Semiconductor chip assembly with metal containment wall and solder terminal

A technology of chip packaging structure and conductor chip, which is used in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

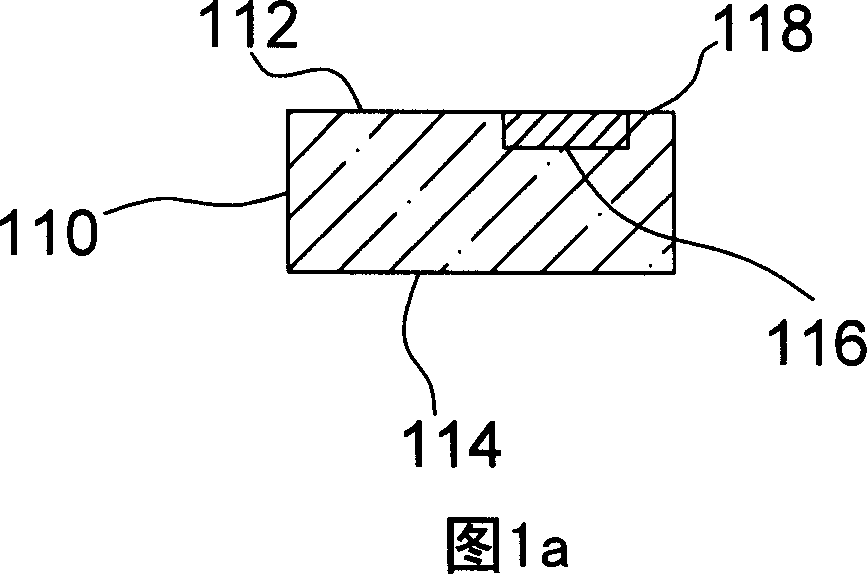

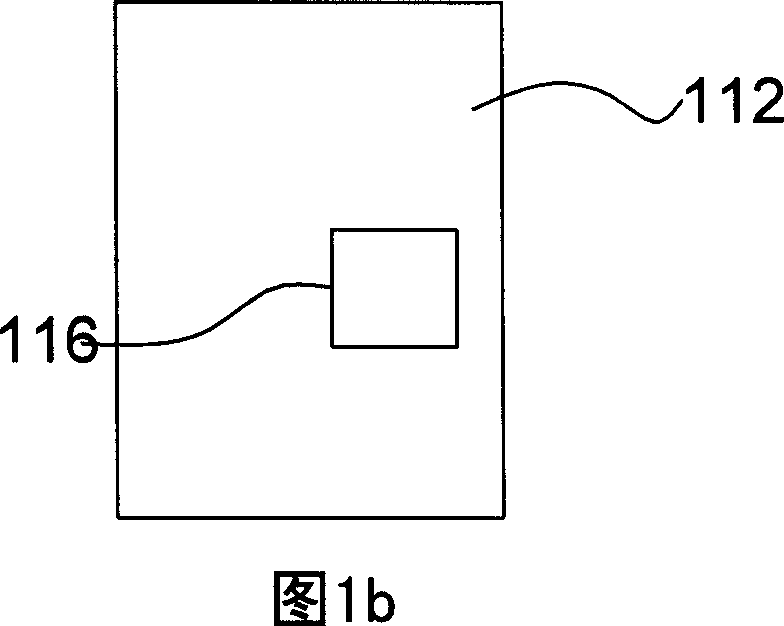

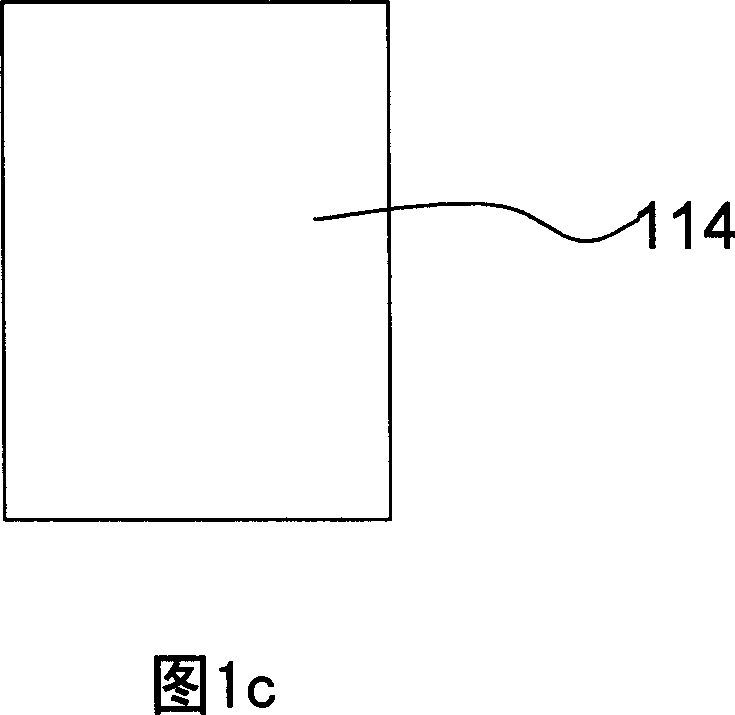

[0347] 1a to 27c are the first embodiment of the method for manufacturing a semiconductor chip package structure, wherein FIGS. 1a to 27a are schematic cross-sectional views, FIGS. 1b to 27b are schematic top views, and FIGS. 1c to 27c are schematic bottom views.

[0348] As shown in FIG. 1a, FIG. 1b and FIG. 1c, it is a schematic cross-sectional view of the semiconductor chip structure of the present invention, a schematic top view of the semiconductor chip structure of the present invention, and a schematic bottom view of the semiconductor chip structure of the present invention. As shown in the figure: the present invention is a semiconductor chip packaging structure with a metal wall at the welding end, wherein the semiconductor chip 110 is an integrated circuit, and is composed of a plurality of transistors, circuits, connecting parts and other connections (in the figure not shown). The semiconductor chip 110 includes a corresponding first plane 112 and a second plane 114...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com