Straight-brace inflatable mattress and manufacture method thereof

A technology of air mattresses and straight-pull belts, which is applied to liquid-filled cushions and other directions, can solve the problems of low comfort and poor disturbance, and achieve improved user comfort, good air flow, and variable force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

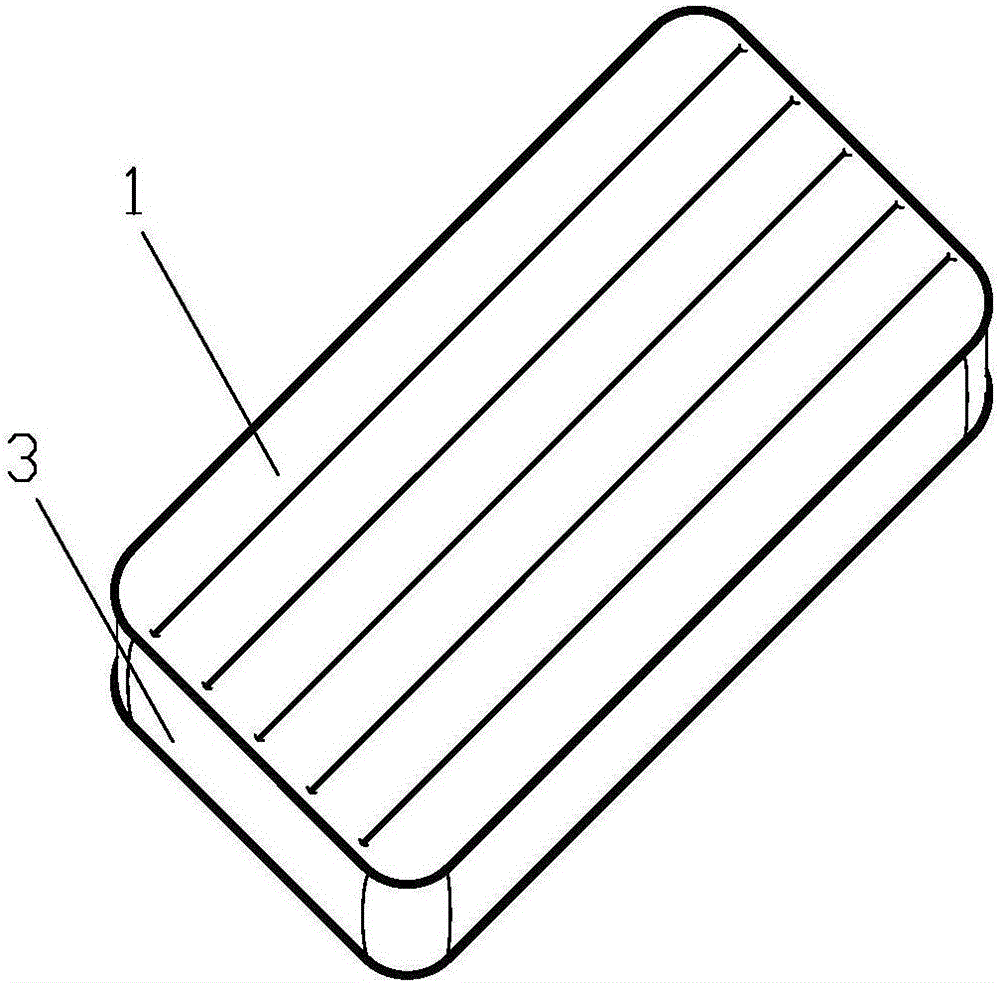

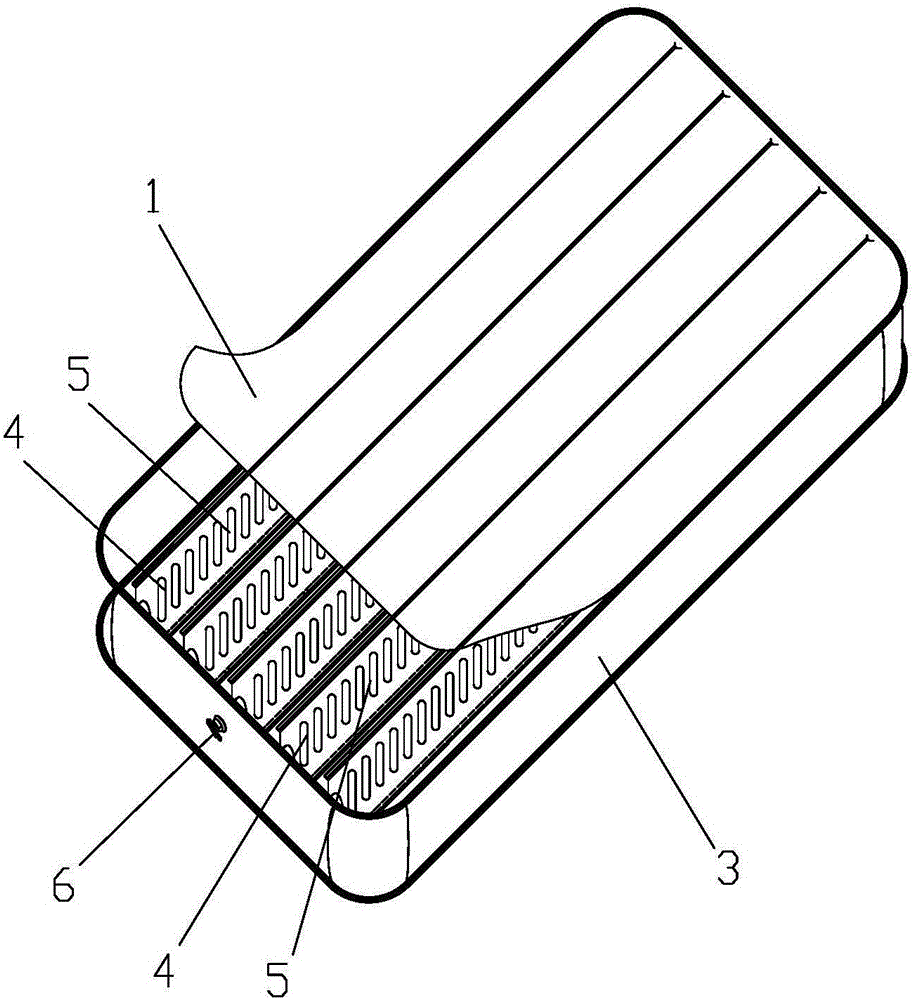

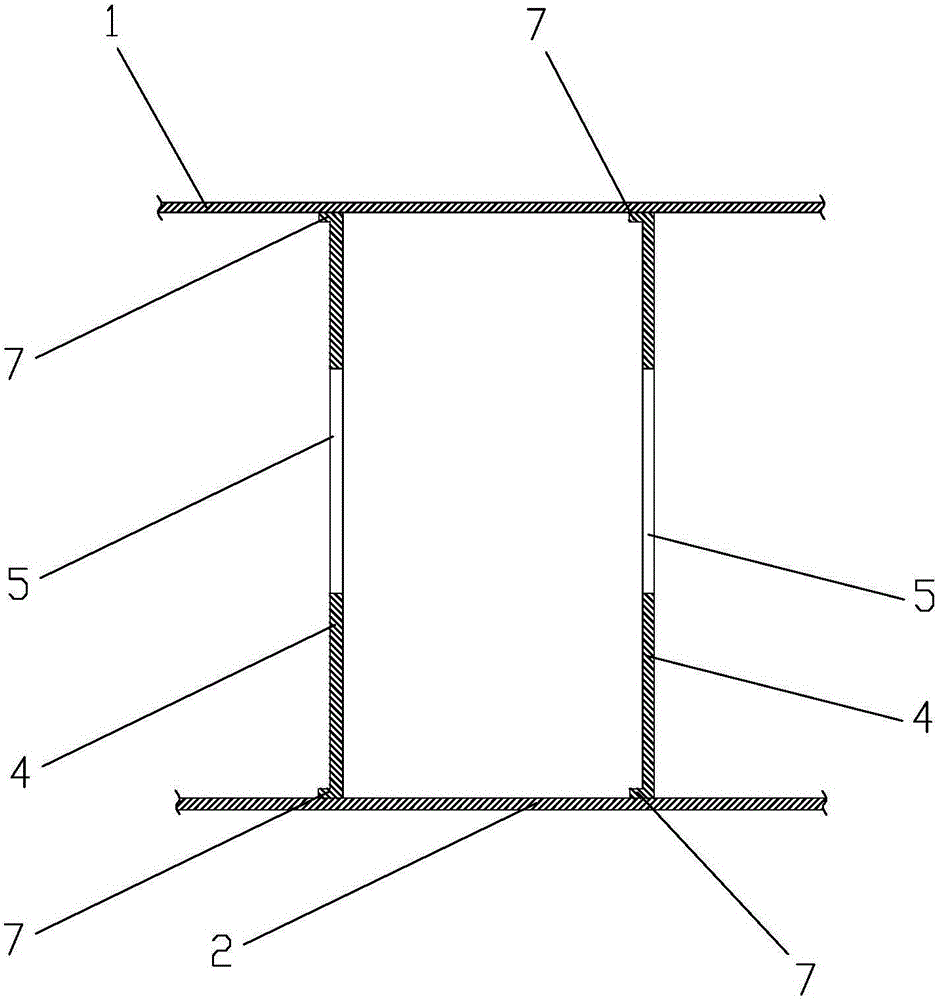

[0033] An inflatable mattress with a straight pull belt is characterized in that it includes an upper sheet material 1 and a lower sheet material 2, and the upper sheet material 1 and the lower sheet material 2 are provided with a belt connecting them and surrounding them. Form a surrounding material 3 of a sealed space, and between the upper sheet material 1 and the lower sheet material 2, there are also a plurality of sheet-shaped straight pull belts 4 that are hot-melt welded, and each of the straight pull belts 4 is provided with There are a plurality of through holes 5, and an inflation nozzle 6 is also arranged on the air mattress. Straight pull belt 4 is provided with a plurality of through holes 5, thus greatly reducing the weight of the air mattress, because the through holes 5 are located in the middle of straight pull strap 4, therefore, the bearing capacity of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com