Heating container for preventing leakage of high-temperature metal material and manufacturing method thereof

A metal material, heating container technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of material loss, heating container material loss, etc., to ensure quality, improve the cycle of continuous and stable operation , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

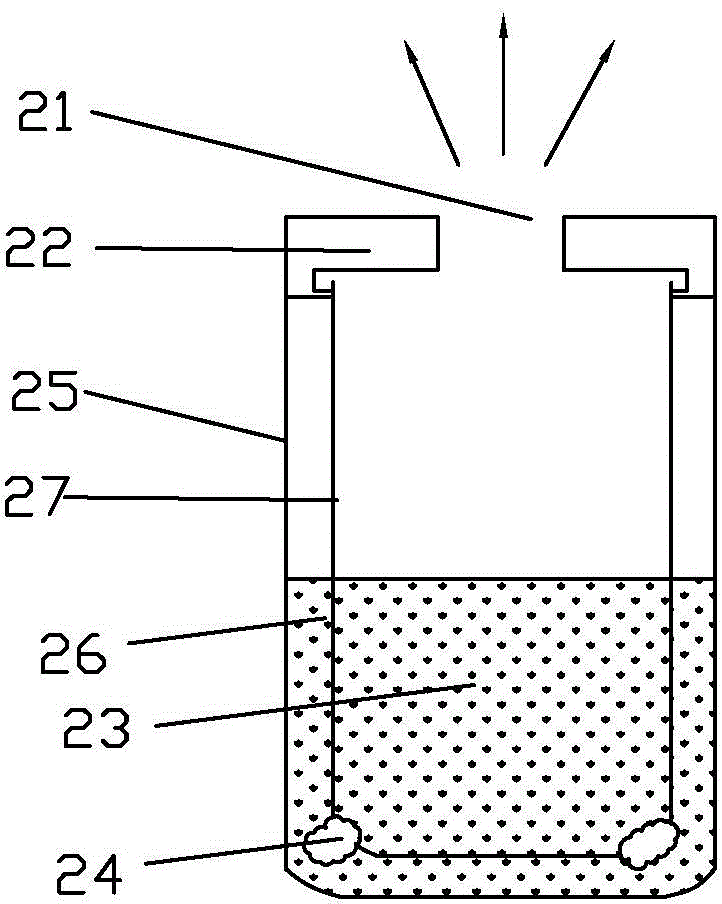

[0038] see figure 2 , which is a schematic cross-sectional view of the first preferred embodiment of the heating container for preventing leakage of high-temperature metal materials according to the present invention. Made in the direction of the cylindrical diameter. The heating container for preventing the leakage of high-temperature metal materials in this preferred embodiment mainly includes: an internal heating container 27 for containing the metal material, an external heating container 25 for receiving heating from a heating device, and a heating container for escaping after the metal material evaporates. The upper cover 22 of the air hole 21; the inner heating container 27 is fully accommodated in the outer heating container 25 and the position is fixed relative to the outer heating container 27, and the inner heating container 27 side wall and the outer heating container 25 side walls are provided There is a gap, the upper cover 22 is fixed above the inner heating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com