Carbon fiber composite material product and manufacturing method thereof

A composite material and carbon fiber technology, which is applied in ceramic products, fiber processing, textiles and papermaking, can solve the problems of cumbersome and time-consuming manufacturing methods, low production efficiency and difficult processing, and achieve low cost, high production efficiency and easy processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] A preferred embodiment of the present invention will be described in detail below by taking the case of a mobile phone as an example.

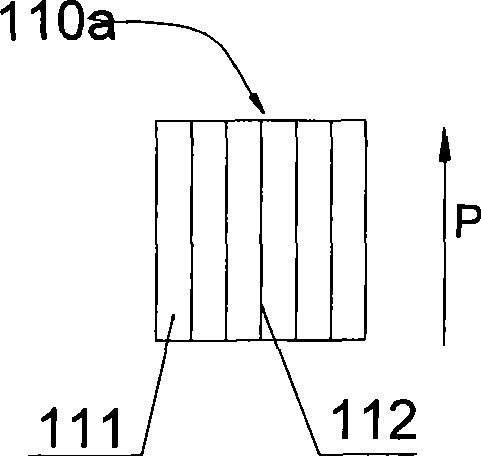

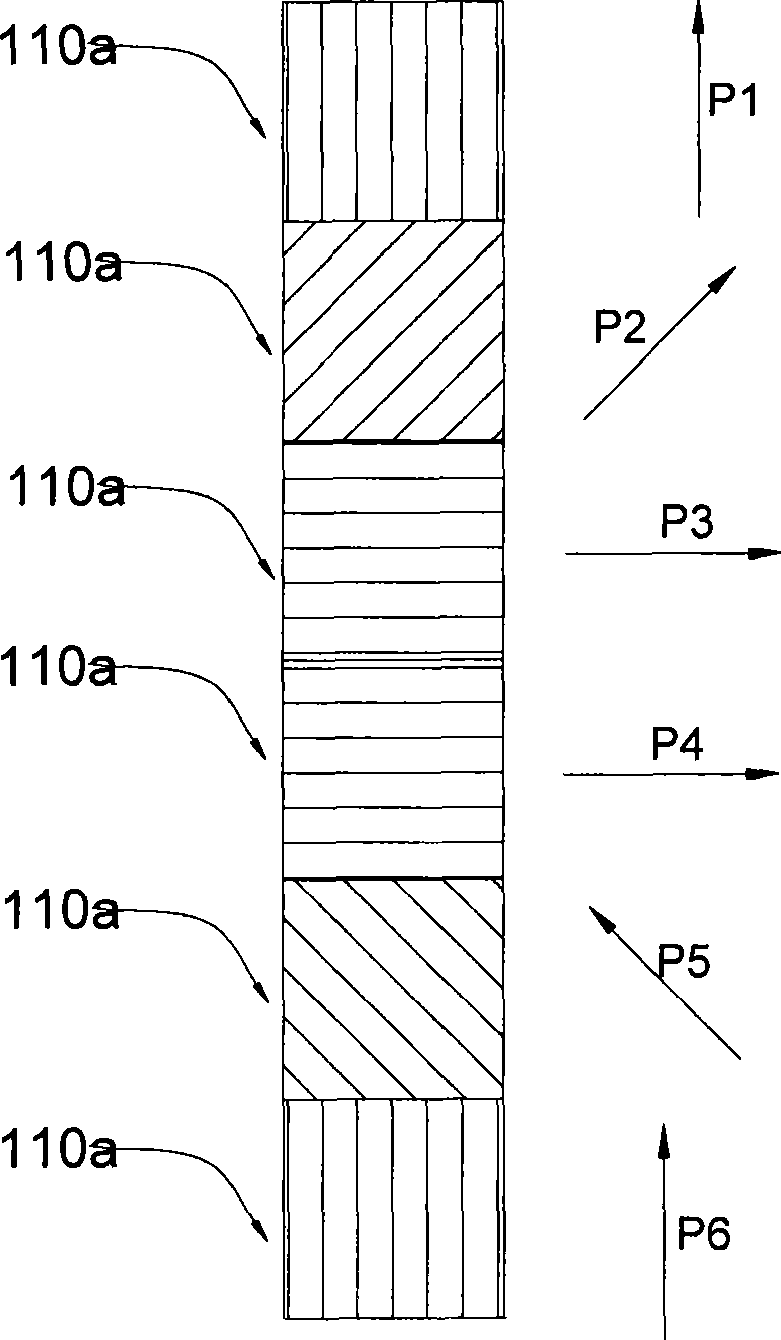

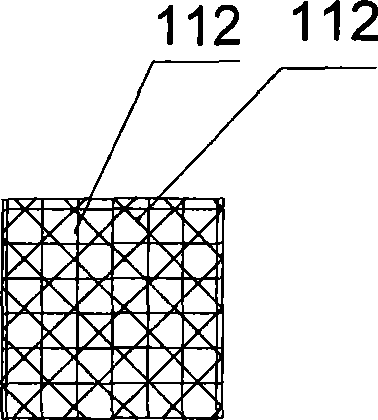

[0038] like Figure 8 As shown, the mobile phone case mainly includes a mobile phone case main body 1 and a buckle 2, and the buckle 2 is mainly used to fix the mobile phone case to the mobile phone main body. Figure 9 The front schematic diagram of the mobile phone case is illustrated. In this figure, the buckle 2 is not shown. From this figure, it can be seen that the surface of the main body 1 of the mobile phone case has a carbon fiber visual effect. Figure 10 Yes Figure 8 The schematic cross-sectional view of the mobile phone shell shown in the figure, as can be seen from the figure, the mobile phone shell includes a cell phone shell blank 11, a paint layer 12 formed on the outer surface of the mobile phone shell blank 11 and a buckle (not shown in the figure). shown), wherein the structural member 13 can also include an adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com