Making method for dual lead device clamp

A technology for equipment wire clips and manufacturing methods, which is applied in the manufacturing of contacts, circuit/collector parts, multi-core cable end parts, etc., can solve problems such as power interruption, manufacturing inconvenience, manufacturing troubles, etc. , The effect of saving manufacturing cost and good structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The features and advantages of the present invention are described in detail below in conjunction with the accompanying drawings:

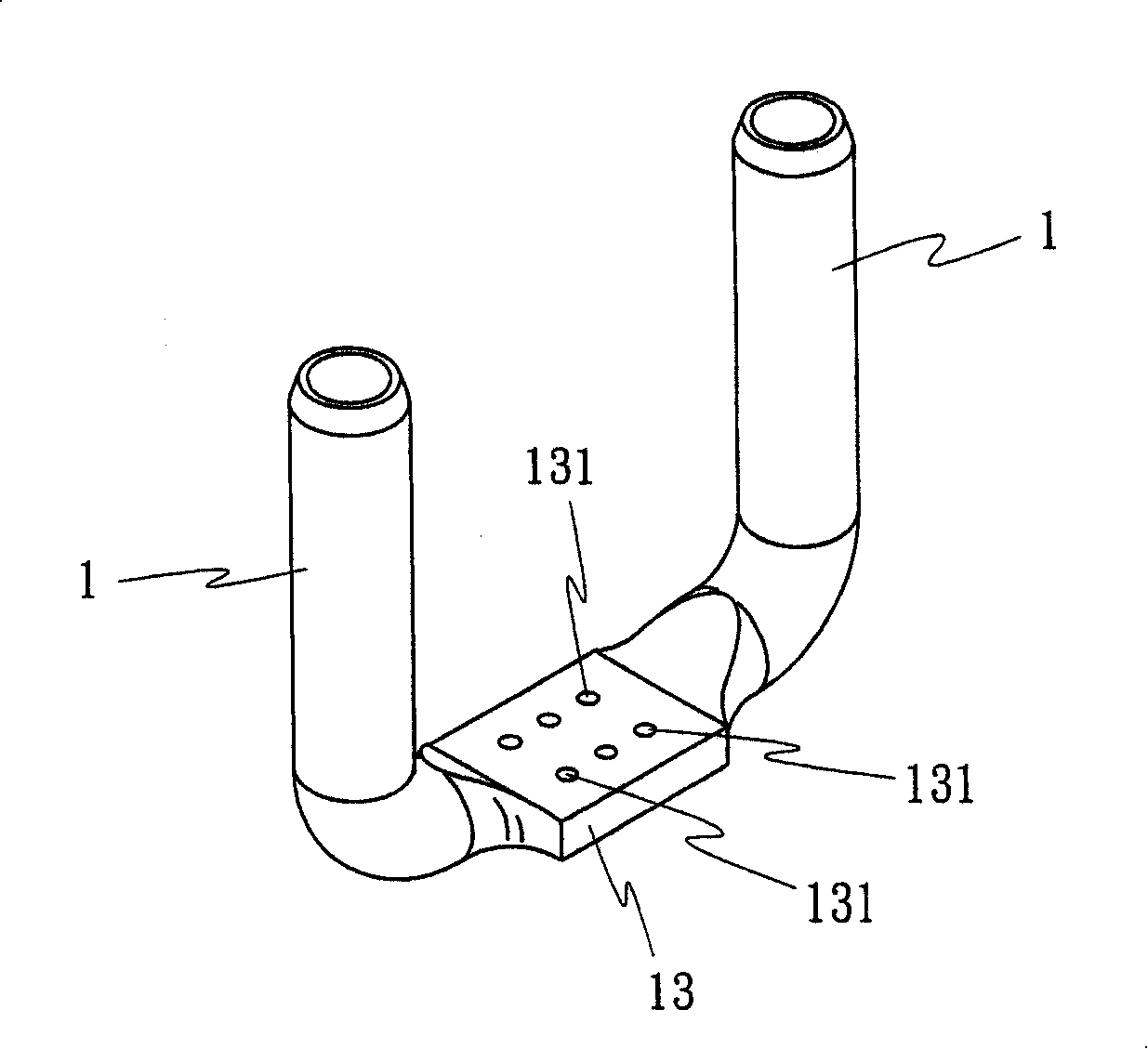

[0027] As shown in the accompanying drawings, the manufacturing method of the forged double-conductor equipment clamp provided by the present invention mainly uses two aluminum tubes 1 to pass through: bending, forging, welding, drilling and other implementation steps, so that the two aluminum tubes The tube is thus combined into an equipment clamp (eg figure 1 shown), where:

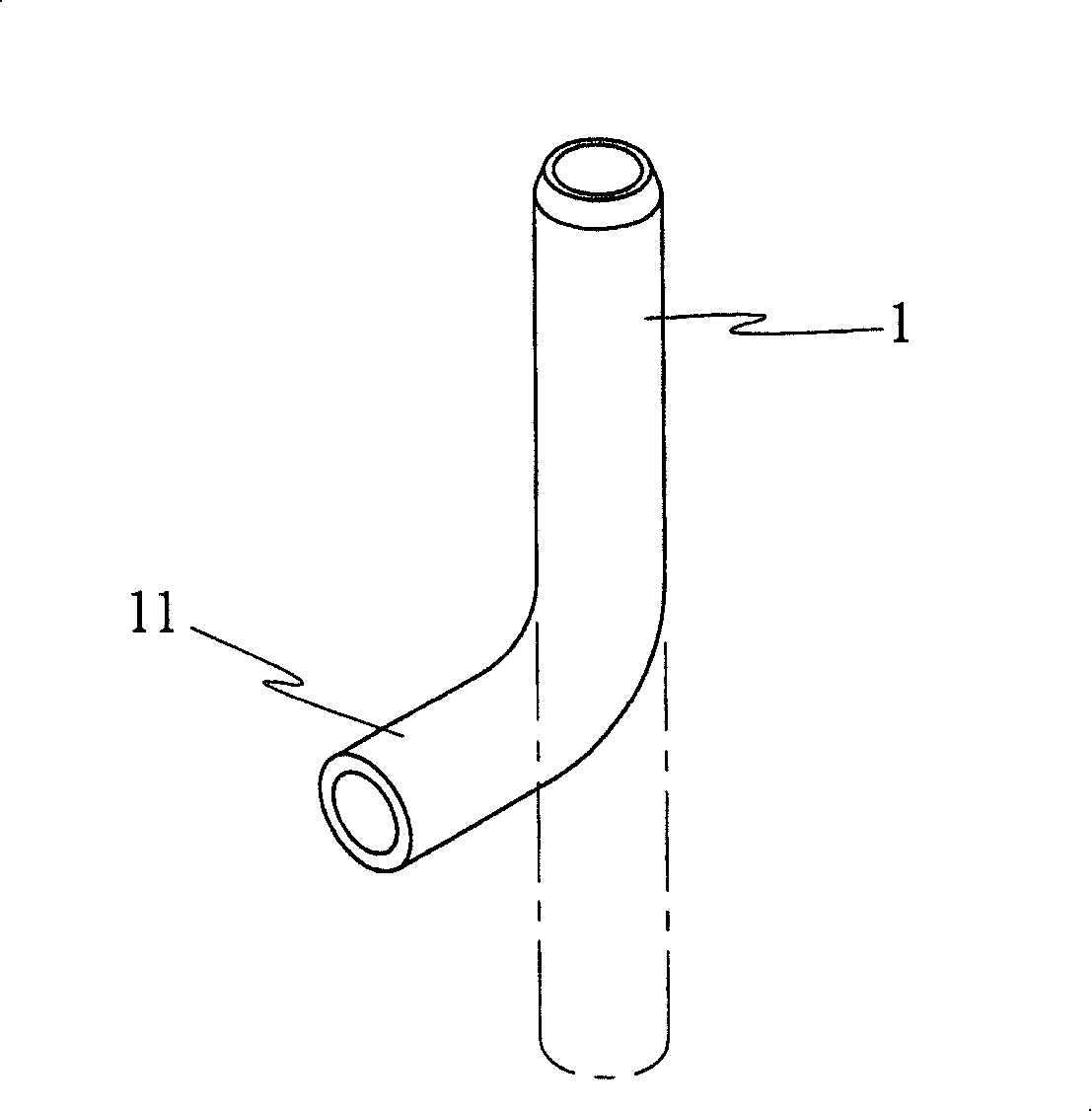

[0028] Pipe bending implementation steps: such as figure 2 As shown, the aluminum tube 1 tail 11 is processed and bent to about ninety degrees;

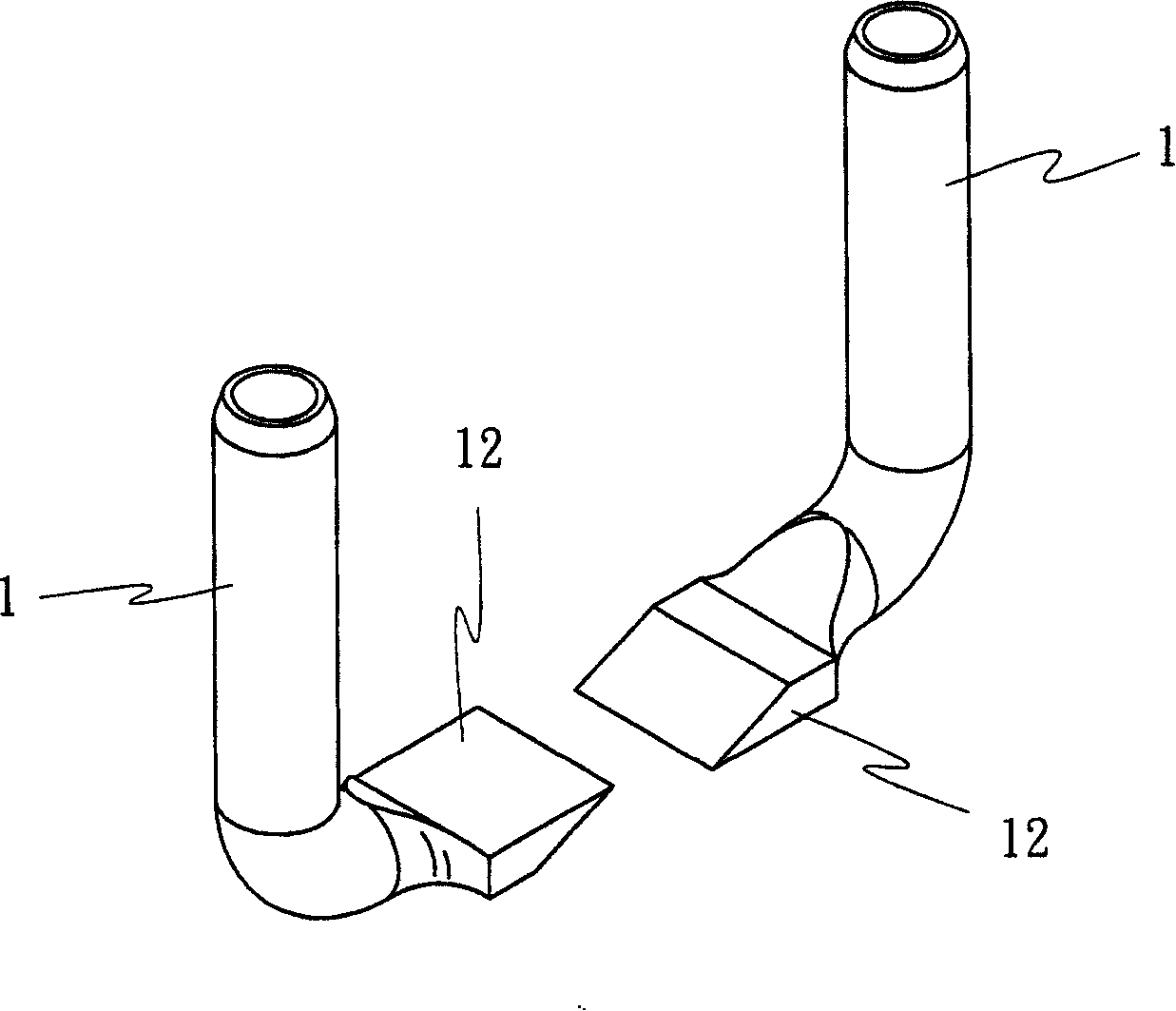

[0029] Forging implementation steps: such as image 3 As shown, the tail of the bent aluminum tube 1 is processed and forged, so that the tail 11 of the aluminum tube can form a relatively matching block-shaped part to be welded 12. During the forging process, the predetermined configuration angle of the part to be wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com