Heat radiation seat using graphite as base and method for prepn. of said graphite

A manufacturing method and technology for a heat sink, which are applied in the field of manufacturing heat sinks and their graphite, can solve the problems of shortening the life of electronic components, shortening the life of electronic components, increasing costs, etc. The effect of shortening the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

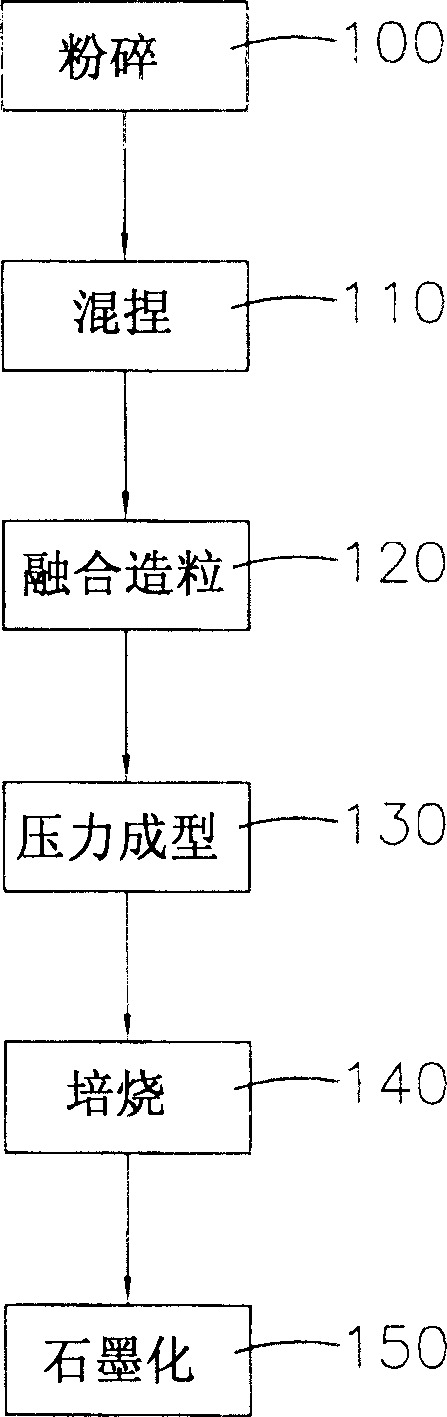

[0037] see image 3 Shown, be graphite manufacturing method flow chart of the present invention, can know clearly by the figure, when utilizing the present invention to manufacture bulk graphite, carry out according to the following steps:

[0038] Step 100(A), pulverizing: pulverizing the natural graphite into micron particles.

[0039] Step 110(B), kneading: the particles with a particle size of micron are mixed with an adhesive, and the adhesive can be bitumen or mesophase pitch.

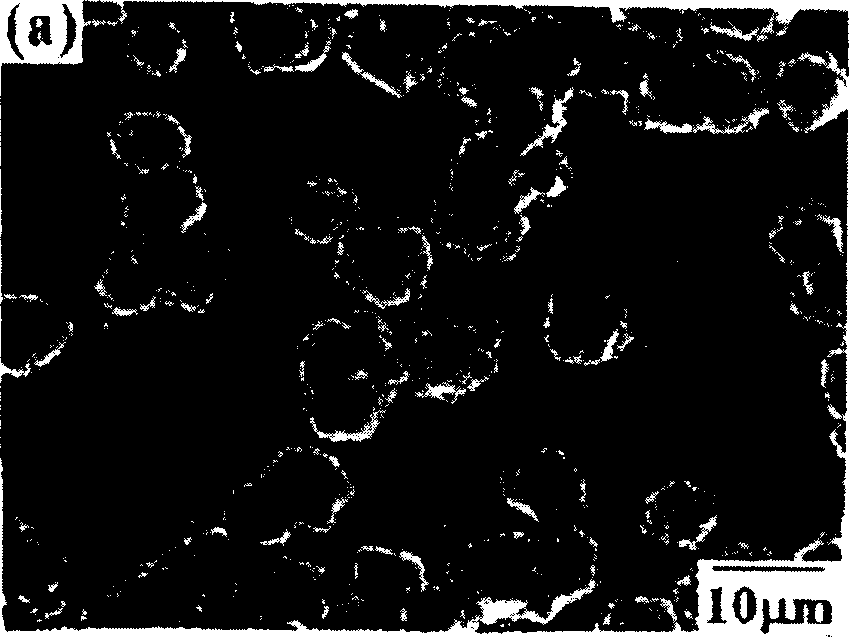

[0040] Step 120(C), fusion granulation: crush the particles of the mixed binder again, and evenly disperse the graphite powder to obtain spherical graphite (such as Figure 4 shown).

[0041] Step 130(D), pressure forming: the spherical graphite is formed into a block by high pressure, cold pressing and hot pressing vibration.

[0042] Step 140(E), calcining: impregnating the bulk graphite in the pitch of the liquid phase to fill the gaps, so as to increase the density and strength.

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com