Patents

Literature

90results about How to "Manufacturing Method Improvements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

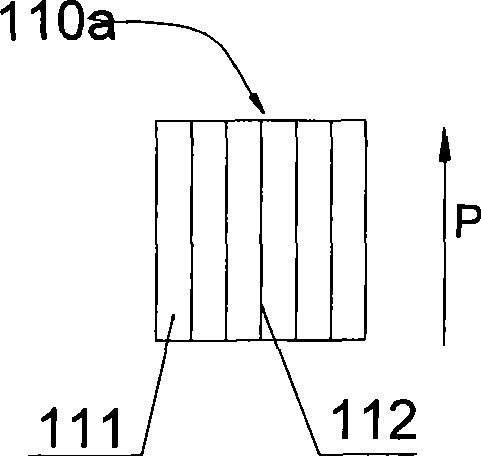

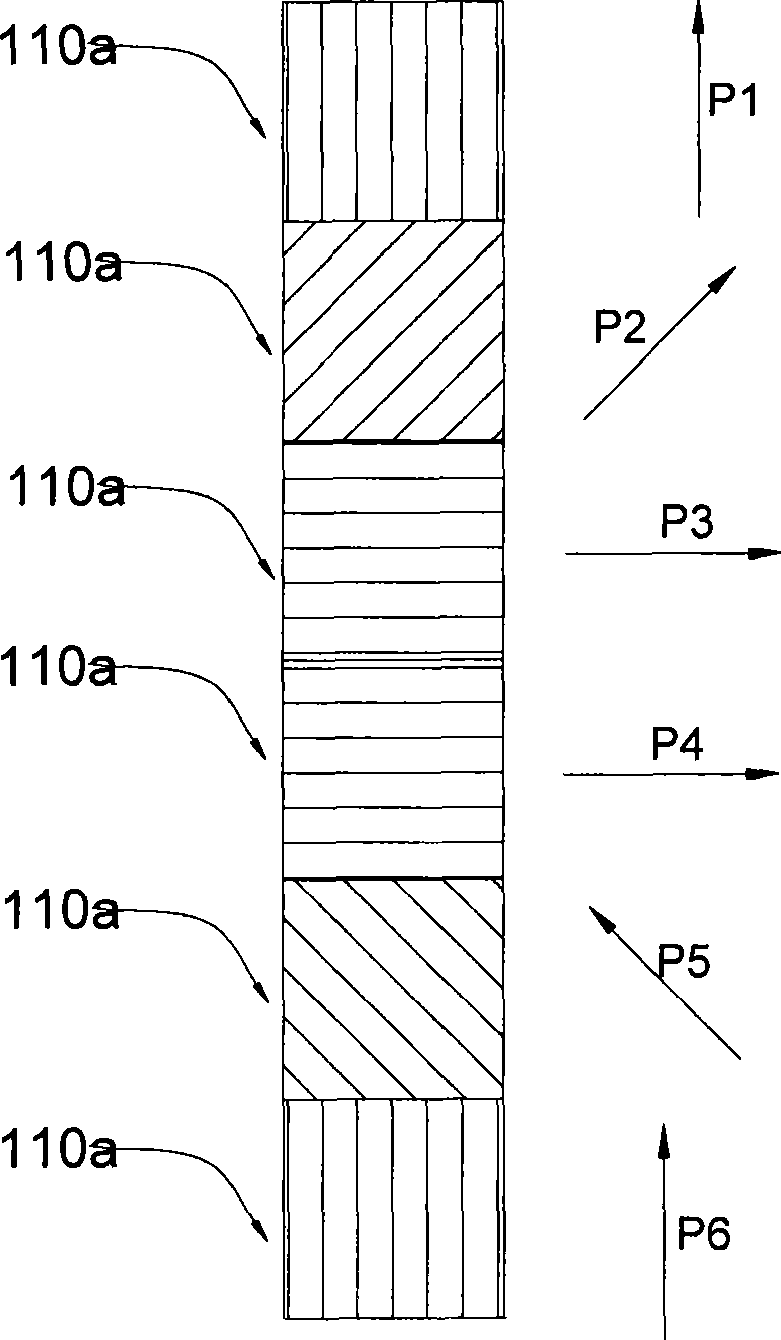

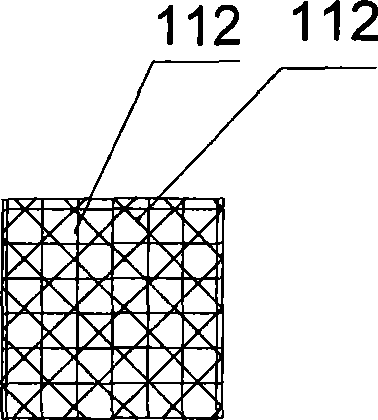

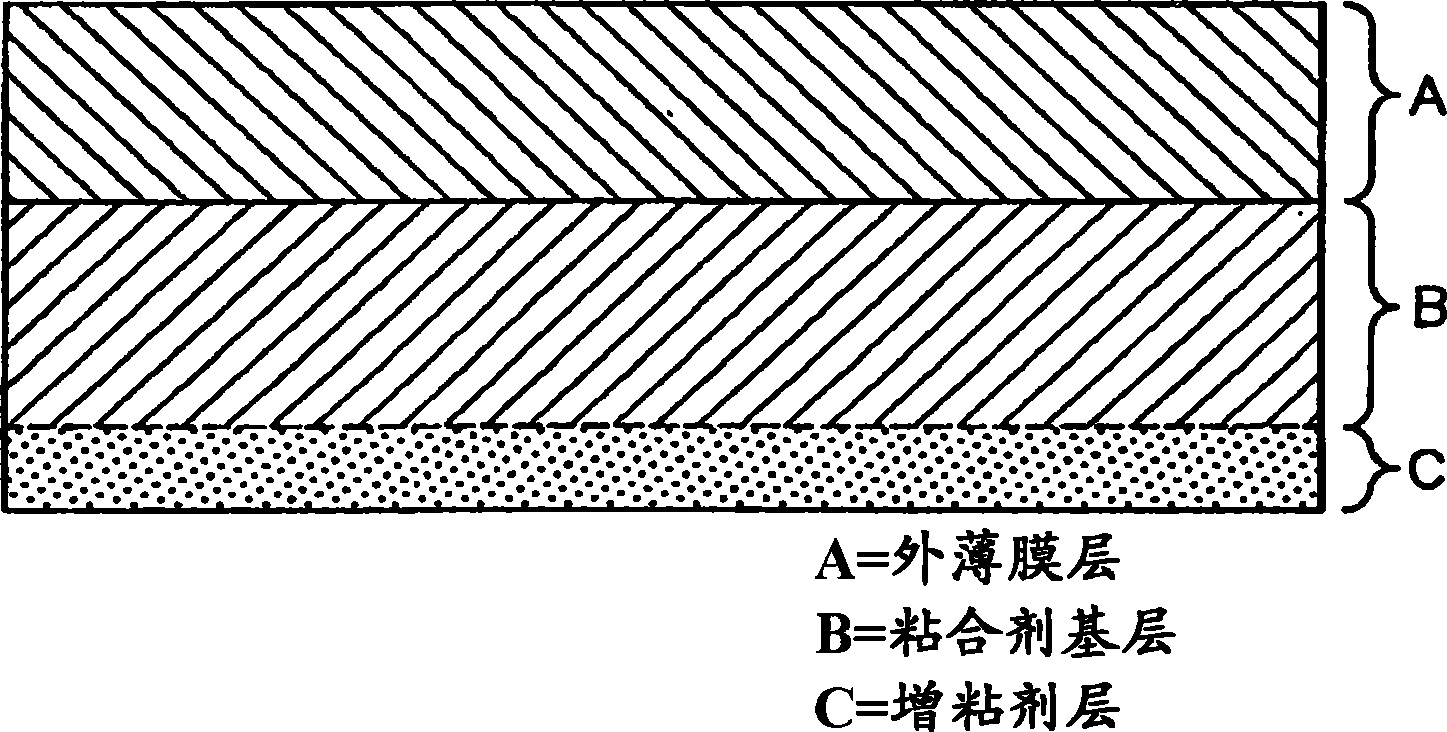

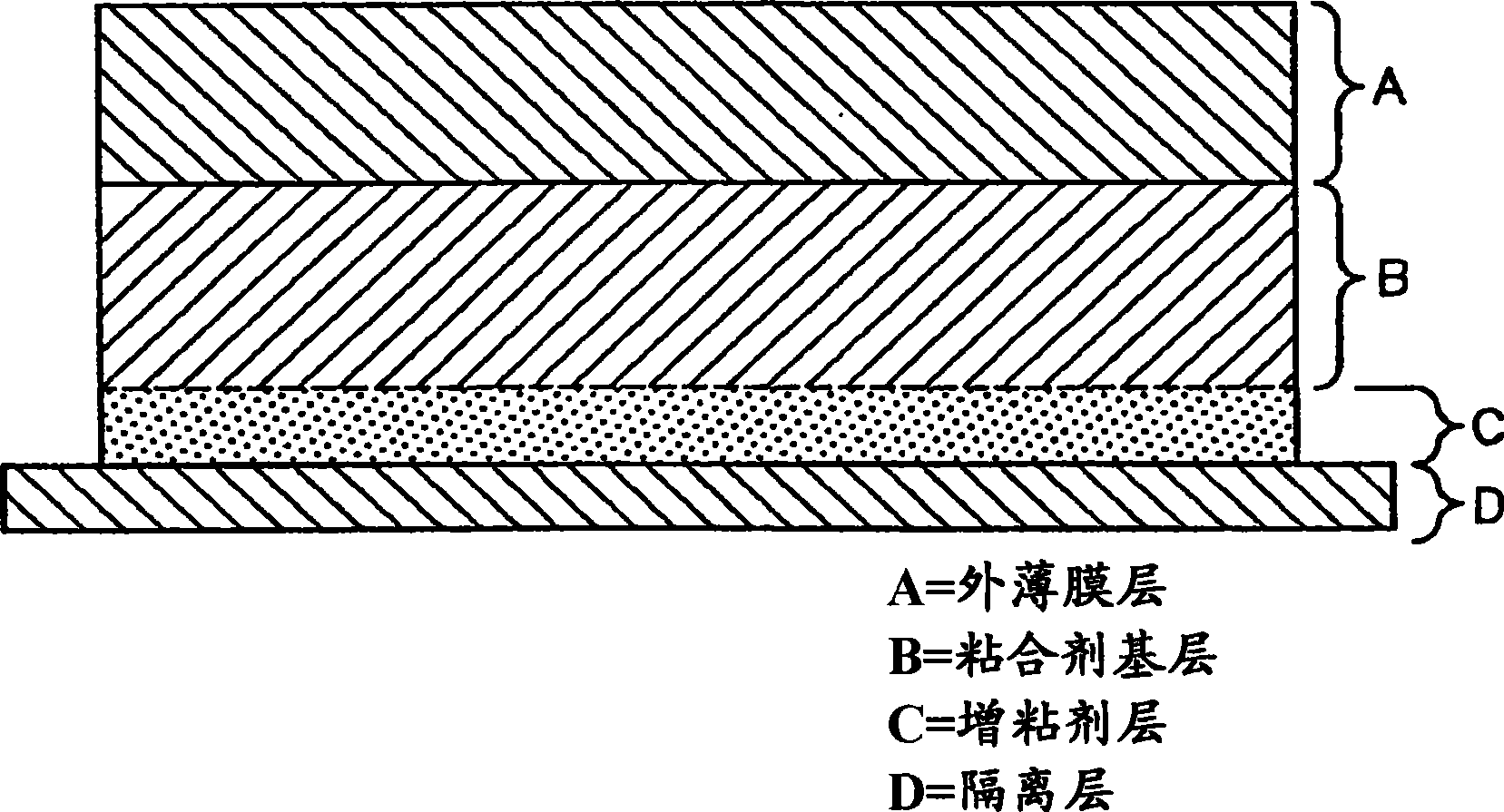

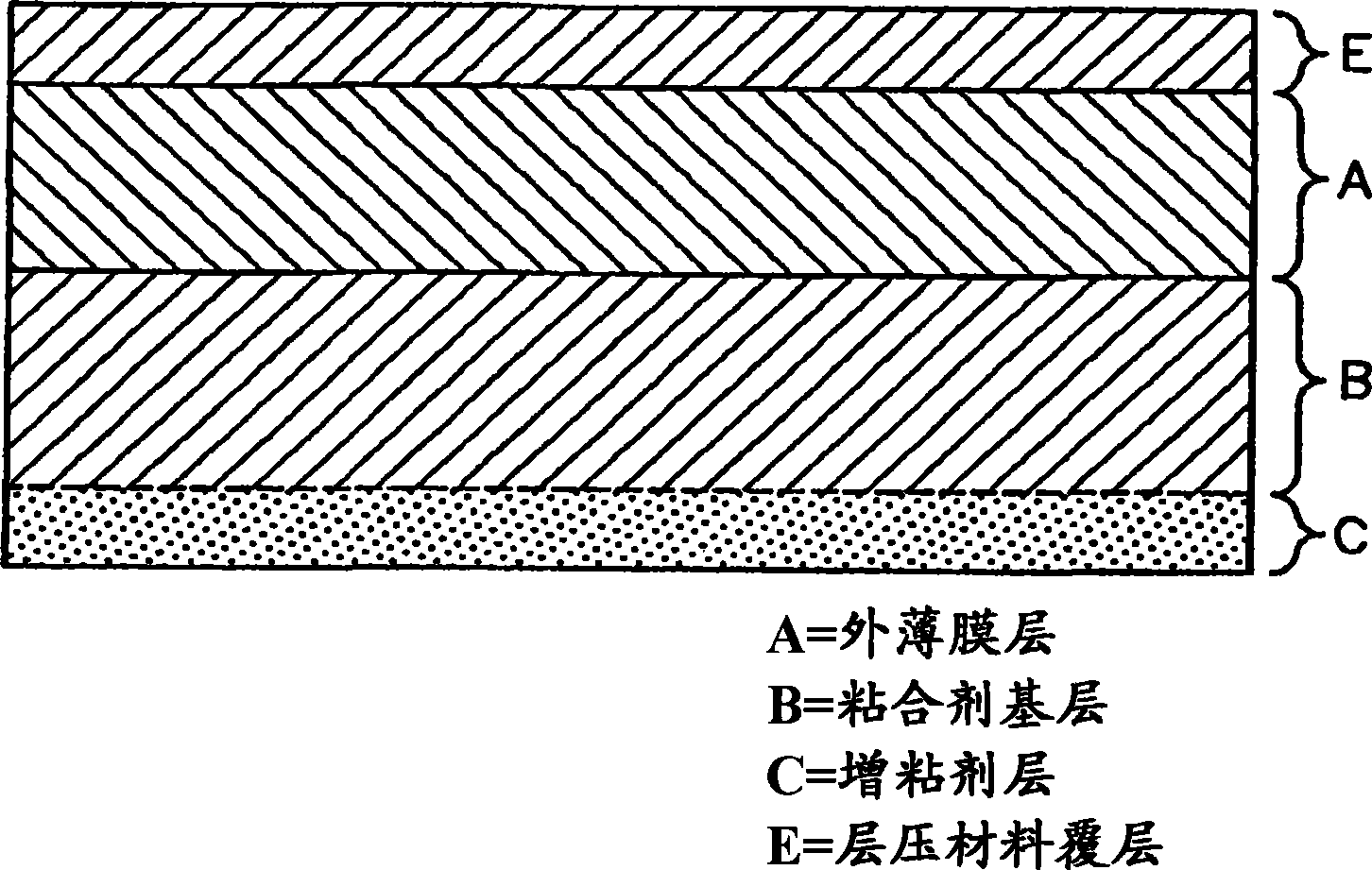

Pressure sensitive adhesive (psa) laminates

InactiveCN101454416AManufacturing Method ImprovementsCoating temperature is lowFlat articlesThin material handlingPolymer scienceTackifier

A PSA laminate is provided comprising at least one non-adhesive laminate and at least one tackifier layer; wherein the non-adhesive laminate comprises at least one facestock layer and at least one adhesive base layer; wherein the facestock layer comprises at least one facestock material; wherein the adhesive base layer comprises at least one adhesive base polymer; wherein the tackifier layer comprises at least one tackifier; wherein the tackifier composition is not a PSA; and wherein the tackifier layer is applied to the adhesive base layer side of the non-adhesive laminate to produce the PSA laminate. Processes for producing the PSA laminate are also provided as well as articles comprises the PSA laminates.

Owner:EASTMAN CHEM CO

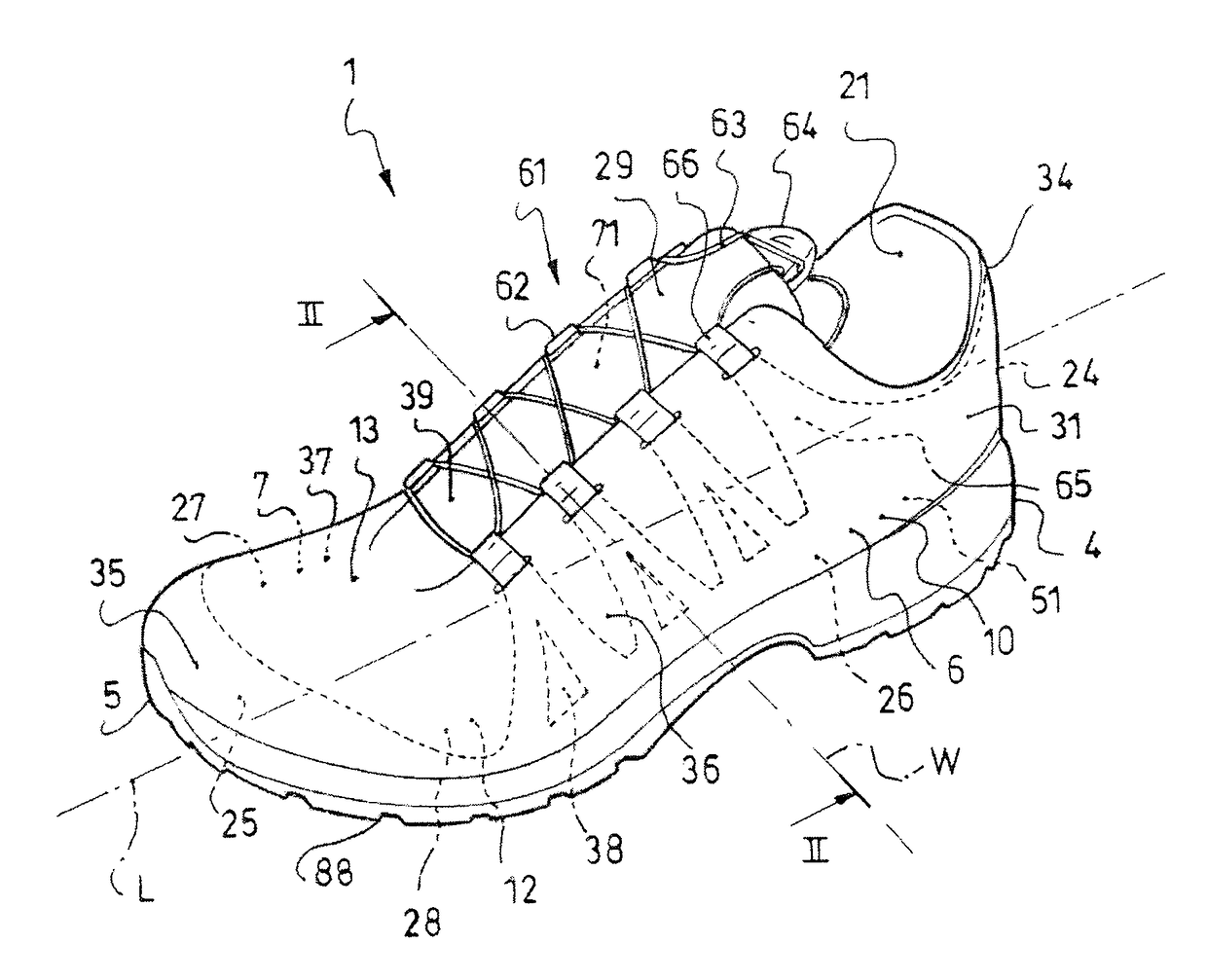

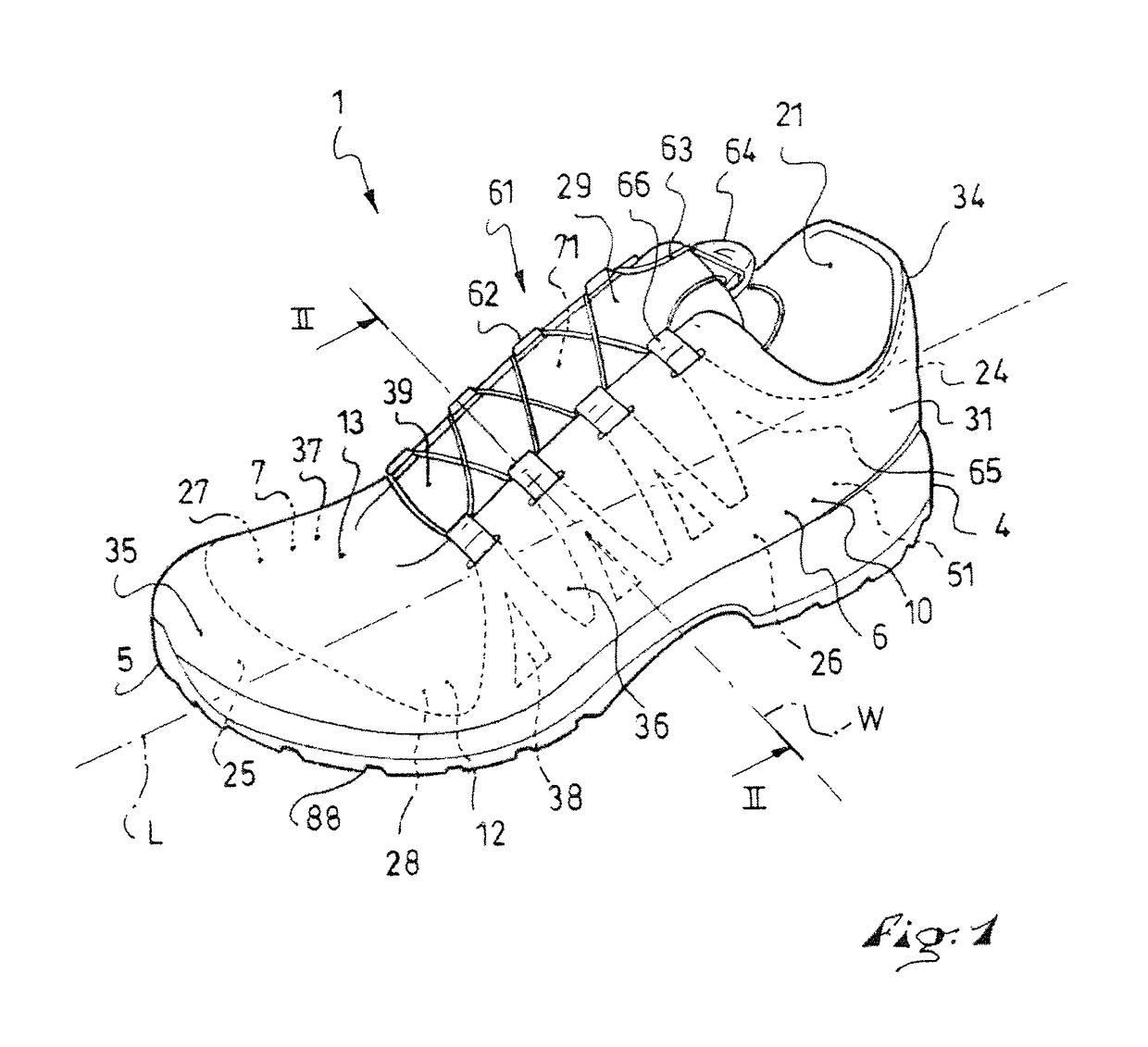

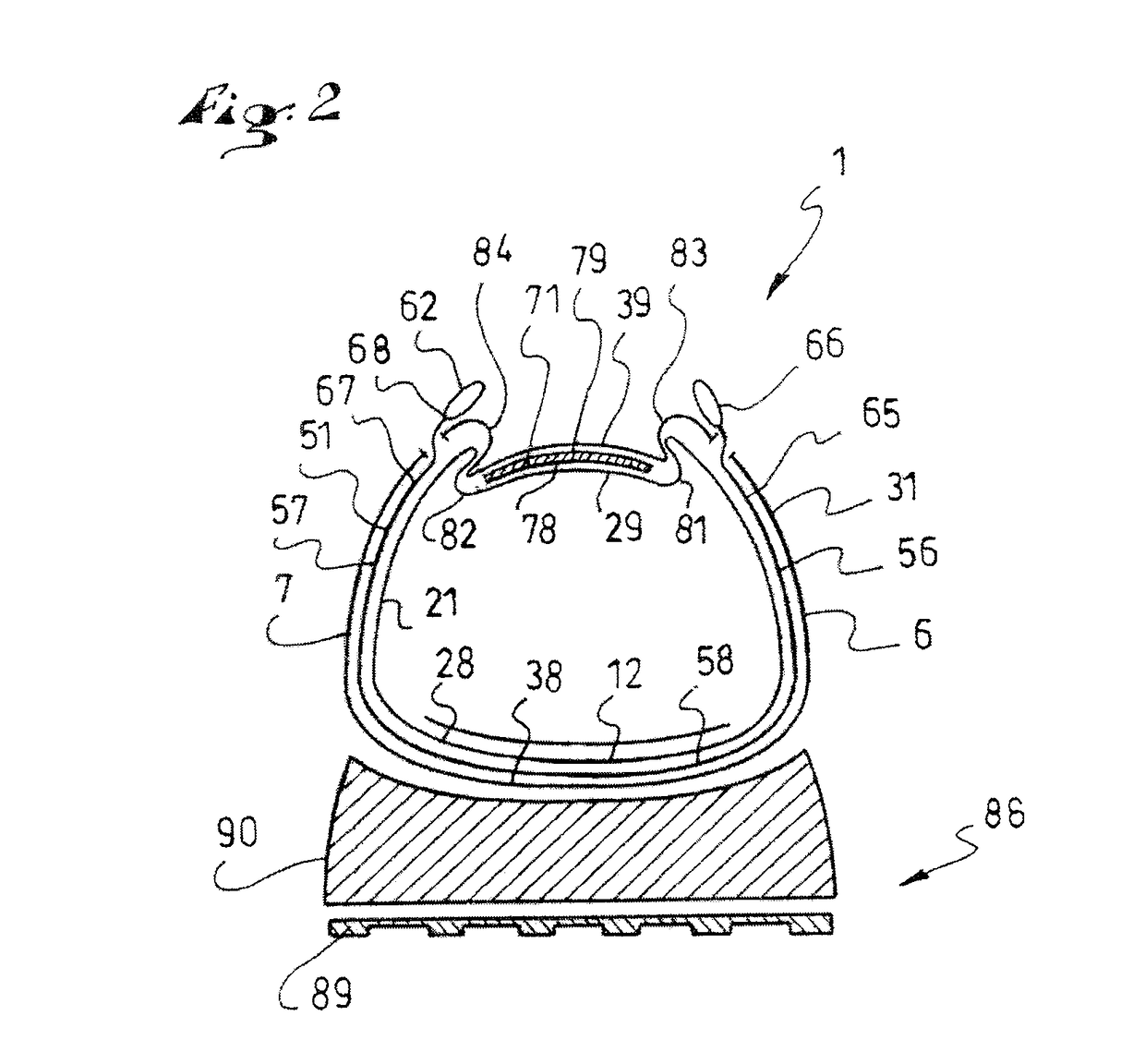

Article of footwear with improved structure

An article of footwear that includes a first envelope extending lengthwise from a rear end to a front end, widthwise between a lateral side and a medial side, and heightwise from a bottom to a top end, the first envelope demarcating a volume for receiving a foot, the article of footwear including a second envelope extending lengthwise from a rear end to a front end, widthwise between a lateral side and a medial side, and heightwise from a bottom to a top end, the second envelope demarcating a volume for receiving a foot, the first envelope and the second envelope being arranged opposite one another. In the area of at least one subdivision, the article of footwear includes an intermediate component deformable elastically and reversibly, the intermediate component being arranged between the first envelope and the second envelope.

Owner:SALOMON SA

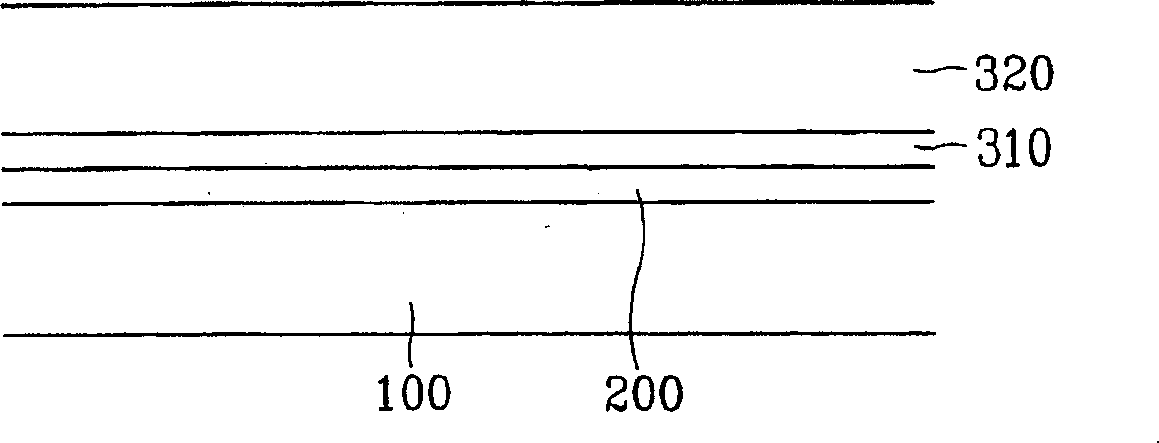

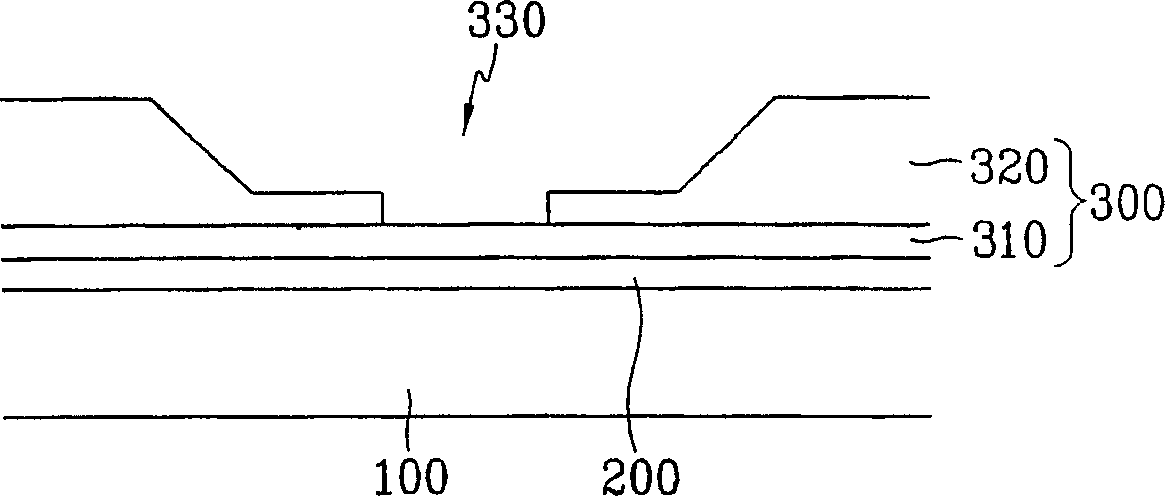

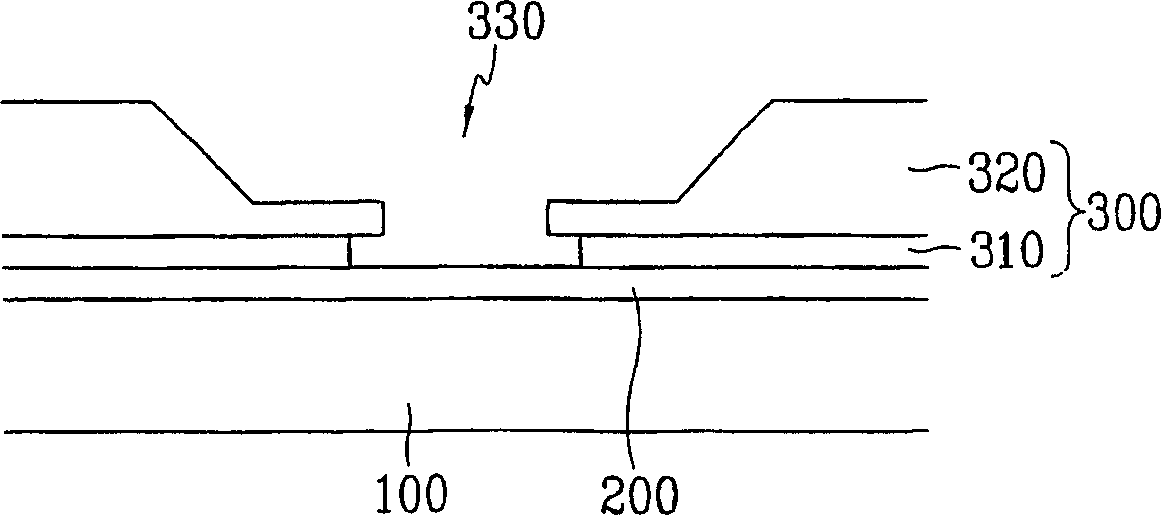

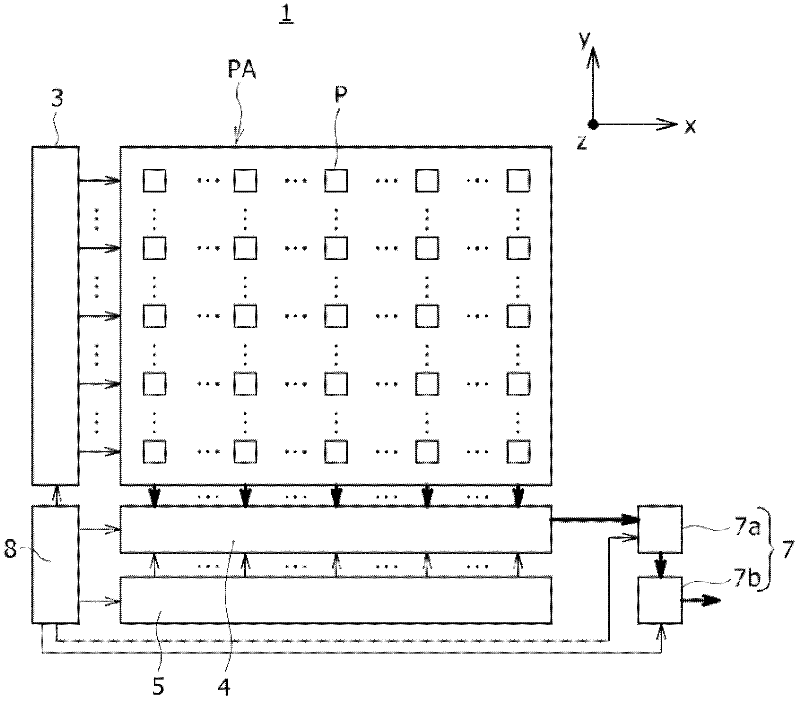

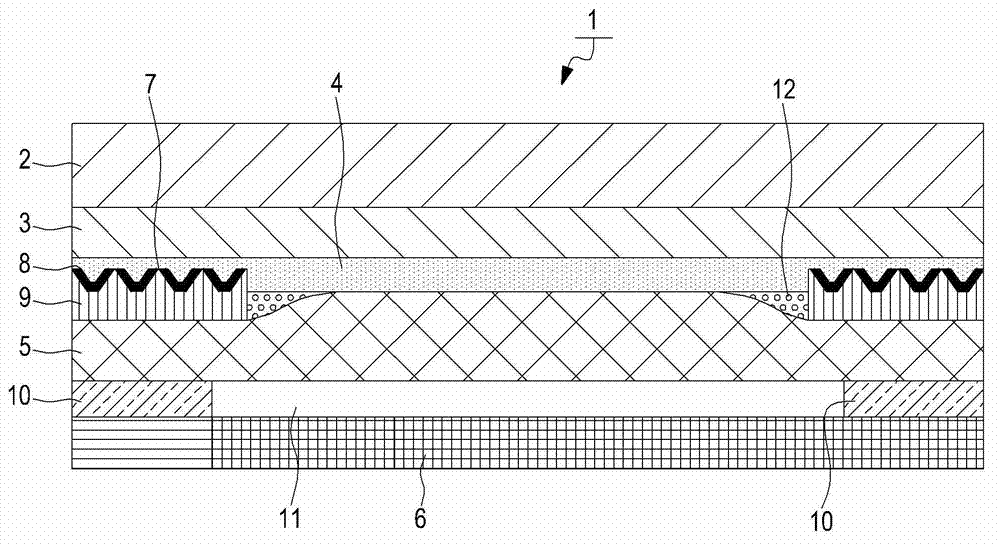

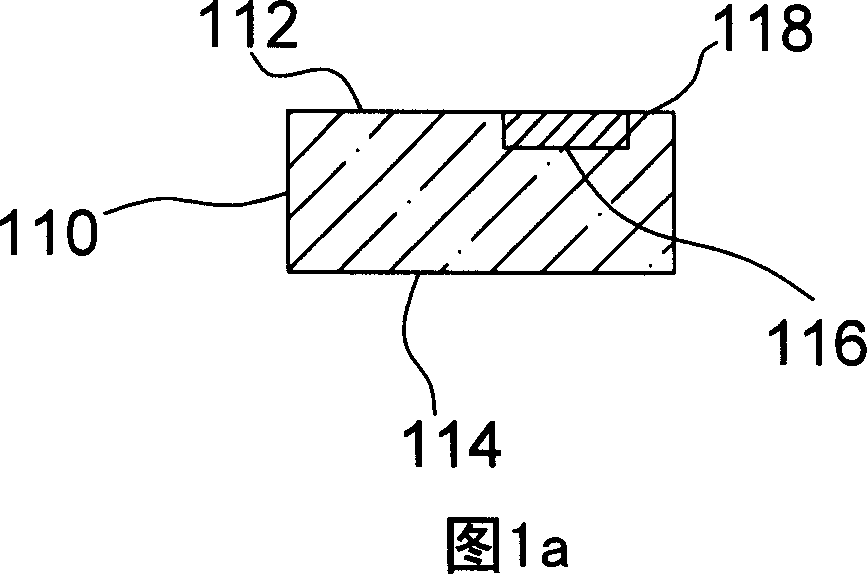

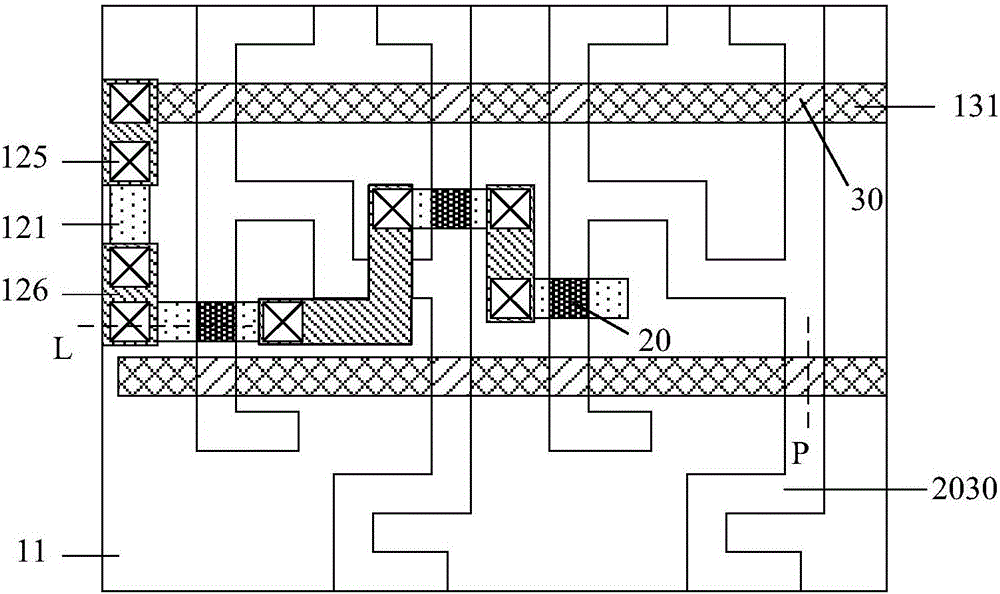

Contact portion of semiconductor device and thin film transistor array panel for display device including the contact portion

InactiveCN1491442AIncrease contactSimple methodTransistorSemiconductor/solid-state device detailsElectrical conductorOhmic contact

A gate wire is formed on a substrate. Next, after forming a gate insulating film, a semiconductor layer and an ohmic contact layer subsequently are formed thereon. Next, a data wire is formed. Next, a passivation layer and an organic insulating film are deposited, and patterned to form contact holes for exposing the drain electrode, the gate pad and the data pad, respectively. Here, the organic insulating film around the contact holes is formed thinner than that in the other portions. Next, the organic insulating film around the contact holes is removed by an ashing process to expose the borderline of the passivation layer in the contact holes, thereby removing an under-cut. Then, a pixel electrode, an assistant gate pad and an assistant data pad respectively connected to the drain electrode, the gate pad and the data pad are formed.

Owner:SAMSUNG DISPLAY CO LTD

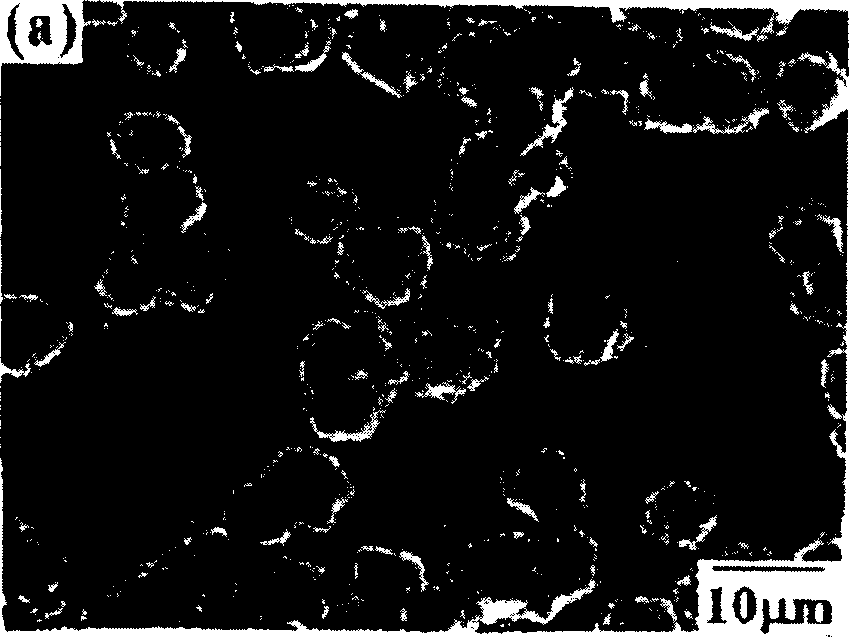

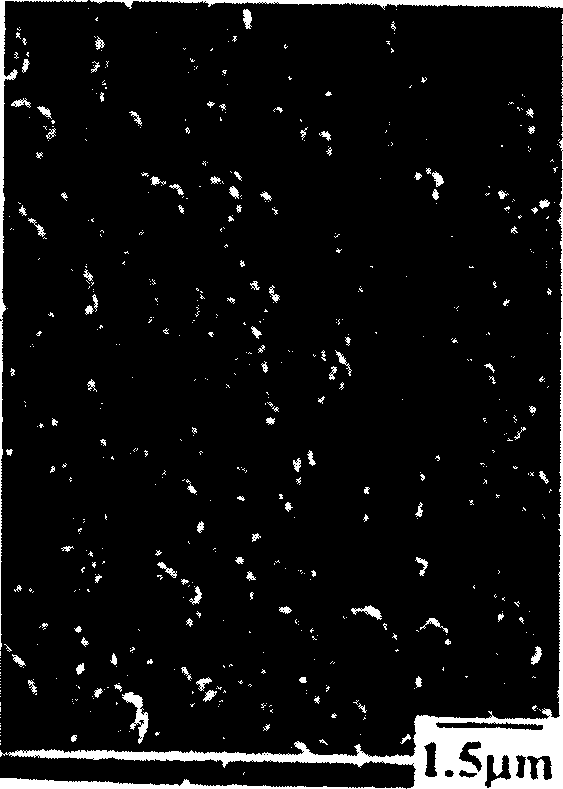

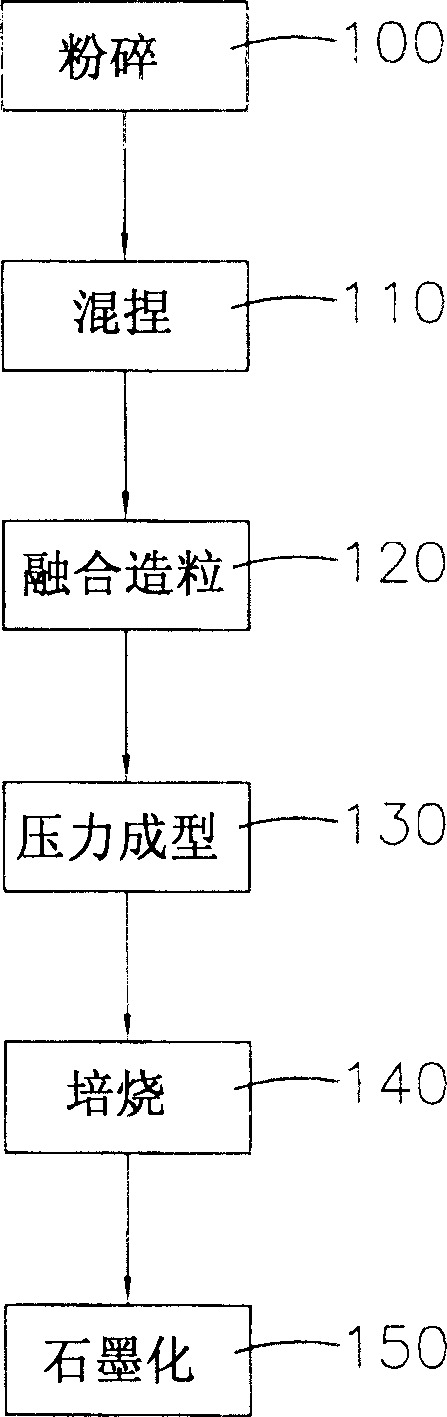

Heat radiation seat using graphite as base and method for prepn. of said graphite

A heat radiator with graphite base for electronic device is prepared by plating a metal layer on the graphite base. Its graphite base is prepared from natural graphite through pulverizing to obtain micron-particles, mixing with adhesive, granulating, mixing, high-, cold-, or hot-pressure vibrating to become block, immersing it in liquid-phase asphalt, and graphitizing.

Owner:林恺玉 +1

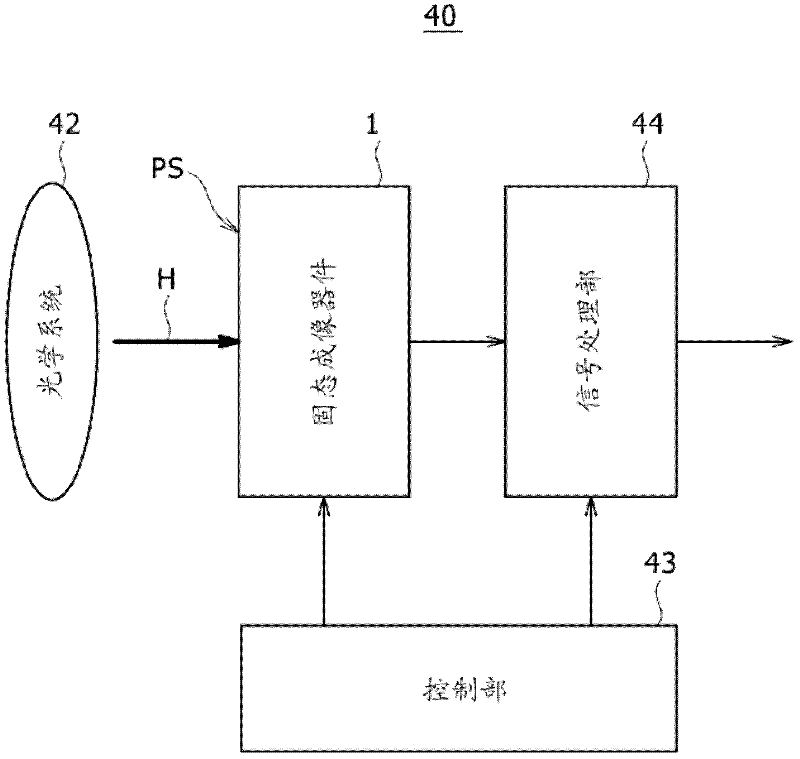

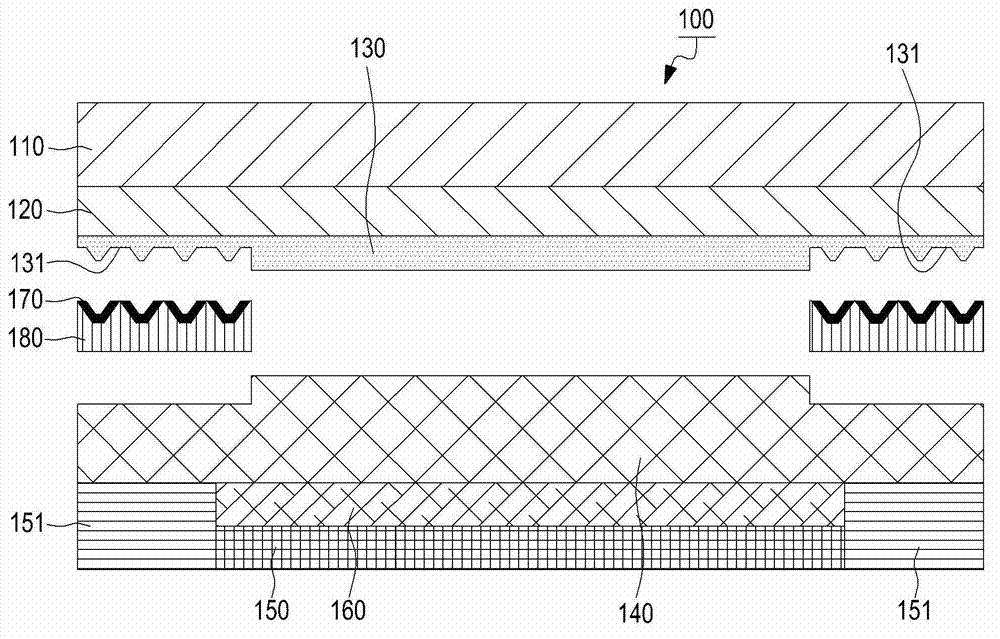

Solid-state imaging device, electronic equipment, semiconductor device and manufacturing method of solid-state imaging device

InactiveCN102651377AImprove reliabilityManufacturing Method ImprovementsSolid-state devicesRadiation controlled devicesMetallic materialsEngineering

The invention discloses a solid-state imaging device, an electronic equipment, a semiconductor device and a manufacturing method of the solid-state imaging device.Disclosed herein is a solid-state imaging device including: a sensor element having a plurality of pixels each having a photoelectric conversion section; and a logic element attached to the sensor element in such a manner as to be stacked on the sensor element face-to-face and provided with a pad electrode. In a stacked body of the sensor and logic elements, a pad opening is provided above the top surface of the pad electrode facing the sensor element, and a pad periphery guard ring is provided to surround the side portion of the pad opening. The pad periphery guard ring is formed by integrally filling, on the side of the pad opening, an entire trench that is at least as deep as the pad opening with a metal material.

Owner:SONY CORP

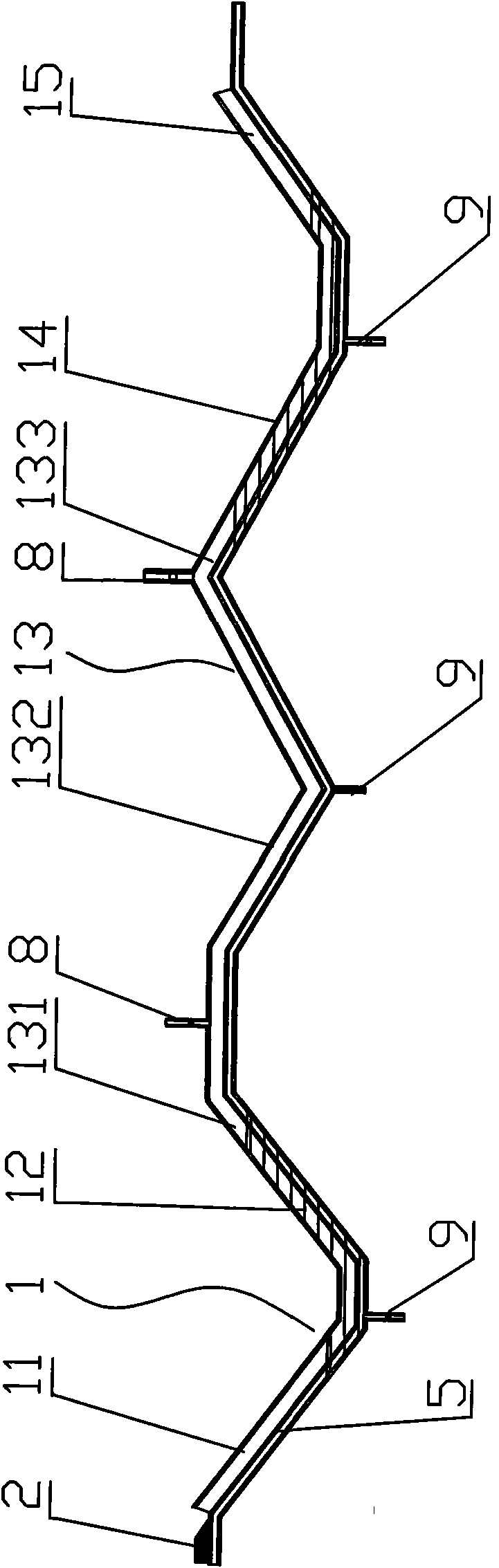

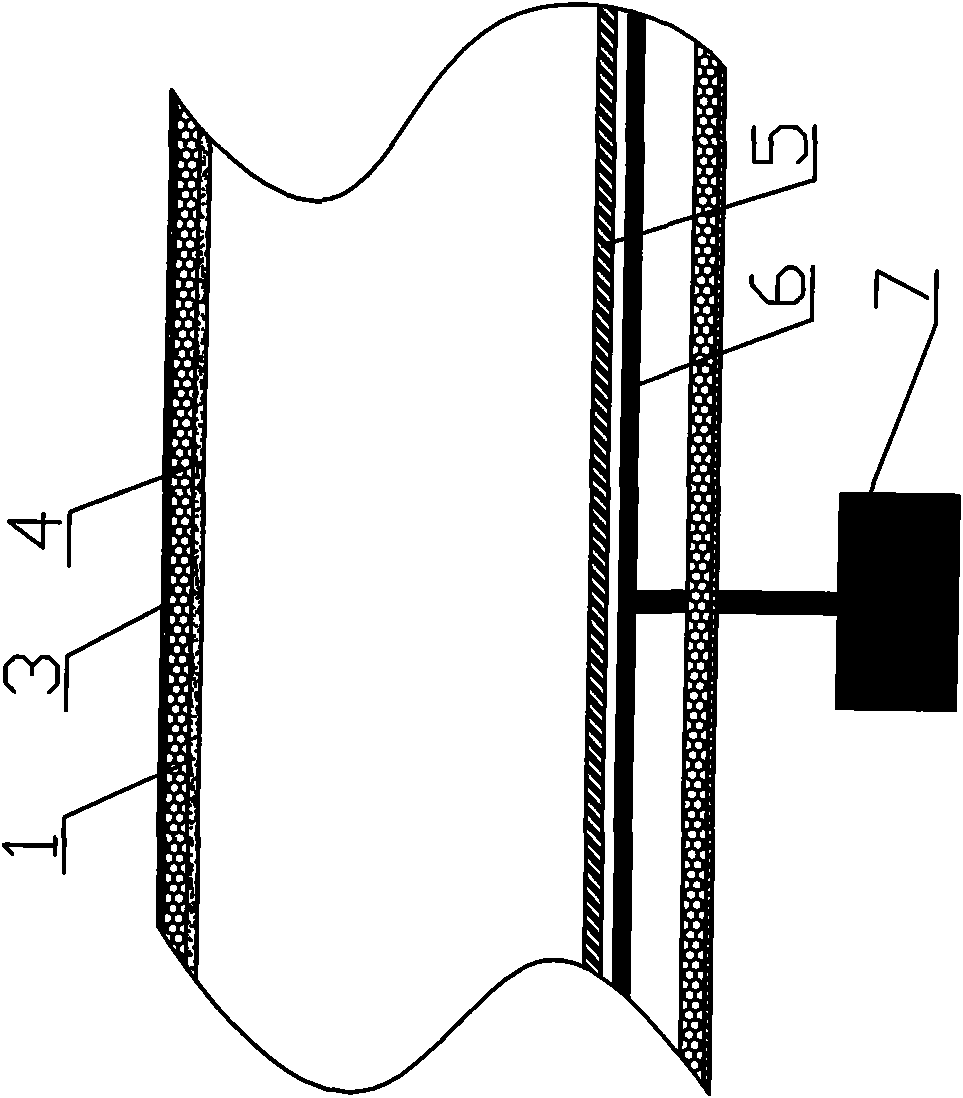

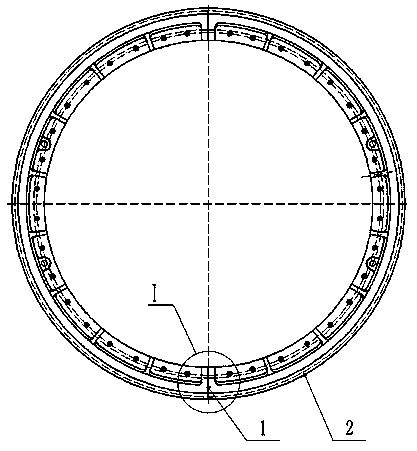

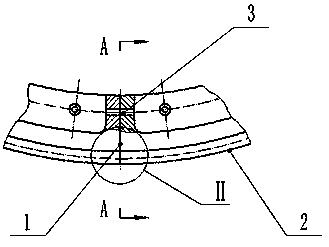

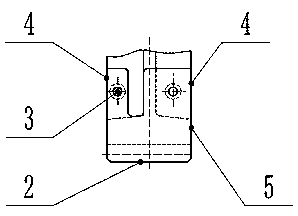

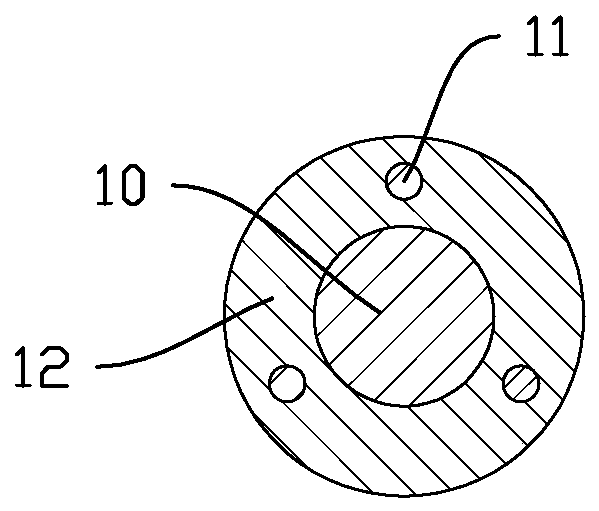

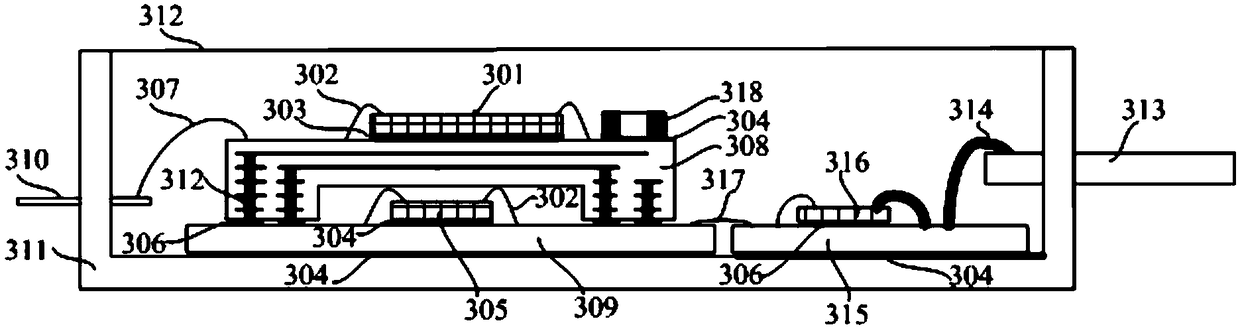

Transport system and producing method of sub-vacuum duct

The invention discloses a transport system and a producing method of a sub-vacuum duct in a rail transport system. The transport system of the sub-vacuum duct comprises the sub-vacuum duct and a closed train, wherein the sub-vacuum duct comprises a downslope section of inlet normal atmosphere, a closed section of inlet liquid, a sub-vacuum section, a closed section of outlet liquid and an upslope section of outlet normal atmosphere, the cross section of the duct is in an elliptical shape, silencing materials, force-bearing components, a vent valve, a drain valve, and the like are installed on the duct, the train is an amphibious train, and the body of the train is made of warer-proof materials. The producing method of the sub-vacuum duct comprises the following steps: A. producing the body of the duct; B. installing the vent valve and the drain valve; and C. generating sub-vacuum: producing the duct into a sub-vacuum duct by a method for generating sub-vacuum by pumping liquid. The invention solves the problems of high manufacturing cost of sub-vacuum ducts, inconvenience for passengers to get on and get off the train when the train passes through the sub-vacuum duct and influence on the vacuum state of the duct. Meanwhile, the invention has the advantages of high efficiency, low energy consumption, simple equipment, and the like.

Owner:谢建新

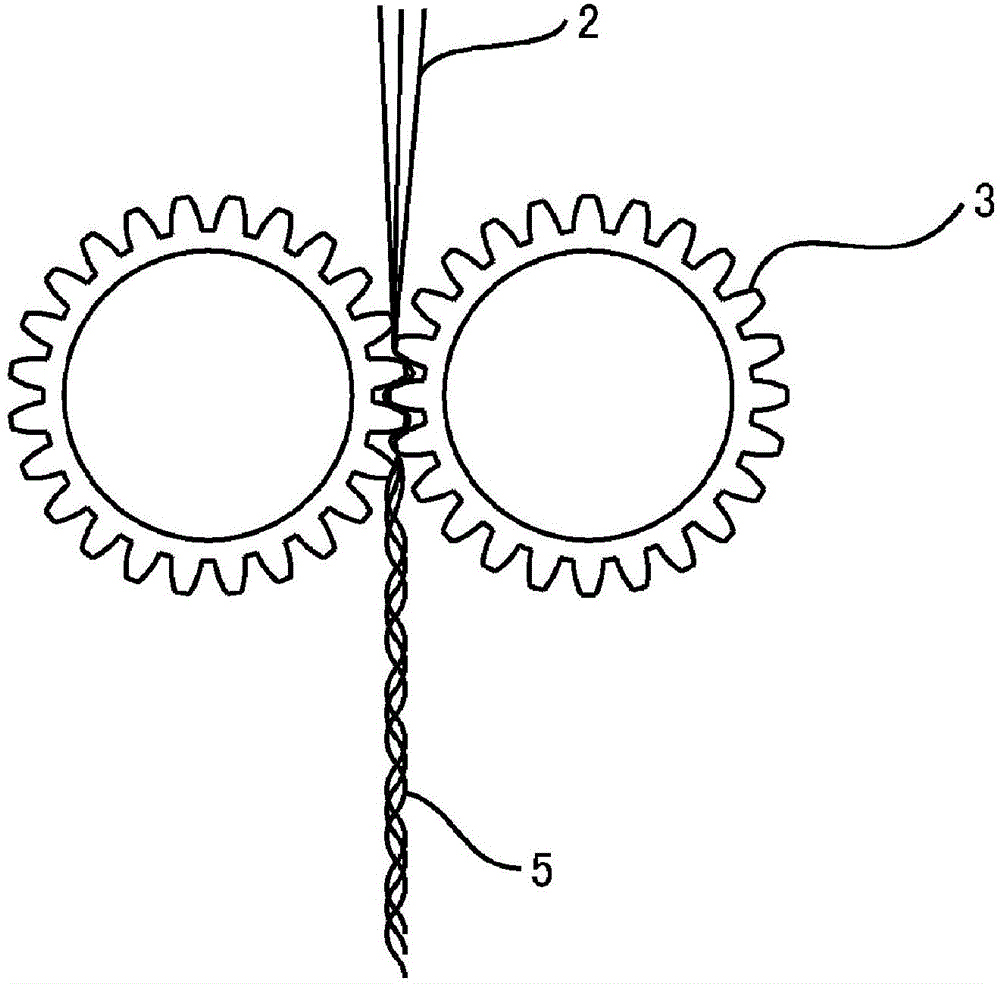

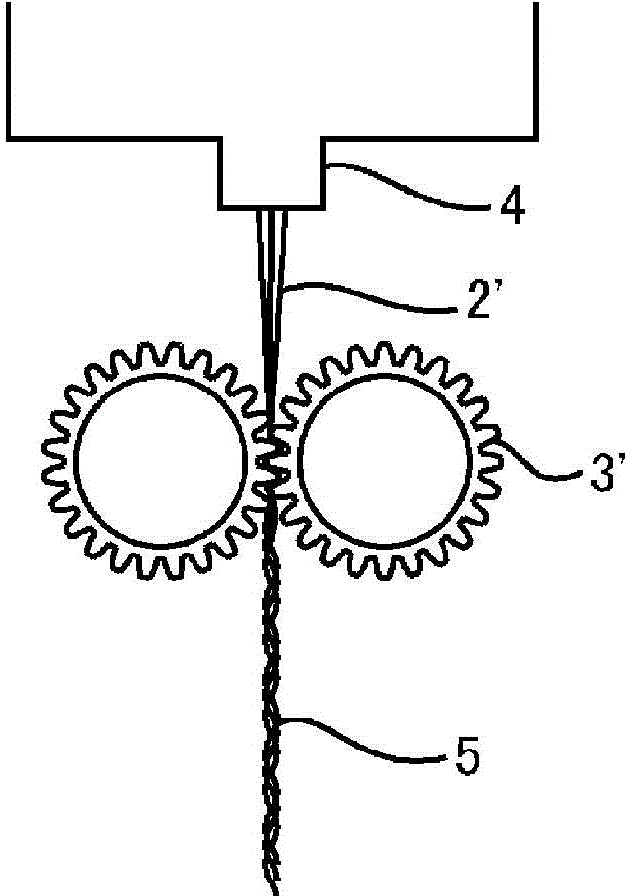

Manufacturing method of big-modulus cast steel large gear ring

ActiveCN109262213AAvoid deformationSolve the problem of large processing volumeGear wheelEngineering

The invention discloses a manufacturing method of a big-modulus cast steel large gear ring, and belongs to the technical field of machining. By the method, the problem of large machining amount of a blank and teeth during manufacturing of an existing large gear ring is solved by improving a cast blank and tooth machining process, and by an operation of retaining a tie bar after the large gear ringis manufactured, deformation of the large gear ring during long-time storage, transportation and hoisting is prevented. The manufacturing method is convenient and feasible, by practice verification,on the premise of guaranteeing quality and precision of the large gear ring, the machining efficiency is greatly improved, and the manufacturing cost is reduced. The tooth machining efficiency is improved by 2 times or above, and the manufacturing cost of the large gear ring is reduced by 20% or so. When the large gear ring manufactured by the method of the invention is used for key equipment suchas a ball-miller, a mixing machine and a drying kiln, the equipment runs stably and smoothly, and gear transmission faults are never caused.

Owner:甘肃酒钢集团西部重工股份有限公司

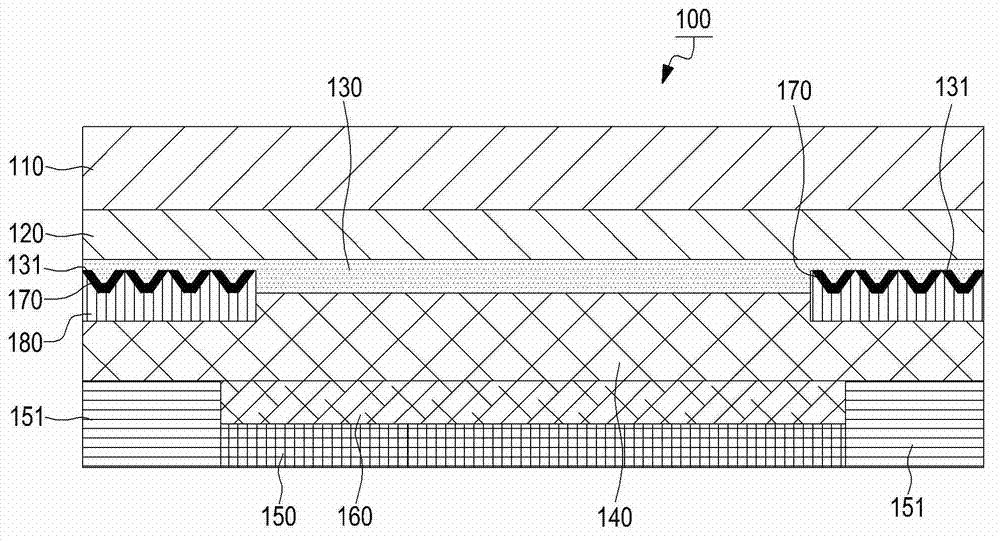

Touch panel having improved visibility and method of manufacturing the same

ActiveCN103294303AManufacturing Method ImprovementsImprove visibilityCircuit arrangements on insulating boardsAdhesivesVisibilityUltraviolet

A touch panel having improved visibility is provided. The touch panel includes a window part having a polymer film layer, a first ultraviolet (UV) curable resin layer attached to a bottom surface of the window part, a second ultraviolet (UV) curable resin layer attached to a bottom surface of first ultraviolet (UV) curable resin layer and used for preventing light refraction and reflection, and a display part including a touch sensor film module attached to a bottom surface of the second ultraviolet (UV) curable resin layer.

Owner:SAMSUNG ELECTRONICS CO LTD

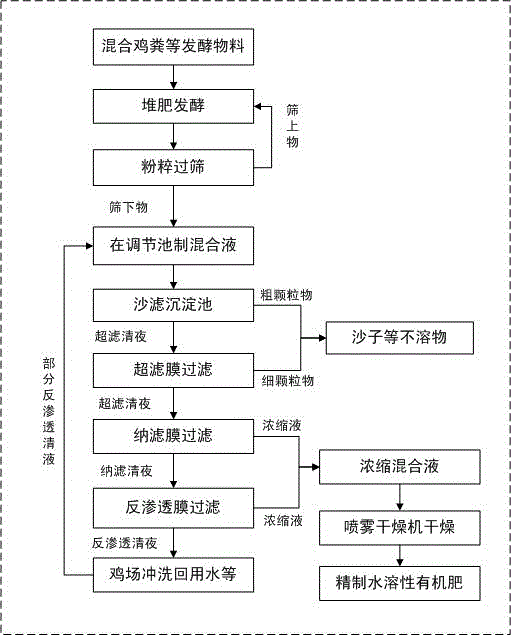

Preparing method for converting chicken dung into refined water-solubility organic fertilizers

InactiveCN105084952AManufacturing Method ImprovementsImprove qualityBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringWater soluble

The invention discloses a preparing method for converting chicken dung into refined water-solubility organic fertilizers. The preparing method for the water-solubility organic fertilizers aims at solving the problems that as for organic fertilizer products generated by composting poultry dung, quality is instable, the heavy metal content exceeds the standard, certain foul smells exist, and automatic fertilizer applying is inconvenient. The preparing method for the water-solubility organic fertilizers is rapid, convenient, free of the foul smells and capable of achieving industrial mass production, and the obtained products have the advantages that the fertilizer efficiency is obvious, quality is stable, and automatic fertilizer applying is convenient.

Owner:GUANGZHOU YANGHUAHU AGRI TECH CO LTD

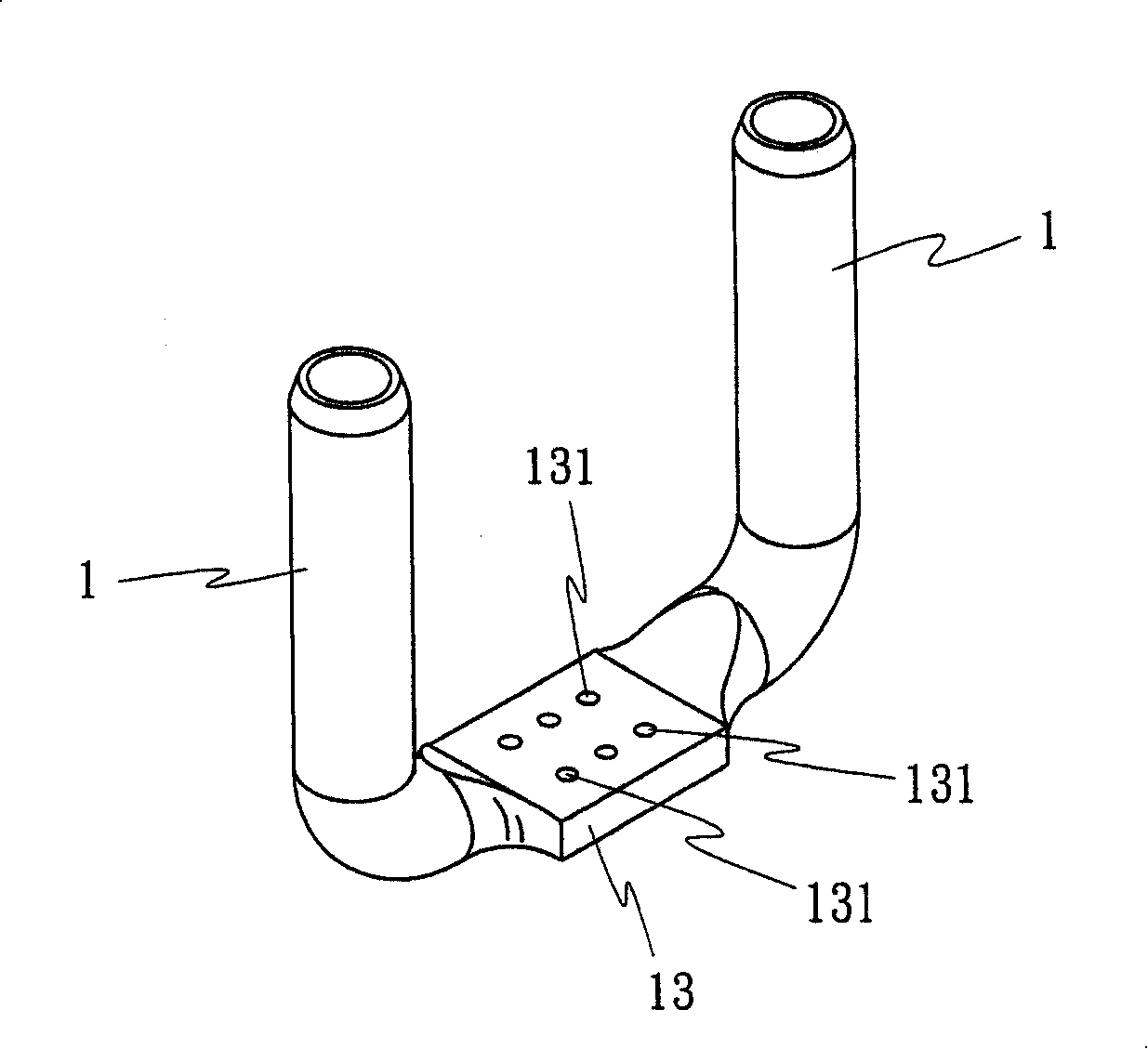

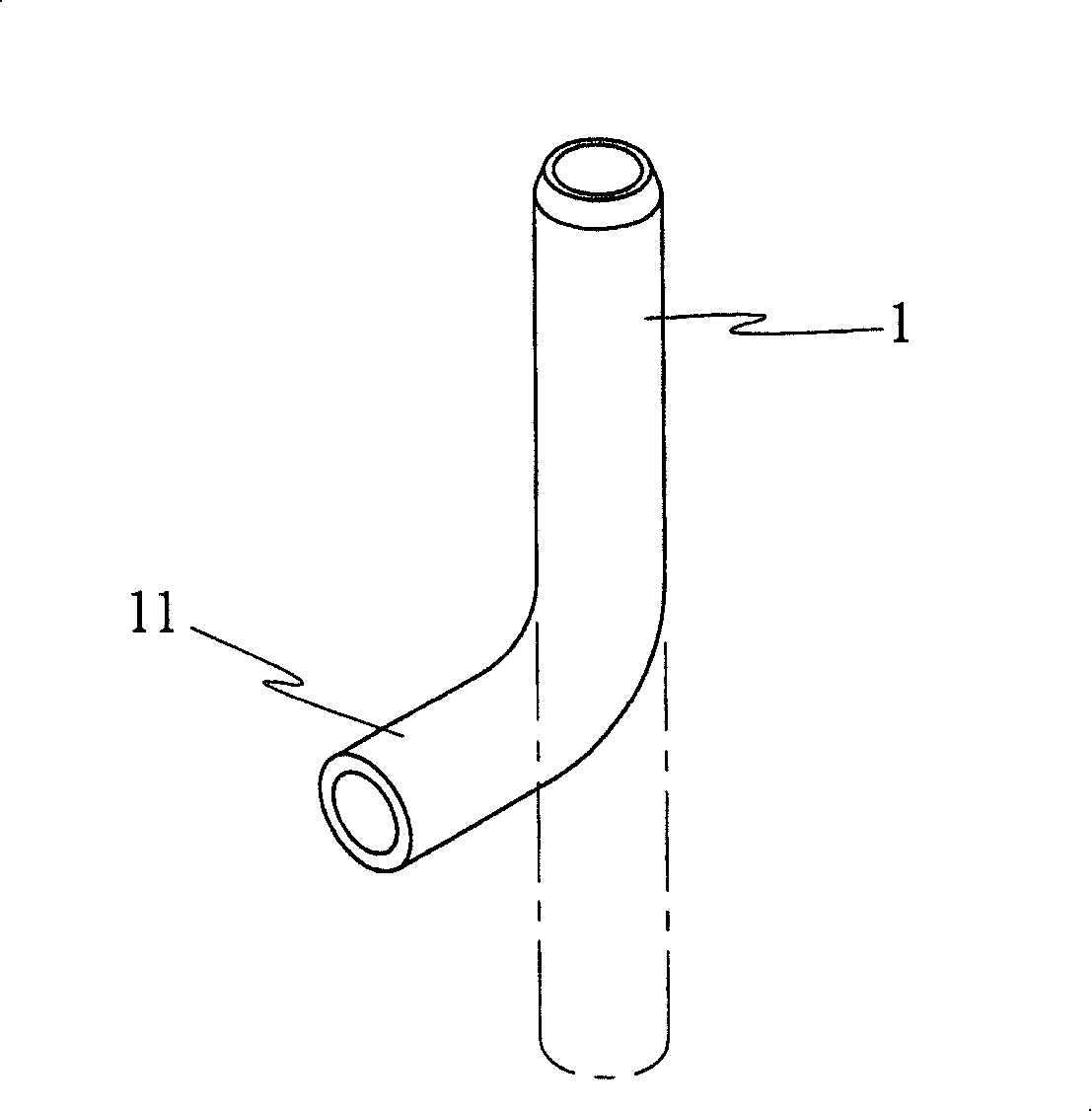

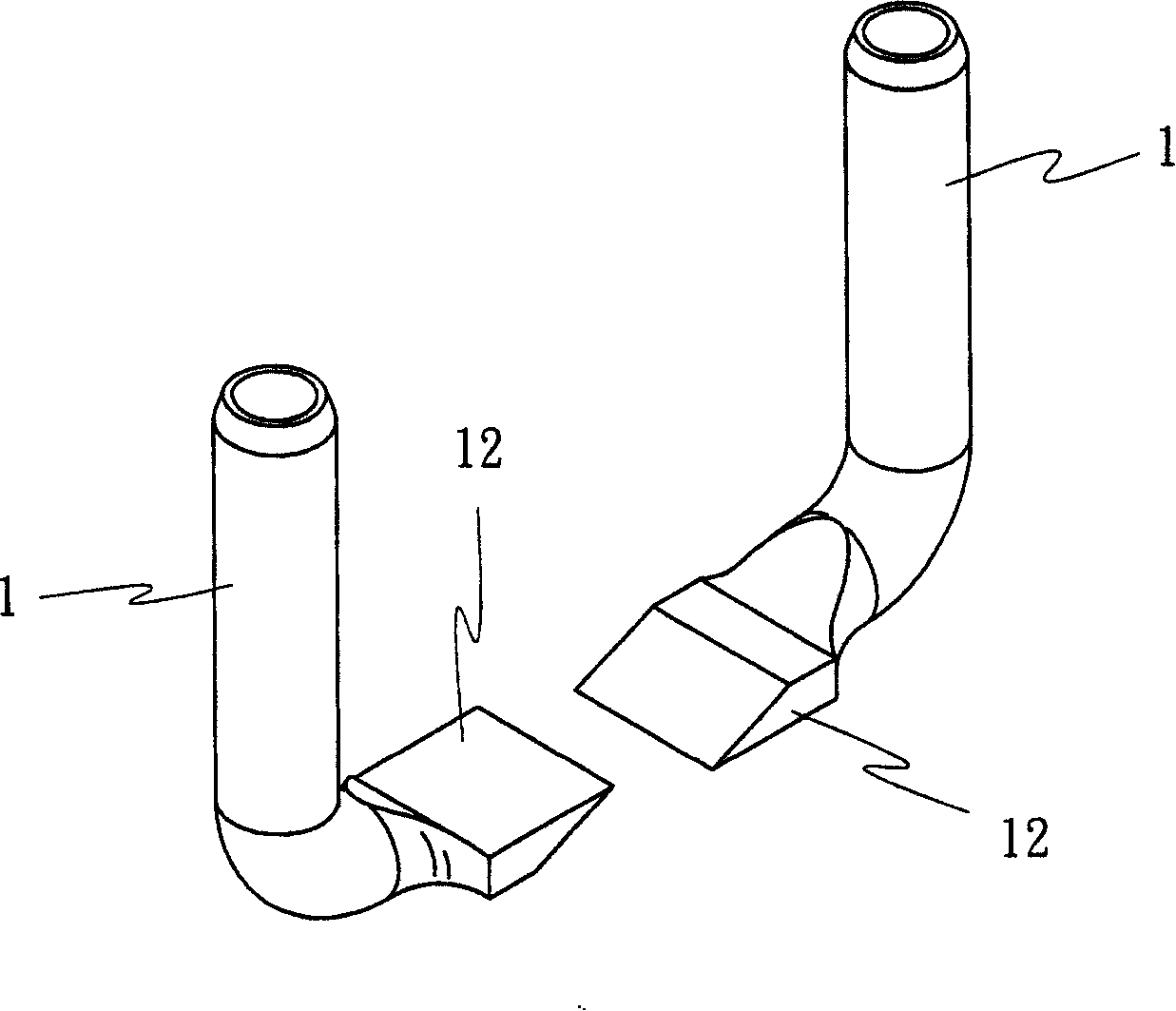

Making method for dual lead device clamp

InactiveCN101242064AEasy to manufactureConvenient manufacturing methodContact member manufacturingMulticonductor cable end piecesYarnSoldering

The present invention discloses a method for manufacturing a double-conductor equipment cable clamp, in the method for manufacturing the double-conductor equipment cable clamp two aluminum pipes are combined to an equipment pipe clamp through the procedures of pipe bending, smithing, soldering, hole drilling and the like, wherein, in the cable bending actualizing procedure: the tail of the aluminum pipe is processed and bent; in the smithing actualizing procedure: the bent aluminum pipe tail is executed with processing and smithing, and the tail of the aluminum pipe can form a block part which is matched comparatively and is to be soldered; in the soldering actualizing procedure: the parts of two aluminum pipes to be soldered is executed with relative soldering combination to compose an intermediate lock plate; in the hole drilling actualizing procedure: the intermediate lock plate is perforated to compose plural holes; after the actualizing procedures of pipe bending, smithing, soldering, hole drilling and the like a pair of double-conductor equipment cable clamp can be quickly and easily manufactured to provide the connecting and combination of the cable yarn. Through the manufacturing method of the invention the equipment cable clamp can be facilitated to possess the advantages of excellent quality, good structure strength, simple production, saving manufacturing cost and the like.

Owner:高裕彬

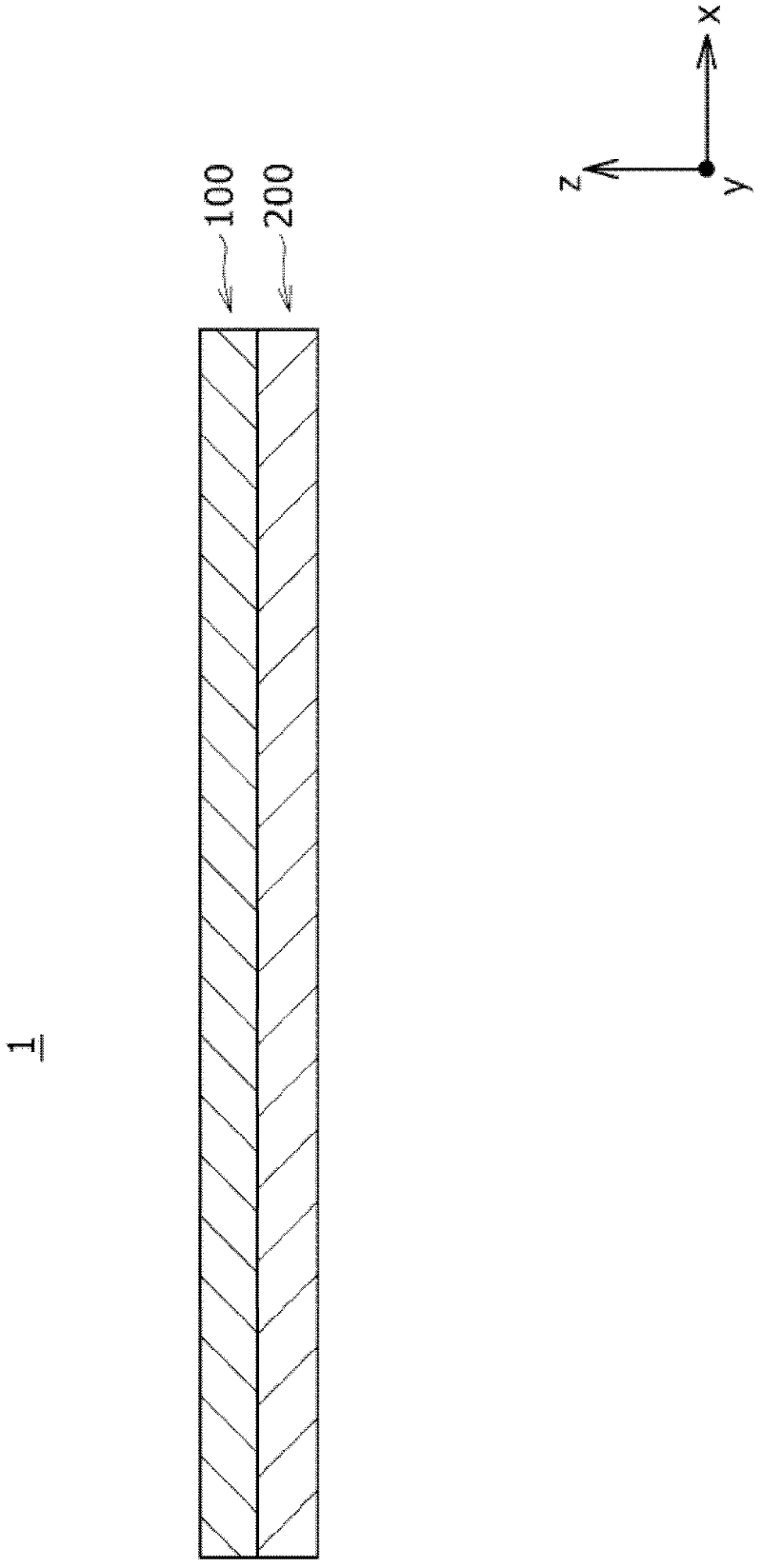

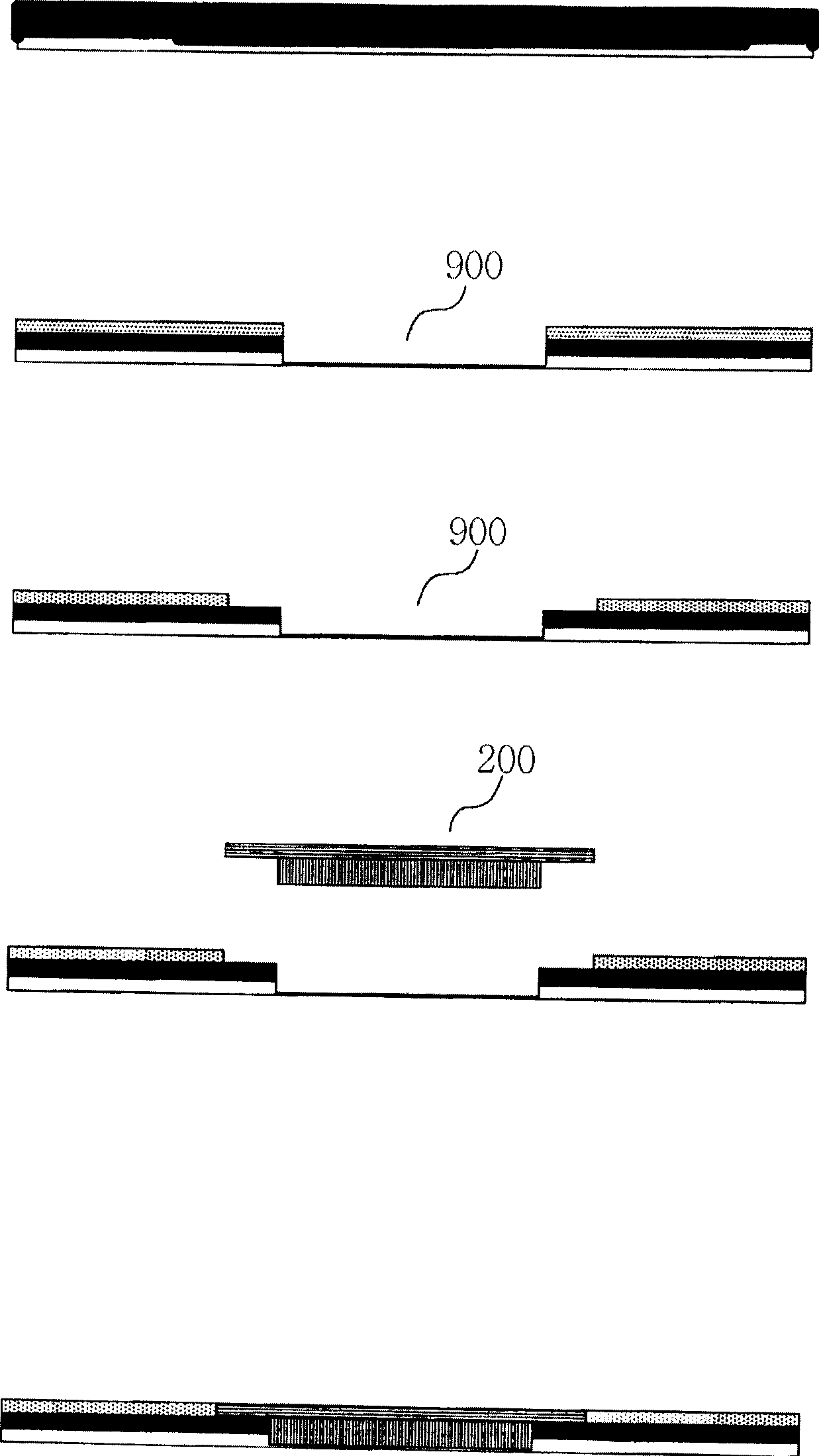

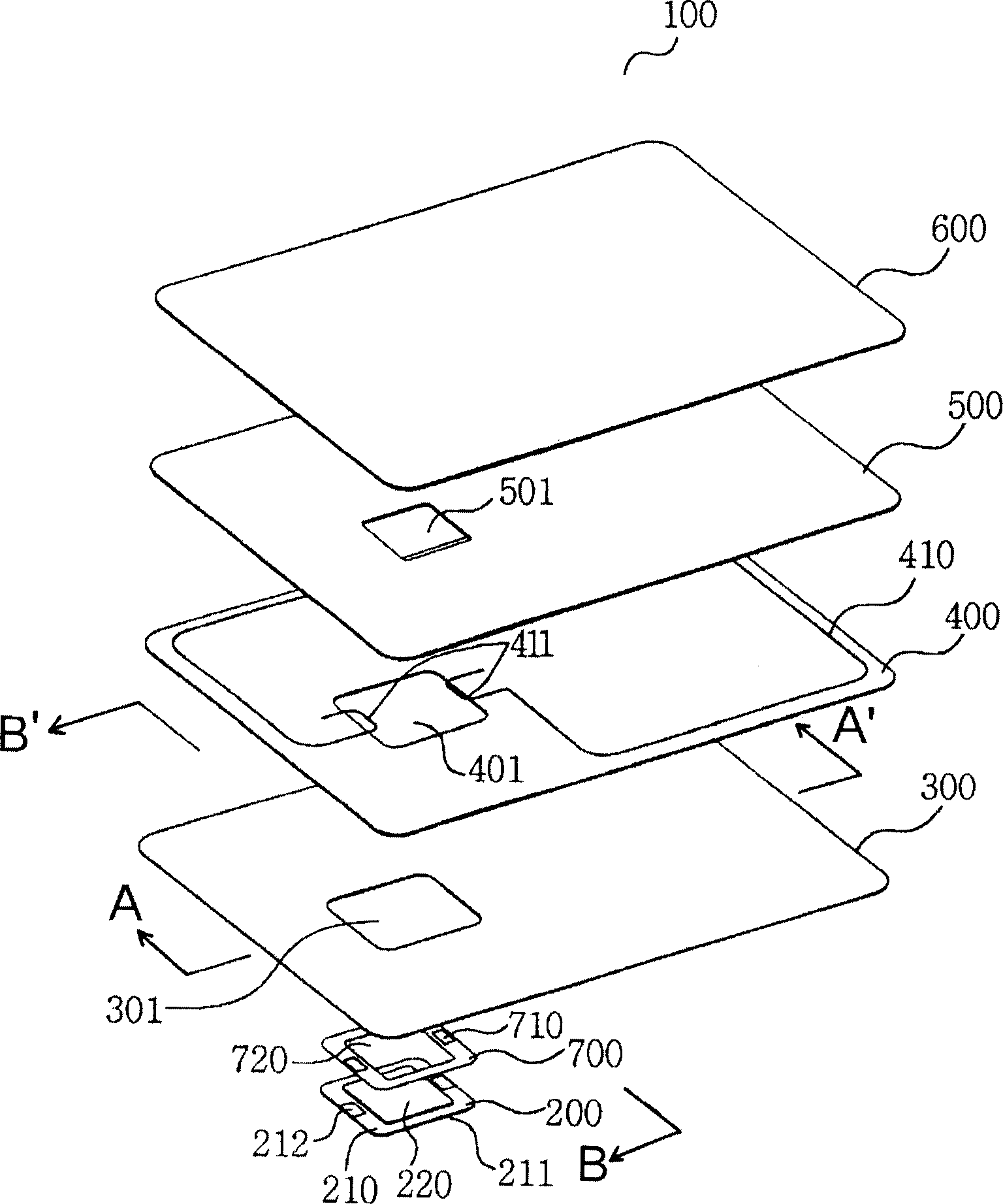

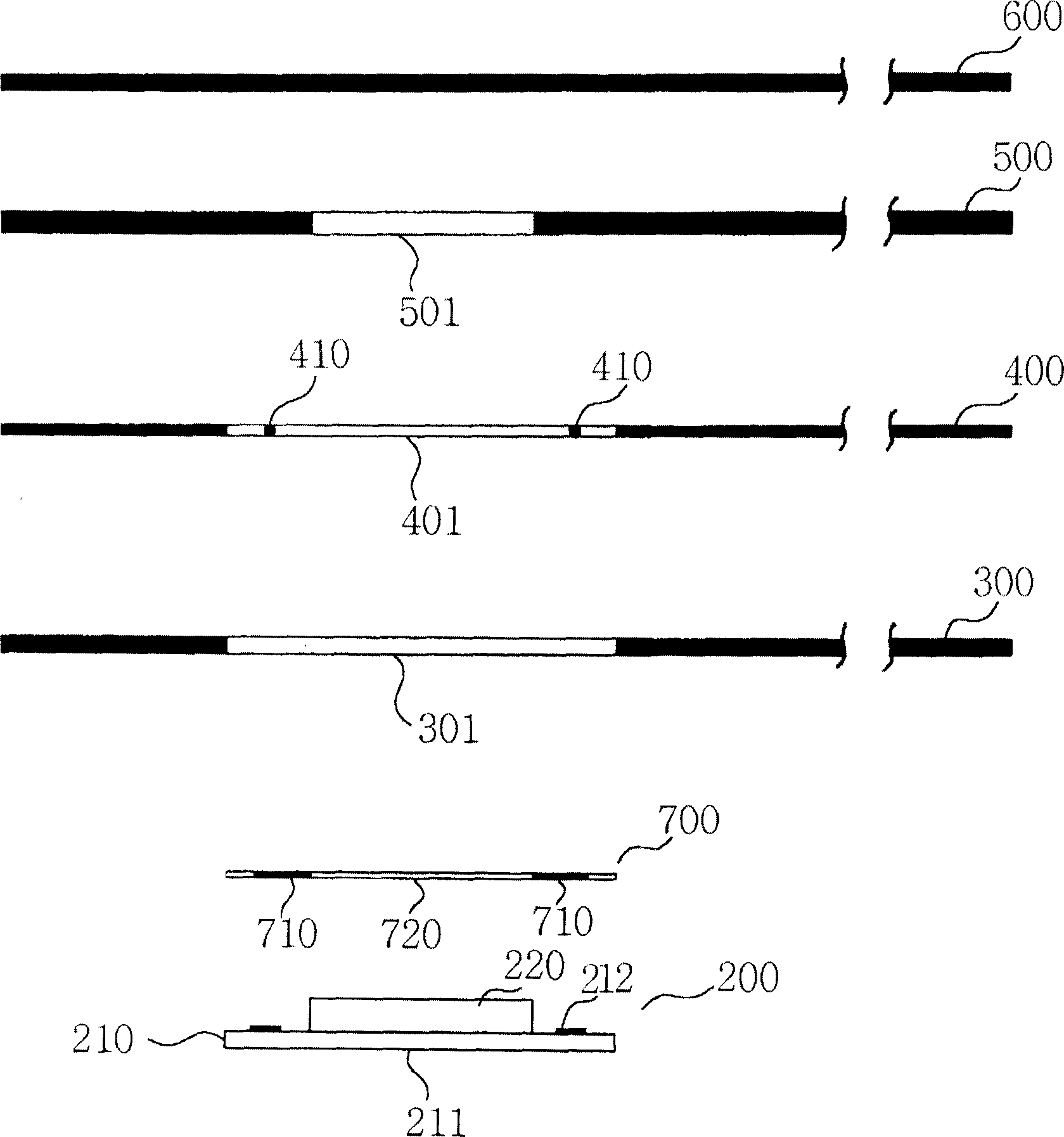

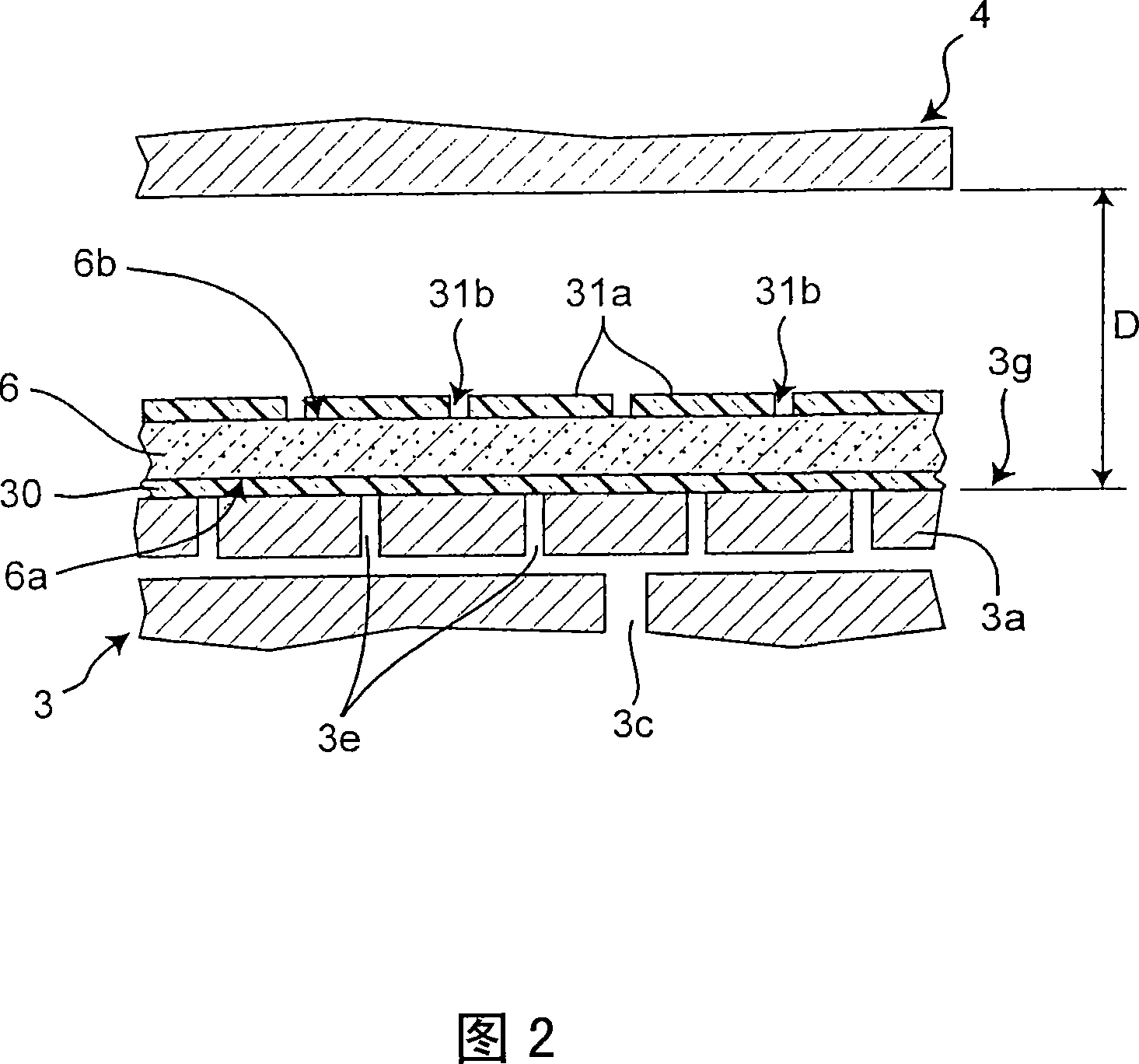

Method for manufacturing ic card by laminating a plurality of foils

InactiveCN1714368AManufacturing Method ImprovementsResolve shrinkageRecord carriers used with machinesOn boardEngineering

PURPOSE: A method for manufacturing an IC card by layering foils is provided to remove a step for digging out a groove again after layering the foils, firmly join the COB(Chip On Board) and a card plate, occur no gap between the COB and the card plate, and firmly join an electrode of the COB and an antenna. CONSTITUTION: The COB(200) is placed by facing an electrode surface of a terminal in the COB downwardly. At least more than two foils(300,400,500) having a hole(301) of the same area as the COB are layered by inserting the COB into the hole. A back side cover foil(600) having no hole is layered to an opposite side of the surface exposing the electrode surface of the terminal in the COB of the layered foils, and the foils are compressed.

Owner:JT

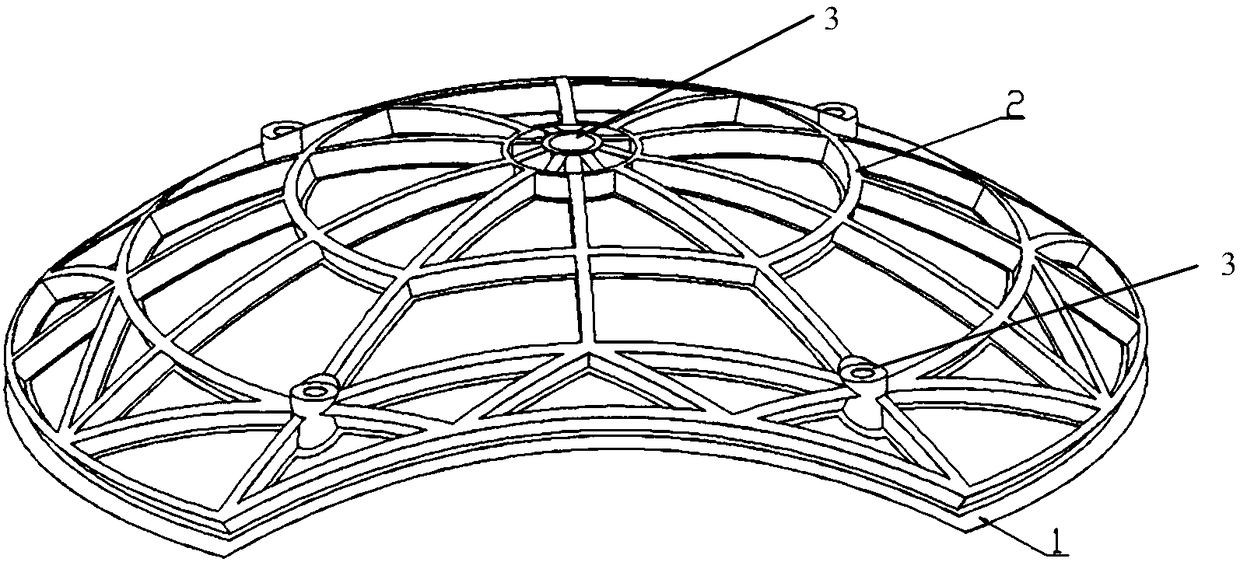

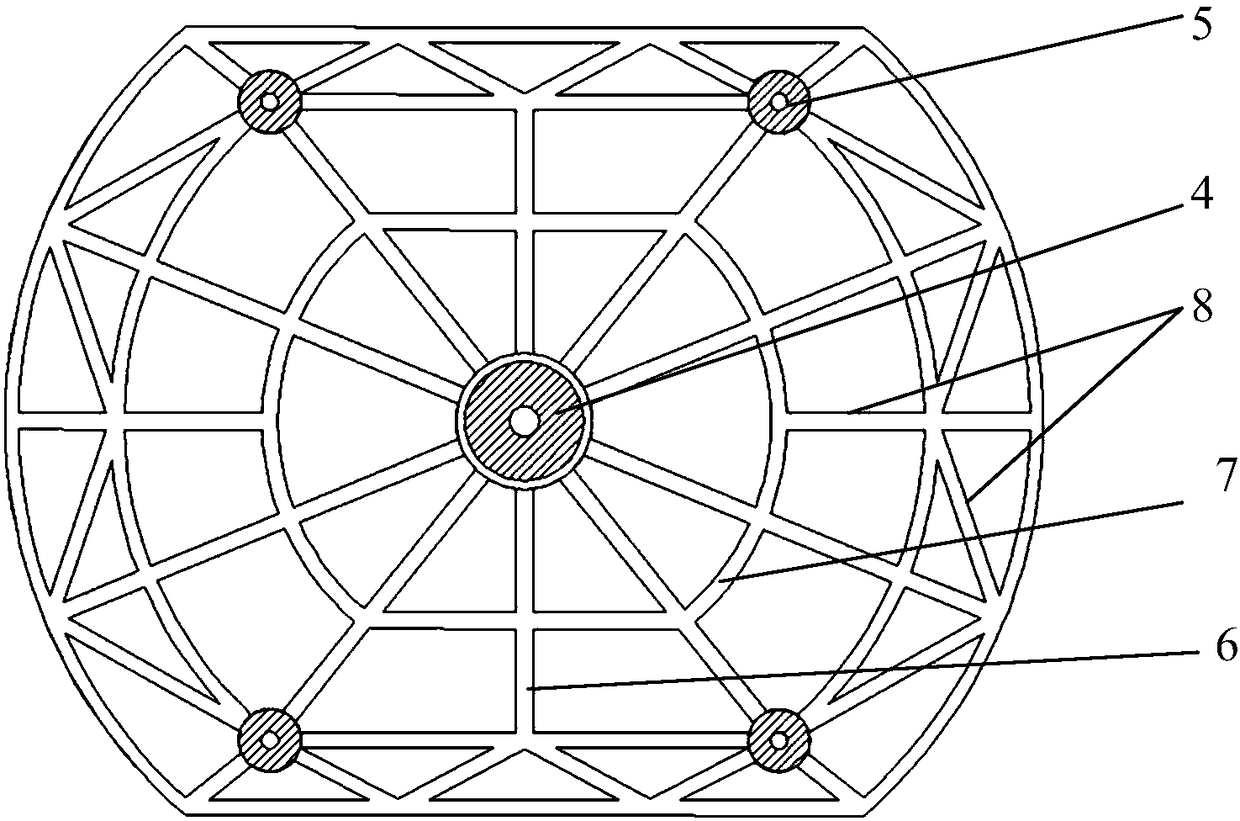

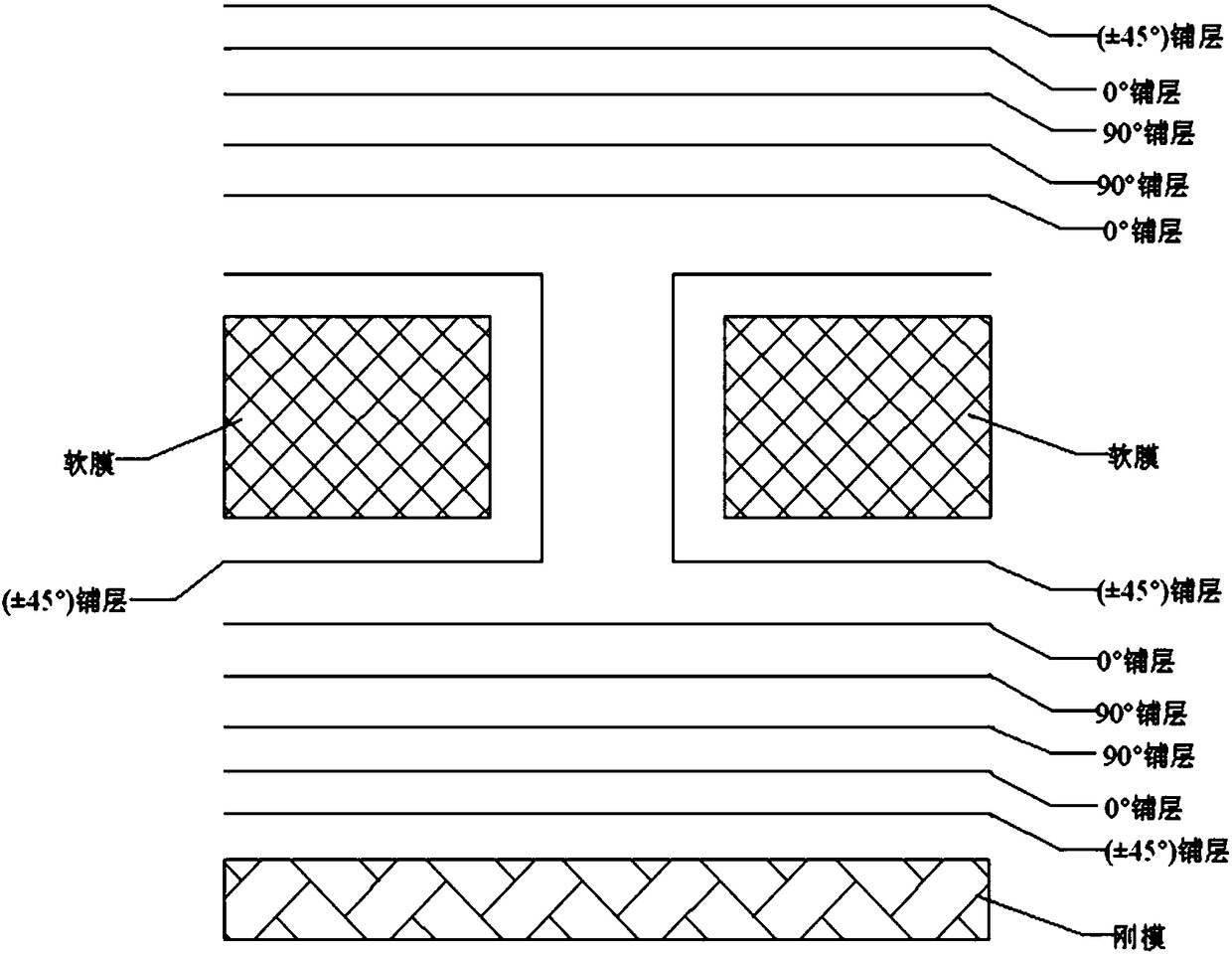

Skin reinforced structure antenna reflector and preparation method thereof

InactiveCN108511920AFlexible and controllable designSimplified quantityAntennasThermal deformationEngineering

The invention provides a skin reinforced structure antenna reflector and a preparation method thereof; the reflector comprises a plane of reflection and back ribs arranged on the side of the plane ofreflection; the plane of reflection comprises a single layer skin; the back ribs are in a curved surface multi-grid frame structure; the reflector preparation method comprises the following steps: S1,respectively making the skin and the back ribs; S2, gluing, assembling and curing the skin with the back ribs; S3, demoulding after curing is done, and obtaining the final product. The rigidity and thermal expansion coefficient of the skin and the back ribs are matched; the back ribs can be integrally designed and moulded with an external interface and a joint; the prepared antenna reflector is light in weight, good in rigidity, high in profile precision, and good in thermal stability; the antenna reflector with the caliber of 2.5m can realize the effect that the profile precision root mean square (RMS) reaches 15um; when the ambient temperature rises from 20 to 120 DEGC or drops to 180 DEG C, the plane of reflection profile thermal deformation RMS value can be only 5um or 12 um.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

Polazied plate and its producing method and liquid crystal display

InactiveCN1409135AManufacturing Method ImprovementsPolarising elementsNon-linear opticsLiquid-crystal displayPolyvinyl alcohol

A polarized light sheet can be used to improve LCD of nonuniform display caused by nonuniform dyeing. The dyeing bath with concentration of iodine or the dichroic dyestuff bigger than 0.02 wt.% should be used to control its temperature in the range of 15-50 degrees C and to control the stretching multiplying power less than 5 times as well as agitating the bath solution while dyeing, when the polyvinyl alcohol film is under the dyeing course.

Owner:NITTO DENKO CORP

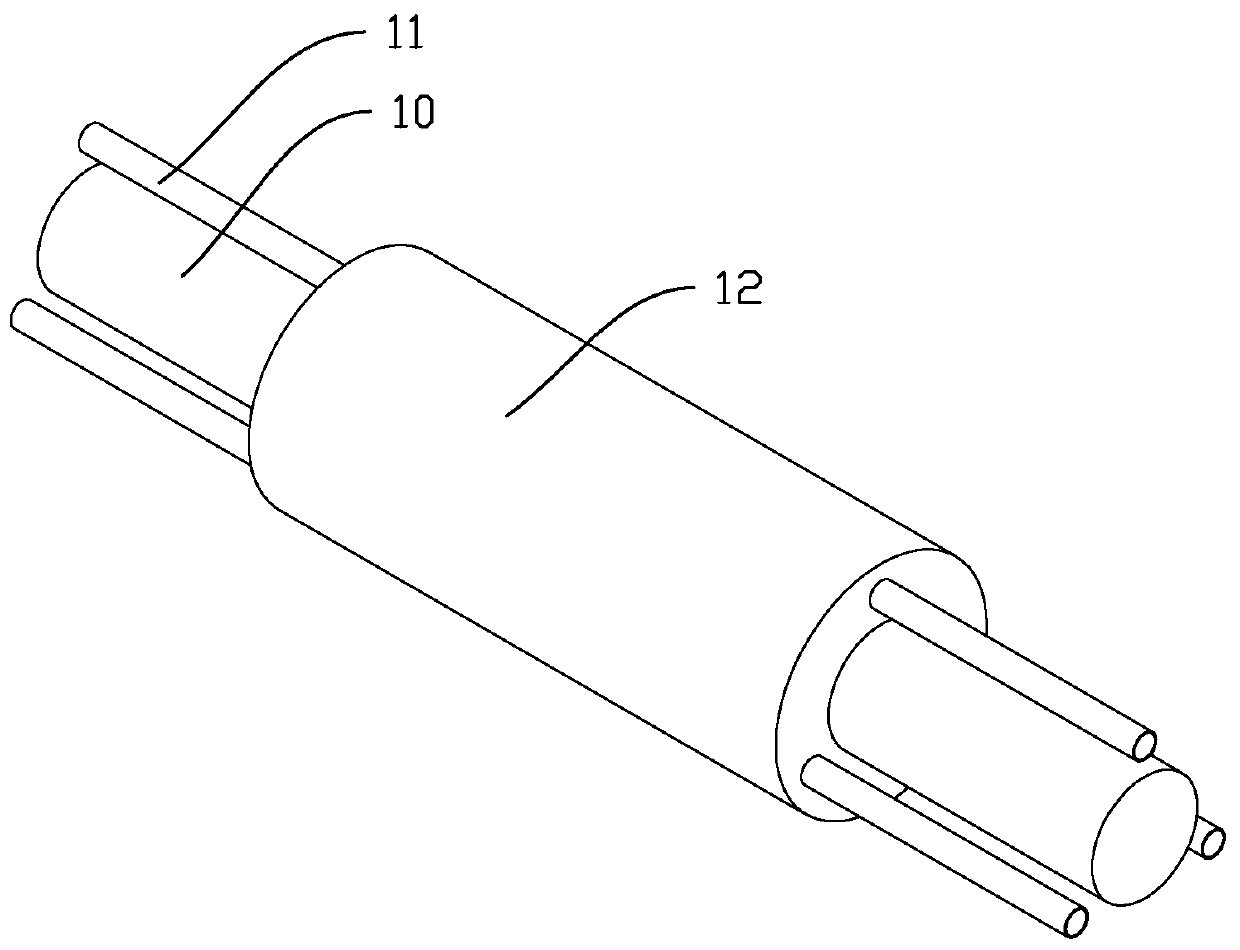

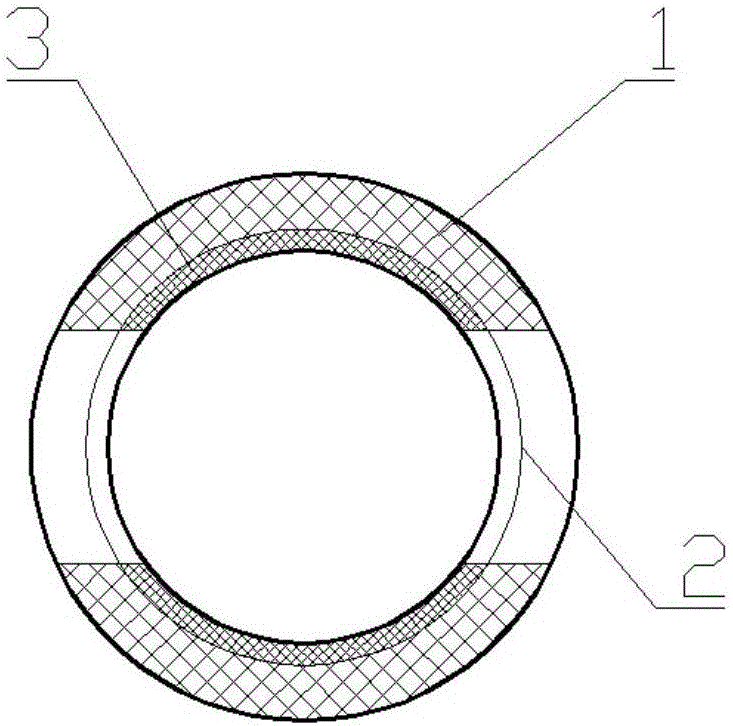

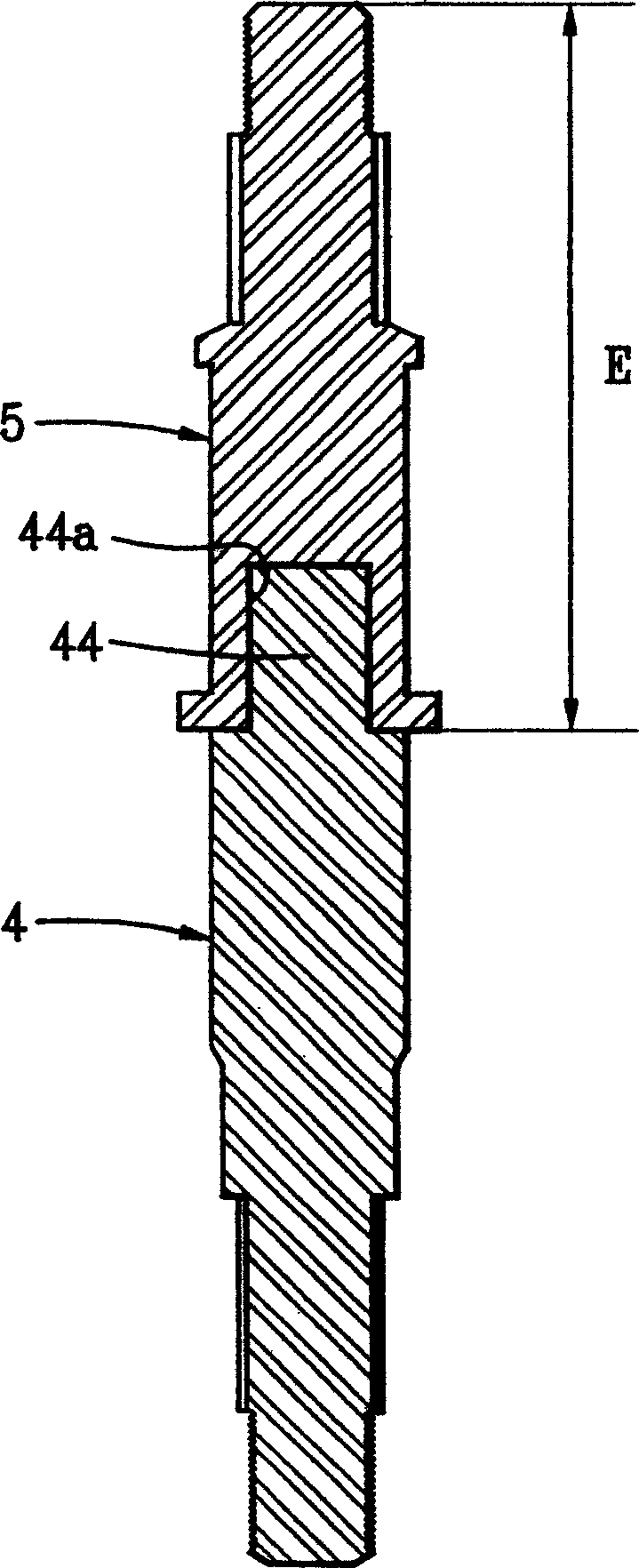

Optical fiber composite insulator prefabricated core rod, mold and manufacturing method of optical fiber composite insulator prefabricated core rod

ActiveCN111029054AAvoid air gapStandardized manufacturing methodInsulatorsComposite insulatorsBonding process

The invention discloses an optical fiber composite insulator prefabricated core rod, a mold and a manufacturing method of the optical fiber composite insulator prefabricated core rod. The optical fiber composite insulator prefabricated core rod comprises a core rod body, a silicone rubber layer and at least one optical fiber. The silicone rubber layer is integrally formed on the outer cylindricalsurface of the core rod body in an injection molding mode, and the silicone rubber layer is annular; at least one optical fiber is arranged outside the core rod body, the middle of the optical fiber is embedded in the silicone rubber layer, and one end or two ends of the optical fiber extends / extend out of the rubber layer. The optical fiber and the core rod body are fixed through vacuum injectionmolding of silicone rubber to form a silicone rubber outer coating layer, air gaps are prevented from being generated on the interfaces of the optical fiber, the silicone rubber layer and the core rod, and the problem that the performance and the service life of the optical fiber composite insulator are seriously affected due to bubble defects generated in the optical fiber bonding process duringmanual manufacturing of the optical fiber composite insulator can be overcome.

Owner:SOUTH CHINA UNIV OF TECH

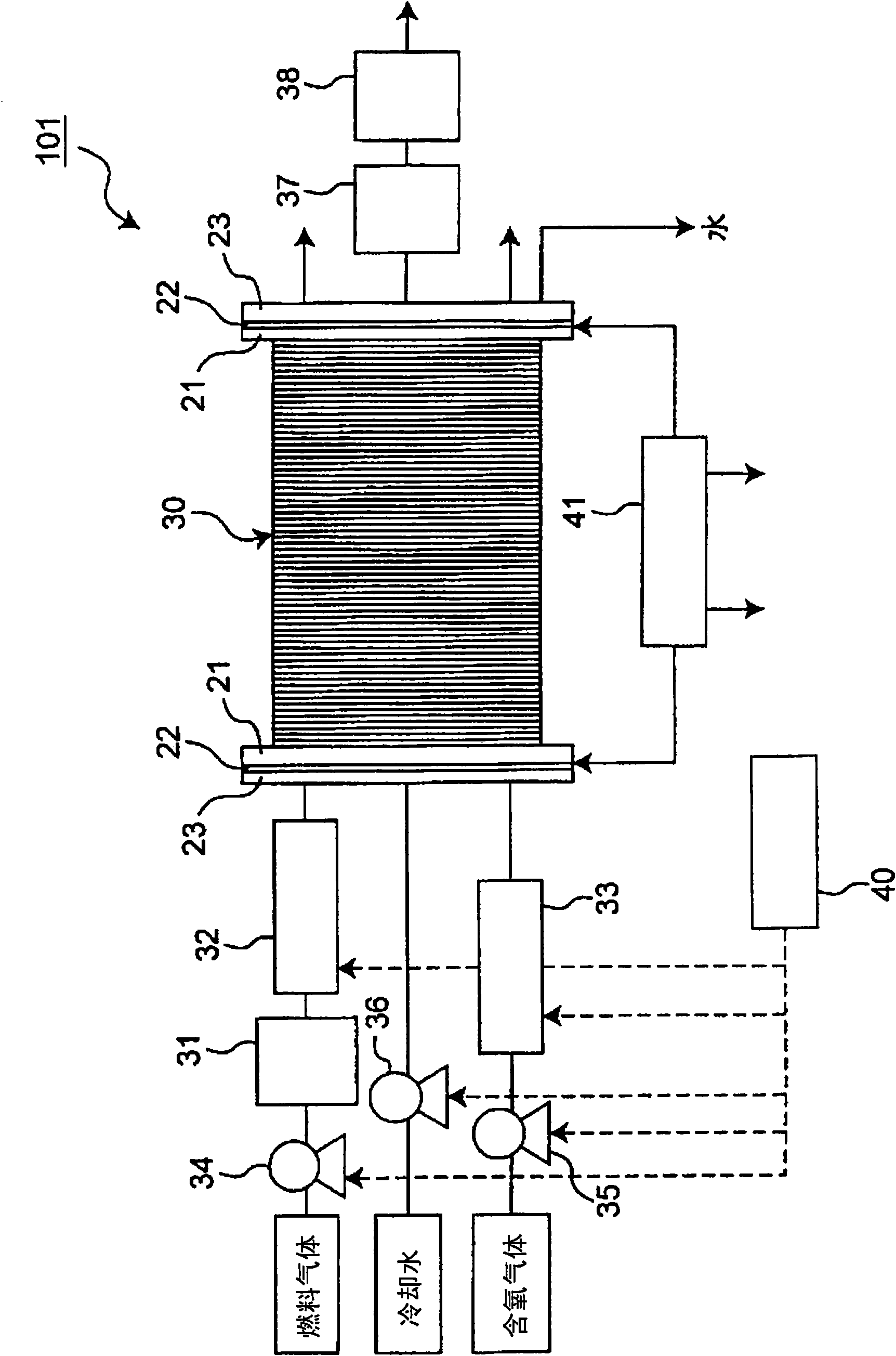

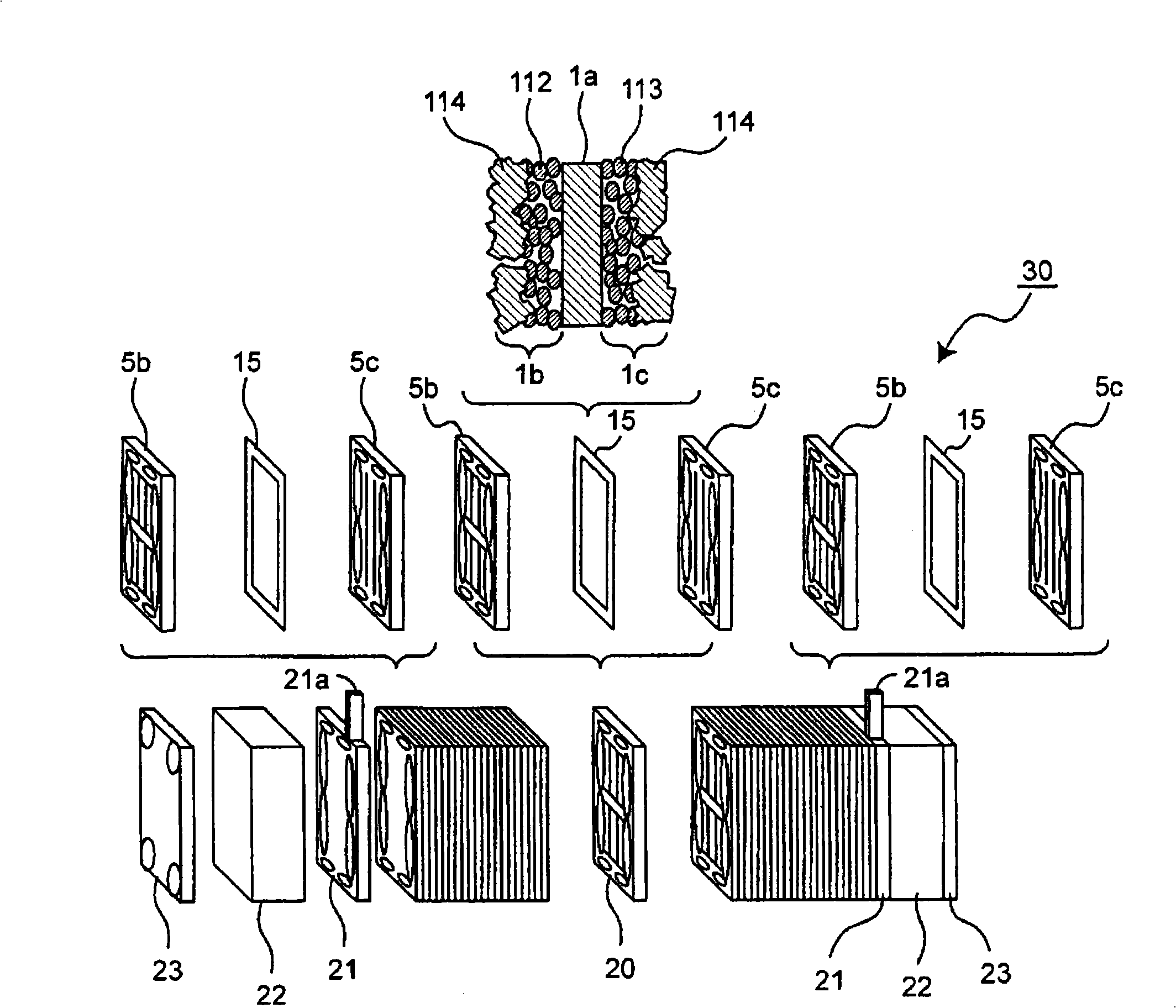

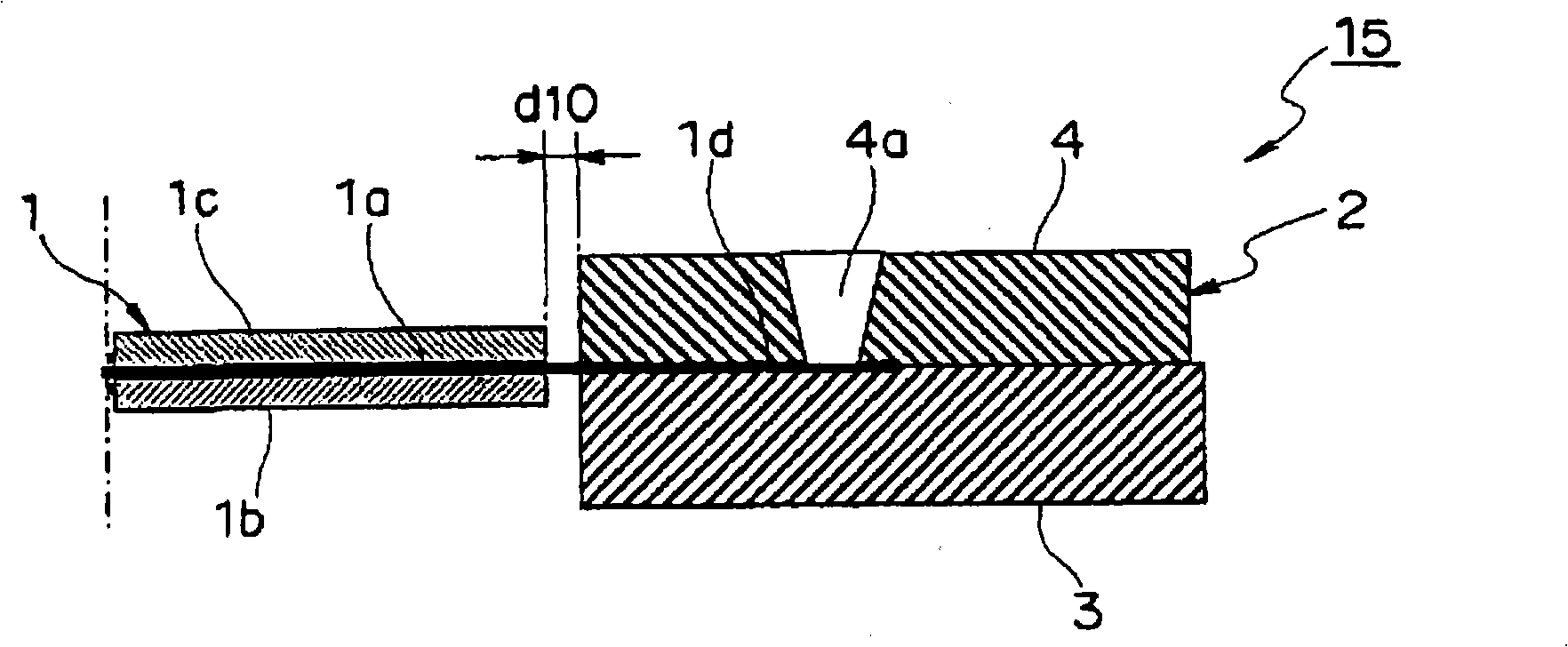

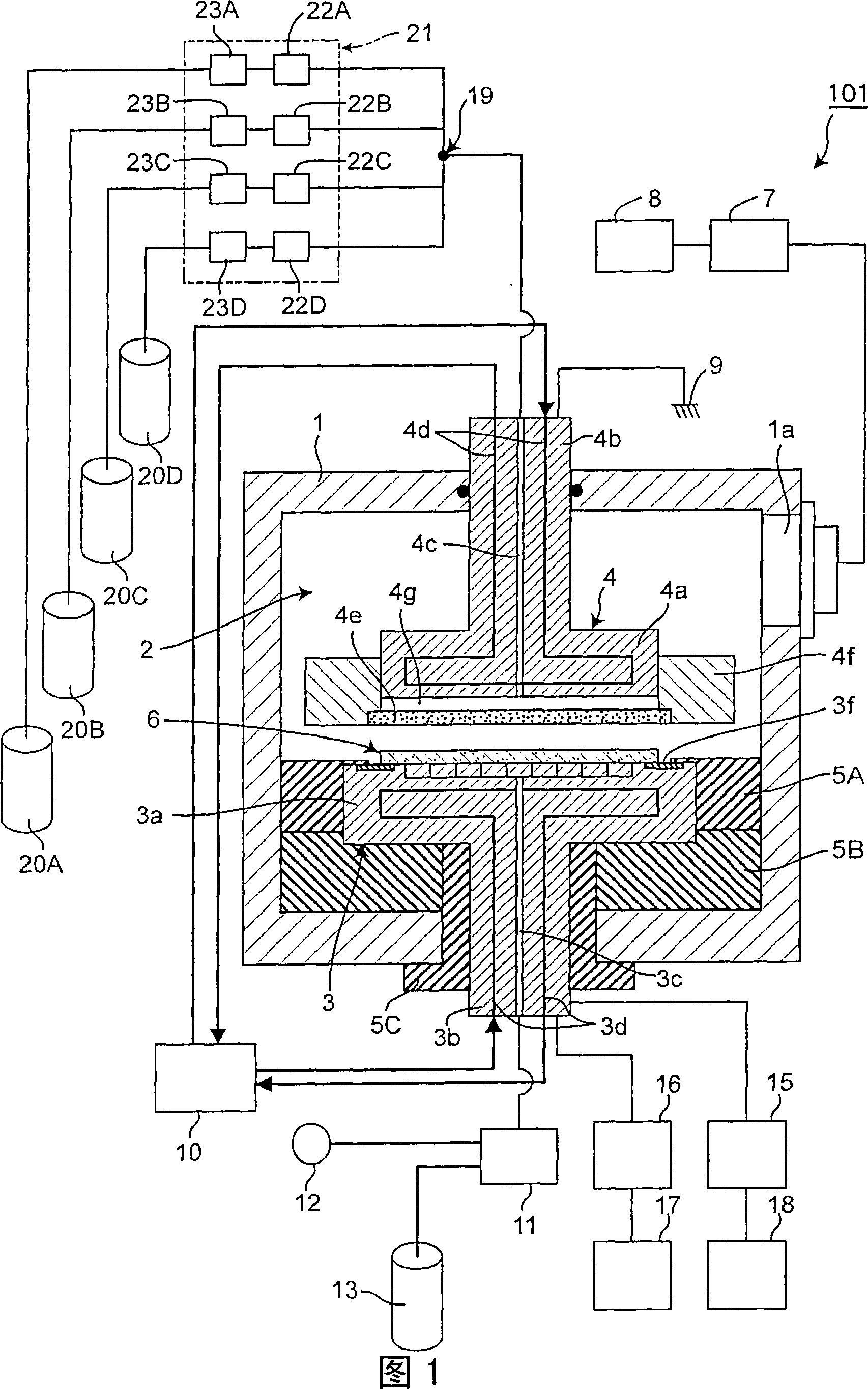

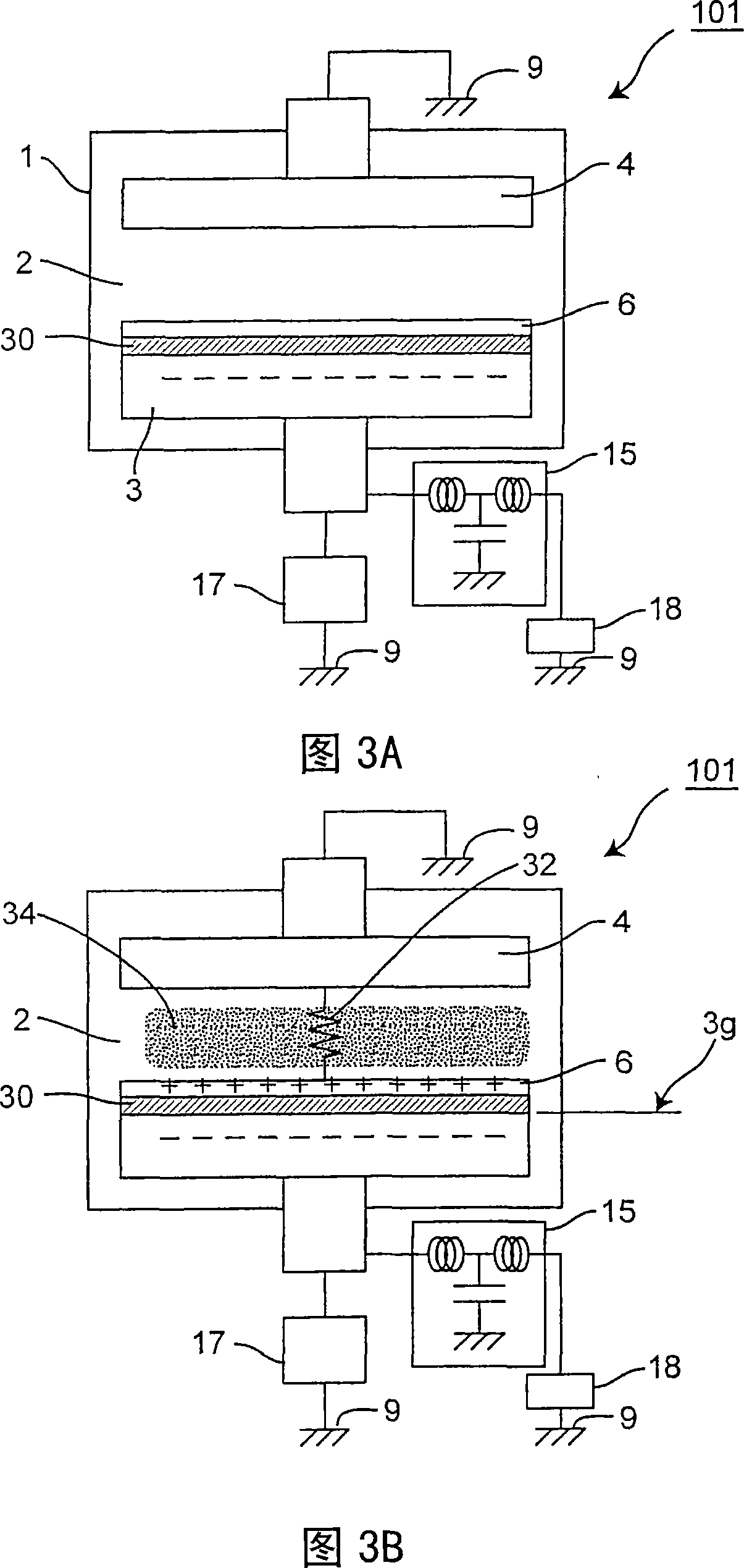

Polymer electrolyte fuel cell and electrode/film/frame assembly manufacturing method

ActiveCN101542798AImprove articulationImprove performanceCell electrodesFinal product manufacturePolymer electrolytesFuel cells

Provided is a method for manufacturing an electrode / film / frame assembly of a fuel cell. In order to arrange a brim portion of an electrolyte film member on a first frame member, the first frame member and the electrolyte film member are placed in a first die for injection molding. Then, a second die is arranged to form a resin channel for forming the second frame member to be contact with the first frame member via the electrolyte film member. A fixing member provided in the second die presses a part of the brim portion of the electrolyte film member against the first frame member so as to be fixed. A molding resin material is introducedinto the resin channel to form the second frame member.

Owner:PANASONIC CORP

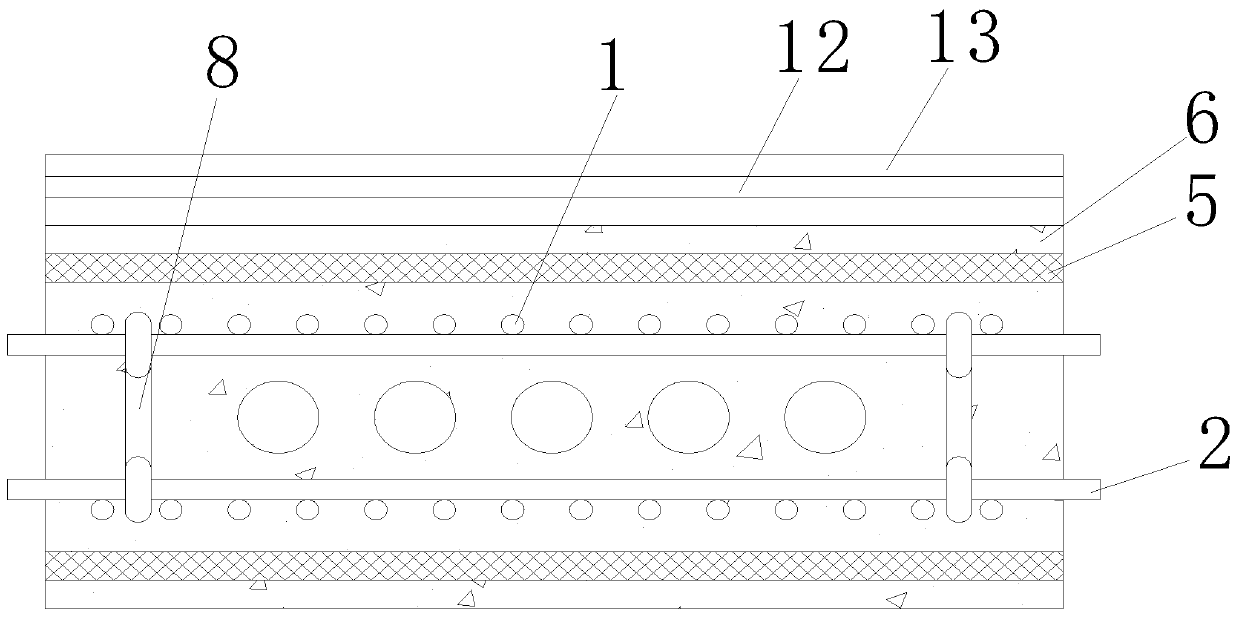

Anti-seismic prefabricated board for building and manufacturing method thereof

InactiveCN109707099ASufficient tensile capacityManufacturing Method ImprovementsConstruction materialFloorsEngineeringRebar

The invention discloses an anti-seismic prefabricated board for a building. The anti-seismic prefabricated board comprises a pouring board body (4), a covering layer attached to the surface of the pouring board body (4), and an internal frame arranged in the pouring board body (4); the internal frame comprises two layers of oppositely-arranged steel bar frameworks which each comprise a plurality of longitudinal steel bar rods (1) arranged in parallel and a plurality of transverse steel bar rods (2) arranged in parallel and at intervals, the longitudinal steel bar rods (1) are arranged in the length extension direction of the pouring board body (4), and the transverse steel bar rods (2) are perpendicular to the longitudinal steel bar rods (1). The anti-seismic prefabricated board has the advantages of being capable of overcoming the defects of the prior art and reasonable and novel in structure design.

Owner:QINGJIAN GRP CO LTD

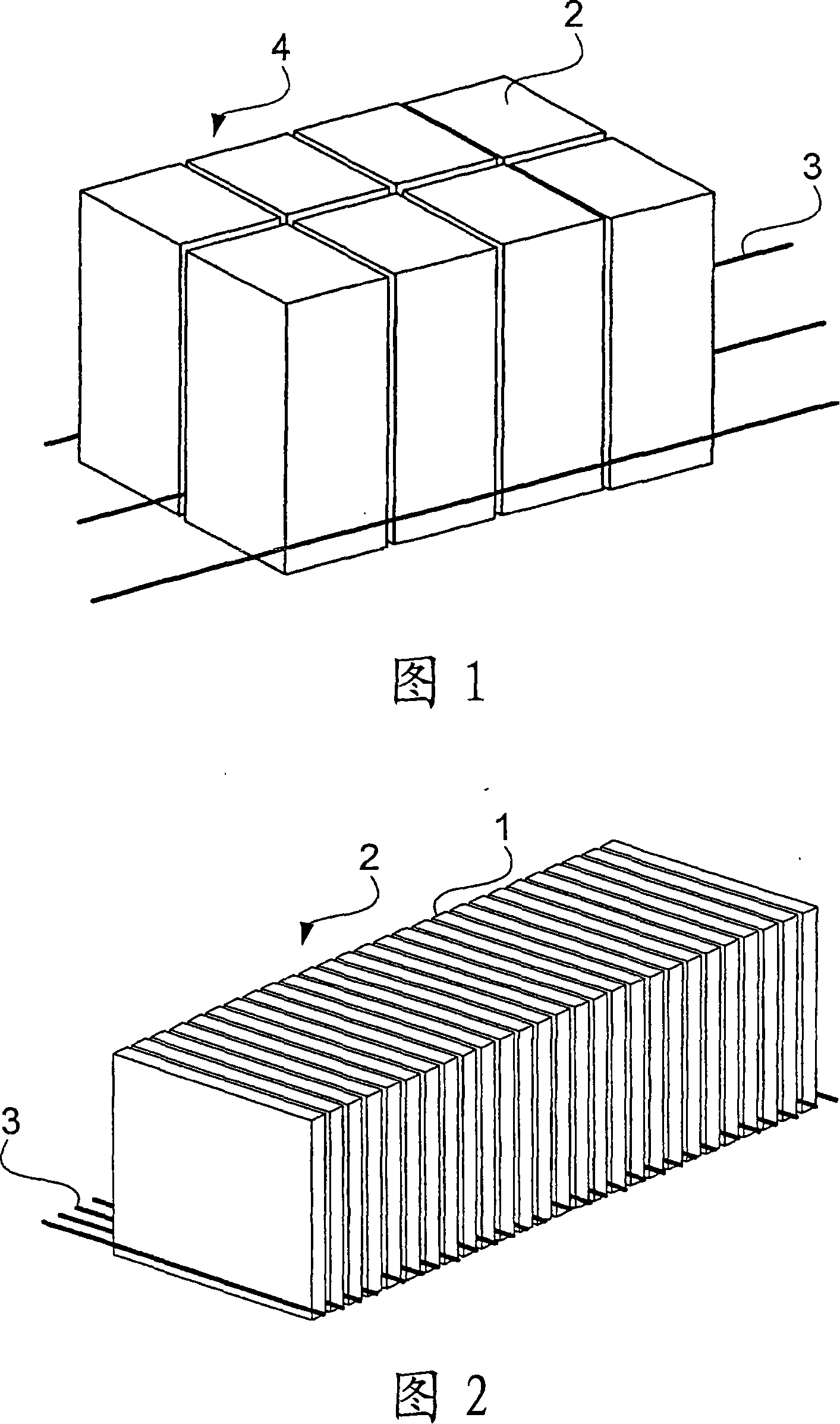

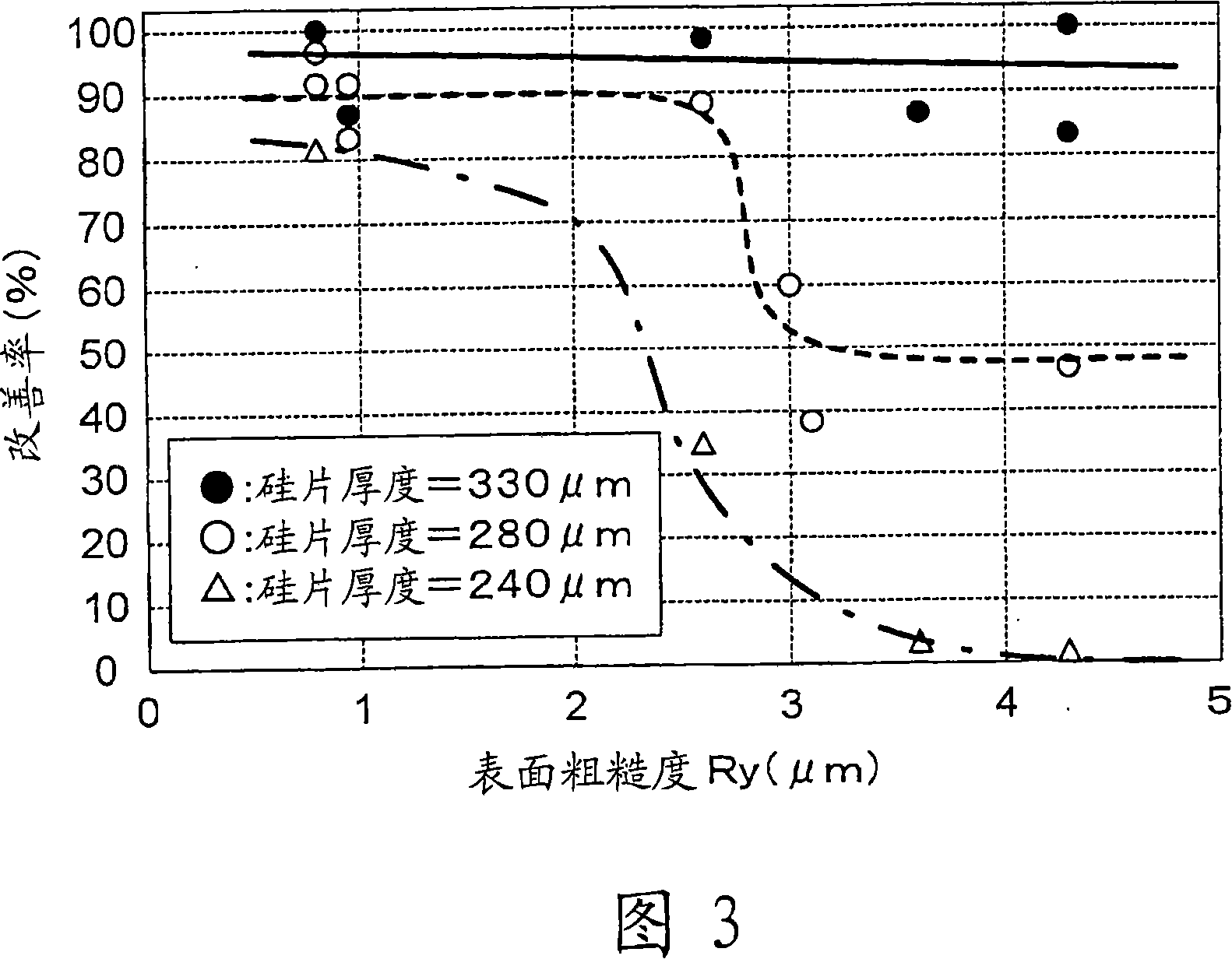

Method for manufacturing silicon block and silicon slice

InactiveCN101132896AFine surface roughnessManufacturing Method ImprovementsOther chemical processesFine working devicesSlurryIngot

The purpose is to provide a silicon block which can be processed into a thin silicon wafer having reduced breakage of a substrate during the manufacture of a solar battery. A method for producing a silicon block by cutting a silicon ingot using a silicon ingot cutting slurry containing abrasive grains and a basic substance, the basic substance being contained in a content of at least 3.5% by mass relative to the total mass of the liquid components of the slurry, the slurry containing an organic amine at a ratio of 0.5 to 5.0 inclusive by mass relative to the mass of the moisture in the liquid components of the slurry, and the slurry having a pH of 12 or higher and being used at a temperature within the range from 65 to 95 DEG C.

Owner:MITSUBISHI ELECTRIC CORP

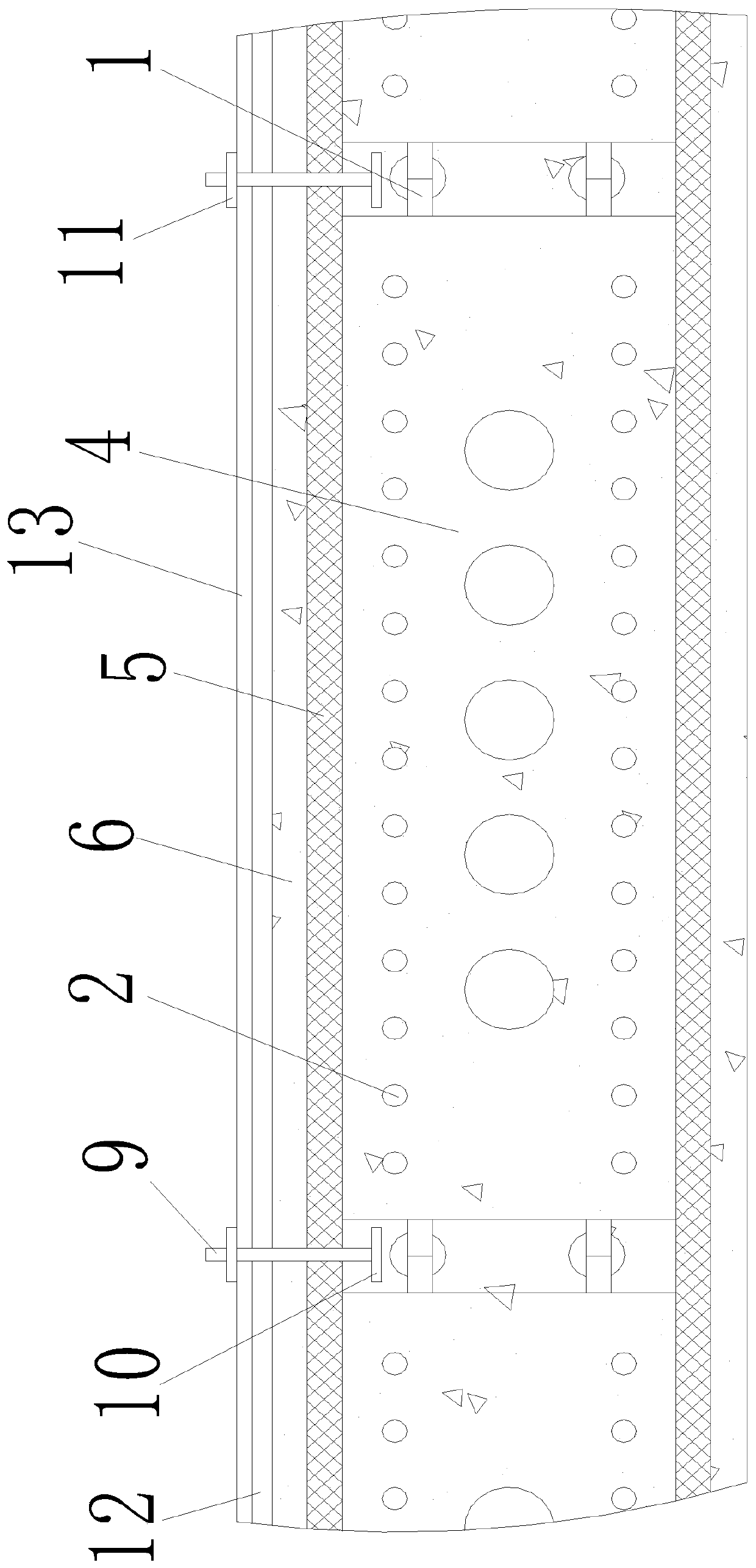

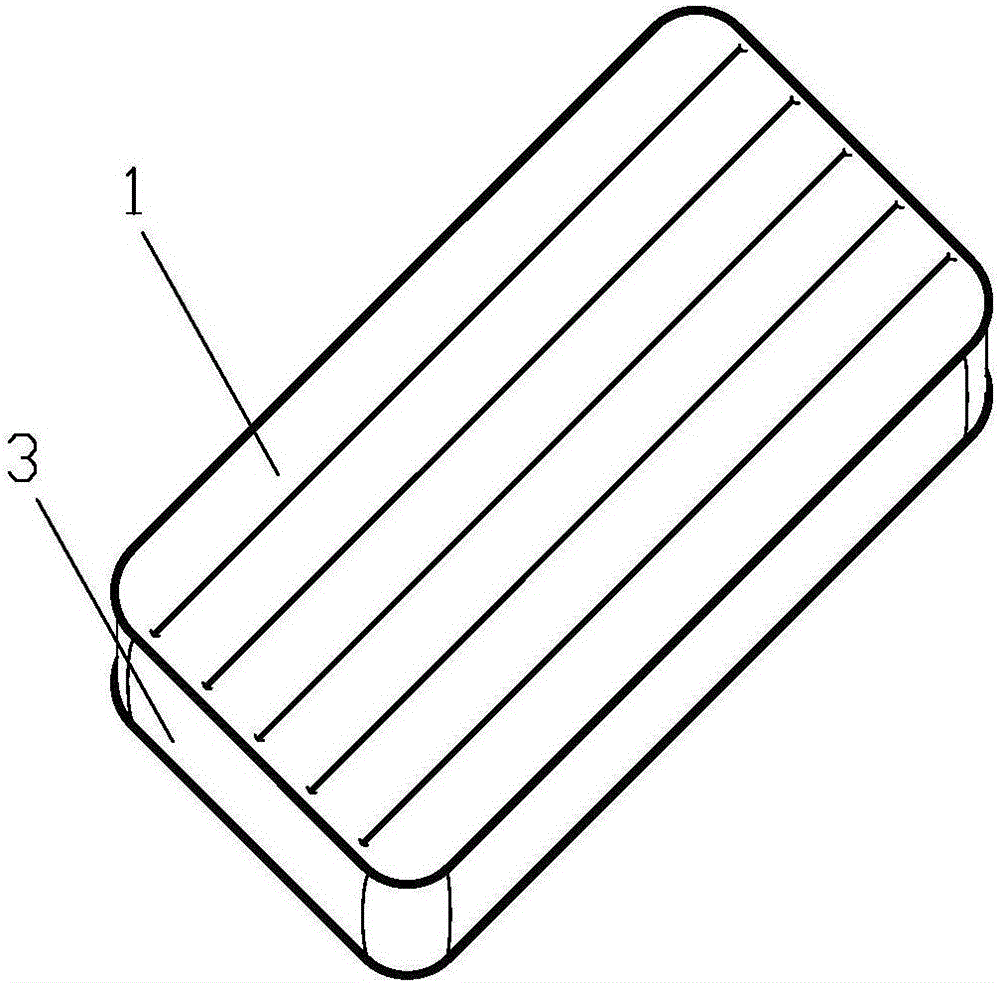

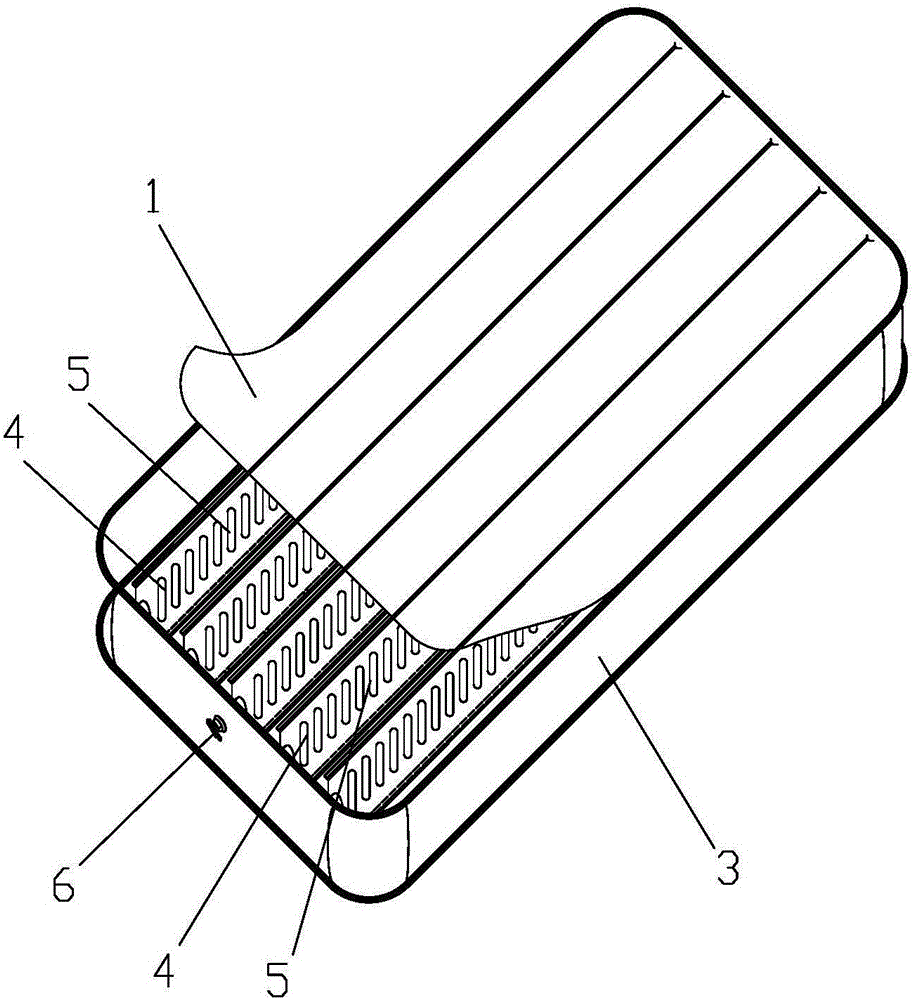

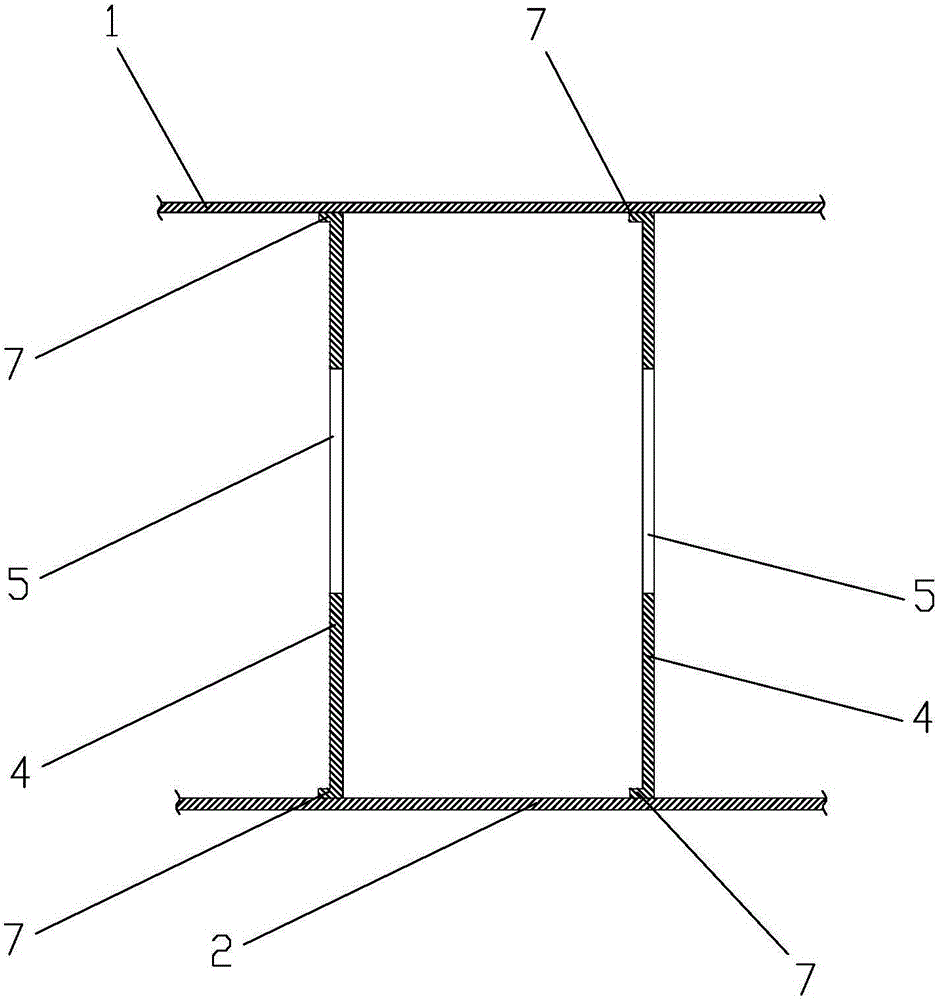

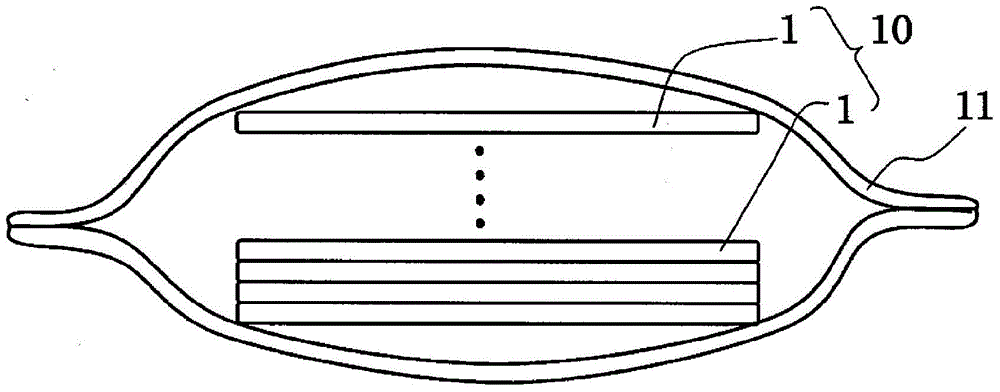

Straight-brace inflatable mattress and manufacture method thereof

The present invention discloses a straight-brace inflatable mattress, characterized in that each straight brace is provided with a plurality of through holes. The inflatable mattress is light in weight, stable in form and good in comfort. The invention also discloses a method of manufacturing the straight-brace inflatable mattress, including: A: manufacturing upper sheeting, lower sheeting, the straight braces and an enclosure; B: punching the straight braces to obtain through holes; C: spreading the lower sheeting on a machine; D: attaching the straight braces to a straight brace die so that the lower ends of the straight braces is abutted to the lower sheeting; E: spreading the upper sheeting on the straight brace die so that the upper sheeting is abutted to the upper ends of the straight braces; F: fusing the upper sheeting and the lower sheeting respectively with the straight braces; G: removing the straight brace die and the fused upper sheeting, straight braces and lower sheeting; H: sleeving an enclosure die with the enclosure, and spreading the upper sheeting and lower sheeting of step G respectively on upper and lower surfaces of the enclosure die; I: fusing the upper sheeting and the lower sheeting with the enclosure; J: cutting off surplus edges; K: obtaining the finished product. The process is simple and low in cost.

Owner:刘炜舜

Semiconductor chip assembly with metal containment wall and solder terminal

InactiveCN1921096AEasy to separateEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringMetal

The present invention relates to a semiconductor chip assembly which includes a semiconductor chip that includes a conductive pad, a conductive trace that includes a routing line, a metal containment wall and a solder terminal, and a connection joint that electrically connects the routing line and the pad. The metal containment wall includes a cavity, and the solder terminal contacts the metal containment wall in the cavity and is spaced from the routing line.

Owner:BRIDGE SEMICON

Hair nourishing liquid and manufacturing method thereof

InactiveCN101869616ASimple manufacturing methodEasy to manufactureHydroxy compound active ingredientsDermatological disorderMedicinal herbsHair roots

The invention relates to hair nourishing liquid with effect of treating alopecia and a manufacturing method thereof. The hair nourishing liquid comprises the following components: 10 to 15 percent of tuber fleeceflower root, 10 to 15 percent of incised notopterygium rhizome, 10 to 15 percent of dense-fruit Pittany root-bark, 40 to 60 percent of fresh arborvitae leaf, and alcohol in an amount which doubles the total weight of the four gouts of Chinese medicinal herbs. The hair nourishing liquid can promote blood circulation of scalps, effectively control grease secretion of the scalps, sterilize the scalps, stop itch, dispel wind and remove dampness, clear heat and release toxin for the scalps, effectively grow hair, prevent alopecia, stop alopecia and enhance hair follicles, enhance the firmness of hair, make hair roots firm, powerfully grow the hair, and realize healthy new growth of the hair follicles of the scalps.

Owner:郑志强

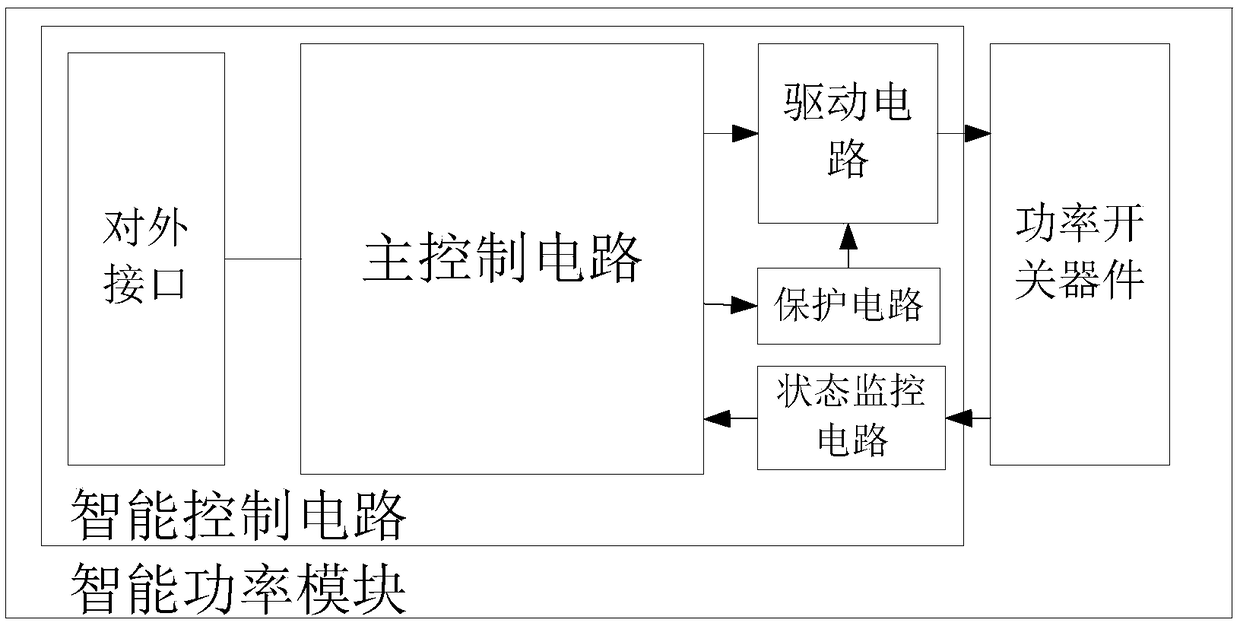

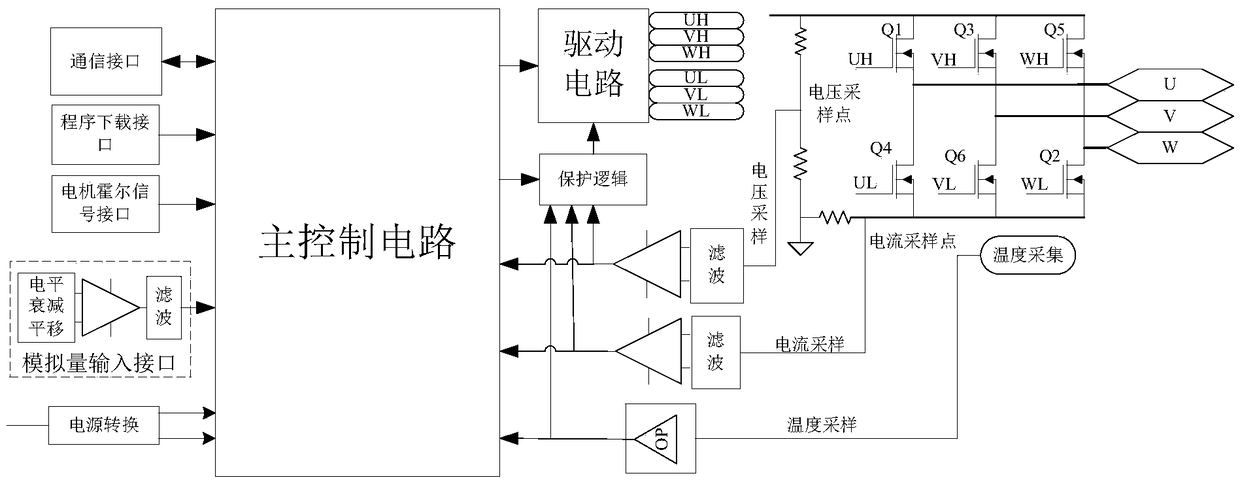

Three-dimensional integrated intelligent power module and manufacturing method thereof

ActiveCN108809056ASimple designReduce distractionsPrinted circuit board receptaclesSemiconductor/solid-state device manufacturingPower semiconductor deviceDriver circuit

The invention discloses a three-dimensional integrated intelligent power module and a manufacturing method thereof. The three-dimensional integrated intelligent power module comprises a power switch circuit, a drive circuit, a master control circuit and a state monitoring and protecting circuit and is characterized in that the master control circuit and the state monitoring and protecting circuitare connected with the power switch circuit and the drive circuit thereof, the master control circuit is assembled to an upper substrate, the state monitoring and protecting circuit is assembled to alower substrate, the upper substrate and the lower substrate are connected with each other by through guide holes to form a three-dimensional intelligent control unit, and the power switch circuit andthe drive circuit thereof are welded to a high-heat-conductivity substrate and connected with the intelligent control unit through lead welding. The intelligent power module has the advantages that the intelligent power module integrates the power switch circuit and the drive circuit thereof, the master control circuit and the state monitoring and protecting circuit; by using the three-dimensional integration form, module power density can be increased, device size can be reduced, the length of the lead between power semiconductor device pins is shortened, parasitic parameters and noise peakvoltage are lowered, and the application reliability of power devices is increased.

Owner:郑州兴航科技有限公司

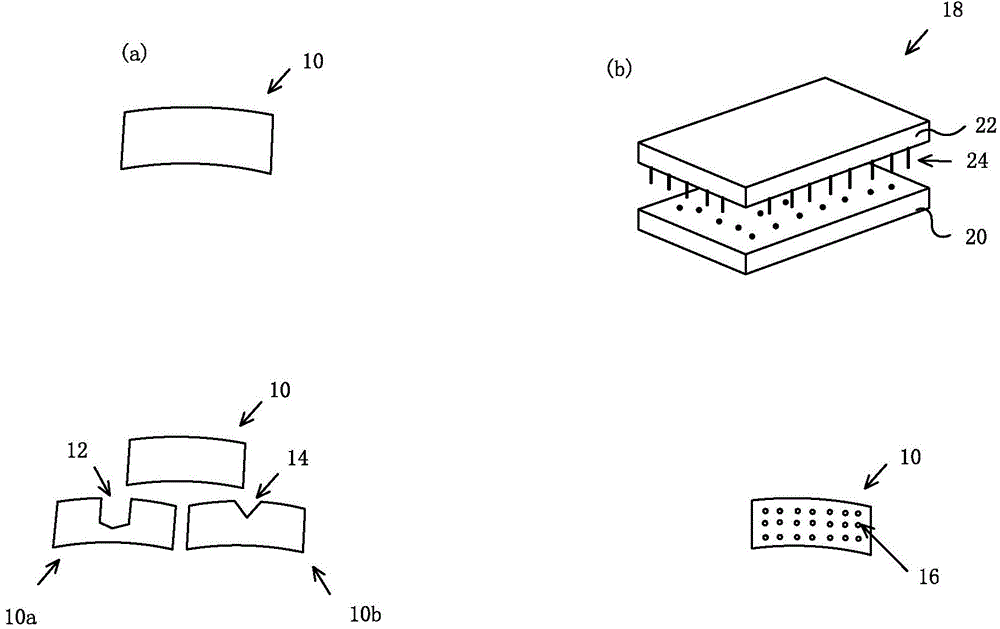

Diamond cutter tooth and method for manufacturing diamond cutter tooth by using rigid material

The invention discloses a diamond cutter tooth. Diamond particles are directly bonded on a rigid material, and have no need to bond powder brazing filler metal. A manufacturing method of a diamond saw blade cutter tooth comprises the following steps: a solid material basal body is selected; holes or grooves having smaller diameters than the diamond particles are punched in the basal body; the diamond particles are paved on the basal body; the diamond particles are accommodated in the holes or the grooves by the holes or the grooves; and the holes or the grooves can be arranged according to the arrangement requirements of cutter tooth diamonds. The method needs no third materials or mediums and electroplating, directly paves the diamond particles on such rigid materials as carbon steel and alloy steel, and is few in procedures.

Owner:侯家祥

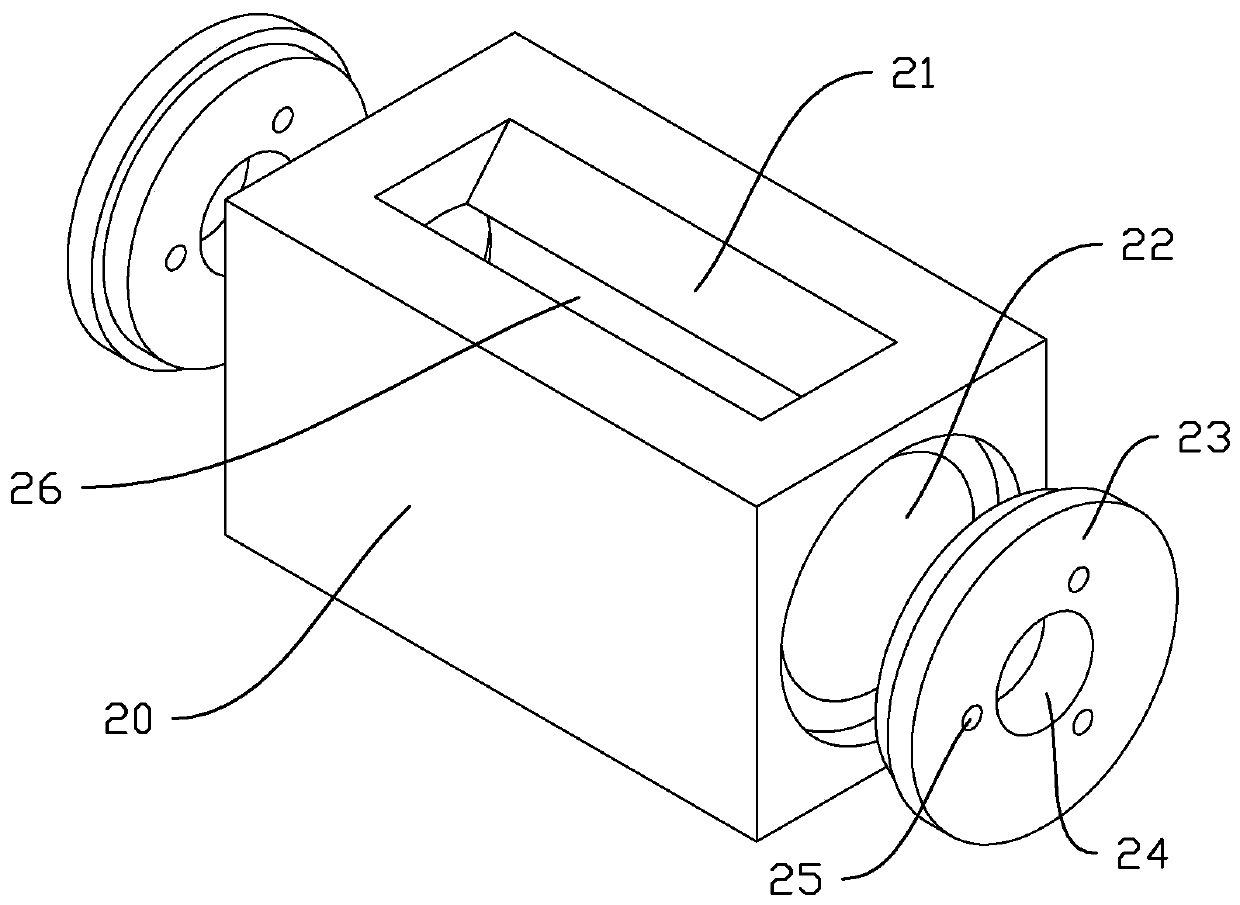

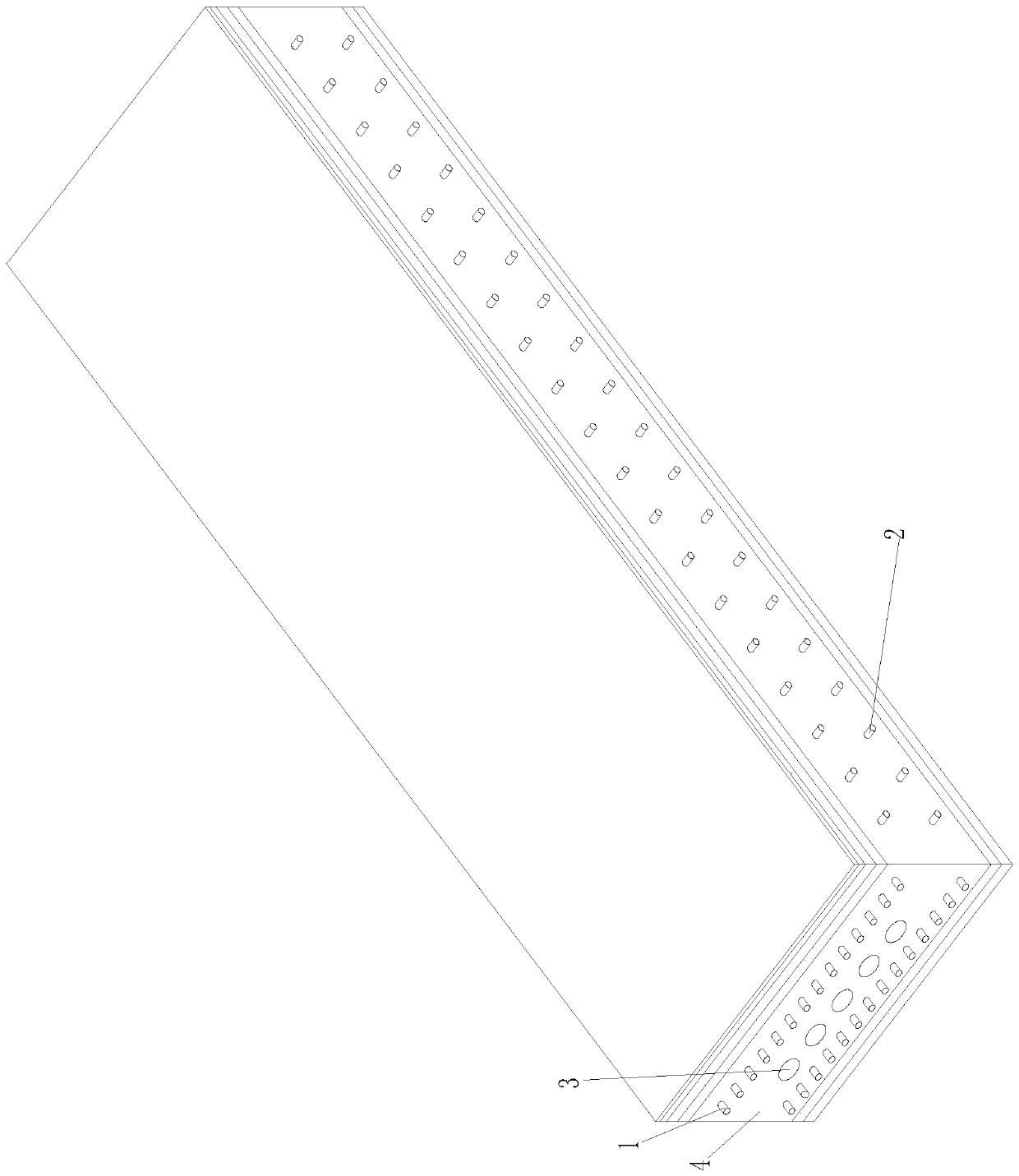

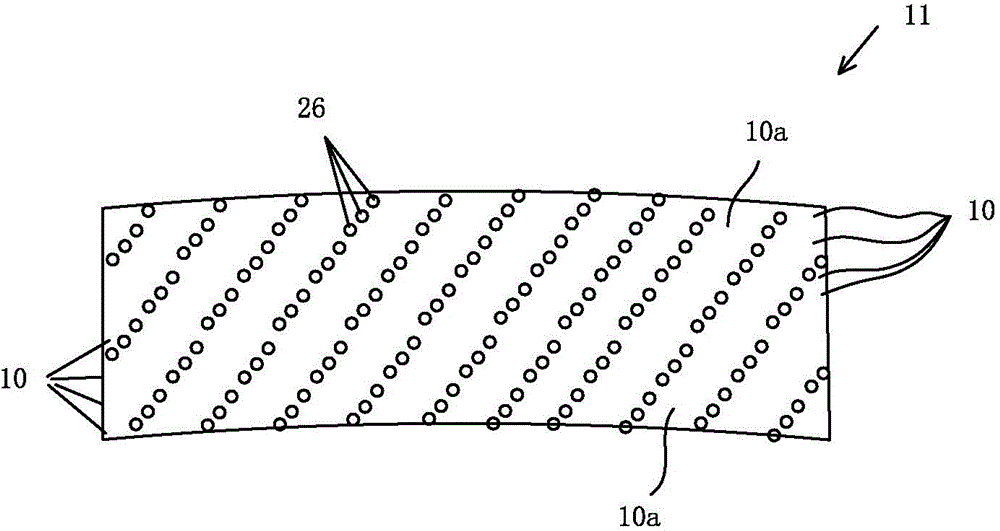

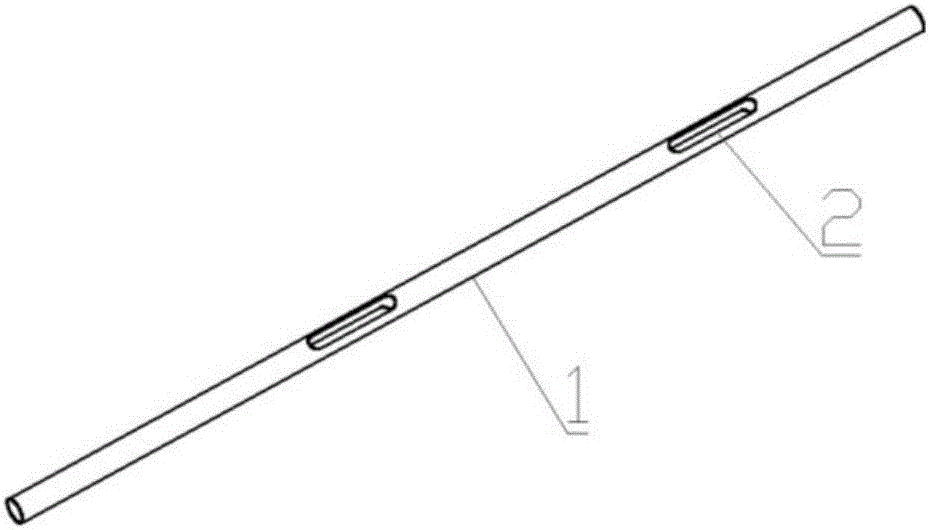

Light foldable rod antenna for aerospace and preparation method thereof

InactiveCN106571510AEfficient receptionEfficient emissionsAntenna adaptation in movable bodiesFlexible aerialsEpoxyFiber

The invention provides a light foldable rod antenna for aerospace, which comprises a rod piece main body, and is characterized in that the rod piece main body comprises a supporting column section (1) and strain energy holes (2) arranged in the supporting column section (1); and the inner hole wall of the supporting column section (1) is provided with a conductive layer (3). The rod piece main body is made by adopting a composite material system. The conductive layer (3) is a metal aluminum layer. The composite material system is made by adopting epoxy resin and carbon fibers. The high-performance rod antenna prepared through adopting a light carbon fiber composite material with high performance, adopting a foldable elastic strain energy structure and preparing the metal layer with excellent conductivity at the surface of the composite material can realize automatic unfolding, and substantially simplifies an telescopic control mechanism and reduces the overall weight of the antenna under the premise of maintaining effective receiving and emitting of electric signals.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

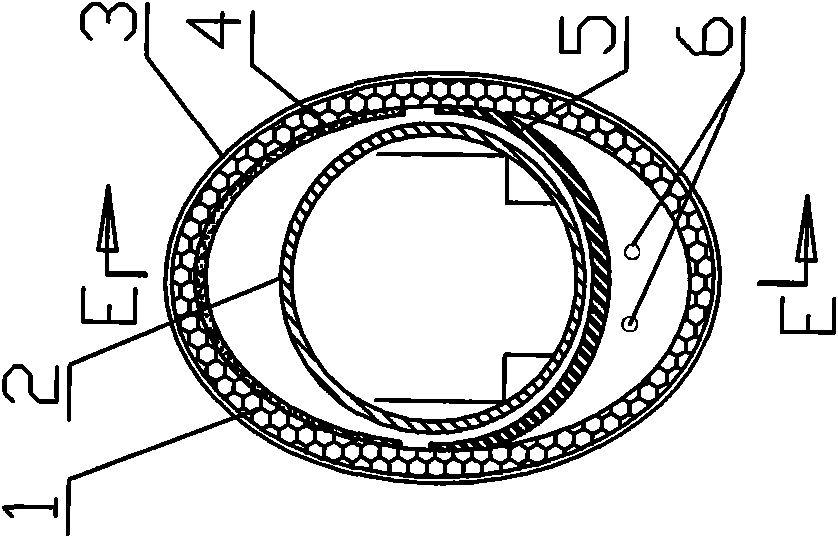

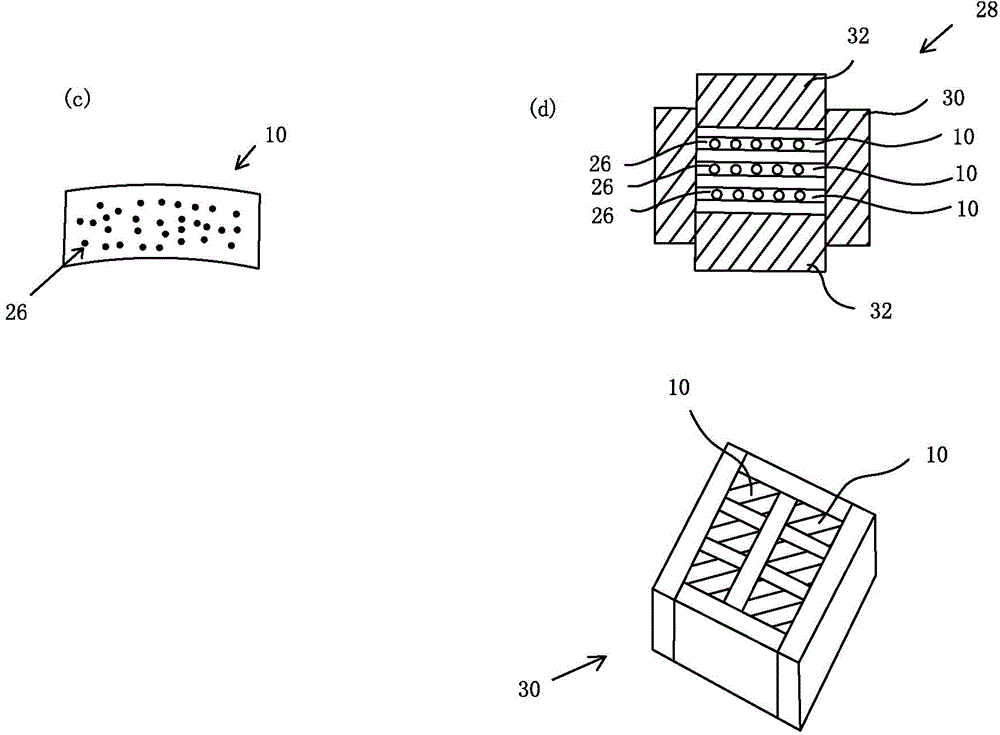

Vacuum insulation material and method for manufacturing same

ActiveCN104105917AGood insulation performanceImprove productivityThermal insulationPipe protection by thermal insulationFiberThermal insulation

Provided is a vacuum insulation material that has a stable quality, that is capable of maintaining initial thermal insulation properties over a long period of time, and that is capable of maintaining the form of a sheet even when the use of a binder, which causes the problem of volatilization in a vacuum state, is avoided. The vacuum insulation material according to the present invention includes a laminated body (10) of inorganic fiber sheets (1), and an enveloping member (11) that vacuum-seals the laminated body. In the inorganic fiber sheets, inorganic fiber strand groups that contain curved inorganic fiber strands having a cut length (L) of between 3mm and 12mm are randomly distributed, and at least some of the inorganic fiber strand groups are engaged with each other.

Owner:IMAE KOUGIYOU KK

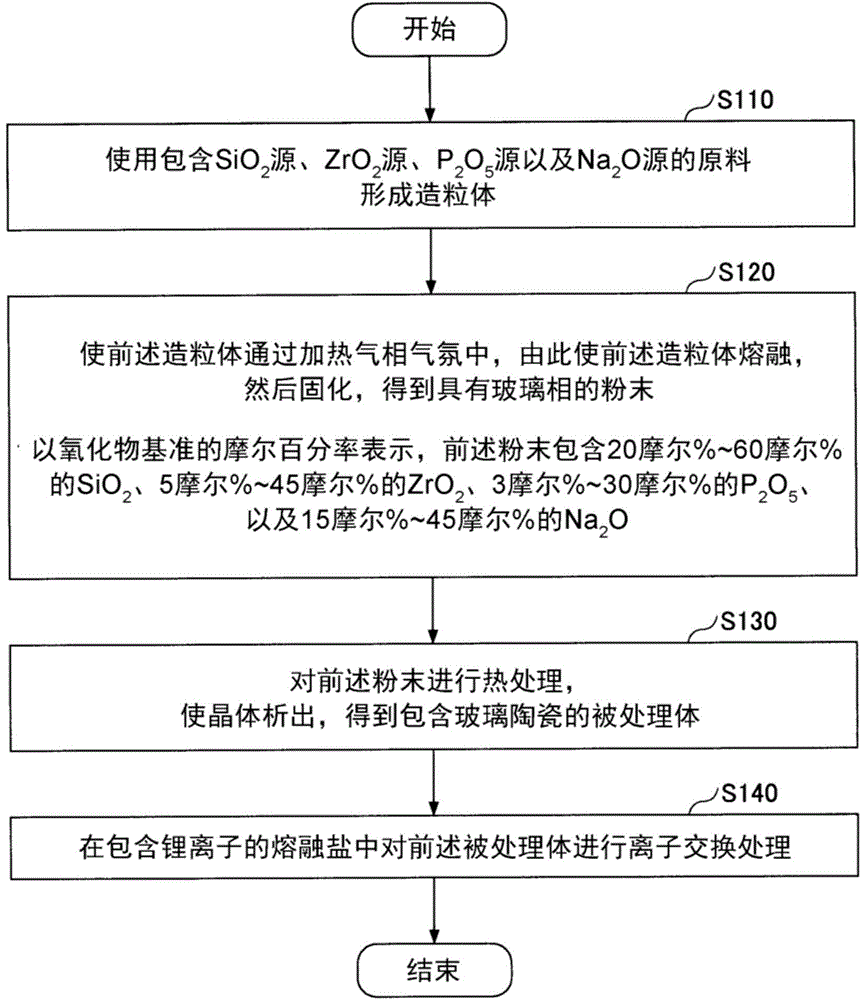

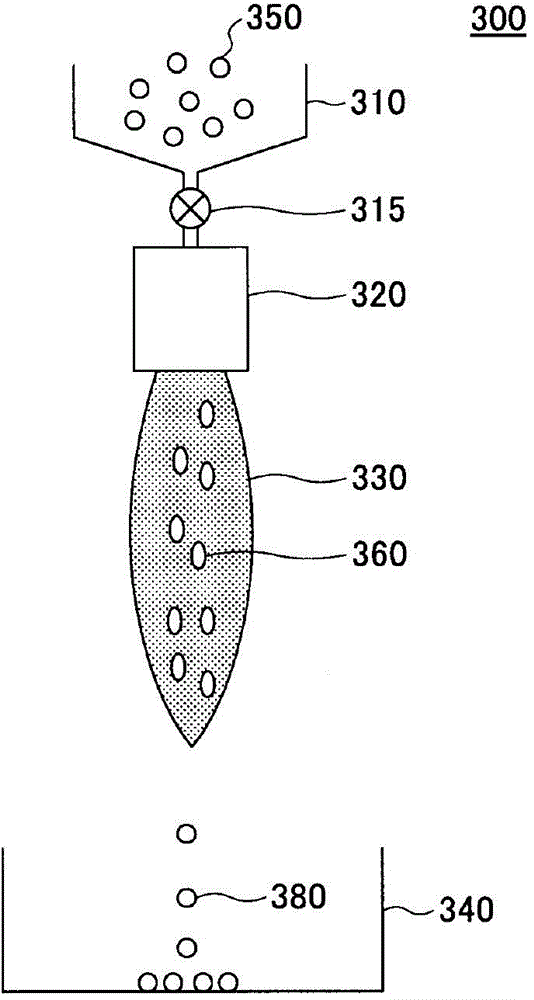

Method for manufacturing lithium-ion-conducting glass ceramic

InactiveCN104583144AManufacturing Method ImprovementsHigh ion conductivityGlass shaping apparatusElectrolytesParticulatesGas phase

This invention has: a step for forming a particulate using a raw material including a SiO2 source, a ZrO2 source, a P2O5 source, and a Na2O source; a step for causing the particulate to pass through a heated gas-phase atmosphere and thereby causing the particulate to melt and then solidify into a powder having a glass phase, the powder containing 20 to 60% of SiO2, 5 to 45% of ZrO2, 3 to 30% of P2O5, and 15 to 45% of Na2O (all figures representing the oxide-basis molar percentage); a step for heat-treating the powder and causing a crystal to be deposited to yield a processed body including a glass ceramic; and a step for performing ion exchanging on the processed body in a molten salt containing lithium ions to yield a lithium-ion-conducting glass ceramic.

Owner:AGC INC

Water-soluble amino acid fertilizer prepared from folium mori and preparation method thereof

InactiveCN105712749AManufacturing Method ImprovementsLow costNitrogenous fertilisersMicrobial agentWater soluble

The invention discloses a water-soluble amino acid fertilizer prepared from folium mori and a preparation method thereof.The water-soluble amino acid fertilizer is characterized by being prepared from, by mass, 100 parts of folium mori powder, 0.5-1.5 parts of compound microbial agent, 5-10 parts of molasses concentrated fermentation liquor, 2-5 parts of brown sugar and 1-3 parts of acetic acid.The preparation method includes the preparation process of 1, preparation of a fermentation reactor; 2, even mixing of materials; 3, inoculation of the materials; 4, water adjustment; 5, temperature controlled fermentation.The amino acid fertilized prepared from the folium mori powder contains amino acid components with full varieties and a large number of N, P, K, Ca and other nutrient elements needed for crops, and can be directly used as a leaf fertilizer, a seed fertilizer, a root fertilizer and the like; meanwhile, the preparation method of the fertilizer is rapid and convenient to carry out and low in cost, and the obtained product has the advantages of being obvious in fertilizer effect, high in utilization rate and the like.

Owner:青岛漾花湖农业科技有限公司

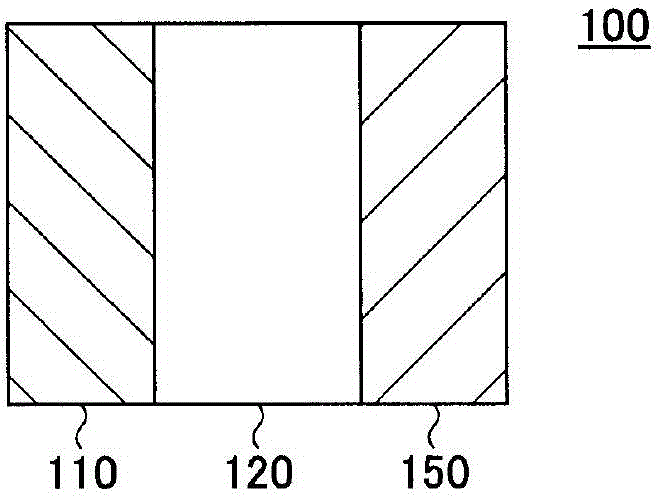

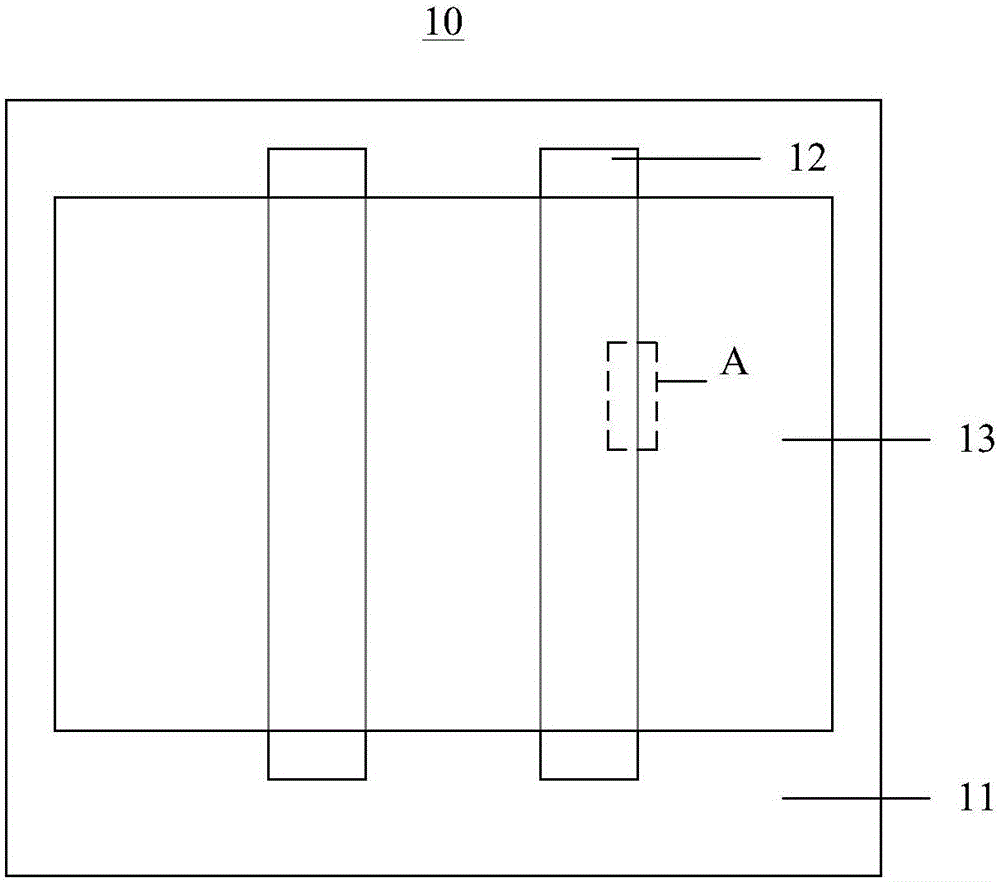

Display panel and manufacturing method thereof

ActiveCN106449706AImplementation settingsRealize narrow-edge structureSolid-state devicesSemiconductor/solid-state device manufacturingEdge structureEngineering

The invention discloses a display panel and a manufacturing method thereof. According to the display panel and the manufacturing method thereof, a first thin-film transistor of a grid drive circuit adopts a bottom-grid structure, a second thin-film transistor of a pixel circuit adopts a top-grid structure, and the first thin-film transistor and the second thin-film transistor share one polycrystalline silicon layer, the grid drive circuit is electrically connected with the pixel circuit, thus the aim of arranging the grid drive circuit below the pixel circuit is achieved, surrounding area of the pixel circuit is saved and a narrow-edge structure is better obtained.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Manufacturing method for semiconductor chips

ActiveCN101160653AManufacturing Method ImprovementsImprove structural strengthSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipPlasma etching

By performing plasma etching on the second surface of a semiconductor wafer on the first surface of which an insulating film is placed in dividing regions and on the second surface of which a mask for defining the dividing regions are placed, the second surface being located opposite from the first surface, the insulating film is exposed from an etching bottom portion by removing portions that correspond to the dividing regions. Subsequently, by continuously performing the plasma etching in the state in which the exposed surfaces of the insulating film are charged with electric charge due to ions in the plasma, corner portions put in contact with the insulating film are removed. Subsequently, by removing the mask and thereafter performing plasma etching on the second surface, corner portions located on the second surface side are removed.

Owner:PANASONIC CORP

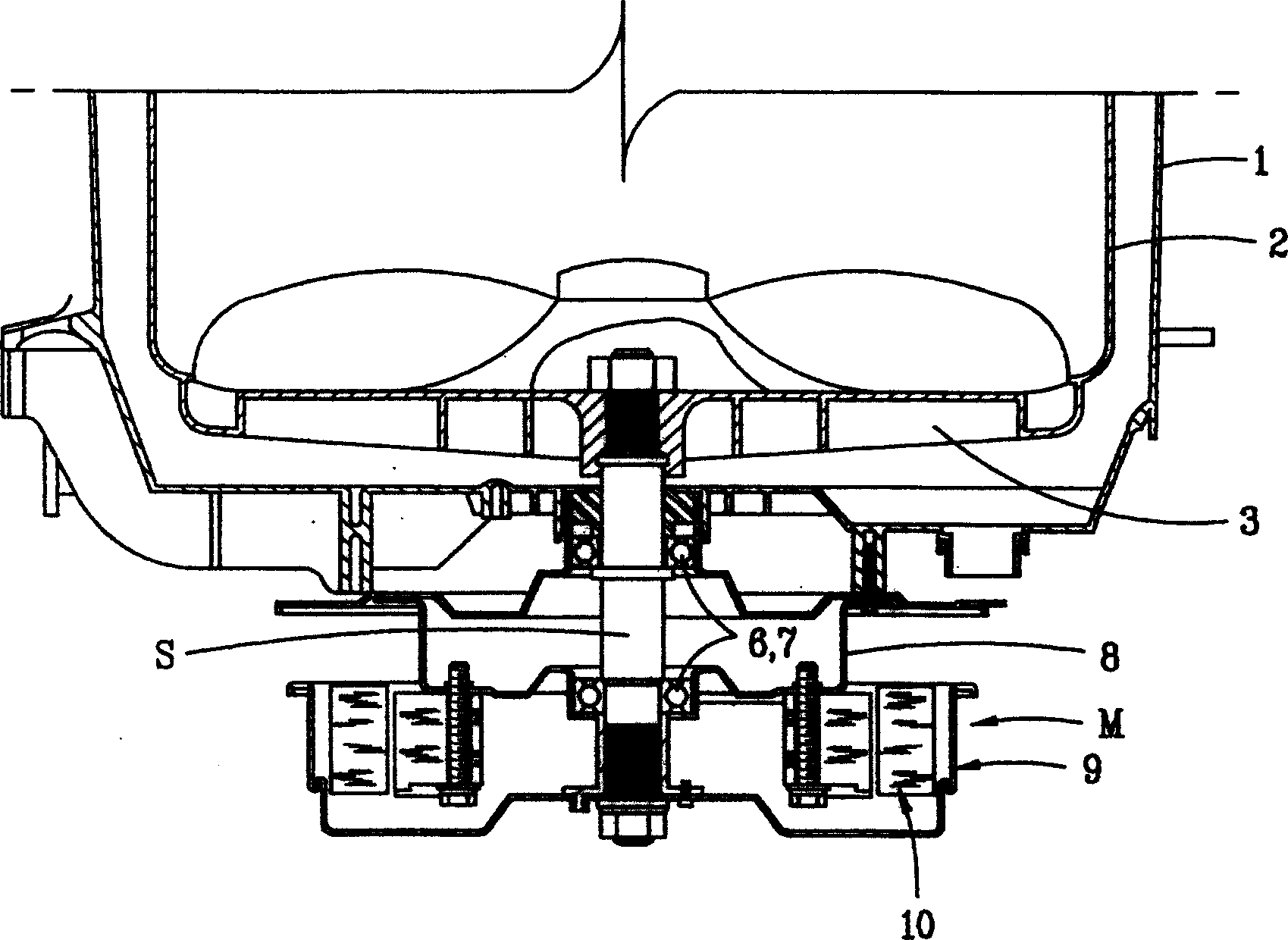

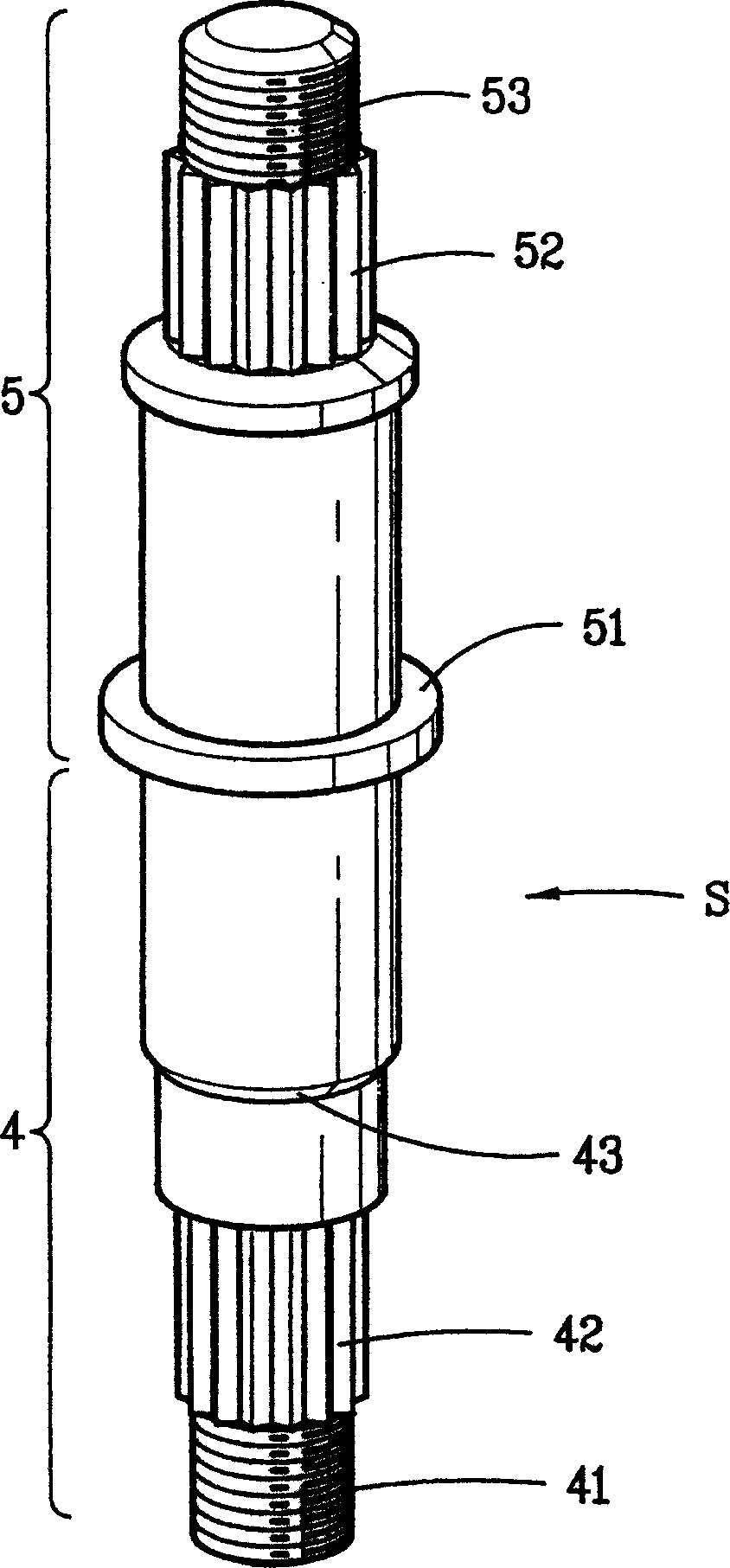

Manufacturing method of actuating shaft for washing machine

InactiveCN1565798AManufacturing Method ImprovementsHigh strengthOther washing machinesTextiles and paperHobbingDrive shaft

The invention provides a preparing method for a driving shaft of a washing machine. The preparing process is as follows: 1) cutting: cutting a stainless steel plate according to the cylinder processing request; 2) welding: welding the joint to obtain a cylinder-shape pipe structure; 3) shaping: shaping the outer surface of the cylinder-shape pipe according to the defined shape; 4) hobbing: having a hobbing process on the defined position and forming a gear; 5) grinding: grinding the tooth surface of the gear. The invention improves the driving shaft preparing method and improves the production efficiency and the strength of the driving shaft.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com