Method for detecting surface defects of intaglio roller by using 3D photographing technology

A gravure plate roller and defect detection technology, applied in the direction of cleaning methods using tools, chemical instruments and methods, cleaning methods and utensils, etc., to improve process quality control, improve detection speed and judgment accuracy, and reduce interference points Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

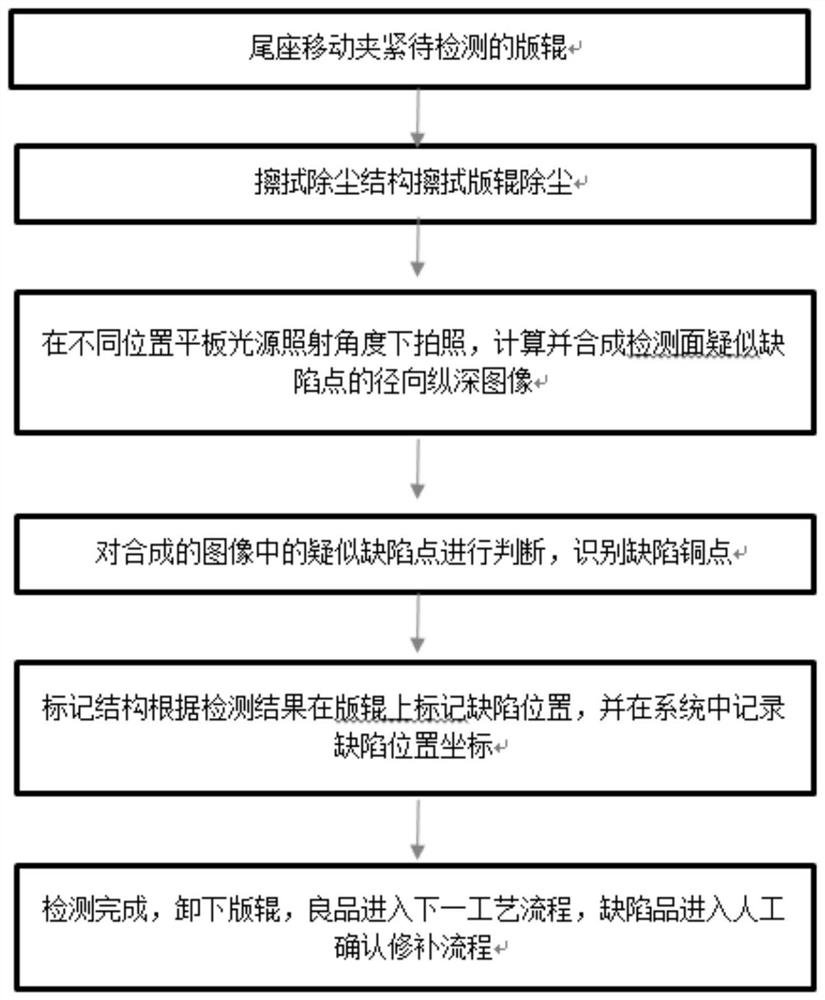

[0034] see figure 1 , the present embodiment provides a method for detecting defects on the surface of plate rollers using 3D photographing technology, comprising the following steps:

[0035] The tailstock drives the top to move the clamping plate roller, and the dust-free cloth wiping assembly mechanism is driven by the horizontal axis motor to move axially. While moving, the dust-free cloth wiping head presses the surface of the plate roller, and the plate roller is driven by the plate roller rotation motor Perform radial rotation and wipe the surface of the plate roller with a lint-free cloth. After the wiping is completed, the wiping assembly mechanism rotates and rolls through its own dust-free cloth, and the rotating dust-free cloth rolls a group of pressing plate rollers radially, ensuring that a new dust-free cloth is used for the next inspection. prevent cross-contamination;

[0036]The photo industrial camera is automatically fine-tuned along the radial direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com