System and method for controlling material level of sintering mixing material bin

A sinter mixture and material level control technology, which is applied in the direction of furnace control devices, furnaces, lighting and heating equipment, etc., can solve the problems of reducing sinter output, short-term system shutdown, waste of time, etc., to eliminate human error factors and improve The effect of production profit and broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

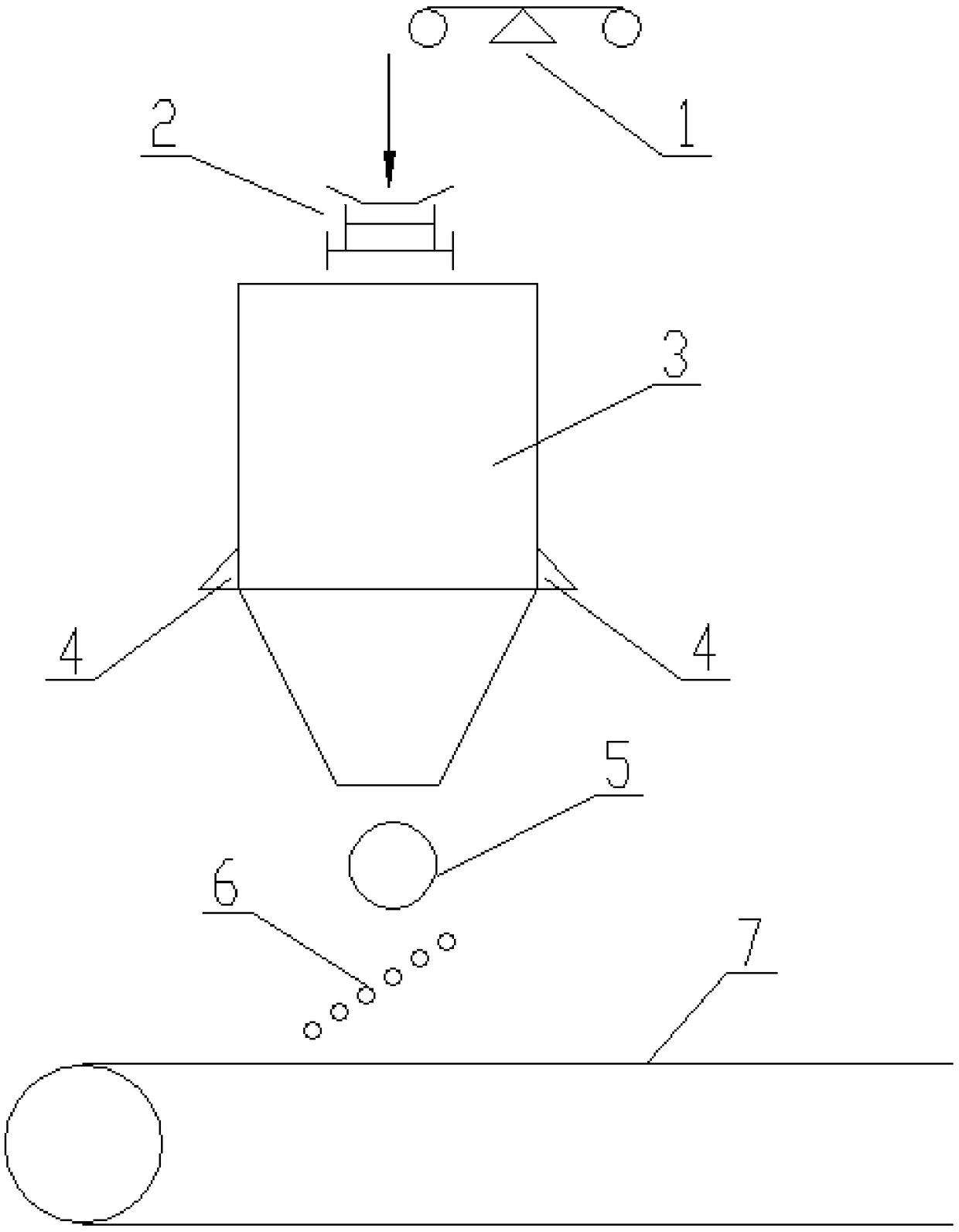

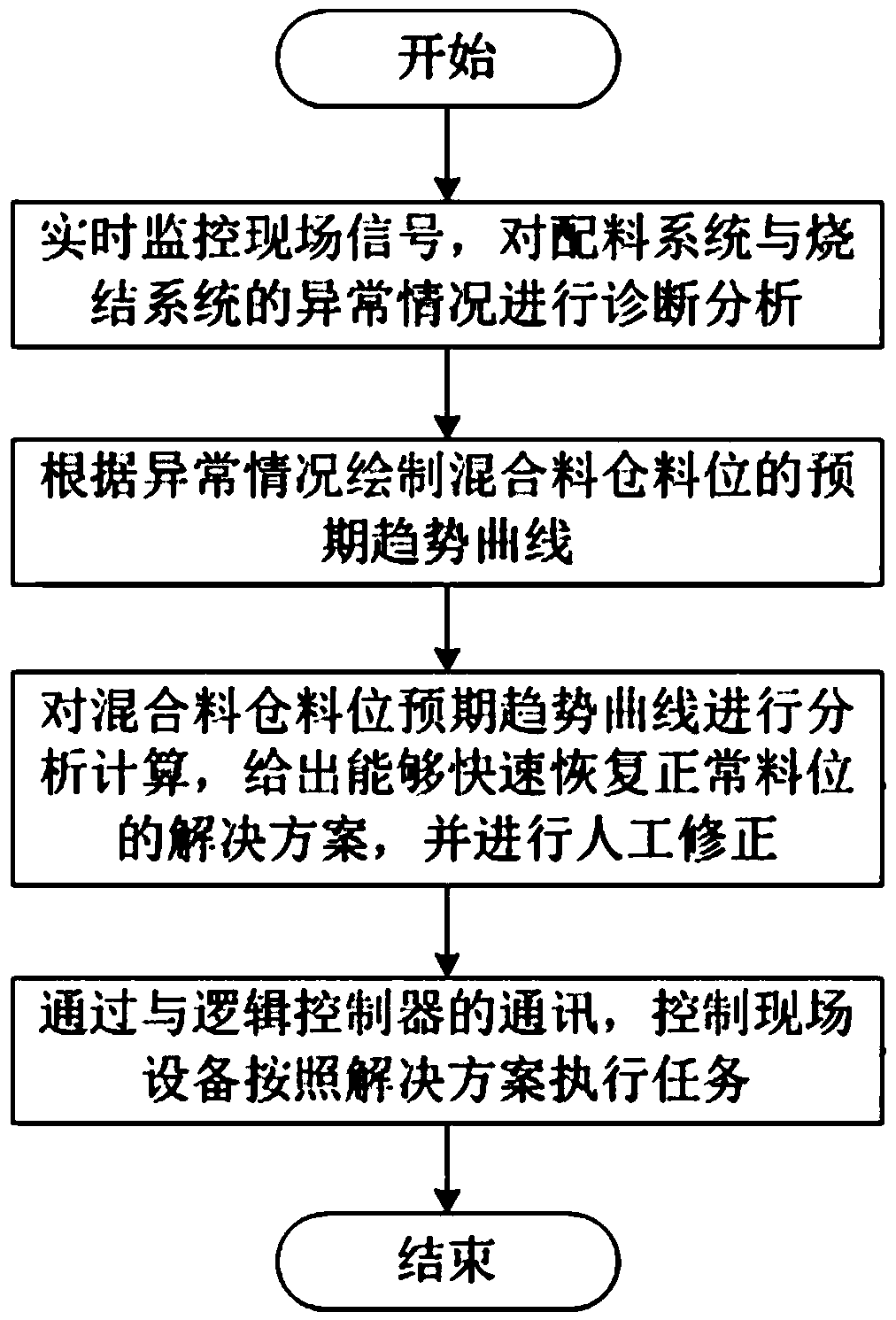

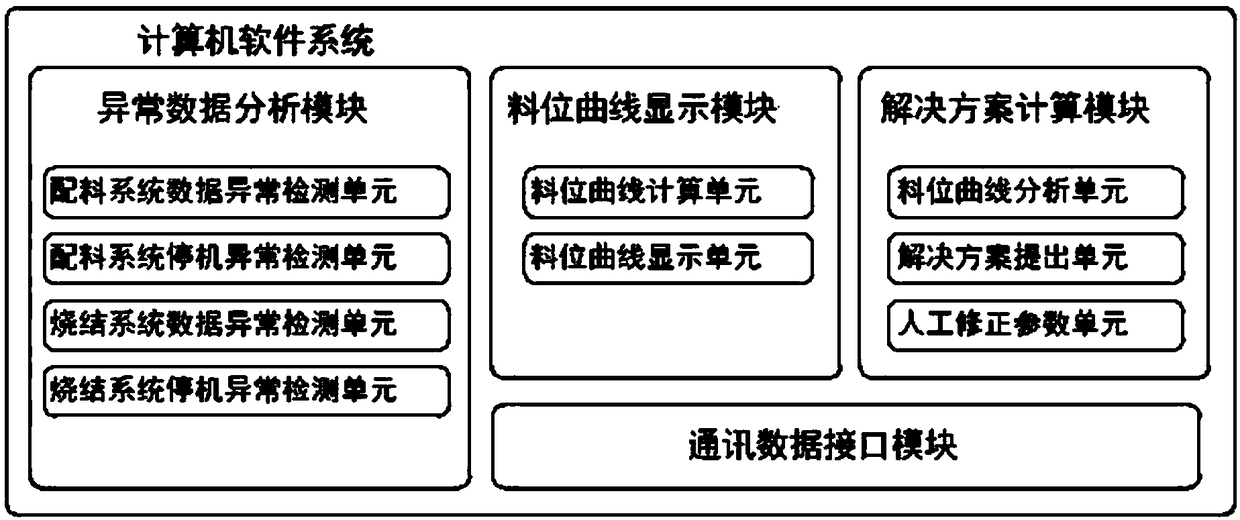

[0023] Such as Figure 1-5 As shown, the sintering mixing bin material level control system of the present invention is characterized in that it includes a real-time monitoring mechanism, a signal acquisition and analysis mechanism connected with the real-time monitoring mechanism, and a control executive mechanism connected with the signal acquisition and analysis system. The real-time monitoring mechanism includes a feeding belt scale 1 arranged above the mixing bin 3, a warehouse load cell 4 arranged on the mixing bin 3, and a round roller arranged below the mixing bin 3. The frequency converter on the feeder 5 and the sintering machine 7 detects the speed feedback device, the described signal acquisition and analysis mechanism includes a computer analysis system, the described control executive mechanism includes a logic contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com