Contact portion of semiconductor device and thin film transistor array panel for display device including the contact portion

A semiconductor and array board technology, which is applied in the field of contact parts of semiconductor devices and thin film transistor array boards for displays including the contact parts, and can solve problems such as poor contact and complicated manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

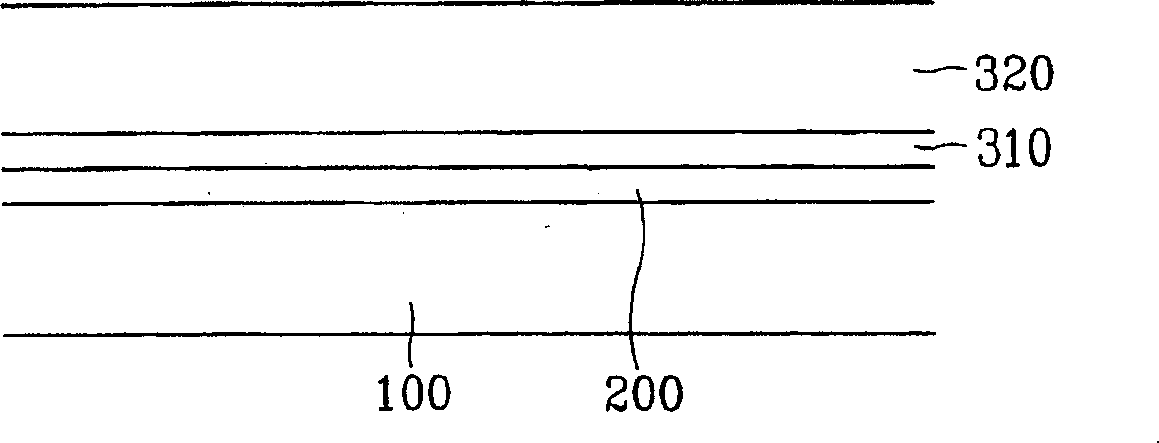

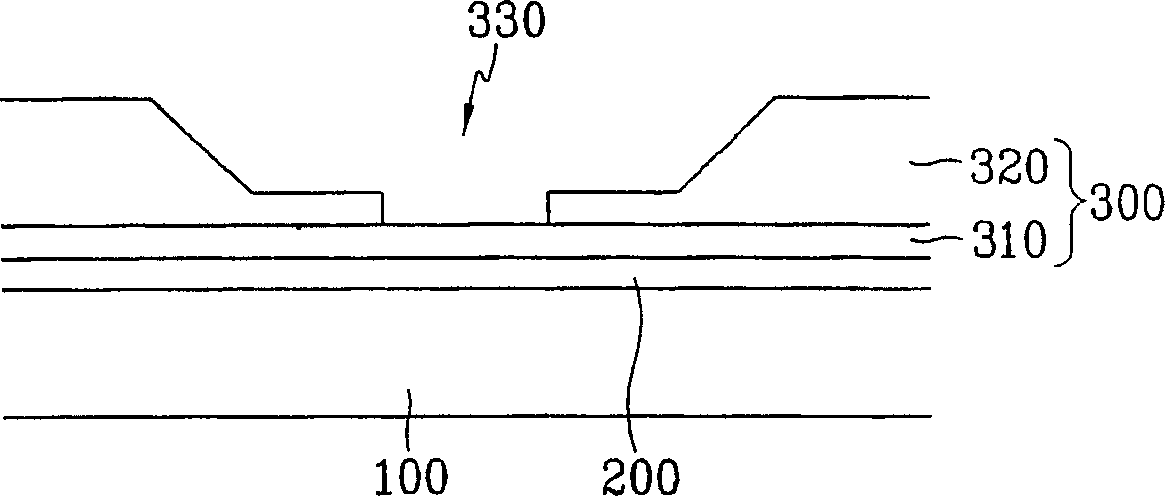

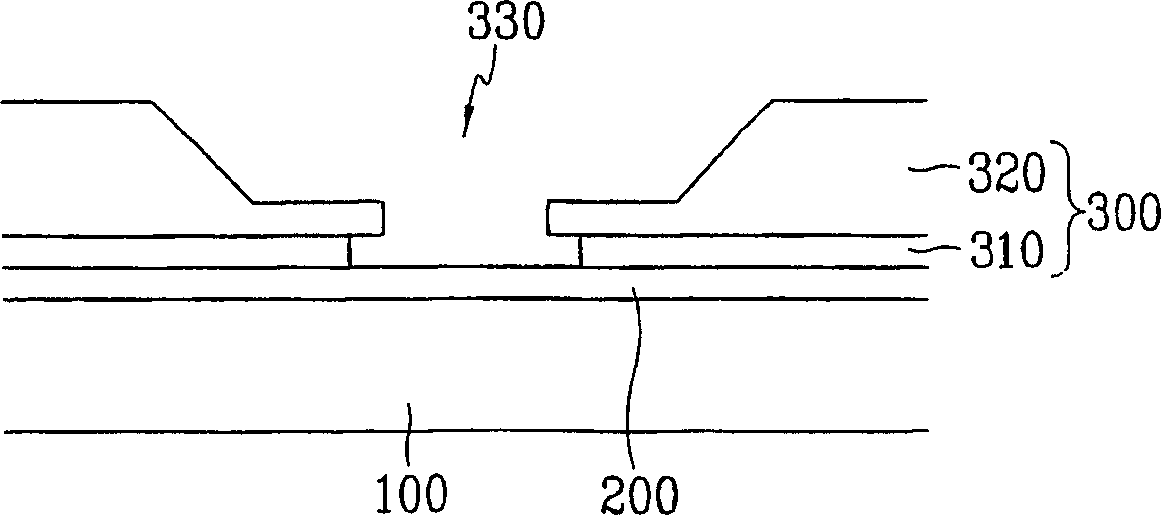

[0047] The semiconductor device contact part of the present invention and its manufacturing method and the thin film transistor array board including the semiconductor device contact part and its manufacturing method will be described in detail according to various embodiments of the present invention below with reference to the accompanying drawings, so that those skilled in the art can easily implement.

[0048] First, a contact portion and a manufacturing method thereof will be described according to an embodiment of the present invention.

[0049] Generally, when a semiconductor device is highly integrated, it is preferable to optimize the area of the device and arrange its wiring in multiple layers, so as to facilitate the connection of pads and signal lines receiving signals from external devices. A semiconductor device according to an embodiment of the present invention includes an interlayer insulating film having a low dielectric constant so as to minimize disturban...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com