Vacuum insulation material and method for manufacturing same

A technology of vacuum heat insulation material and manufacturing method, which is applied in non-woven fabrics, heat exchange equipment, textiles and papermaking, etc., to achieve the effects of excellent productivity, convenient manufacturing method, and excellent heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

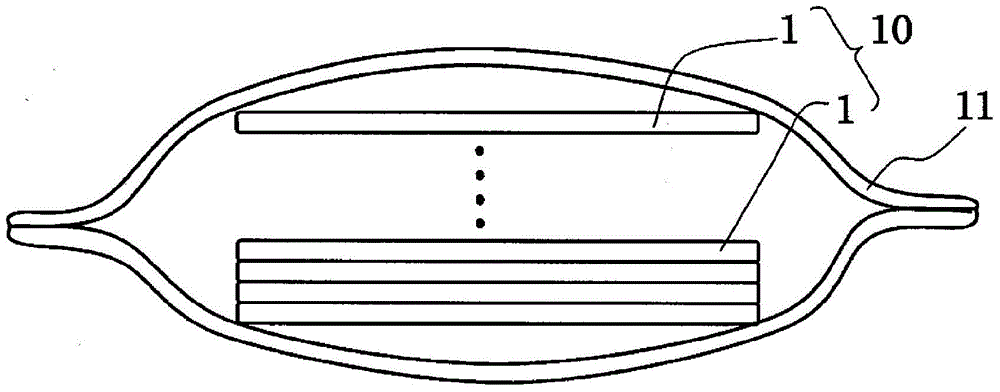

[0041] Such as figure 1 As shown, the vacuum heat insulating material of the present invention is a vacuum heat insulating material comprising a laminate 10 formed by laminating inorganic fiber sheets 1, 1 .

[0042] In addition, in the inorganic fiber sheet 1, inorganic fiber strands including curved inorganic fiber strands with a cut length (L) of 3-12 mm are randomly dispersed, and at least a part of the inorganic fiber strands are bonded to each other to form Flaky.

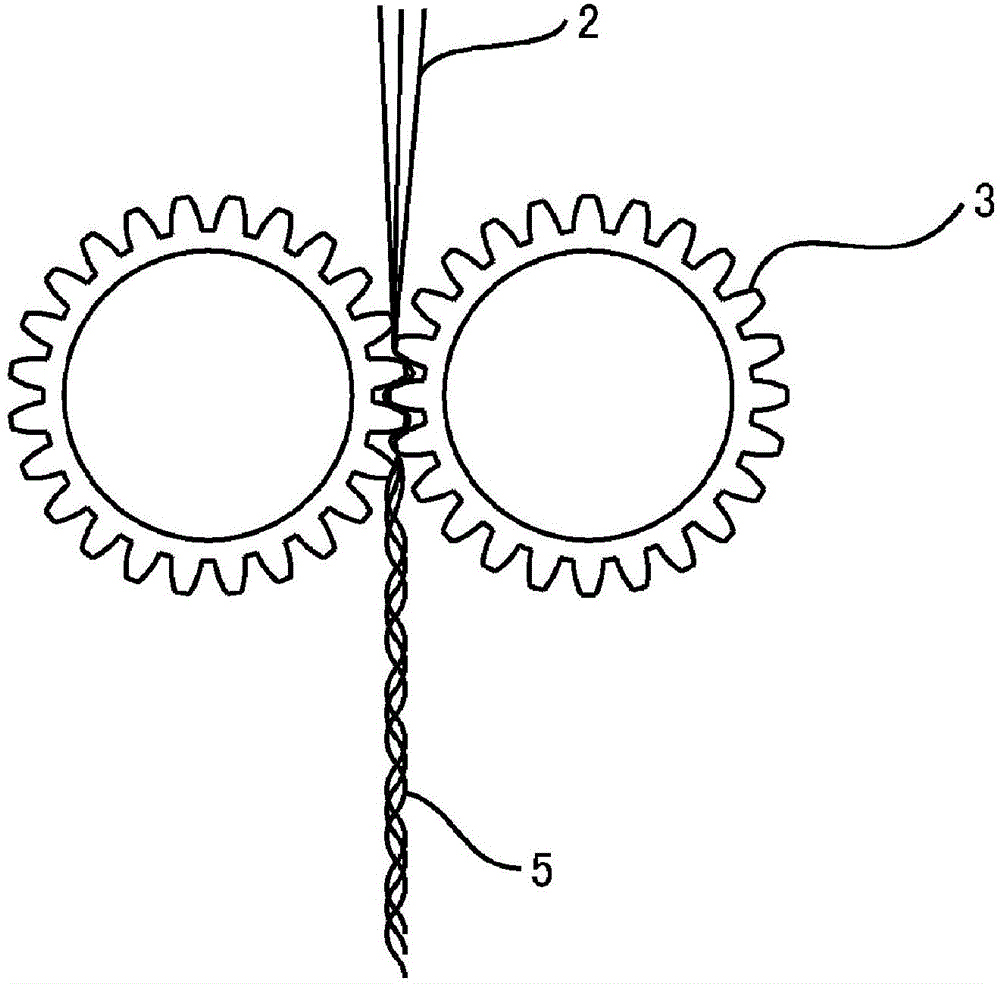

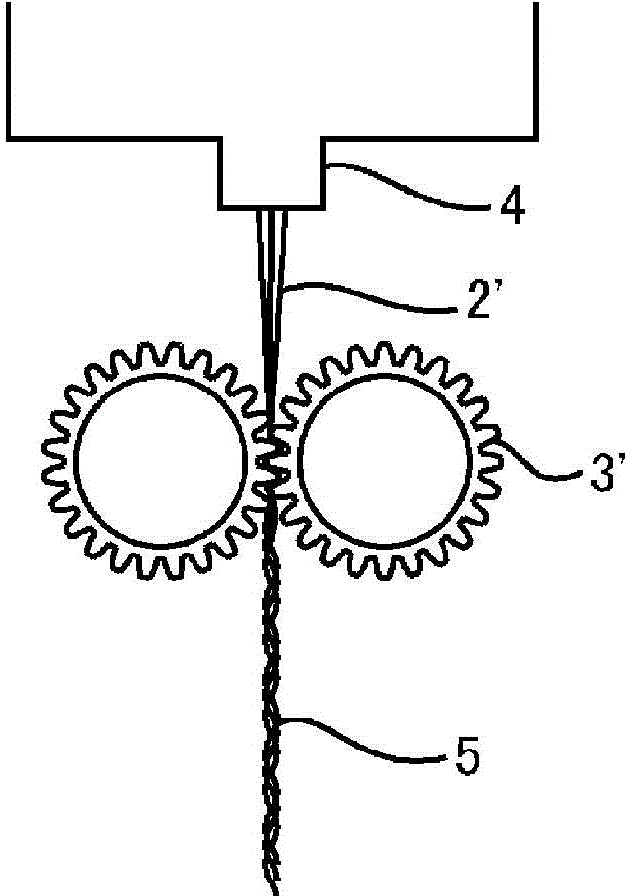

[0043] The curved inorganic fiber thread can be obtained by cutting a filament of a wavy curve (two-dimensional curve) at a specific length, can also be obtained by cutting a filament of a helical three-dimensional curve at a specific length, or can be obtained by cutting a random filament at a specific length. Curvilinear filaments with loops or curves are obtained. Representative examples include: filaments shaped into a wave formed by a curved line (wave forming wire) that are cut at intervals of 3 mm to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cutting length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com