Twin data-driven ship assembly product quality control system and configuration method

A data-driven, product quality technology, applied in the field of shipbuilding, can solve the problems of failure to predict the quality to be processed in advance, no analysis, simulation of the construction process technology, and failure to predict the components to be processed in advance, so as to achieve the effect of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

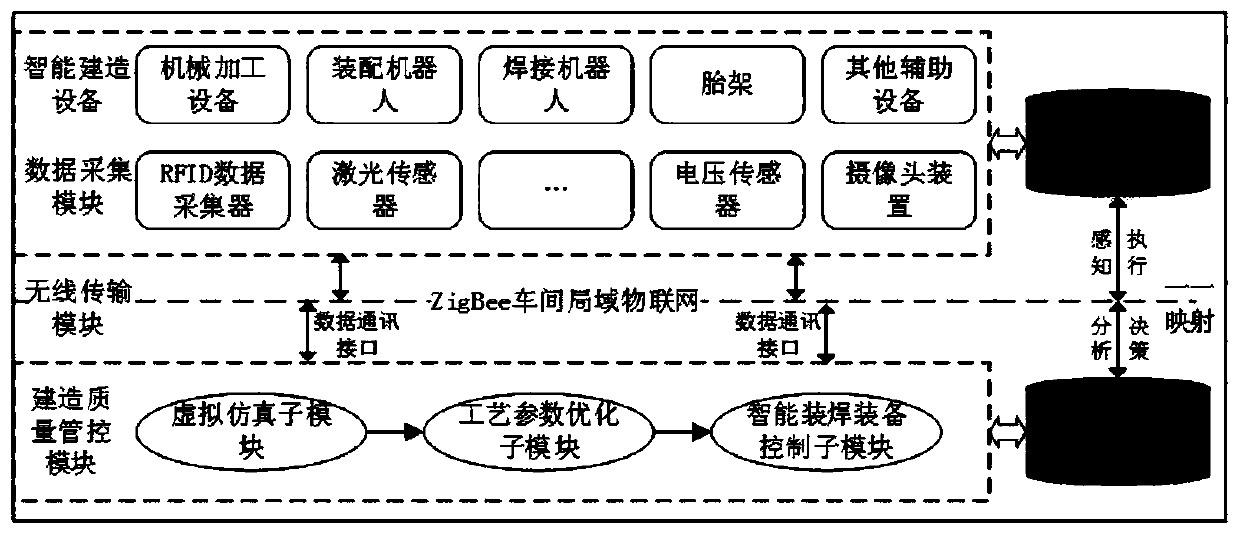

[0049] The structure of the product quality control system for ship assembly driven by twin data is as follows: figure 1 As shown, the system is divided into intelligent construction equipment, data acquisition module, wireless transmission module and construction quality control module.

[0050] Among them, intelligent construction equipment is the execution object of the physical space, which is used to complete the assigned construction tasks such as processing, assembly and welding, including mechanical processing equipment, assembly robots, welding robots, tire racks and other auxiliary equipment. A flexible production line is formed in accordance with the processing-assembly-welding construction process.

[0051] The data acquisition module is used for real-time collection of process data and equipment operation status data of the small group, medium group and large group in the shipbuilding process, equipped with a PLC embedded system equipment, RFID handheld data colle...

Embodiment 2

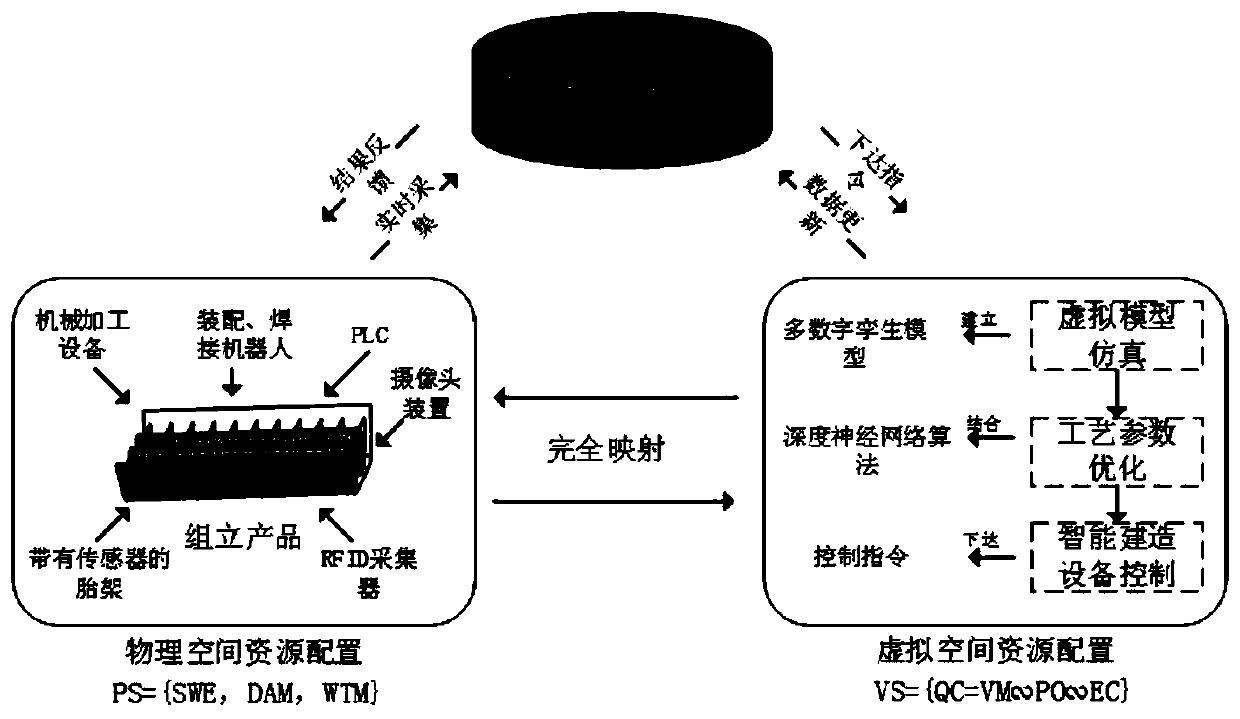

[0055] The configuration method of ship assembly product quality control system based on twin data drive is as follows: figure 2 As shown, the configuration of physical space resources includes the configuration of SWE for intelligent construction equipment, the configuration of DAM for data acquisition modules, and the configuration of WTM for wireless transmission modules.

[0056] First of all, intelligent construction equipment is equipped with several tire frame process equipment with sensor equipment, machining equipment, assembly and welding robots, a PLC embedded system equipment and camera device for the assembly of products in the process of ship segmental construction. Set up a flexible processing line for products. The modeling expression of intelligent construction equipment configuration is:

[0057] SWE={SC i , ME, WR, ES, CE}

[0058] SC i ={SC 1 , SC 2 …SC n-1 , SC n},

[0059] {SC 1 , SC 2 … SC n-1 , SC n} = {SS, TS, ... CS, VS}

[0060] Seco...

Embodiment 3

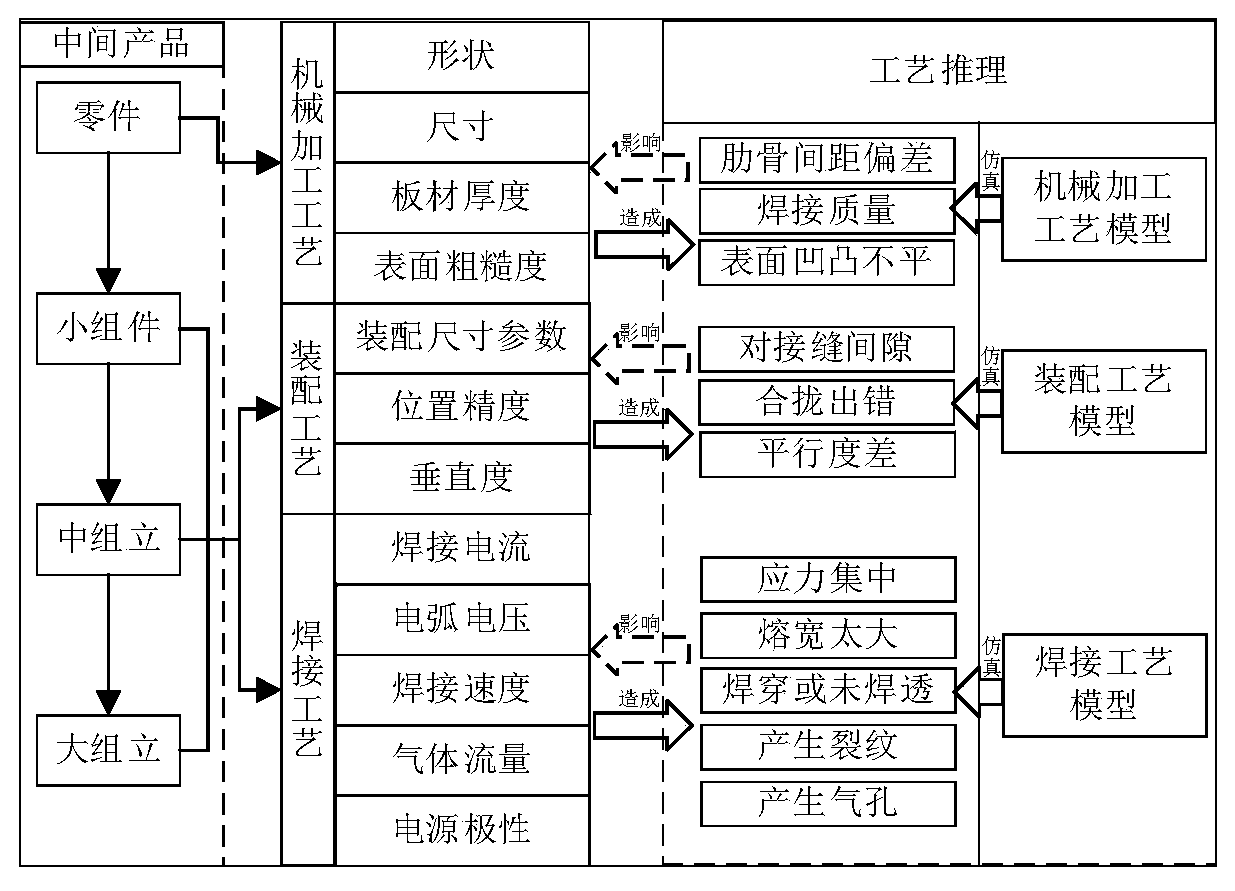

[0071] The process reasoning process of the digital twin process model is as follows: image 3 As shown, the intermediate products of ship block construction are composed of parts, small components, medium components and large components. The parts are matched with the machining process, and the small components, medium components and large components are matched with the assembly process and welding process respectively. Among them, the machining process parameters include parameters such as size, shape, plate thickness, and surface roughness; the assembly process parameters include parameters such as dimensional accuracy, position accuracy, and verticality; the welding process parameters include welding current, arc voltage, welding speed, and gas flow. As well as parameters such as the polarity of the power supply, process reasoning can deduce the quality defects caused by the process parameters, which are further confirmed by the digital twin process model, so as to accurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com