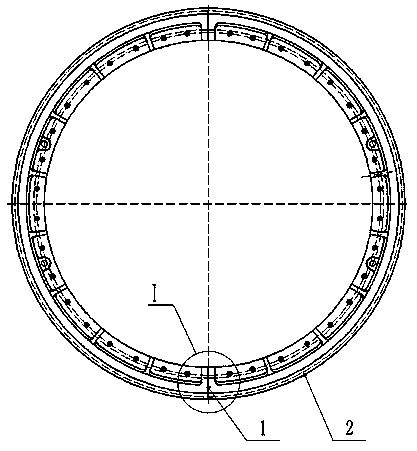

Manufacturing method of big-modulus cast steel large gear ring

A manufacturing method and technology for a large ring gear, which are applied in the field of machining, can solve the problems of large processing volume of blanks and tooth profiles, difficulty in controlling the deformation of the large ring gear, and high manufacturing costs, so as to improve the processing efficiency of the tooth profile, reduce the manufacturing cost, Manufacture method convenient and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of modulus of the present invention is 40mm, and the manufacturing method of the cast steel girth gear that diameter is 5440mm, specifically comprises the following steps:

[0035] Step 1: Use the CAPP system to compile the blank manufacturing process, and through the conventional "modeling→smelting→pouring→cleaning→checking the blank→heat treatment" process to produce a qualified semi-gear blank with casting reinforcement; in order to compensate for the shrinkage of the casting, To prevent shrinkage cavities and porosity defects in castings, set 6 common risers with a size of 450×540×700mm during molding;

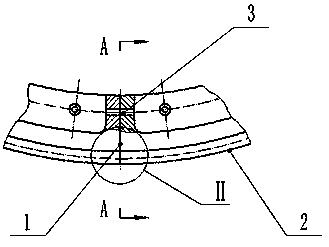

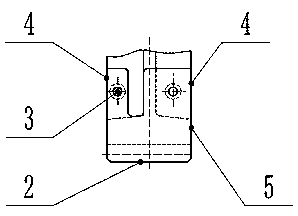

[0036] Step 2: Machining the joint surface and the joint hole of the large gear ring on the floor boring machine, the joint surface is left 50mm, the joint hole is left 30mm, and the large gear ring is closed by the reaming hole bolt;

[0037] Step 3: Align the center of the large ring gear and the rotary table on the floor boring machine, use a disc milling ...

Embodiment 2

[0050] A kind of modulus of the present invention is 32mm, and the manufacturing method of the cast steel girth gear that diameter is 4736mm, specifically comprises the following steps:

[0051] Step 1: Use the CAPP system to compile the blank manufacturing process, and produce qualified casting blanks through the conventional "modeling → smelting → pouring → cleaning → inspection blank → heat treatment" process to produce qualified casting semi-gear blanks with casting bars ;In order to compensate the shrinkage of the casting and prevent the casting from shrinkage cavity and shrinkage defects, 6 common risers with a size of 300×450×500mm are set up during molding;

[0052] Step 2: Machining the joint surface and the joint hole of the large gear ring on the floor boring machine, the joint surface is left 40mm, the joint hole is 14mm, and the large gear ring is closed by the reaming hole bolt;

[0053] Step 3: The operation is the same as that in Example 1, and the amount of th...

Embodiment 3

[0063] A kind of modulus of the present invention is 22mm, and the manufacturing method of the cast steel girth gear of 4620mm in diameter specifically comprises the following steps:

[0064] Step 1: Use the CAPP system to compile the blank manufacturing process, and through the conventional "modeling→smelting→pouring→cleaning→checking the blank→heat treatment" process to produce a qualified semi-gear blank with casting reinforcement; in order to compensate for the shrinkage of the casting, To prevent shrinkage cavities and porosity defects in castings, set 5 thermal insulation and heating risers with a size of 450×540×650mm during molding;

[0065] Step 2: Machining the joint surface and the joint hole of the large gear ring on the floor boring machine, the joint surface is left to be 30mm, the joint hole is left to be 20mm, and the large gear ring is closed by the reaming hole bolt;

[0066] Step 3: The operation is the same as that in Example 1, and the amount of the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com