Method for manufacturing ic card by laminating a plurality of foils

A manufacturing method and foil technology, which is applied in the field of IC card manufacturing, can solve problems such as COB falling off, insufficient electrical connection between the antenna connecting part and the COB electrode, and electrical connection interruption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

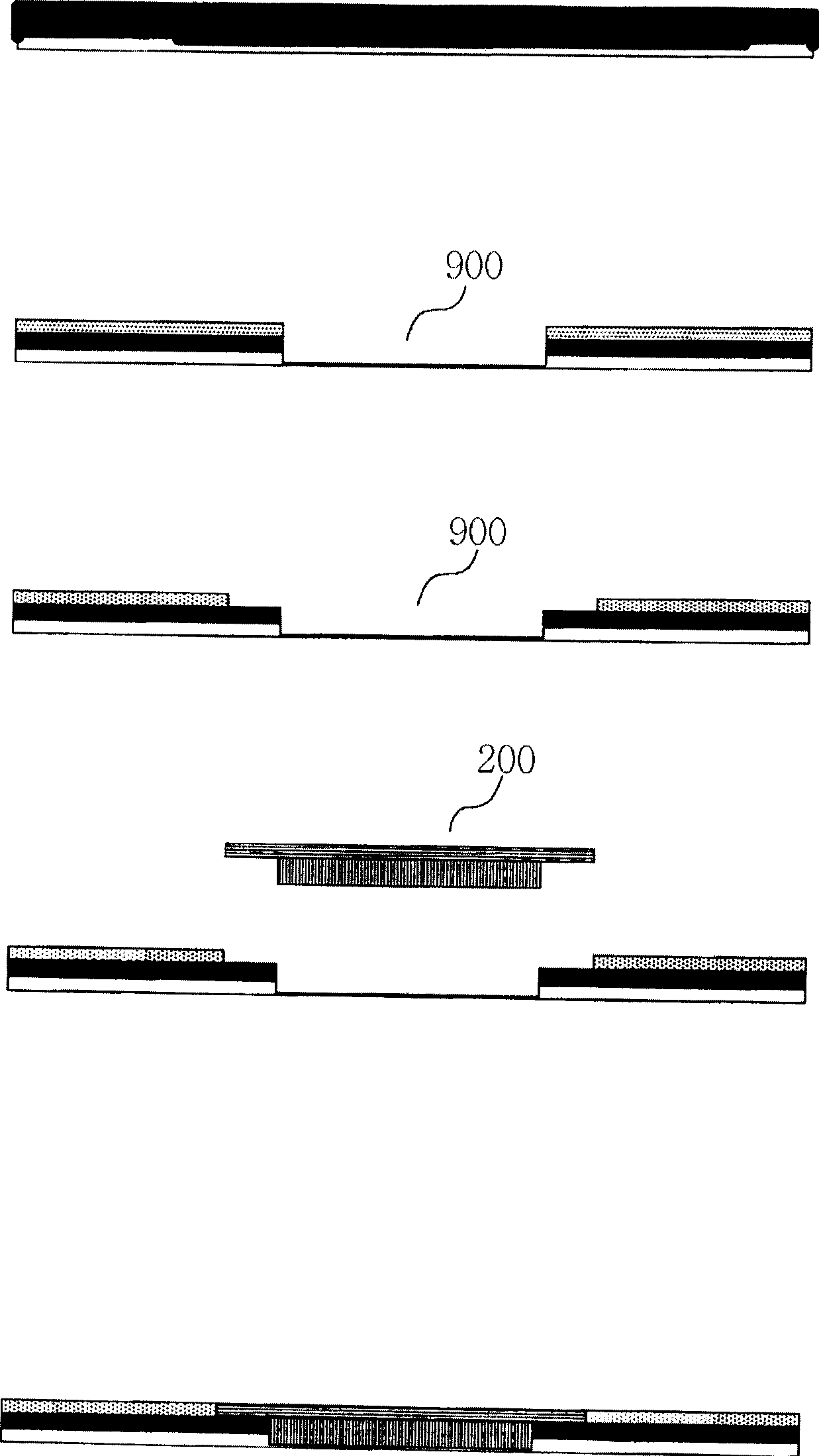

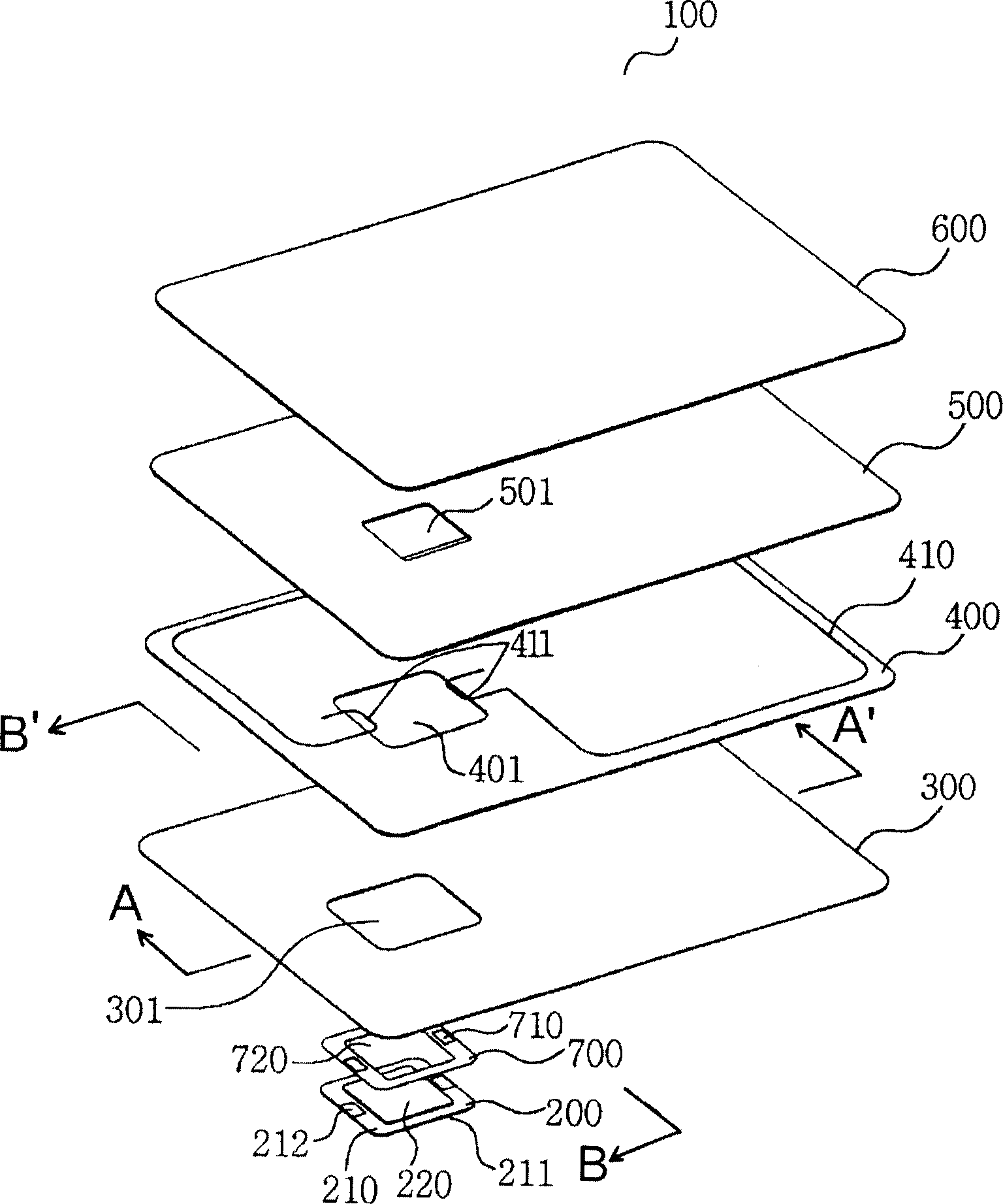

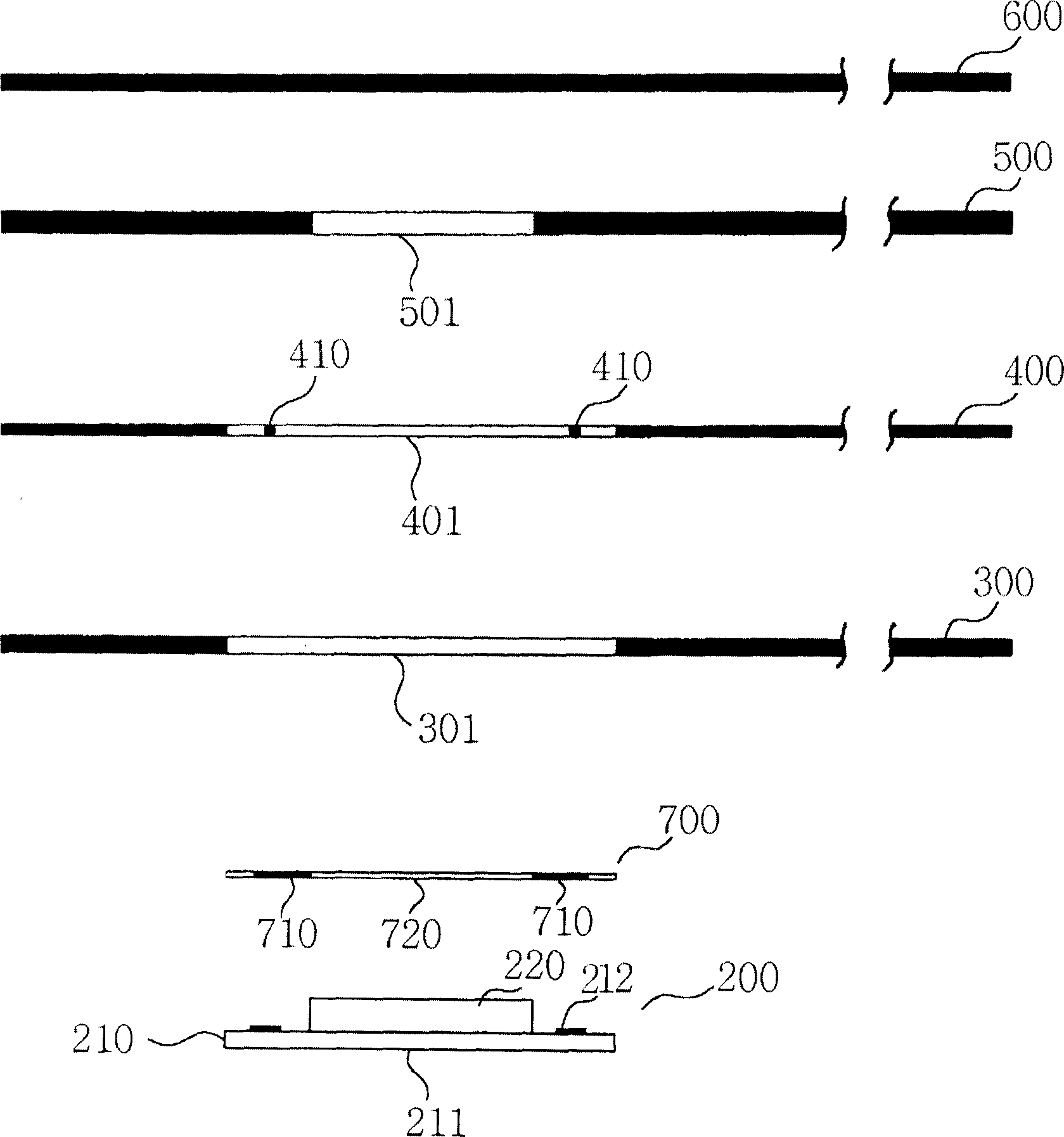

[0027]FIG. 2(A) is a perspective view illustrating a specific example of the IC card manufacturing process according to the present invention, and FIG. 2(B) is a sectional view thereof. The IC card (100) according to the present invention is formed by laminating a plurality of foils. First, a substantially flat working board (not shown) is placed on the bottom, and the COB ( 200 ) is placed on the working board. The working plate is preferably a metal plate having a certain thickness, which will be described below, and it has the advantage of being easy to heat and crimp the working plate. The above-mentioned COB (200) is a commonly used COB, and a chip chip is arranged on a main board (210), and a molding part (220) is formed thereon. The above molding part (220) does not only mean molding (moulding), but also can mean any purpose of protecting the above chip including potting. In this kind of COB (200), for the COB (200) used for contact cards, the lower side of the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com