Detection device of distance between crankshaft locating surface and axis, and usage method thereof

A detection device, positioning surface technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of high labor intensity, can not be found in time, the same quality problems, etc., to reduce fatigue strength and reduce quality problems risk, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

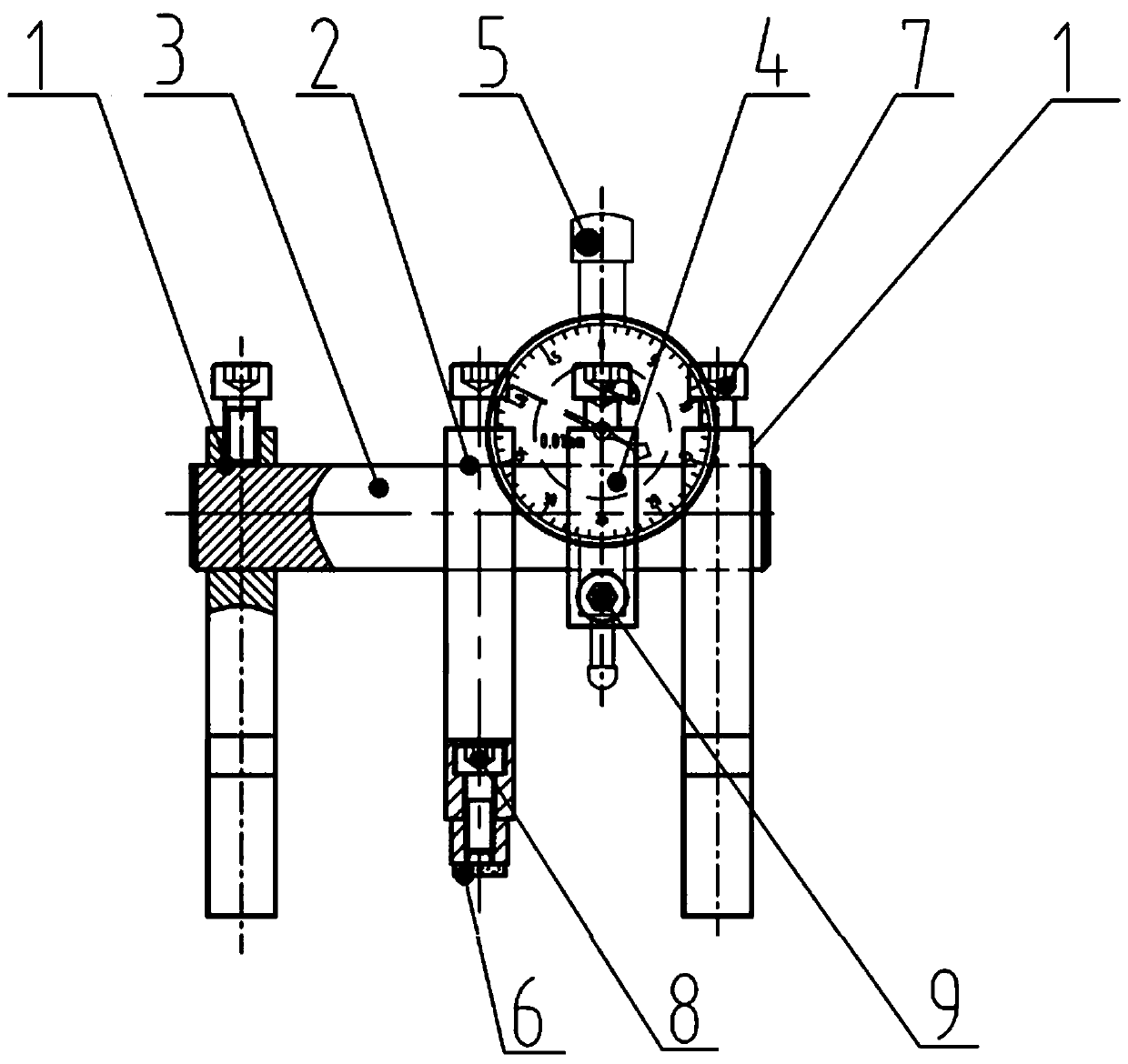

[0043] Reference Figure 1-6 , A device for detecting the distance between the crankshaft positioning surface and the shaft center, comprising a connecting rod 3, a positioning device and a measuring device provided on the connecting rod 3;

[0044] The positioning device includes a connecting rod positioning frame 2, a connecting rod positioning block 6, and a spindle positioning block 1 in an inverted Y shape;

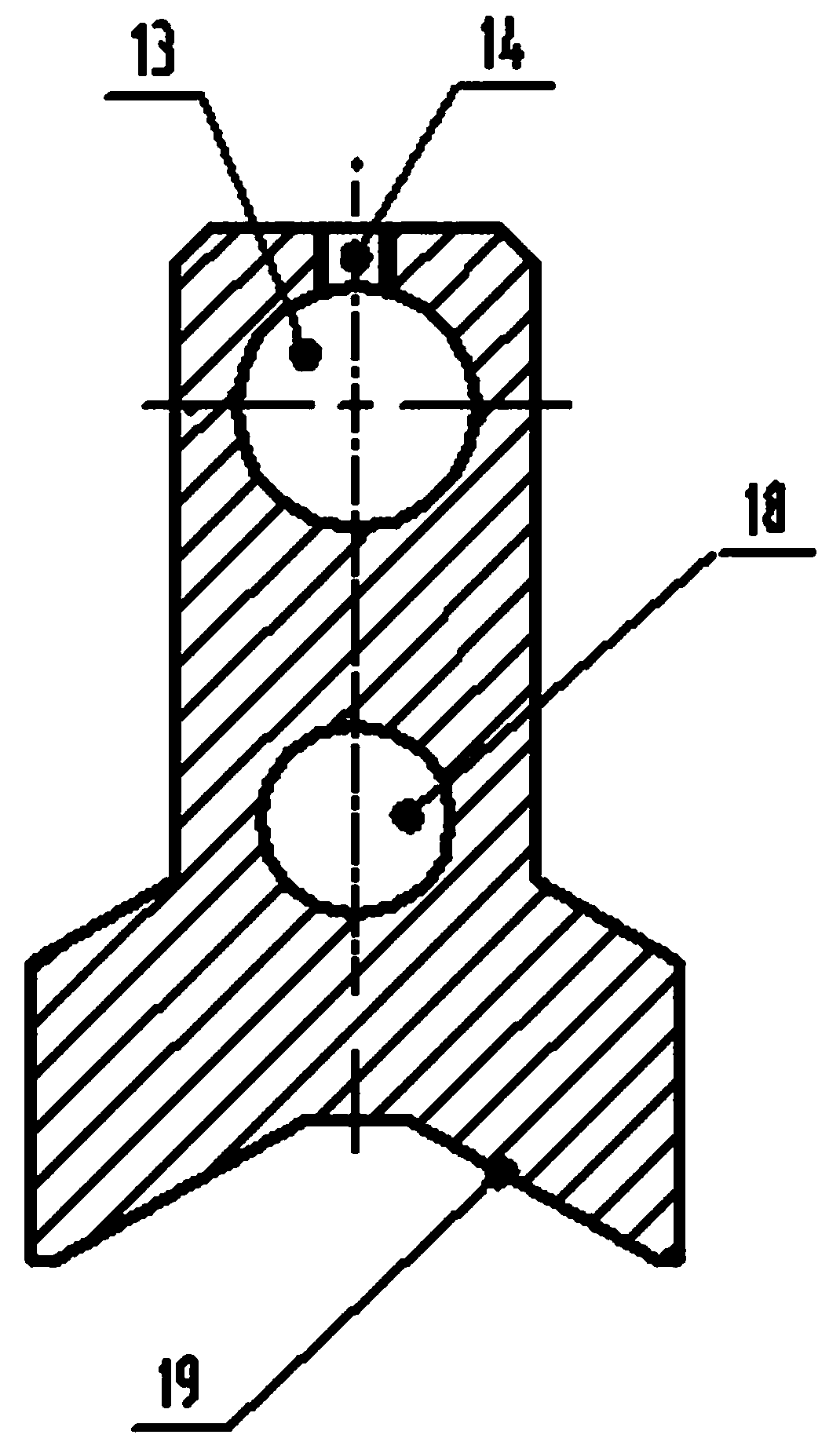

[0045] The upper part of the inverted Y-shaped spindle positioning block 1 is provided with a connecting hole 13, and the included angle 19 of the lower V-shaped opening is 120 degrees;

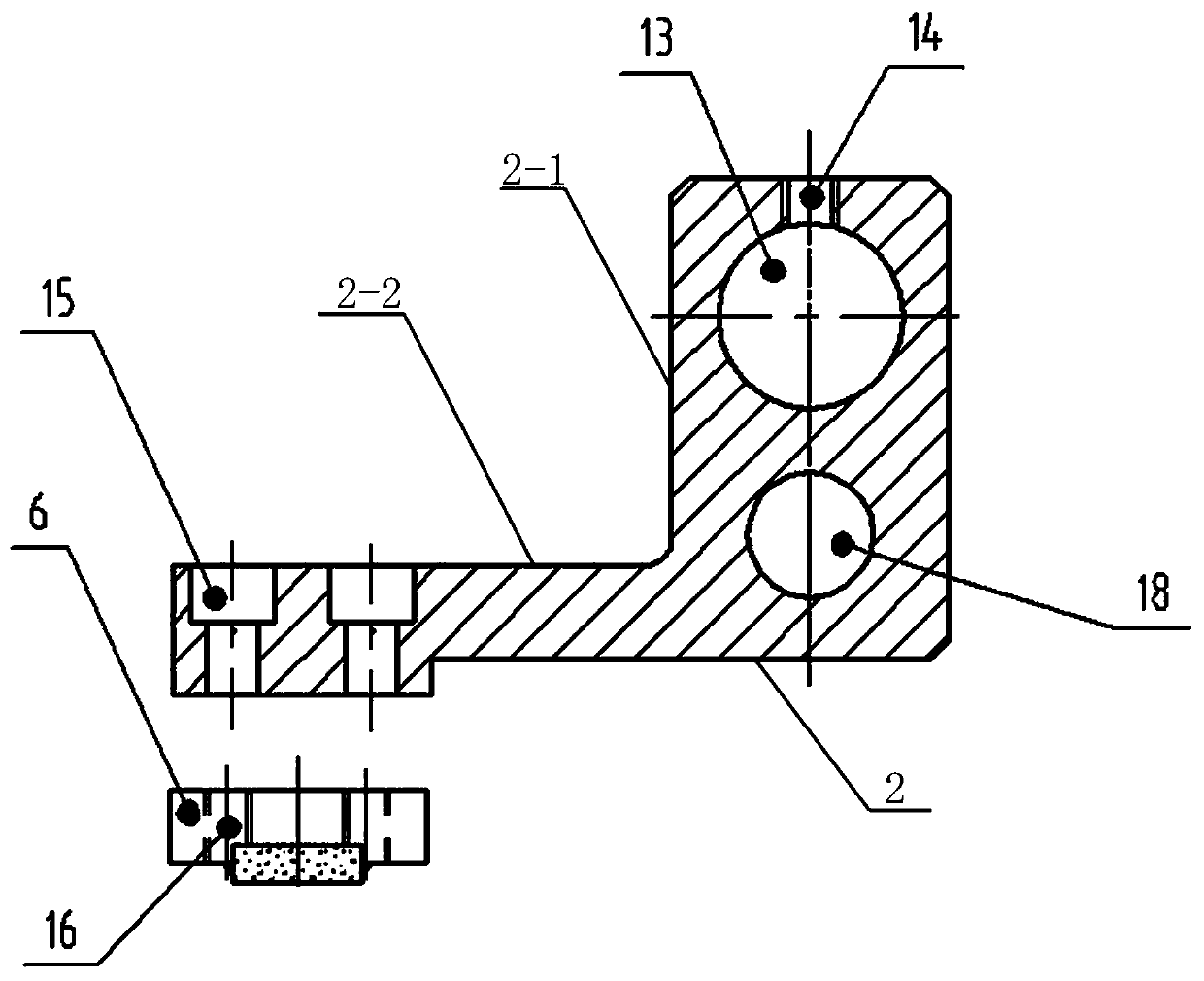

[0046] The connecting rod positioning frame 2 is composed of a longitudinal block 2-1 and a horizontal block 2-2 in an L shape;

[0047] A connecting hole is opened on the longitudinal block 2-1 of the connecting rod positioning frame 2, and an assembly counterbore 15 is longitudinally opened on the transverse block 2-2 of the connecting rod positioning frame 2;

[0048] The connecting rod po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com