Polymer electrolyte fuel cell and electrode/film/frame assembly manufacturing method

A polymer electrolyte and electrolyte membrane technology, applied in solid electrolyte fuel cells, fuel cell parts, fuel cells, etc., can solve problems such as damage to the electrolyte membrane 313, floating of the main part of the MEA, and insufficient maintenance of the MEA314, to achieve Improved jointability and reliable holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

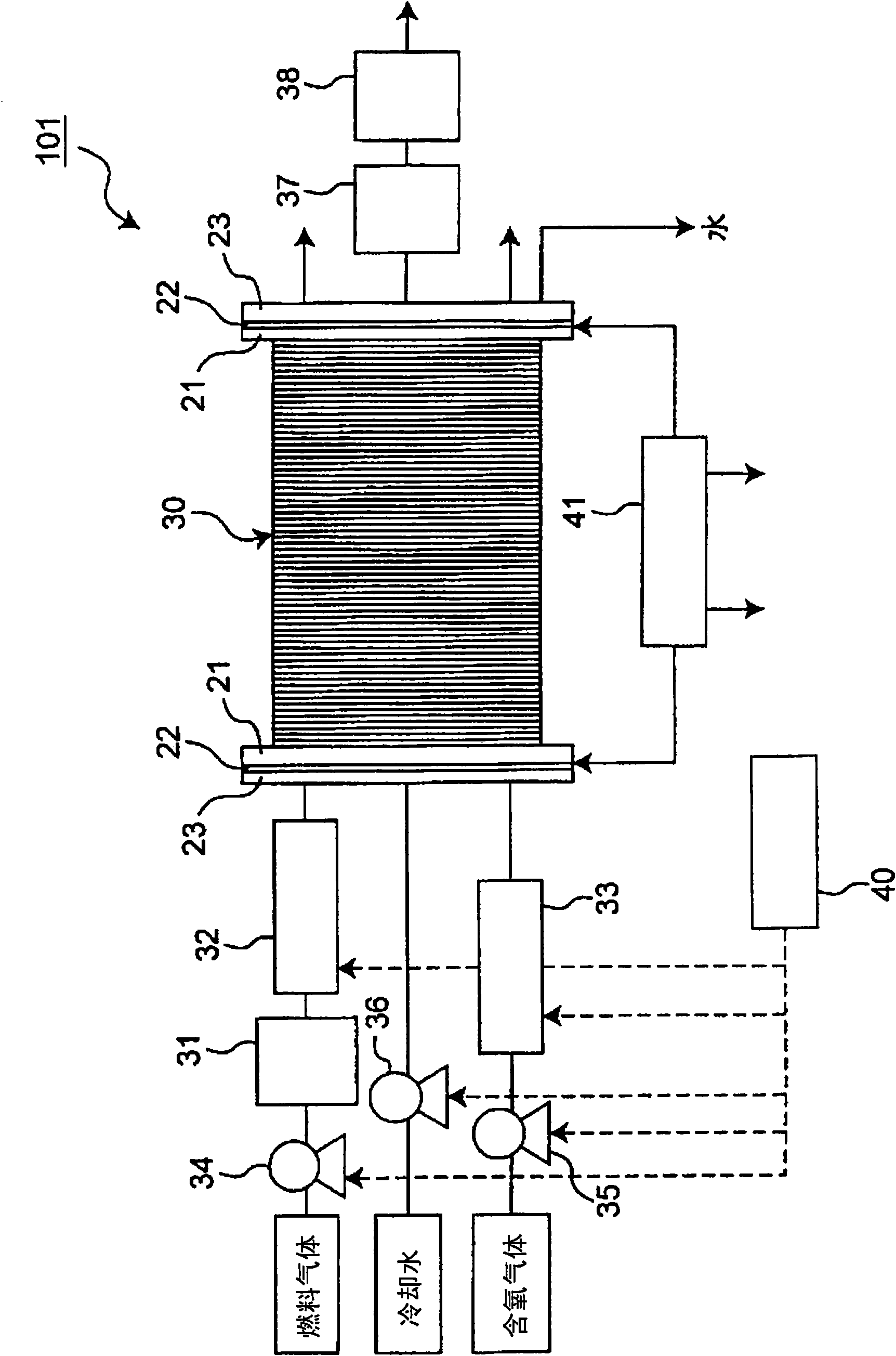

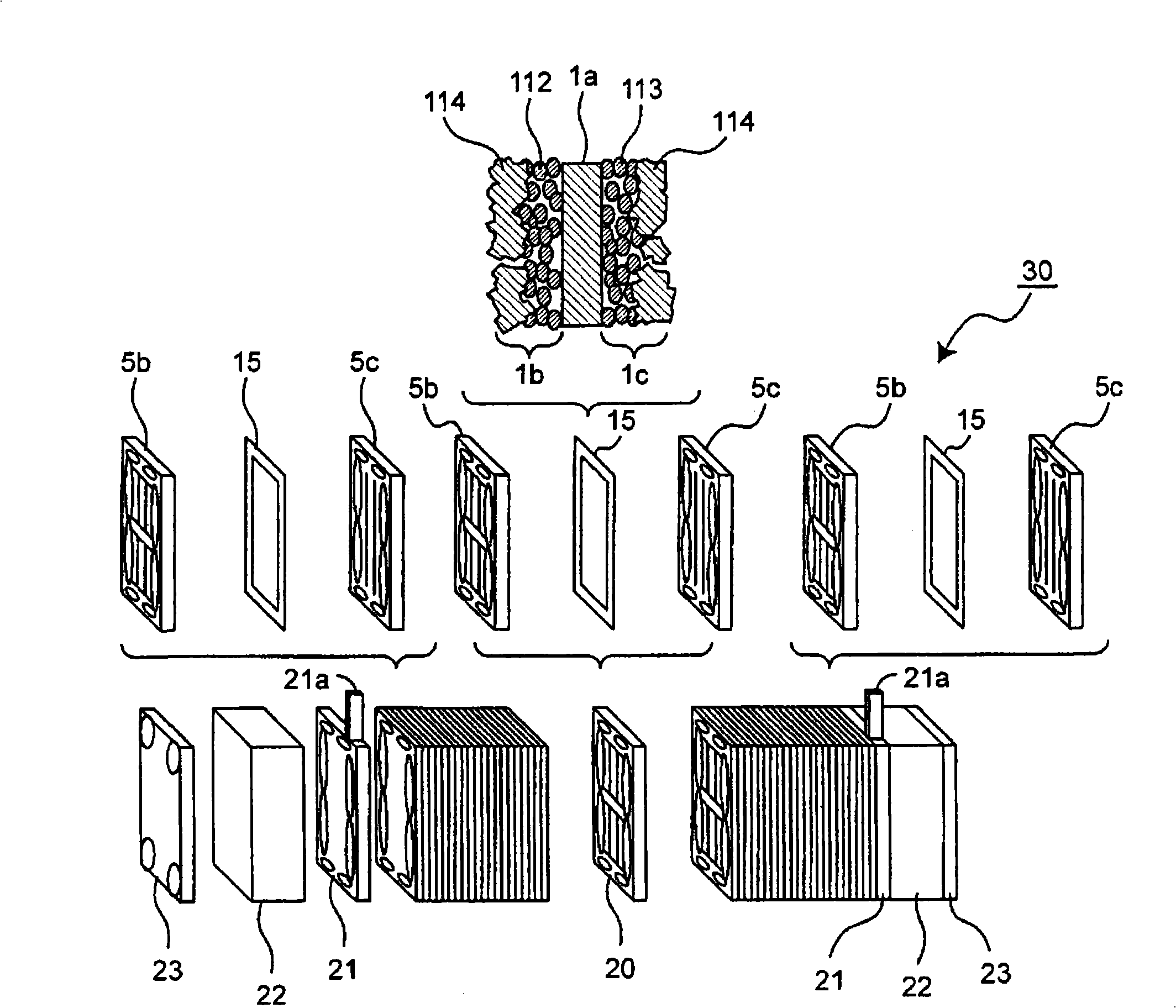

[0068] A schematic configuration diagram of a schematic configuration of a fuel cell including a fuel cell stack in the first embodiment of the present invention is shown in figure 1 . Additionally, the figure 1 A schematic exploded view of a fuel cell stack (hereinafter referred to as a fuel cell stack) included in the fuel cell 101 shown is shown in figure 2 .

[0069] The fuel cell 101 is, for example, a polymer electrolyte fuel cell (PEFC) that electrochemically reacts a hydrogen-containing fuel gas with an oxygen-containing oxidant gas such as air to simultaneously generate electricity, heat, and water. Such as figure 1 As shown, the fuel cell 101 includes: a stacked fuel cell stack 30 in which a plurality of fuel cell units (or single cells) having a pair of poles (or single cells) having an anode and a cathode are connected in series; a fuel processor for extracting hydrogen from fuel gas 31; an anode humidifier 32 for improving power generation efficiency by hu...

no. 2 approach

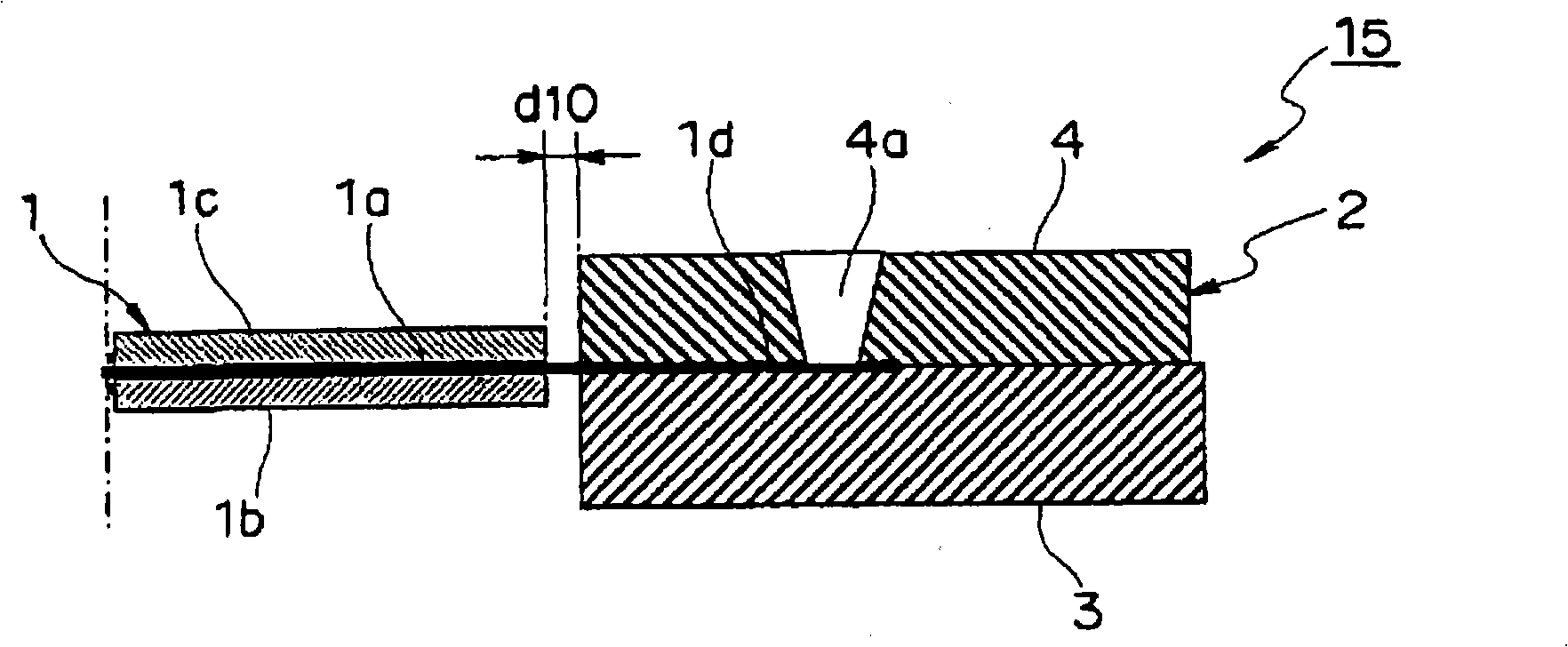

[0098] In addition, this invention is not limited to the said embodiment, It can implement in other various forms. For example, a schematic partial cross-sectional view of the MEA-frame assembly 85 included in the fuel cell in the second embodiment of the present invention is shown in Figure 10 . In addition, in the following description, the same reference number is used for the same structural member, and the description is abbreviate|omitted.

[0099] Such as Figure 10 As shown, the MEA-frame assembly 85 of the second embodiment has a structure in which a stepped portion 86 is formed in the first frame member 83, and the electrolyte membrane 1a is arranged on the lower stepped surface 86a of the stepped portion 86. The second frame member 84 is formed by injection molding so as to embed the stepped portion 86 in a state of being pressed and fixed by the pressing member 56 (through hole 84a ).

[0100] By adopting the structure of the second embodiment in this way, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com