LED packaging structure and method

A technology of LED packaging and LED chips, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of peeling of plastic packaging materials, affecting the sealing of packaging, peeling of plastic packaging materials and substrates, etc., and achieve the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The idea of the present invention is to design an LED chip package that enhances heat dissipation and prevents warping and peeling off, and specific embodiments will be described in the following content.

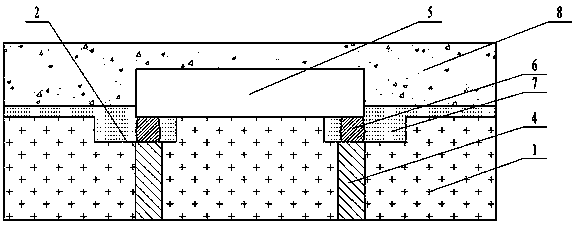

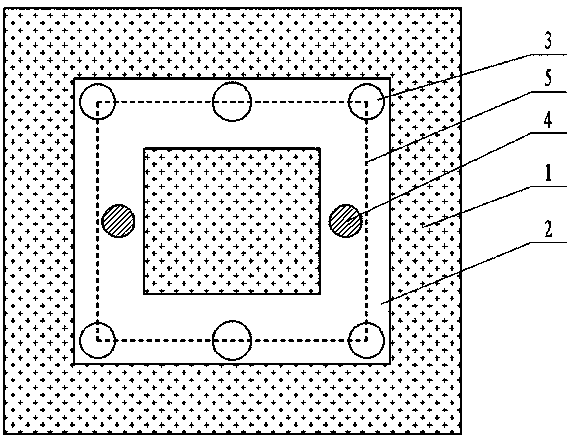

[0034] see figure 1 and 2 , LED encapsulation structure of the present invention, it comprises:

[0035] A heat dissipation substrate 1, the heat dissipation substrate 1 is provided with an annular groove 2, and a plurality of through holes 3 passing through the heat dissipation substrate 1 are arranged at the bottom of the annular groove 2, and the plurality of through holes 3 A part of the through hole is filled with conductive material to form the conductive hole 4; this part of the through hole realizes the function of a conductive path, which should correspond to the position of the electrode of the LED chip.

[0036] The LED chip 5 is flip-mounted on the conductive hole 4 via the solder ball 6 so that the bottom surface of the LED chip 5 contacts the heat d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com