Bragg body grating monochromator prepared from electric tuning holographic polymer dispersed liquid crystal (HPDLC)

A technology of dispersing liquid crystals and volume gratings, which is applied in the field of electro-optical functional materials and optical communications, can solve the problems of reduced diffraction efficiency, large system structure, and no sticking and dyeing, and achieve the effects of avoiding damp and mildew, shrinking the system volume, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

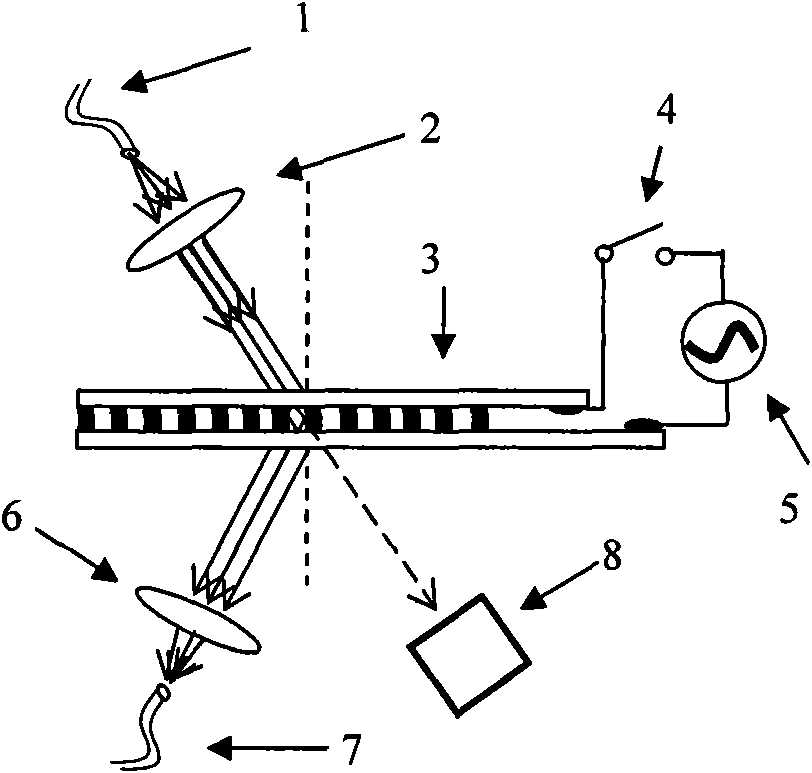

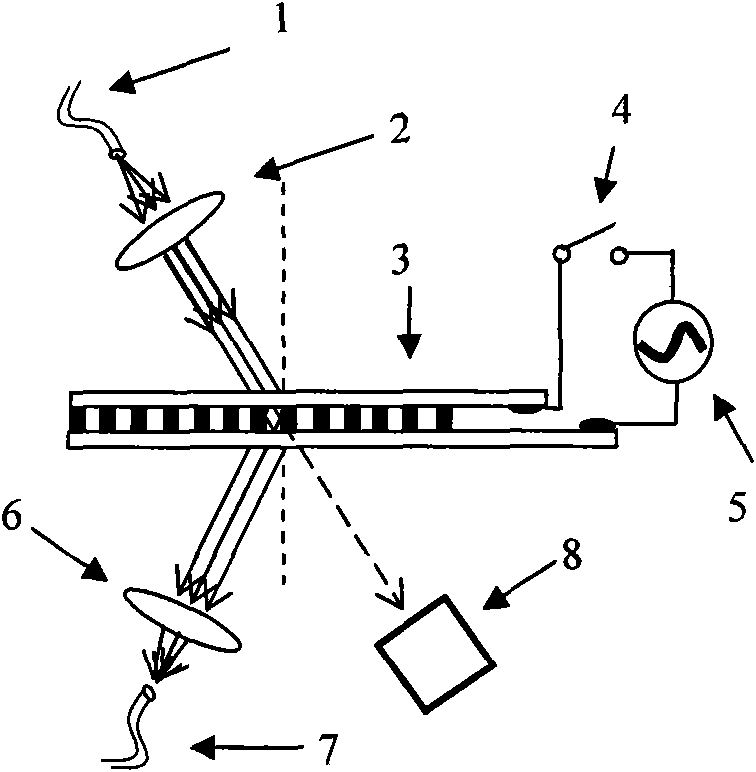

[0021] High-efficiency Bragg volume grating prepared by holographic polymer dispersed liquid crystal (HPDLC), the overall thickness of the grating is less than 2mm, and the grating area is 5×5mm 2 , grating period 1.1μm. When the light is guided into the spectrometer by the input fiber connector (1), it is collimated by the collimating lens (2), and enters the holographic Bragg volume grating (3) at a certain angle with the grating surface normal. If the incident angle makes a certain wavelength (λ) satisfies the Bragg condition, then the light of this wavelength will be maximally diffracted by the holographic Bragg volume grating (3), and exit at the same angle as the normal of the grating (on the same side as the normal of the incident light). The result is as figure 1 Shown in the light path diagram. If the grating electric drive control switch (4) is turned on, the drive signal source (5) is connected to the two electrodes of the Bragg volume grating (3), and as the effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com