Rapid detection method for highway roadbed compaction quality

A technology of compaction quality and detection method, applied in the field of foundation soil survey, foundation structure engineering, construction, etc., can solve problems such as unreasonable, far-fetched, increase in the level and action time of dynamic stress of highway subgrade, etc. The effect of labor intensity, high degree of automation, and fast test speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

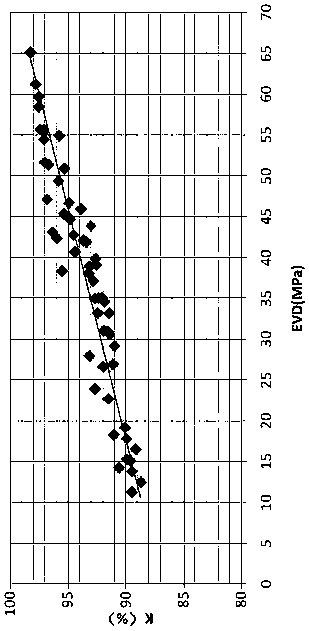

[0031] Example 1 Taking the loess filled subgrade as an example, the specific test steps are as follows:

[0032] (1) At the construction site of the loess filler subgrade, select a subgrade soil area to be inspected, randomly select a test point, and use a portable dynamic deformation modulus tester to test the dynamic deformation modulus E of the point vd value, and record the data.

[0033] ⑵In the specified range of the selected measuring point in step ⑴, select another measuring point, use the sand filling method to detect the degree of subgrade compaction, and record the data.

[0034] ⑶ Repeat steps ⑴~⑵, measure no less than 60 groups of corresponding data, eliminate abnormal data, select no less than 50 groups for numerical analysis, and establish the dynamic deformation modulus E of each soil quality according to the division of soil quality vd The relationship between the value and the degree of subgrade compaction K: K=0.35X+78.85 (see figure 1 ), imported into th...

Embodiment 2

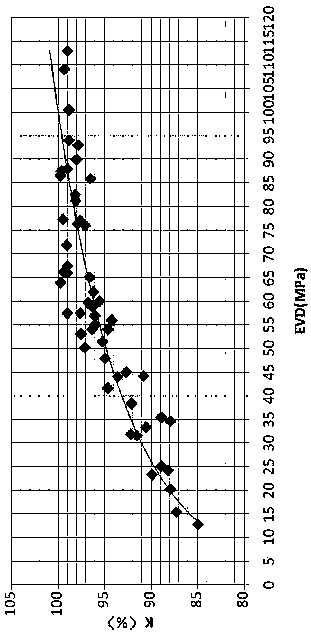

[0041] Example 2 Taking the gravel soil filled roadbed as an example, the specific test steps are as follows:

[0042] (1) At the construction site of the gravel soil filler subgrade, select a subgrade soil area to be inspected, randomly select a test point, and use a portable dynamic deformation modulus tester to test the dynamic deformation modulus E of the point vd value, and record the data.

[0043] ⑵In the specified range of the selected measuring point in step ⑴, select another measuring point, use the sand filling method to detect the degree of subgrade compaction, and record the data.

[0044] ⑶ Repeat steps ⑴~⑵, measure no less than 60 groups of corresponding data, eliminate abnormal data, select no less than 50 groups for numerical analysis, and establish the dynamic deformation modulus E of each soil quality according to the division of soil qualityvd The relationship between the value and the degree of subgrade compaction K: K=11.4lnX+47.21 (see figure 2 ), impo...

Embodiment 3

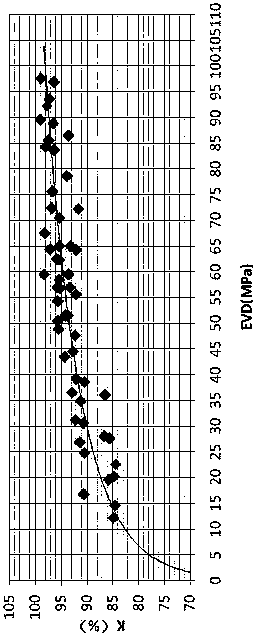

[0051] Example 3 Taking red mudstone filling roadbed as an example, the specific test steps are as follows:

[0052] (1) At the construction site of red mudstone filler subgrade, select a subgrade soil area to be inspected, randomly select a test point, and use a portable dynamic deformation modulus tester to test the dynamic deformation modulus E of the point vd value, and record the data.

[0053] ⑵In the specified range of the selected measuring point in step ⑴, select another measuring point, use the sand filling method to detect the degree of subgrade compaction, and record the data.

[0054] ⑶ Repeat steps ⑴~⑵, measure no less than 60 groups of corresponding data, eliminate abnormal data, select no less than 50 groups for numerical analysis, and establish the dynamic deformation modulus E of each soil quality according to the division of soil quality vd The relationship between the value and the degree of subgrade compaction K: K=8.7lnX+47.21 (see image 3 ), imported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com