Preparing method for converting chicken dung into refined water-solubility organic fertilizers

An organic fertilizer and water-soluble technology, applied in the preparation of organic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve problems such as excessive heavy metal content, foul odor, and unstable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

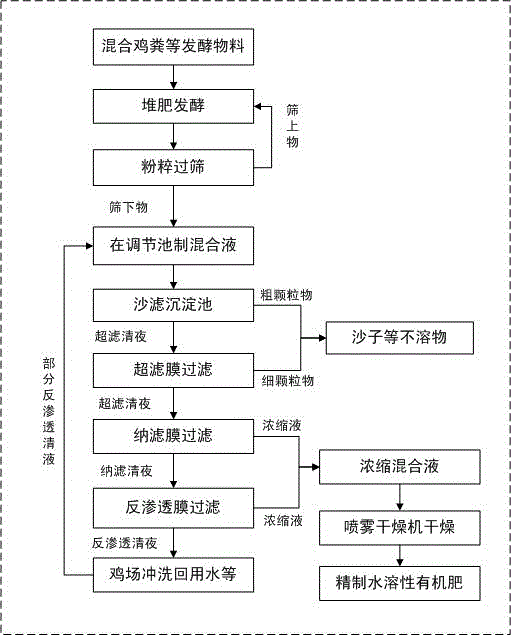

Image

Examples

Embodiment 1

[0027] The specific steps and process conditions of the preparation process of the present invention are as follows.

[0028] (1) Mixed fermentation materials. Add 900kg of chicken manure, 50kg of straw powder, 30kg of mushroom slag, 20kg of bran and 0.2kg of compound bacterial agent for organic fertilizer fermentation into the fermentation tank respectively, and mix well.

[0029] (2) Fermentation process. After the 5th day, the temperature of the pile body rose to above 55°C, and the pile began to be turned over every 3 days. Below ℃, and keep it for 10-15 days. At this time, the particles of the compost become smaller and flocculent, the texture is loose and not sticky, no special smell, the color is dark brown, and there are no mosquitoes and flies around, which conforms to the appearance of typical decomposed compost and can confirm the fermentation. Finish.

[0030] (3) Crush and sieve. The fermented organic fertilizer is air-dried until the water content reaches abo...

Embodiment 2

[0038] The specific steps and process conditions of the preparation process of the present invention are as follows.

[0039] (1) Mixed fermentation materials. Add 850kg of chicken manure, 70kg of straw powder, 20kg of mushroom dregs, 10kg of bran and 0.2kg of compound bacterial agent for organic fertilizer fermentation into the fermentation tank respectively, and mix well.

[0040](2) Fermentation process. After the 4th day, the temperature of the pile body rose to above 55°C, and the pile began to be turned over every 3 days. Below ℃, and keep it for 10-15 days. At this time, the particles of the compost become smaller and flocculent, the texture is loose and not sticky, no special smell, the color is dark brown, and there are no mosquitoes and flies around, which conforms to the appearance of typical decomposed compost and can confirm the fermentation. Finish.

[0041] (3) Crush and sieve. The fermented organic fertilizer is air-dried until the water content reaches abo...

Embodiment 3

[0049] The specific steps and process conditions of the preparation process of the present invention are as follows.

[0050] (1) Mixed fermentation materials. Add 850kg of chicken manure, 70kg of straw powder, 20kg of mushroom dregs, 10kg of bran and 0.2kg of compound bacterial agent for organic fertilizer fermentation into the fermentation tank respectively, and mix well.

[0051] (2) Fermentation process. After the 4th day, the temperature of the pile body rose to above 55°C, and the pile began to be turned over every 3 days. Below ℃, and keep it for 10-15 days. At this time, the particles of the compost become smaller and flocculent, the texture is loose and not sticky, no special smell, the color is dark brown, and there are no mosquitoes and flies around, which conforms to the appearance of typical decomposed compost and can confirm the fermentation. Finish.

[0052] (3) Crush and sieve. The fermented organic fertilizer is air-dried until the water content reaches ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com