Diamond cutter tooth and method for manufacturing diamond cutter tooth by using rigid material

A diamond knife and rigid material technology, applied in the field of methods and tools, can solve the problems of high energy consumption, serious environmental pollution, unstable product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

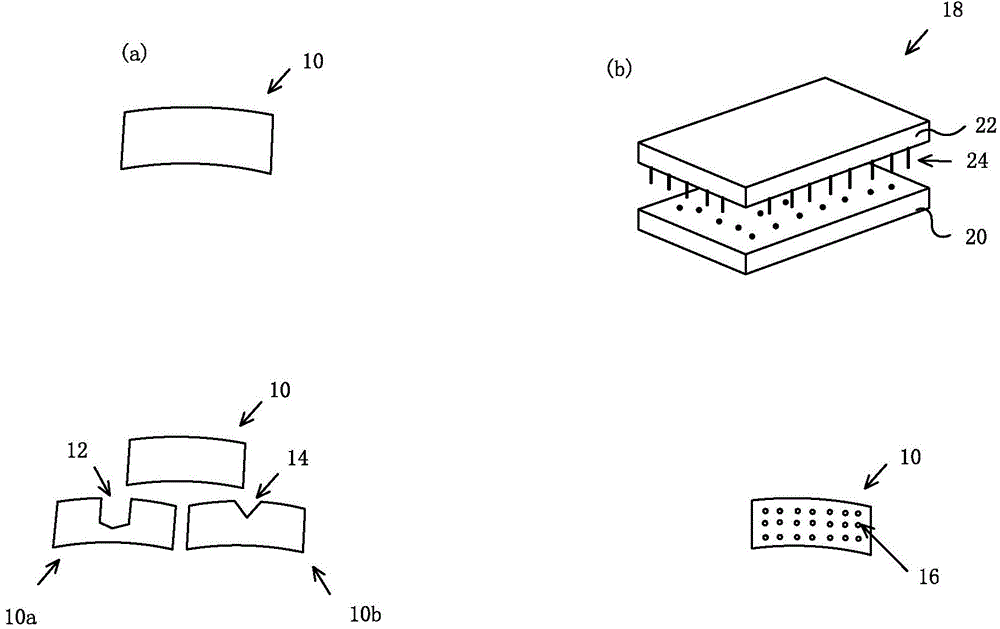

[0031] figure 1 Two steps in the fabrication of a segment for a diamond tooth using this method are shown. In step (a) a rigid part 10, ie a metal sheet. This rigid member is cut from at least one piece of rigid material (not shown). The rigid member 10 is plate-shaped, and thus may be called a rigid plate. Rigid parts or plates may include copper, aluminum, nickel, steel.

[0032] Below the rigid part 10 are 10a and 10b. The rigid part 10a has a socket or circular base channel 12 . The slots or channels 12 are used to cool or transport the cut material for making the pieces while the workpiece is being machined. Thus, the cross-section of the rigid part 10a can be used for drilling or milling diamond tools.

[0033] The rigid member 10b has a slot or pointed base channel 14 for cooling or conveying the cut material for making the segment when engaged with the workpiece. For example, the cross-section of the rigid member 10b may be used for a diamond sawn board, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com