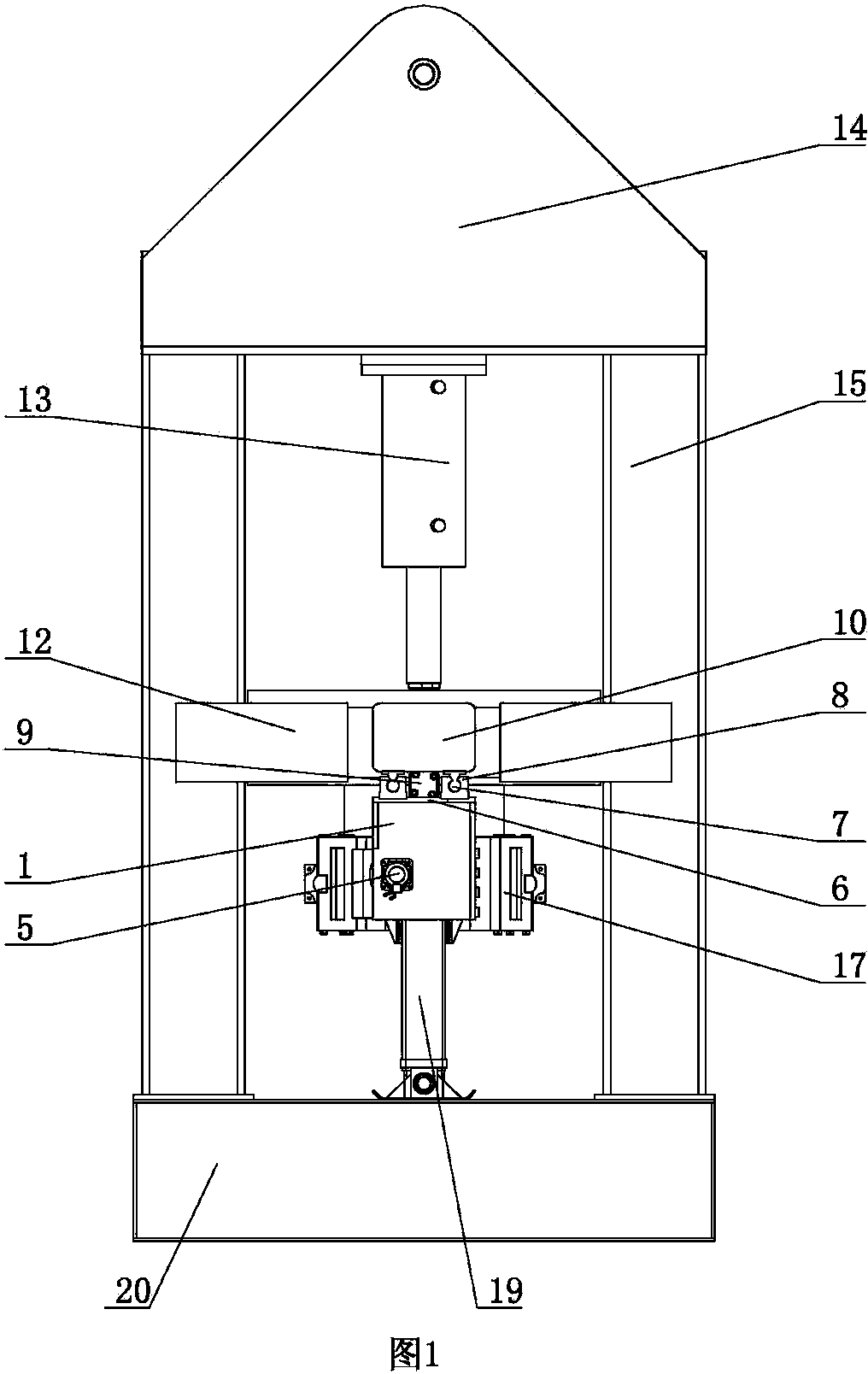

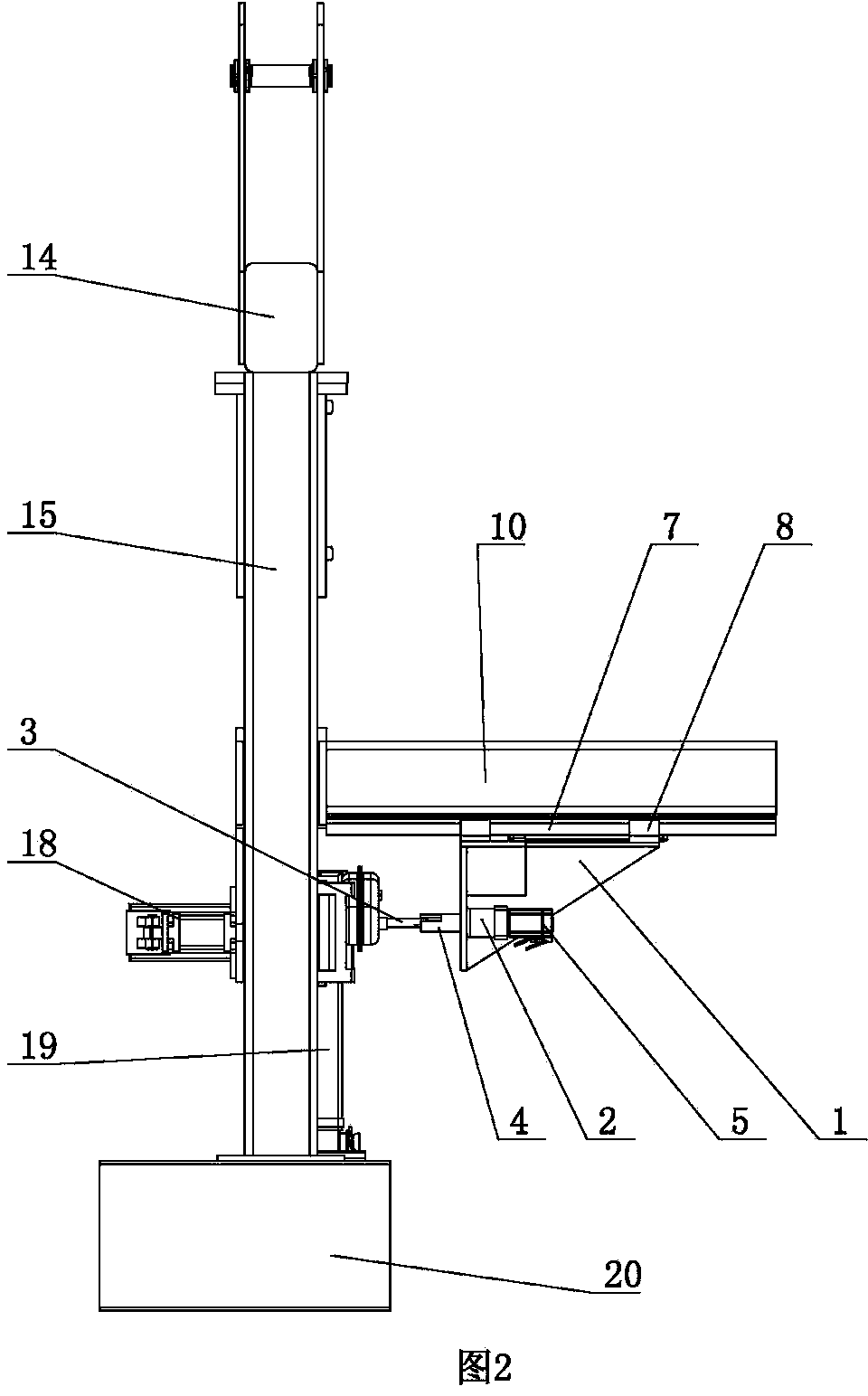

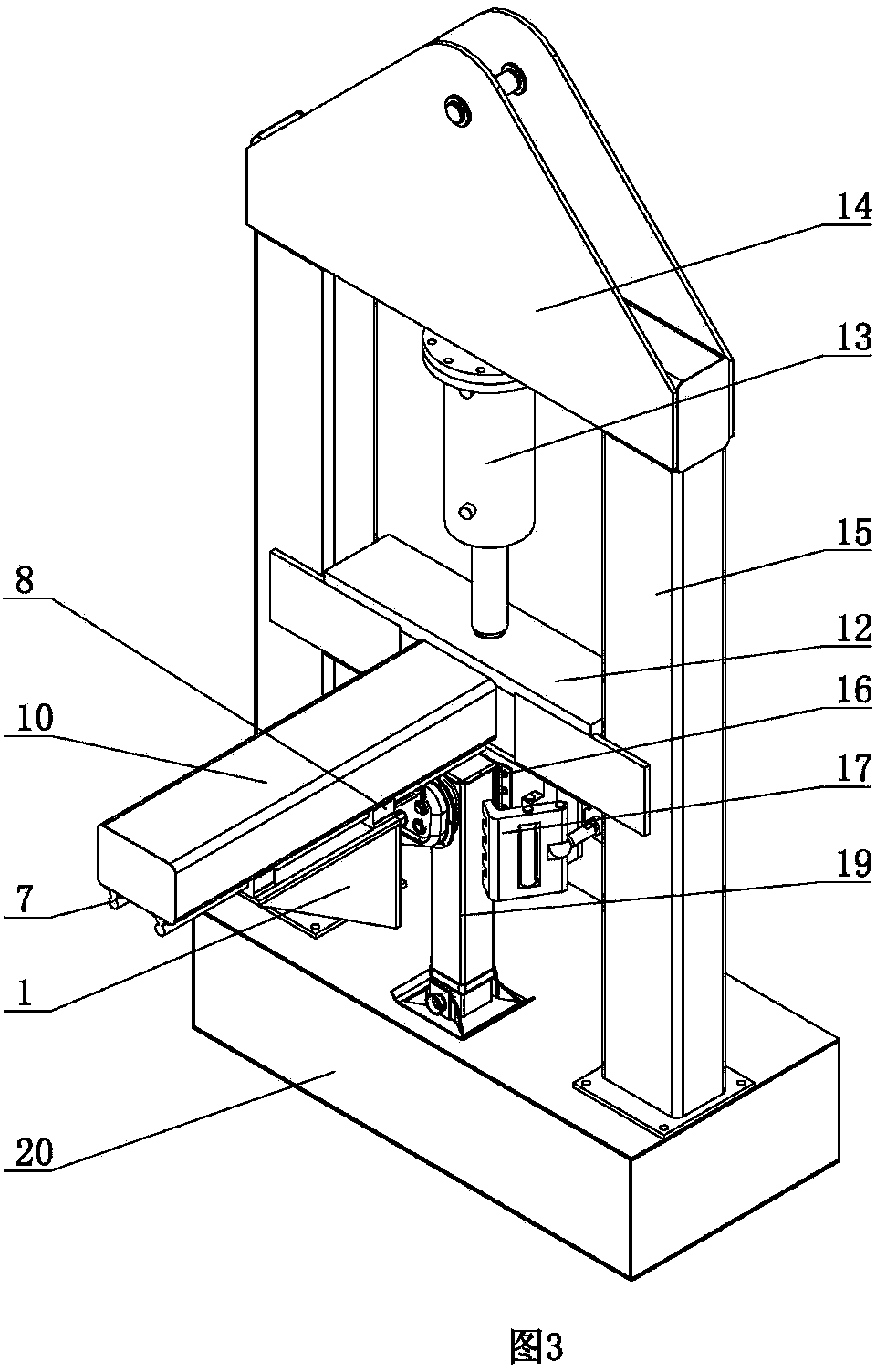

[0009] The outrigger testing machine of the present invention includes a support frame on which a pressing mechanism is installed. The pressing mechanism is upwardly connected with the support frame. The support frame can suspend the pressing mechanism above the legs 19, so that the pressing mechanism exerts a downward force on the legs 19. The execution part of the pressing mechanism is connected with the pressing block 12 downwards. The support frame is provided with a vertical guiding mechanism, which cooperates with the pressing block 12 to guide the pressing block 12 vertically, ensuring that the pressure exerted by the pressing mechanism effectively acts on the supporting leg 19, making the test closer to the supporting leg 19 Realized working environment. At the same time, side bending of the supporting legs 19 can be prevented to a certain extent.

[0010] During detection, the upper part of the supporting leg 19 can be fixed on the pressure block 12 through the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com