Precast assembled pile foundation pier and construction method thereof

A prefabricated assembly and pile foundation technology, which is applied in infrastructure engineering, erection/assembly of bridges, bridges, etc., can solve the problems that do not involve the connection method of prefabricated caps and prefabricated pile foundations, so as to reduce adverse effects and speed up the construction process. , The effect of reducing construction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

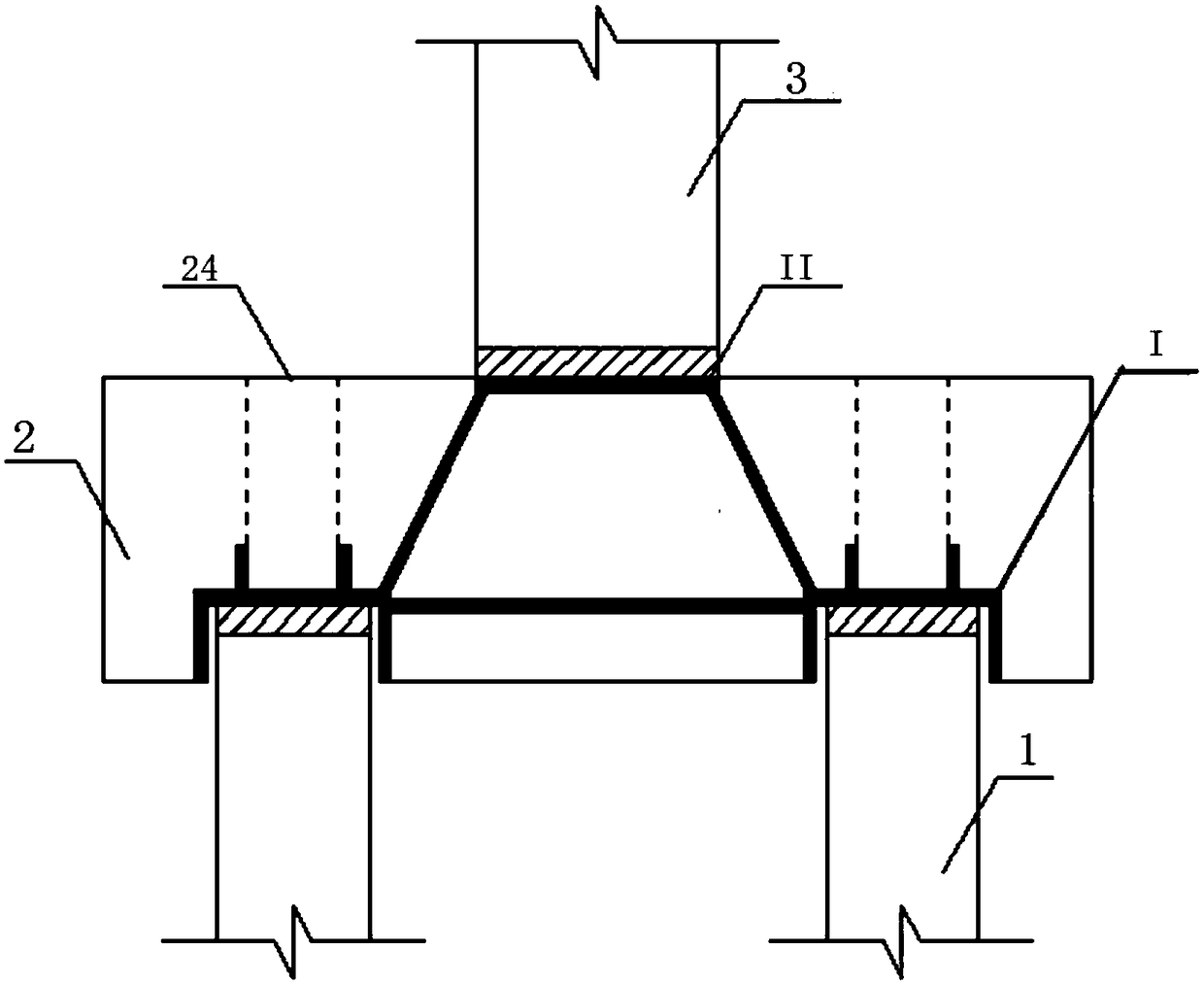

[0040] A prefabricated assembled pile foundation pier, such as Figure 1~6 As shown, it includes prefabricated pile 1, prefabricated cap 2 and prefabricated pier column 3, and the pier of the pile foundation passes through the first connection structure I for connecting prefabricated pile 1 and prefabricated cap 2 and is used for connecting prefabricated pier column 3 and prefabricated pier column 3 and prefabricated pier column 3. The second connection structure II of the platform 2 is connected as a whole:

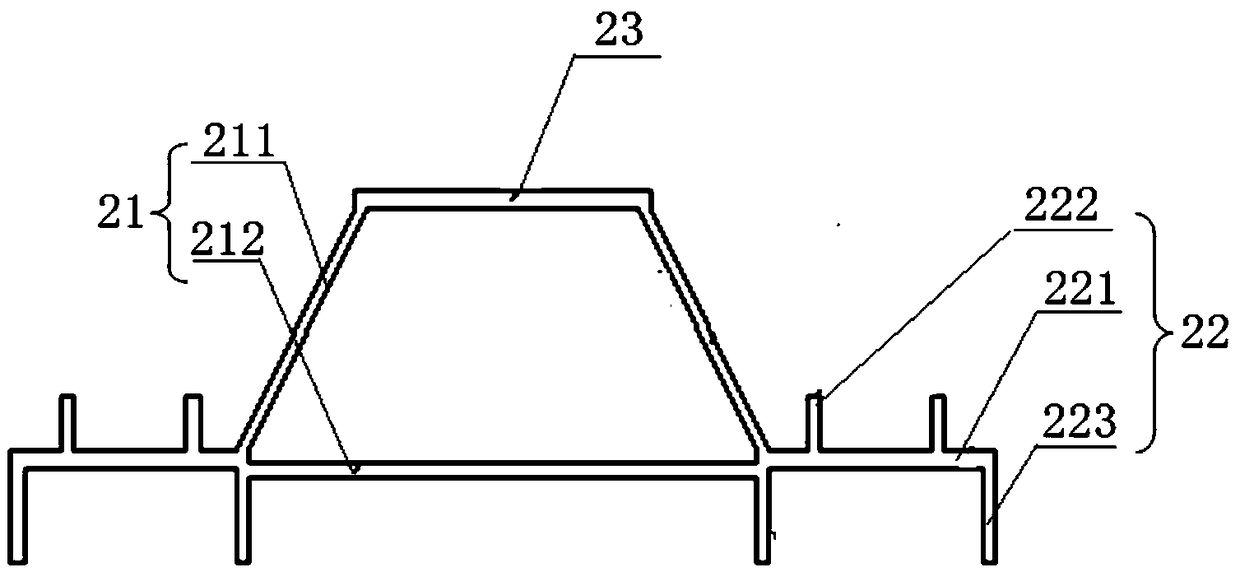

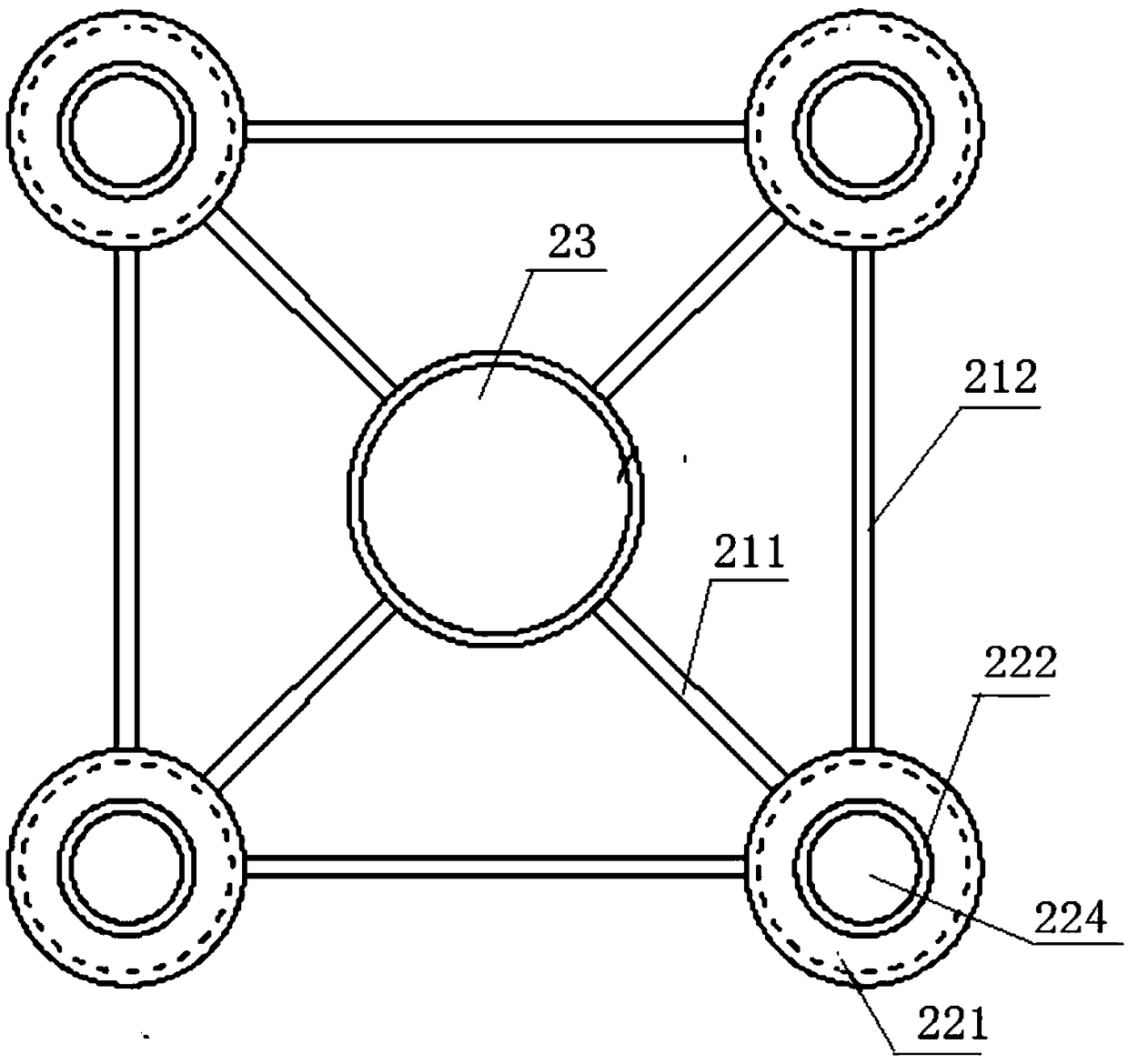

[0041] The prefabricated cap 2 has a pre-embedded steel frame, the pre-embedded steel frame is composed of a top connector 23 and a bottom connector 22 connected by section steel 21, and the prefabricated cap 2 is provided with a reserved channel 24 at the bottom connector 22;

[0042] The first connection structure I includes the embedded part 4 at the bottom of the cap, the embedded part 5 at the pile head, and the fastener 6. Rebar planting 43, the pile head embedded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com