AC LED manufacturing method

A manufacturing method and a technology of a light-emitting area, which are applied in the field of ACLED manufacturing, can solve problems such as burning rectifier module pads, increasing manufacturing costs, and material rework, and achieve the effects of improving yield, increasing production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings of the description.

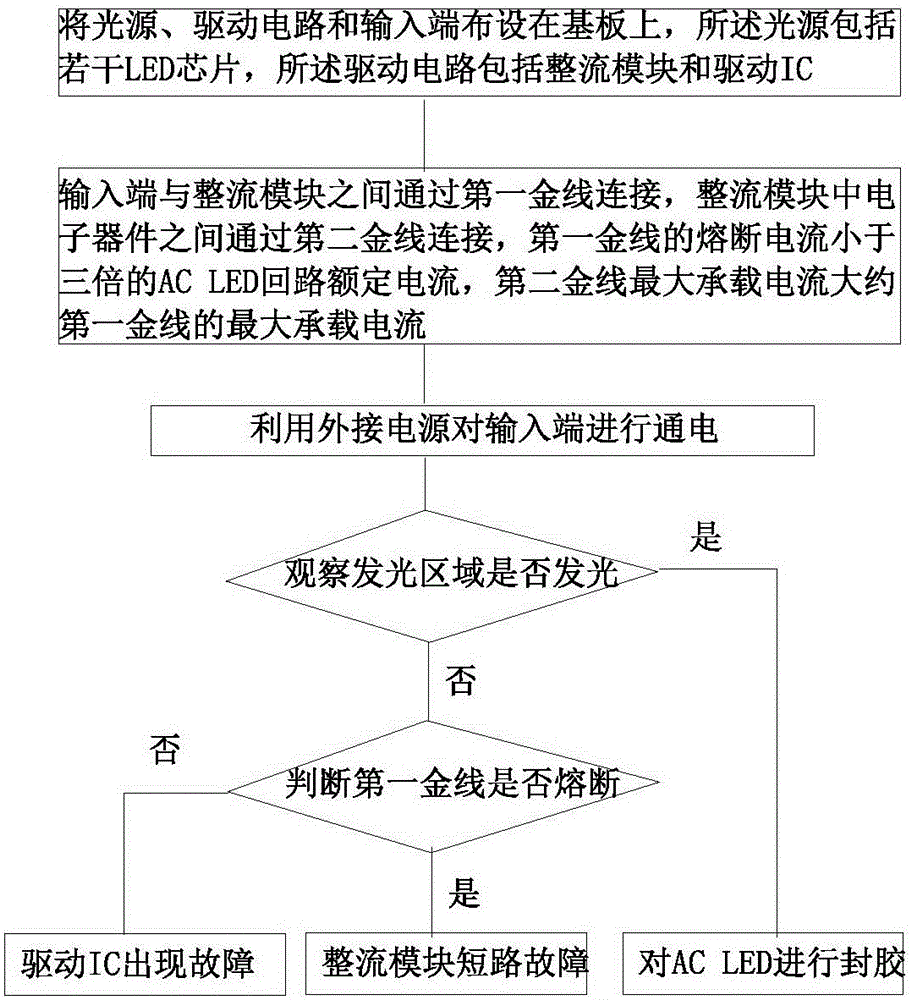

[0020] Such as image 3 Shown, a kind of AC LED manufacturing method comprises the following steps:

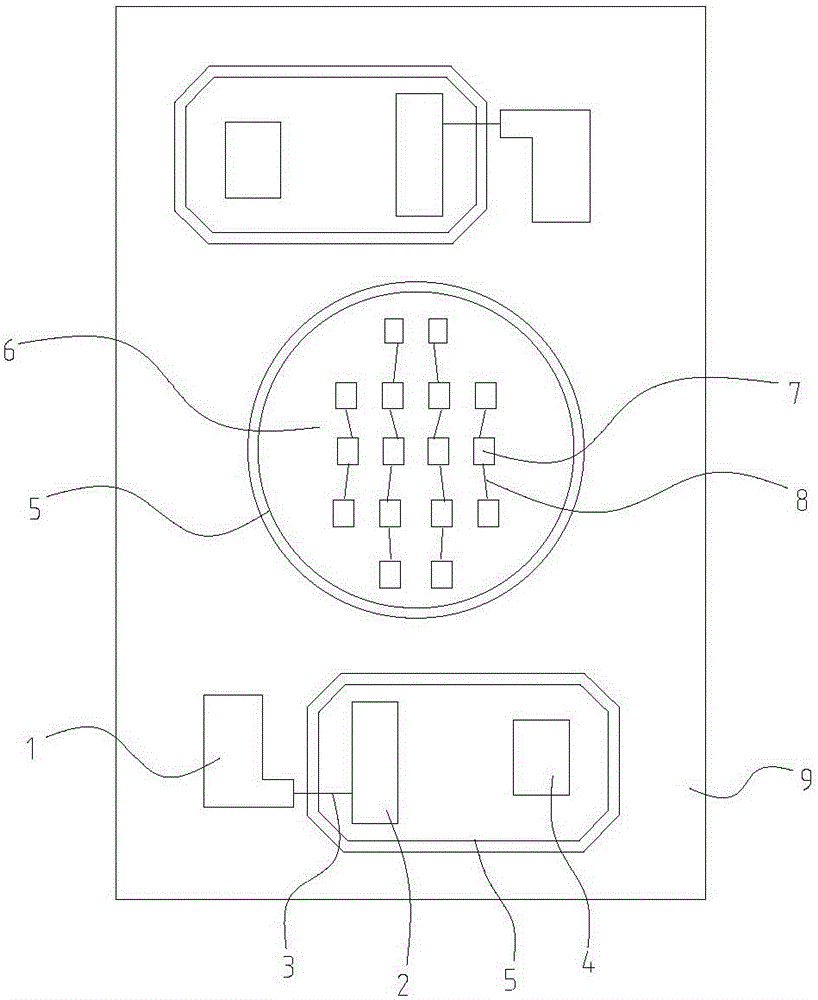

[0021] (1) if figure 1 As shown, cofferdams 5 are provided on the edge of the light-emitting area and the circuit area of the substrate 9, and the light-emitting area is located in the middle of the substrate;

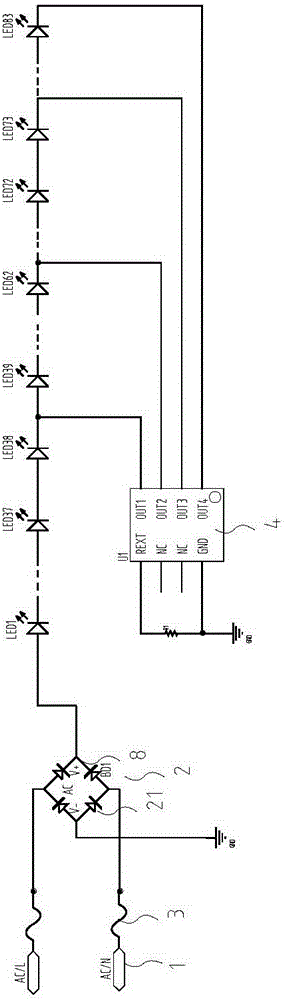

[0022] (2) if figure 1 As shown, the light source 6, the driving circuit and the input terminal 1 are fixed on the substrate 9 with circuit wiring, the driving circuit is arranged in the circuit area, the light source 6 is arranged in the light emitting area, and the input end 1 is arranged outside the circuit area; The light source 6 includes several LED chips 7, and the drive circuit includes a rectifier module 2 and a drive IC 4, and the drive IC 4 is SM2087 in this embodiment;

[0023] (2) The input terminal 1 and the rectifier modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com