Plate detection method, device and system for blanking line

A detection method and blanking line technology, applied in the direction of measuring devices, optical devices, image data processing, etc., can solve the problems of slow manual testing, low accuracy, low efficiency, etc., to avoid errors and improve accuracy , the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

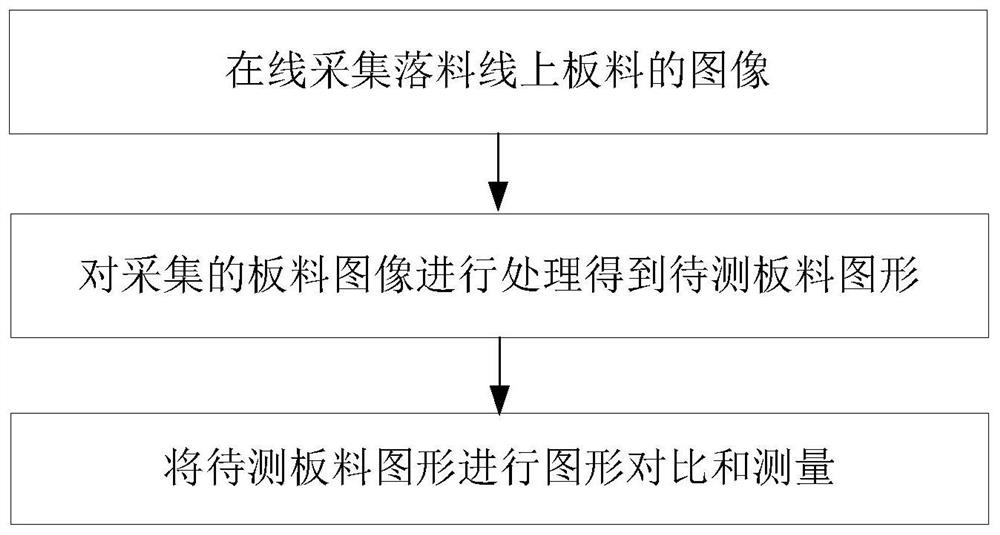

[0102] figure 1 It is a flow chart of a blanking line detection method according to an exemplary embodiment. Such as figure 1 As shown, a blanking line sheet material detection method provided by an embodiment of the present invention includes the following steps:

[0103] Online collection of blanking line sheet images;

[0104] Process the collected sheet metal images to obtain the sheet metal graphics to be tested;

[0105] Compare and measure the graphics of the sheet to be tested.

[0106] As a possible implementation of this embodiment, the online collection of images of blanks on the blanking line includes:

[0107] Collect the real-time speed of the sheet metal movement, and collect the image of the sheet material according to the real-time speed of the sheet material movement.

[0108] As a possible implementation of this embodiment, the processing of the collected sheet image to obtain the image of the sheet to be tested includes:

[0109] Perform binarization ...

Embodiment 2

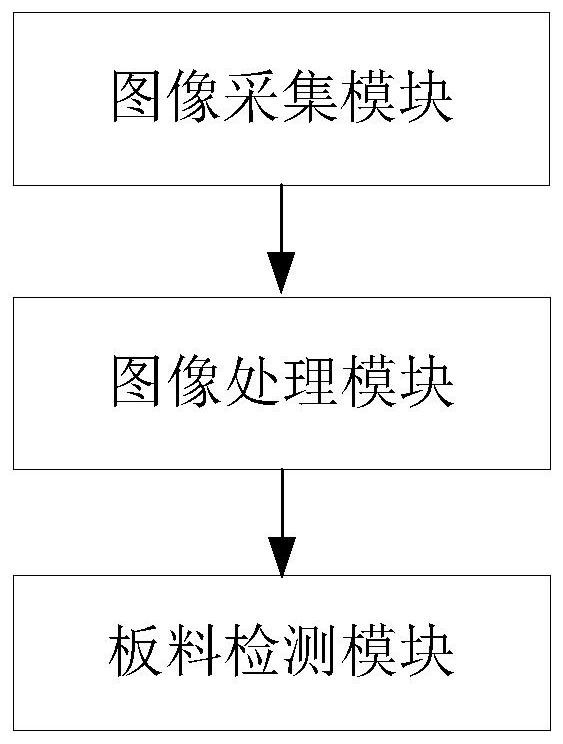

[0114] figure 2 It is a structural diagram of a blanking line detection device according to an exemplary embodiment. Such as figure 1 As shown, a blanking line sheet detection device provided by an embodiment of the present invention includes:

[0115] The image acquisition module is used for online acquisition of images of blanks on the blanking line;

[0116] The image processing module is used to process the collected sheet metal images to obtain the sheet material graphics to be measured;

[0117] The sheet metal detection module is used to compare and measure the graph of the sheet to be tested.

[0118] As a possible implementation of this embodiment, the image acquisition module is specifically configured to: collect the real-time speed of the sheet metal movement, and collect the image of the sheet material according to the real-time speed of the sheet material movement.

[0119] As a possible implementation of this embodiment, the image processing module is speci...

Embodiment 3

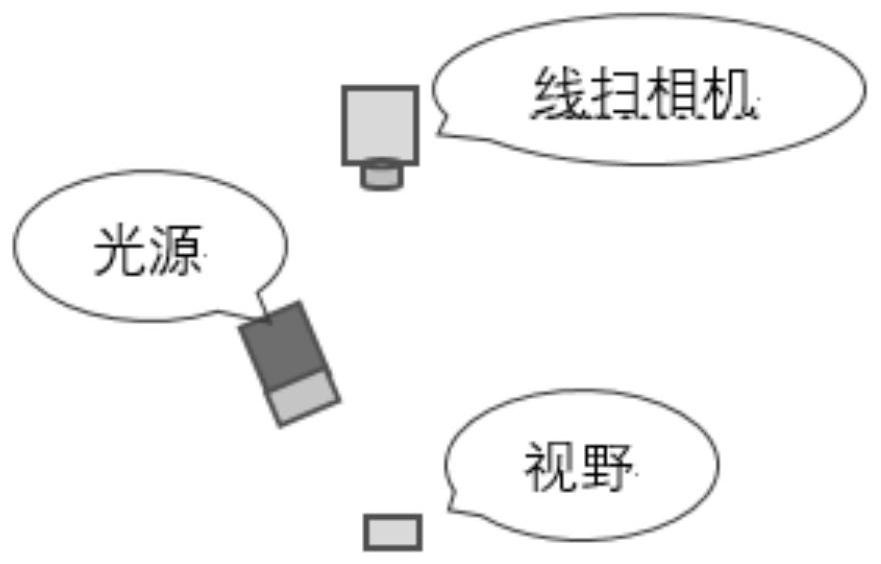

[0124] Such as Figure 3-Figure 6 As shown, a sheet metal detection system for a blanking line provided by an embodiment of the present invention includes: a camera, a light source, and an industrial computer. The camera is arranged above the blanking line and is electrically connected to the industrial computer. Matching settings are for the camera to fill in the light.

[0125] As a possible implementation of this embodiment, the industrial computer is installed with an image processing system program, and the image processing system program executes the steps of the blanking line detection method described in Embodiment 1.

[0126] As a possible implementation of this embodiment, the blank detection system further includes a robot, which is electrically connected with the industrial control and is used for grabbing the blank on the moving belt of the blanking line.

[0127] The camera adopts a line-scan camera: mainly to take pictures of the sheet to obtain the basic data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com