Structure joint of novel reinforced concrete column-steel beam combined framework

A technology of concrete column and frame structure, applied in the direction of building structure, construction, etc., can solve the problems that the joint stiffness is difficult to meet the requirements of rigid joints, pressure damage, complicated construction operations, etc., to achieve convenient replacement and reuse, stiffness and bearing capacity. The effect of superior pressure and reduced welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

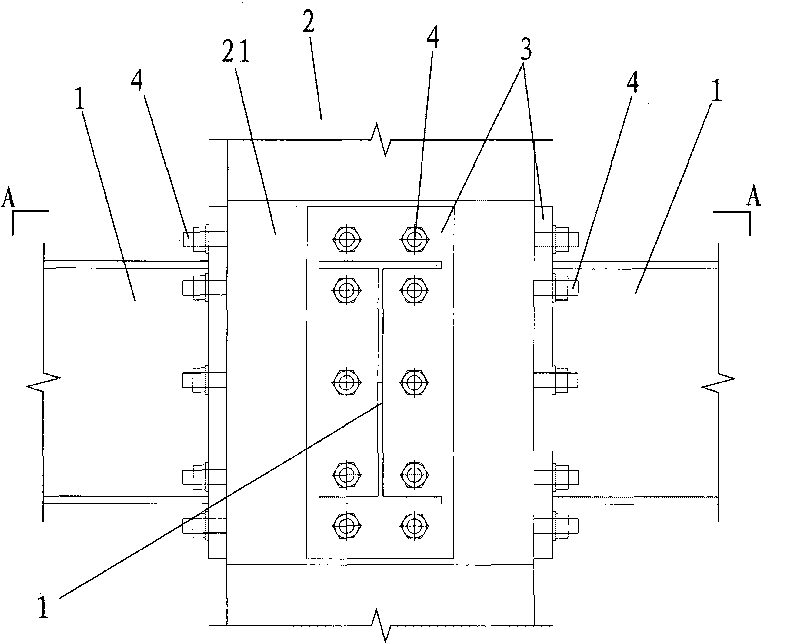

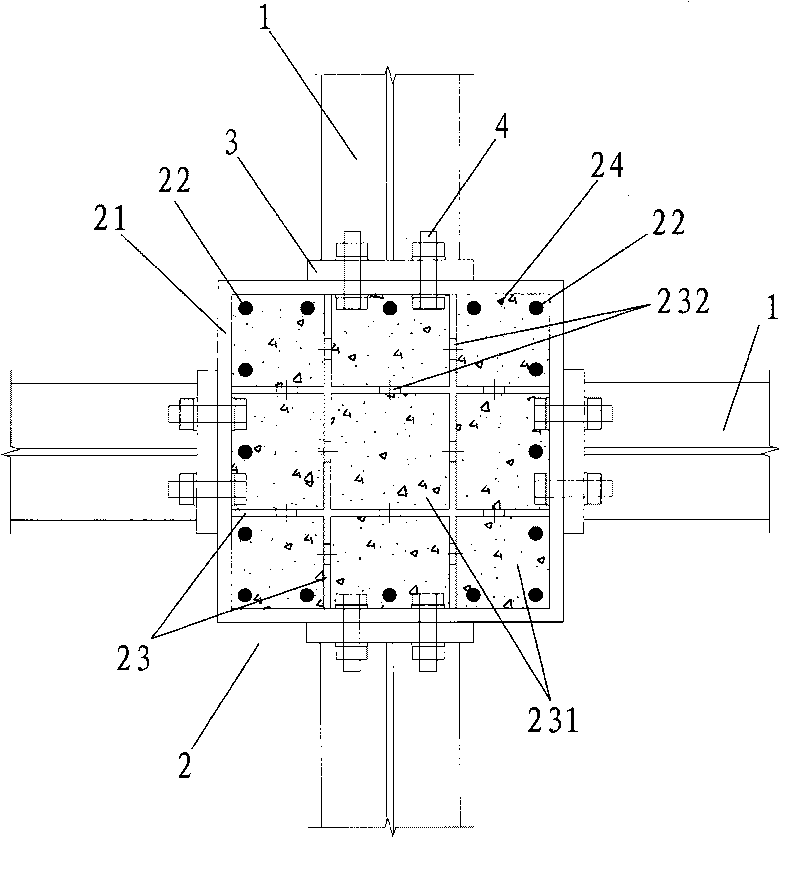

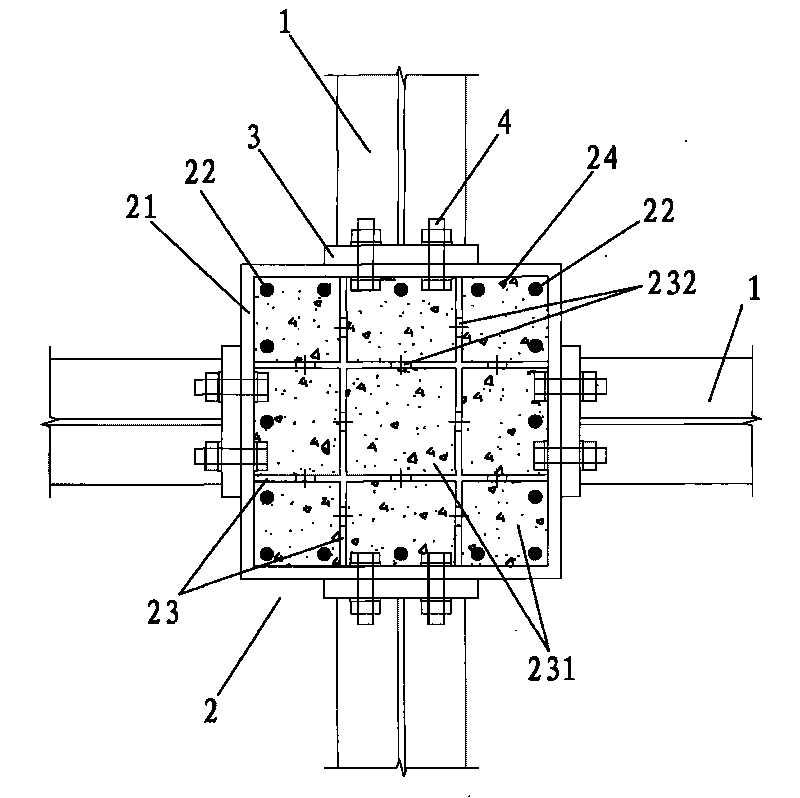

[0011] The concrete column-steel beam composite structure frame node of the present invention, such as figure 1 , 2 As shown, it includes steel beams 1, concrete columns 2, connecting end plates 3 and high-strength connecting bolts 4, and the concrete columns 2 include square steel plate barrels 21, longitudinal steel bars 22 and a plurality of stiffening steel plates 23, and each stiffening steel plate 23 is arranged in a criss-cross pattern. In the square steel barrel 21, the cross-sectional direction of the square steel barrel 21 is divided into a plurality of compartments 231, and each stiffening steel plate 23 and the square steel barrel 21 are welded into a whole, and the longitudinal steel bars 22 pass through each compartment 231 respectively. And each compartment 231 is respectively poured with concrete; the square steel drum 21 is provided with corresponding bolt holes on the surrounding walls and the connecting end plate 3 respectively, and one end of the steel beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com