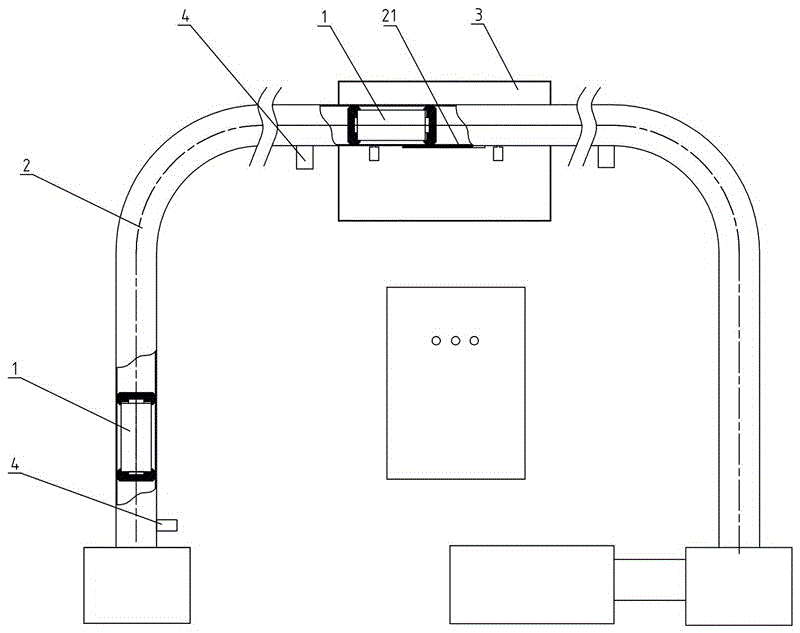

Rapid maintenance device for pneumatic conveying of material and material pneumatic conveying system

A technology of pneumatic conveying and rapid maintenance, applied in the direction of analyzing materials, instruments, etc., can solve the problems of lagging maintenance work, difficult operator stuck positions, and high maintenance costs, so as to improve work efficiency, fast maintenance operations, and reduce difficulty and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

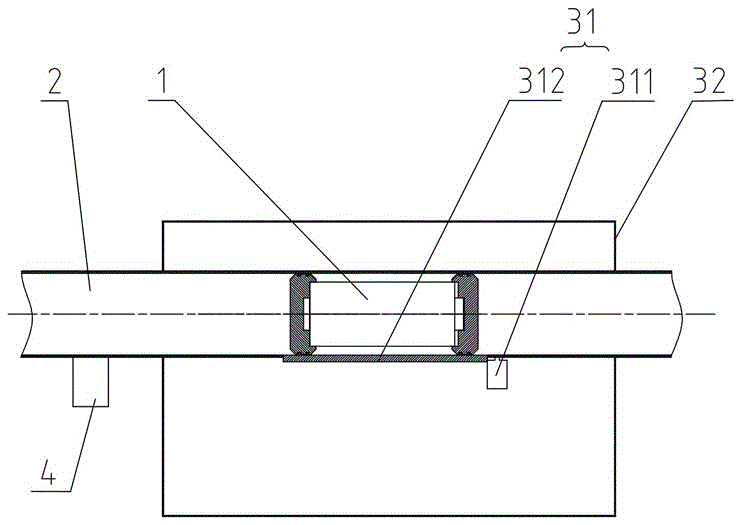

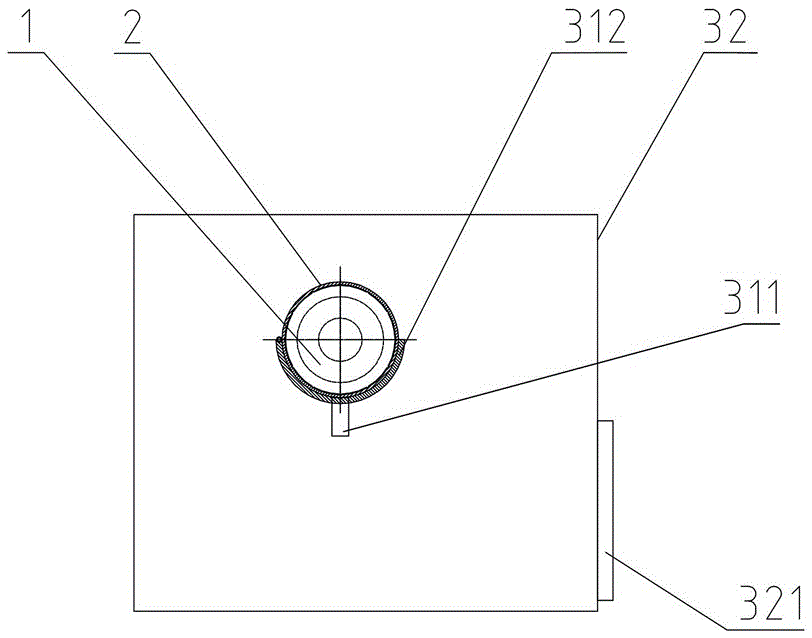

[0036] Specific embodiment 1: as Figure 2 to Figure 4 As shown, in this embodiment, the retaining plate 312 is hinged to the pneumatic transmission pipe 2 , and the retaining plate 312 is turned downwards to open the retaining port 21 under the drive of the retaining drive member 311 . When the operation monitoring unit 4 detects no abnormality, the retaining plate 312 blocks the retaining port 21 under the drive of the retaining drive member 311 , so that the object 1 to be conveyed can quickly pass through the retaining port 21 for pneumatic transmission. Once it is detected that there is an abnormal situation in the object to be conveyed 1 and needs to be intercepted, the interception drive member 311 drives the interception plate 312 to turn down so that the interception port 21 is opened, so that the object to be transported 1 to be passed falls from the interception port 21 to the interception port. Inside the main body 32 of the maintenance box.

specific Embodiment 2

[0037] Specific embodiment 2: as Figure 5 , Image 6 As shown, in this embodiment, the retaining drive member 311 includes a lifting screw assembly connected with the retaining plate 312 , and the lifting screw assembly drives the retaining plate 312 up and down to open / close the retaining port 21 . The lifting screw assembly can be arranged directly under the retaining plate 312 , or can be arranged on both sides above the retaining plate 312 as shown in the figure.

[0038] Such as Figure 1 to Figure 6 As shown, further, in a preferred embodiment, the operation monitoring unit 4 includes a level monitoring sensor assembly, which is arranged on the pneumatic transmission pipeline 2 for monitoring the moving speed of the object 1 to be transported in the pipeline. The level monitoring sensor assembly includes two or more level monitoring sensors, and there is a certain distance a between the two or more level monitoring sensors. When more than two level monitoring sensors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com