Highway subgrade maintenance pavement crack pouring method

A technology for pavement cracks and filling joints, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of empty cracks on the road surface, insufficient durability, poor repair and maintenance effects, etc., to avoid internal emptiness, good durability, and improve filling joints effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the technical solution of the present invention will be described in detail below. Those skilled in the art should know that what are described in the following embodiments are only some specific implementation structures or modes of the present invention, rather than all embodiments, and therefore, the protection scope of the present invention is not limited thereto.

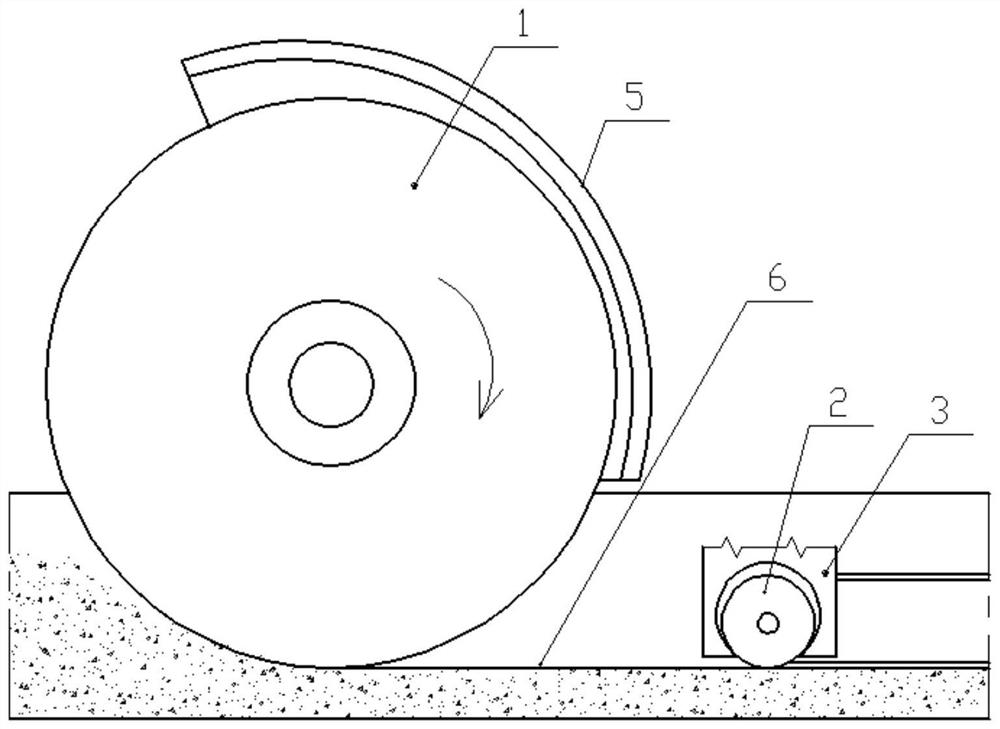

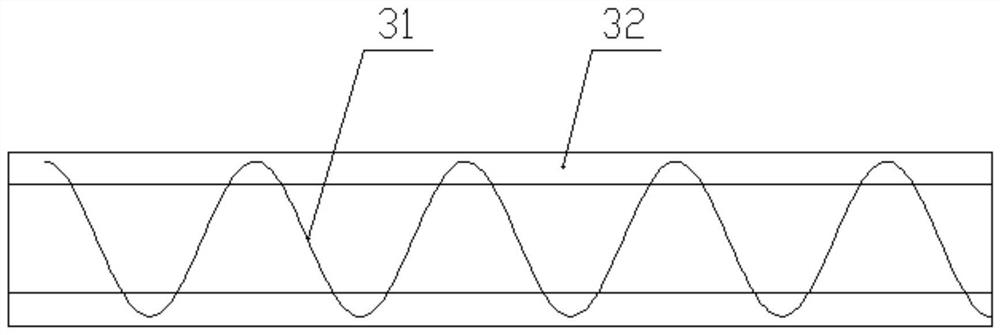

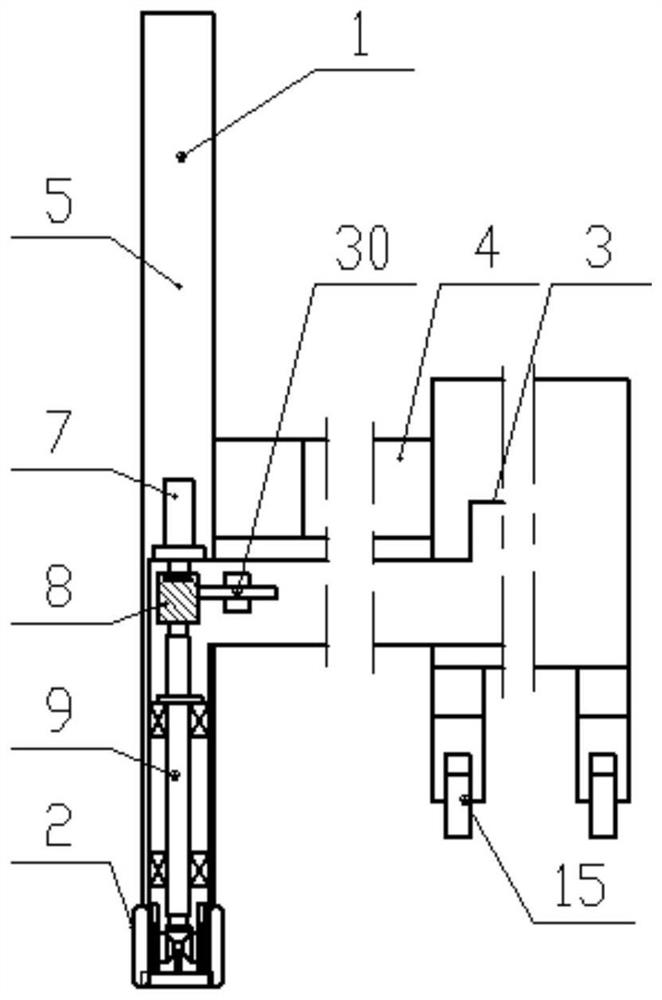

[0027] see Figure 1-6 As shown, the present embodiment discloses a method for filling cracks in the roadbed maintenance pavement. S1. Carry out manual cutting in advance at the initial end of the crack in the road surface to obtain a rectangular slot with a predetermined width. The width of the rectangular slot is the average of the actual width of the crack. 1.25-2 times of the value, the length of the rectangular slot must be such that the slotting mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com