Wafer structure with buffer layer

A buffer layer and wafer technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of poor product yield, lack of resistance, lead-free solder ball cracking, etc., to enhance structural strength and The effect of shock absorption and enhanced bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

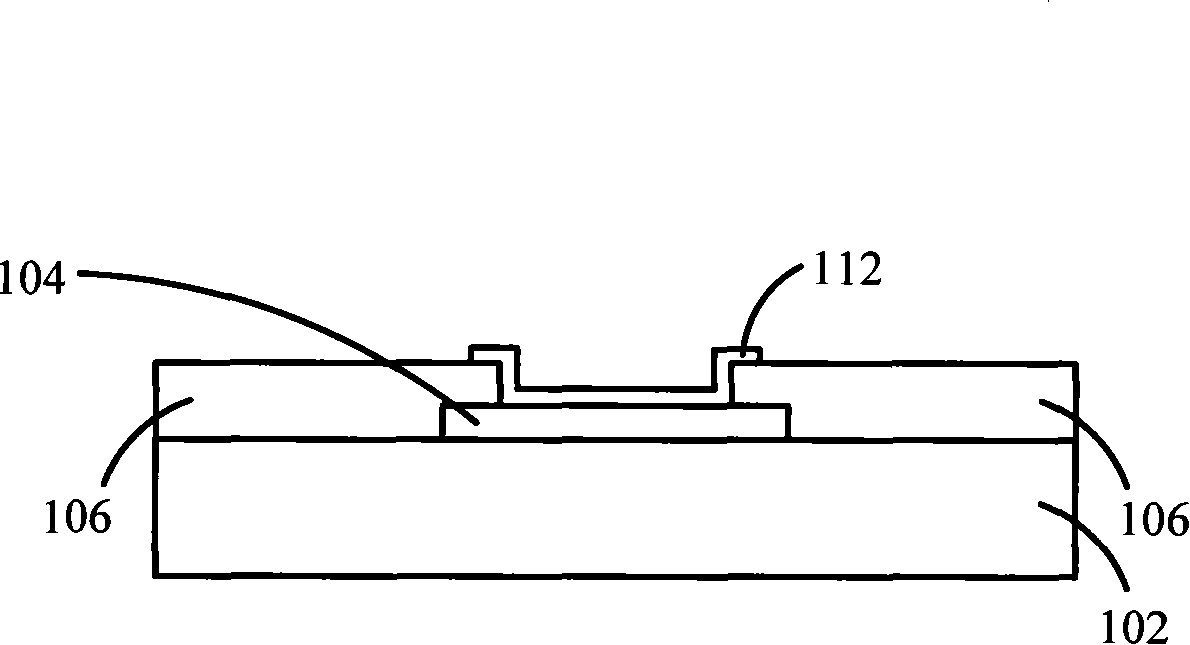

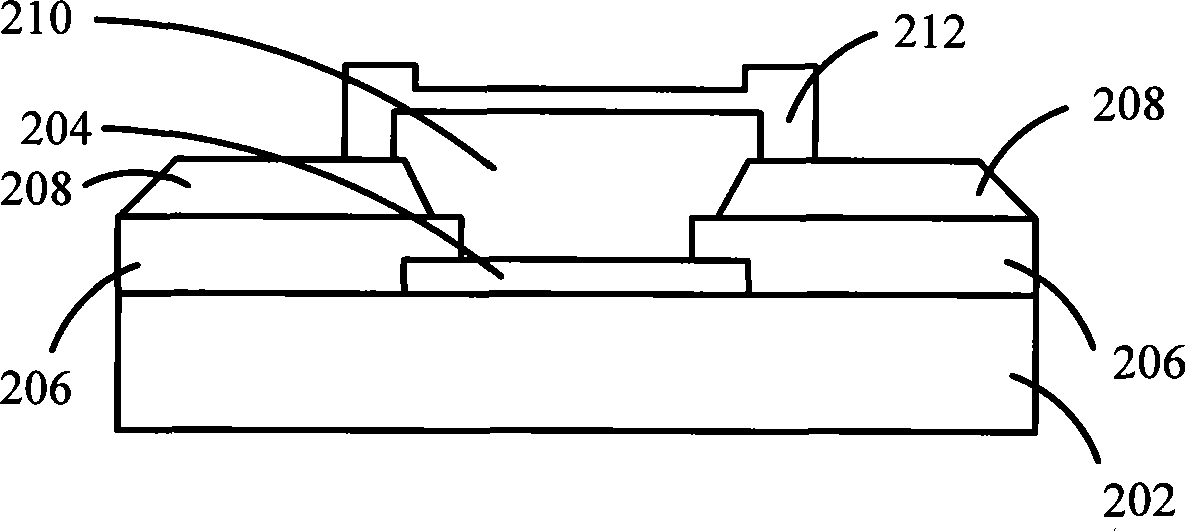

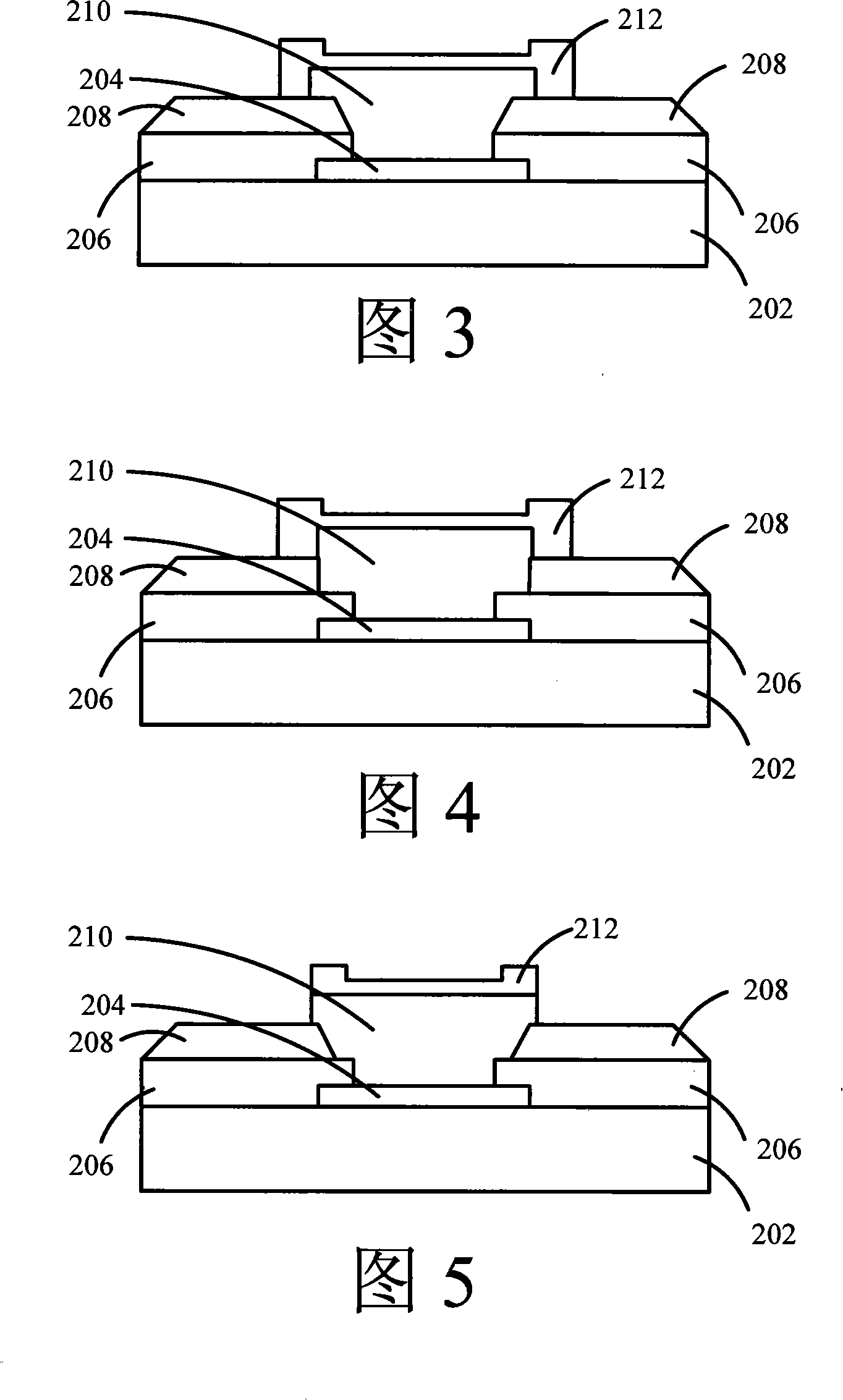

[0026] The present invention provides a wafer structure with a buffer layer, which is to add a buffer layer in the wafer structure to enhance the structural strength of the wafer and prevent the solder balls from falling off. Please refer to figure 2 The schematic diagram of the wafer structure according to the first embodiment of the present invention is shown, the wafer structure includes: a wafer 202, a protective layer 206, an outer buffer layer 208, an inner buffer layer 210 and an under-bump metal layer 212 .

[0027] Wafer 202 has a first surface (such as figure 2 The upper surface shown in ), at least one pad 204 is arranged on the first surface to form an electrical connection with the wafer 202, although only one pad 204 is shown in the figure, it should be known that the wafer A plurality of welding pads 204 may be provided on the first surface of the 202, or other electrical connection elements or other electronic / electrical elements, and these are technologies ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com