Touch panel having improved visibility and method of manufacturing the same

一种触控面板、制造方法的技术,应用在绝缘板上的电路布置、支撑结构上的电路布置、数据处理的输入/输出过程等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

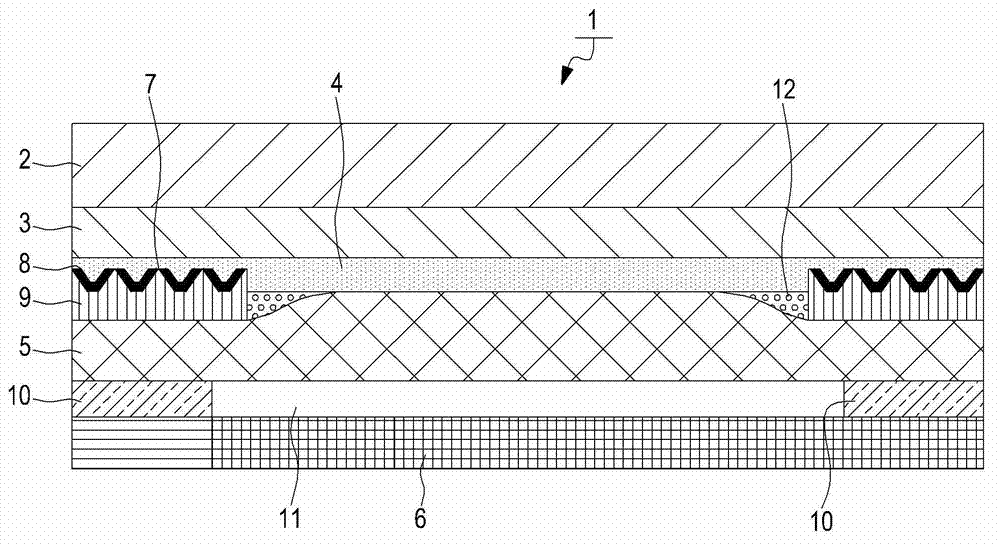

[0037] figure 2 with image 3 It is a diagram showing the composition of the touch panel provided by the present invention.

[0038] Depend on figure 2 with image 3It can be seen that the touch panel 100 includes a window unit 110 with a polymer film layer 120 , a first UV curable resin layer 130 , a second UV curable resin layer 140 , and a display unit 150 with a touch sensor film module 160 . The polymer film layer 120 is pasted on the lower side of the window unit 110 so that the first UV curable resin layer 130 described later can be pasted. The first UV curable resin layer 130 may include the second UV curable resin layer 140 and be pasted on the lower side of the polymer film layer to transmit light. The second UV curable resin layer 140 is disposed on the lower side of the first UV curable resin layer 130 to receive light passing through the first UV curable resin layer 130 and prevent refraction and reflection of the received light. . The touch sensor thin fi...

no. 2 example

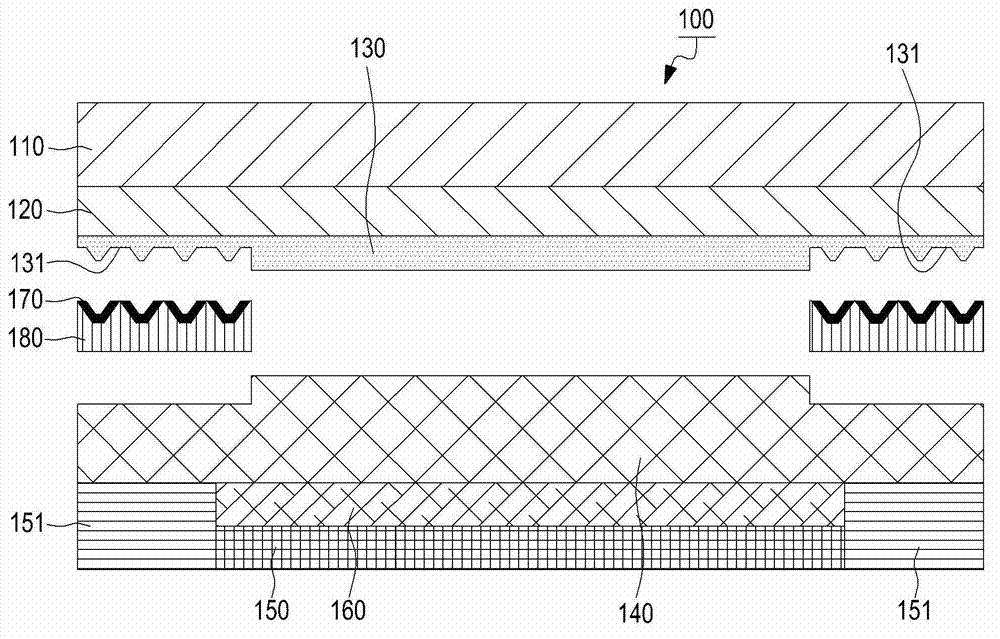

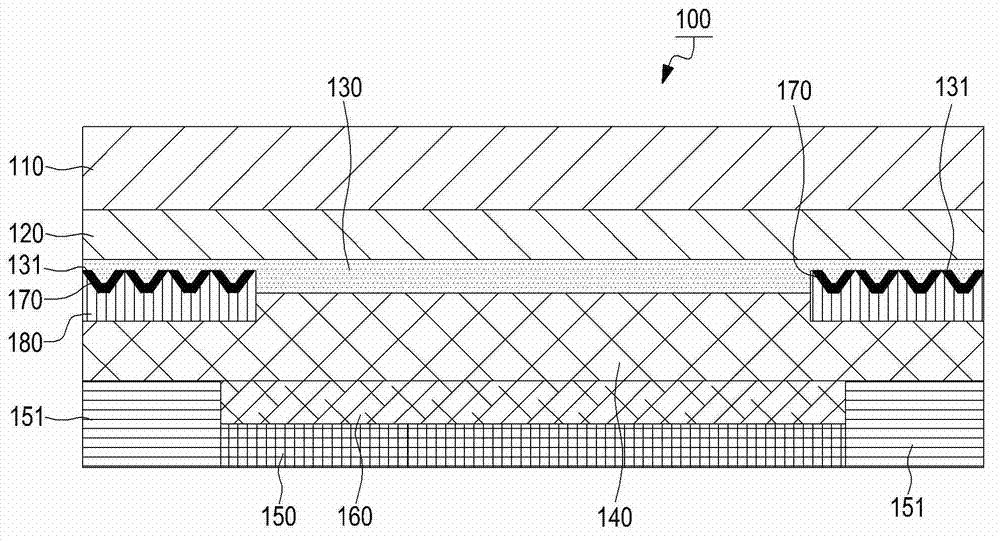

[0071] Image 6 with Figure 7 is a diagram showing the composition of a visibility-improved touch panel according to a second embodiment of the present invention.

[0072] refer to Image 6 with Figure 7 The composition of touch panel 200 for improving visibility will be described. The touch panel 200 includes a window unit 210 with a polymer film layer 220 and a display unit 250 with a first UV curable resin layer 230 , a second UV curable resin layer 240 and a touch sensor film module 260 . The polymer film layer 220 is pasted on the lower side of the window unit 210 described later so that the first UV curable resin layer 230 can be pasted. The first UV curable resin layer 230 is provided with a second UV curable resin layer 240 to be described later, and is attached to the lower side of the polymer film layer 220 in order to transmit light. The second UV curable resin layer 240 receives light passing through the first UV curable resin layer 230 , and is pasted on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com