Ribbed FRP (fiber reinforced plastic) component and concrete composite bridge deck

A concrete surface and concrete technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of restricting popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

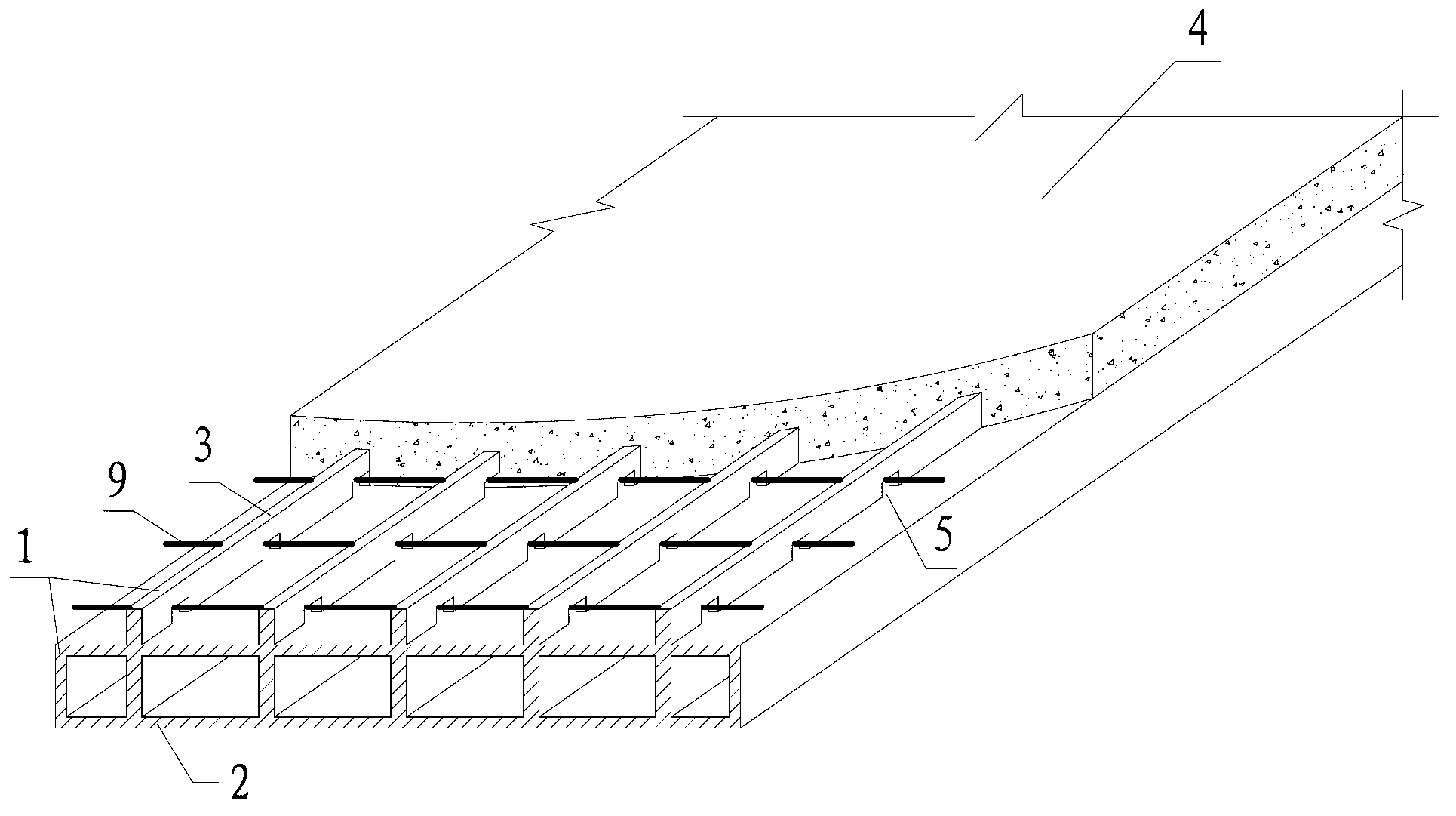

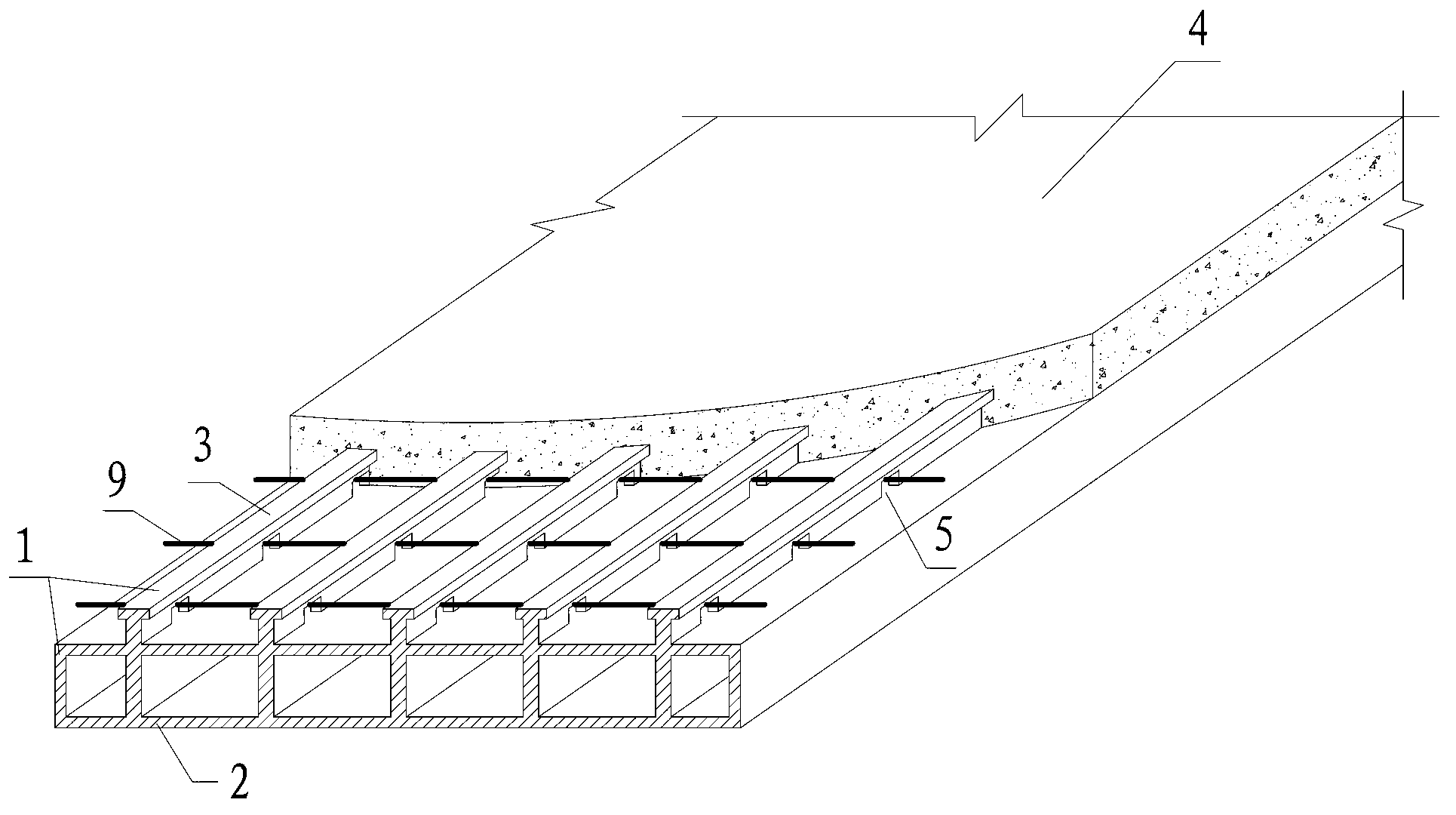

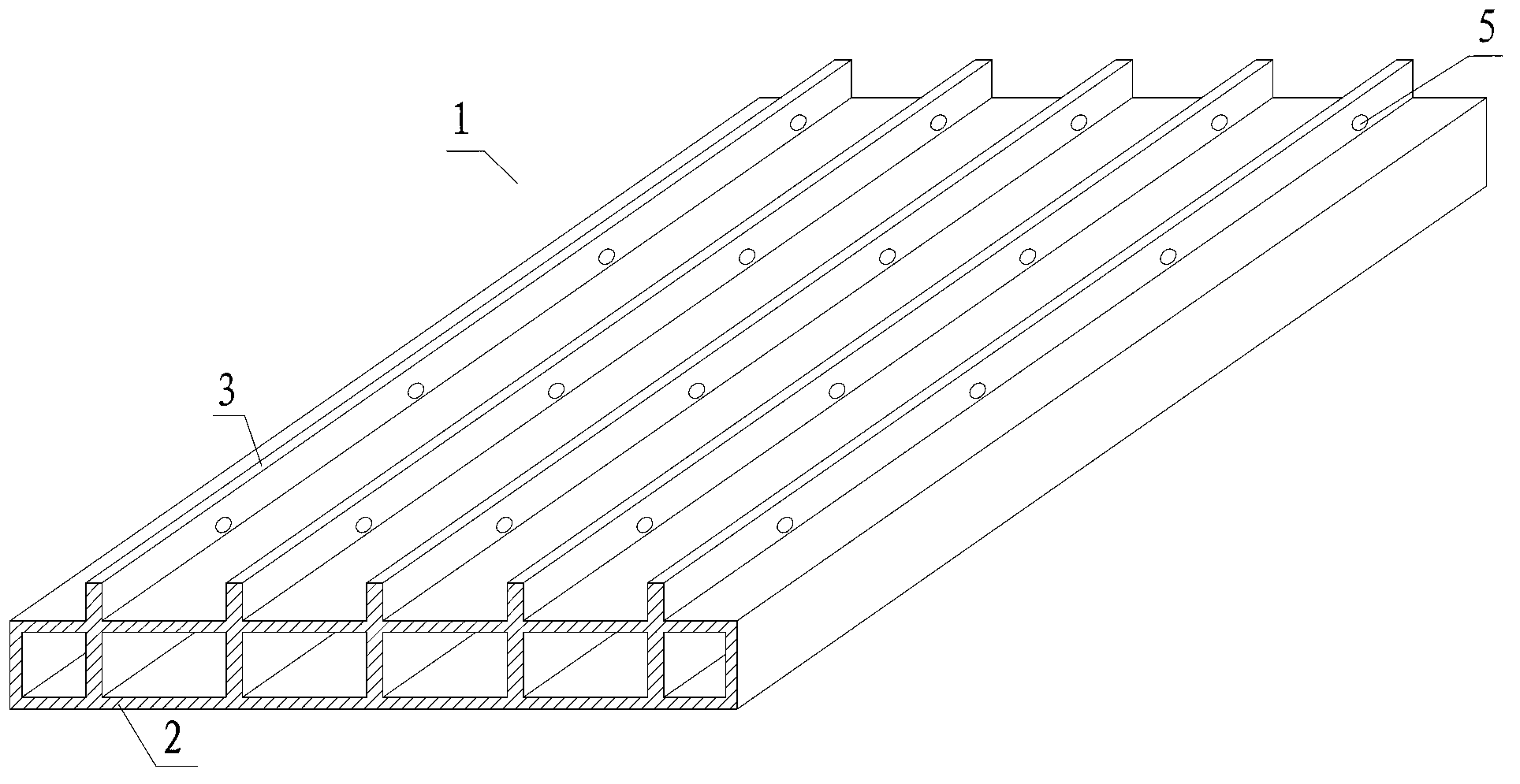

[0026] The invention is attached Figure 1-42 shown.

[0027] refer to Figure 1-33 , the ribbed FRP member and concrete composite bridge deck includes a ribbed FRP member 1 and a post-cast concrete surface layer 4. The ribbed FRP member 1 is divided into two parts: the lower FRP bottom plate 2 and the upper FRP longitudinal slab rib 3. The FRP At least one of the bottom plate 2 and the FRP longitudinal rib 3 is in the form of a hollow section, and the FRP longitudinal rib 2 is provided with a transverse through hole 5 .

[0028] Among them, the cross-sectional shape of the FRP longitudinal plate rib 3 can be rectangular or T-shaped, etc. figure 1 The shape of the middle FRP longitudinal plate rib 3 is a rectangle, figure 2 The shape of the middle FRP longitudinal rib 3 is T-shaped. The rectangular FRP longitudinal rib 3 makes the cross-section of the bottom plate an inverted T shape. Effective; the FRP longitudinal slab rib 3 can be used as a shear key, and the existence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com