Anti-seismic prefabricated board for building and manufacturing method thereof

A manufacturing method and technology for prefabricated panels, which are applied in building structures, buildings, building materials, etc., can solve the problems of affecting the strength of spliced floor slabs, prone to fracture at joints, and low strength at joints, and improve the overall seismic resistance. , the overall strength is improved, the effect of high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

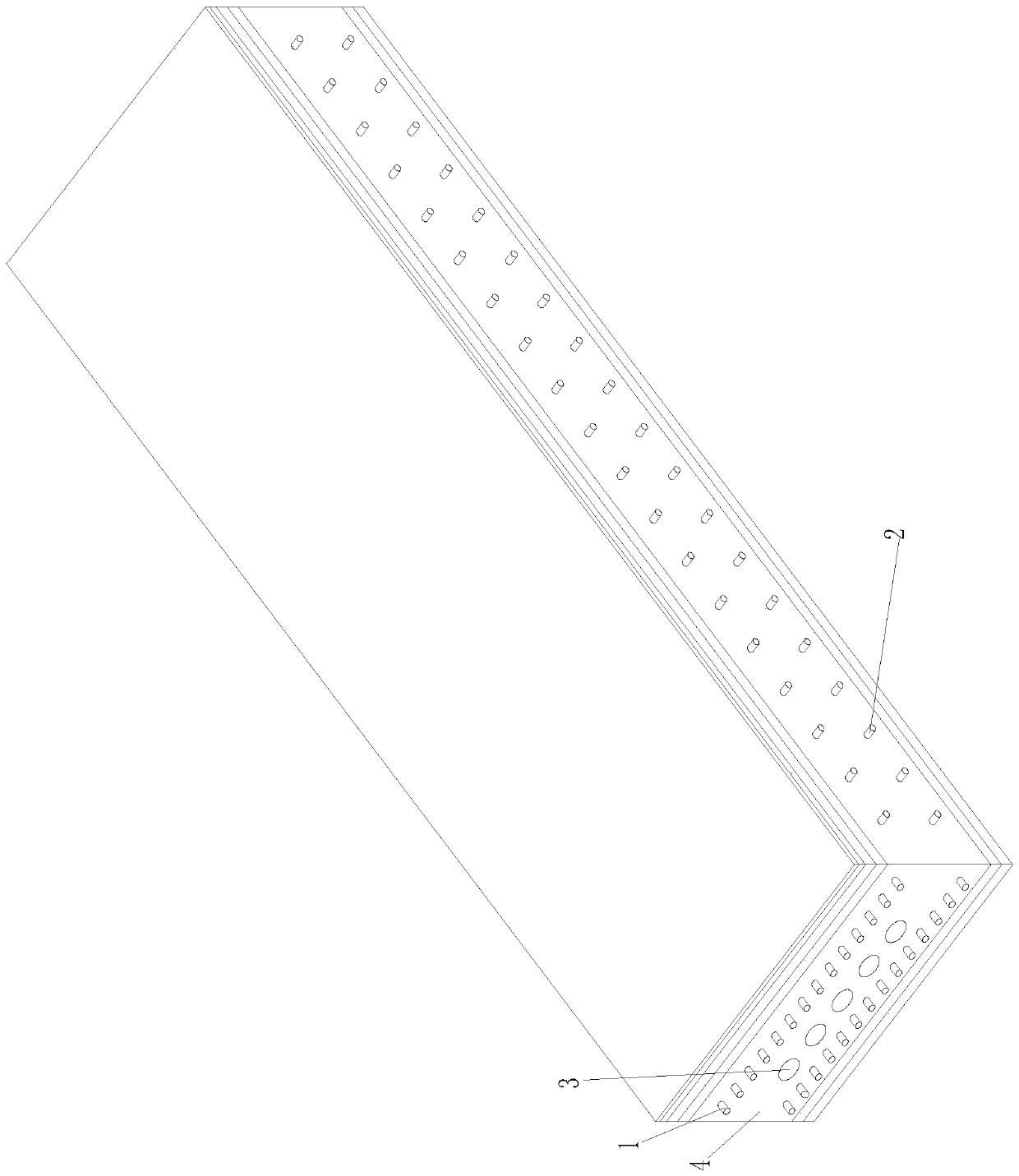

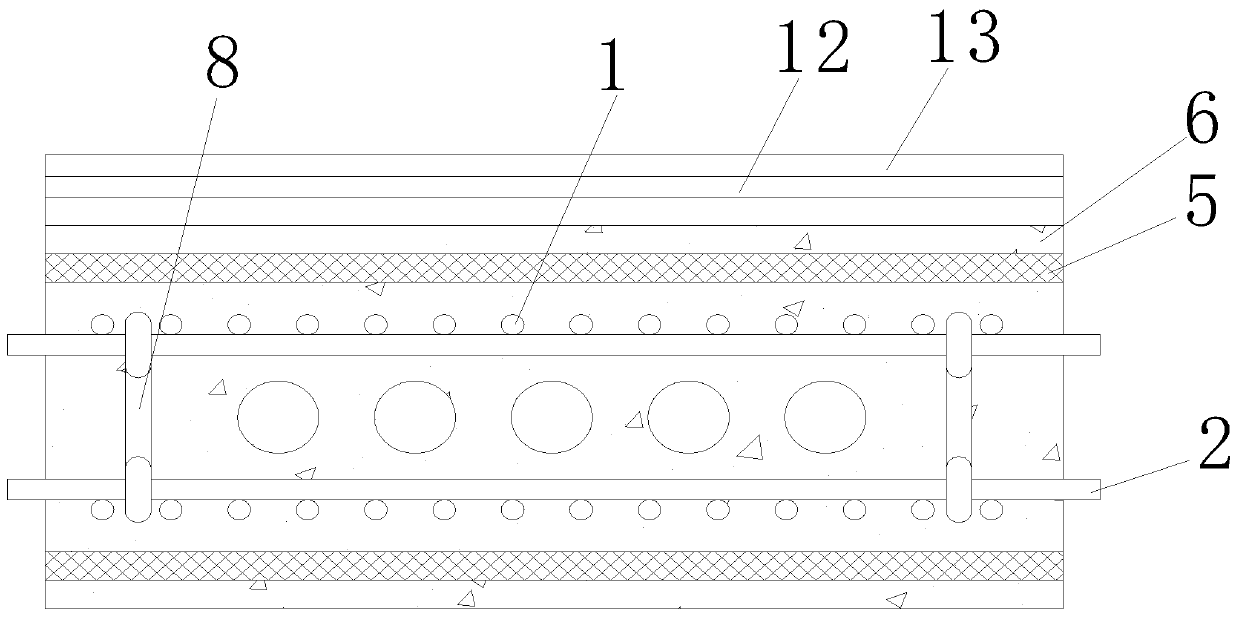

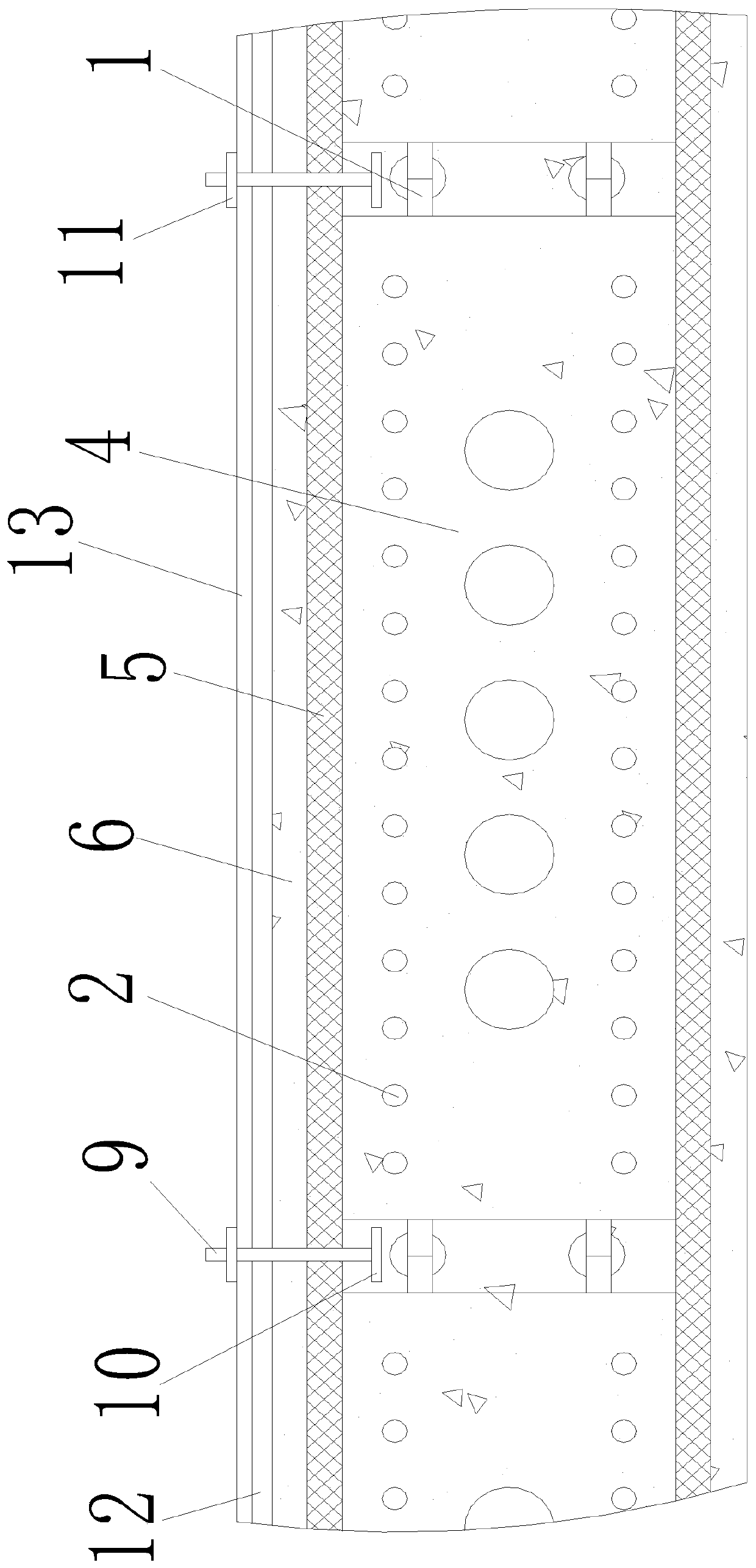

[0038] Such as Figure 1-Figure 3 As shown, the present invention is a kind of anti-seismic prefabricated slab for building, comprising pouring slab body 4, covering layer attached to the surface of pouring slab body 4, and internal frame arranged in pouring slab body 4; The internal frame includes two layers Relatively arranged steel bar frame, the steel bar frame includes a number of longitudinal steel bar 1 arranged in parallel and a number of horizontal steel bar 2 arranged in parallel at intervals, the longitudinal steel bar 1 is arranged along the length extension direction of the pouring plate body 4, and the horizontal steel bar 2 and the longitudinal steel bar 1 is vertically arranged, the two ends of the horizontal steel bar 2 respectively protrude from the surface of both sides of the pouring plate body 4, and the two ends of the longitudinal steel bar 1 respectively protrude from the two ends of the pouring plate body 4; the middle part of the pouring plate body 4 ...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that: the transverse reinforcement rod 2 is arc-shaped, the arc-shaped openings of the transverse reinforcement rod 2 of the two-layer reinforcement frame are oppositely arranged, and the arc of the transverse reinforcement rod 2 is 3.05.

[0067] The concrete is made of the following raw materials in parts by weight: 350 parts by weight of cement, 103 parts by weight of water, 800 parts by weight of recycled concrete aggregate, 1.5 parts by weight of modified starch, 0.4 parts by weight of sugar retarder, and the amount of nylon fiber by weight It is 1 / 150 of the weight of concrete dosage.

Embodiment 3

[0069] The transverse reinforcing bar 2 is arc-shaped, and the arc-shaped openings of the transverse reinforcing bar 2 of the two-layer steel frame are oppositely arranged, and the arc of the transverse reinforcing bar 2 is 3.05.

[0070] The concrete is made of the following raw materials in parts by weight: 335 parts by weight of cement, 103 parts by weight of water, 763 parts by weight of recycled concrete aggregate, 1 part by weight of modified starch, and 0.33 parts by weight of sugar retarder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com